LED (Light Emitting Diode) lamp module and manufacturing method thereof

A technology of LED lamps and modules, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of cumbersome production process, long heat transfer distance, low heat transfer rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

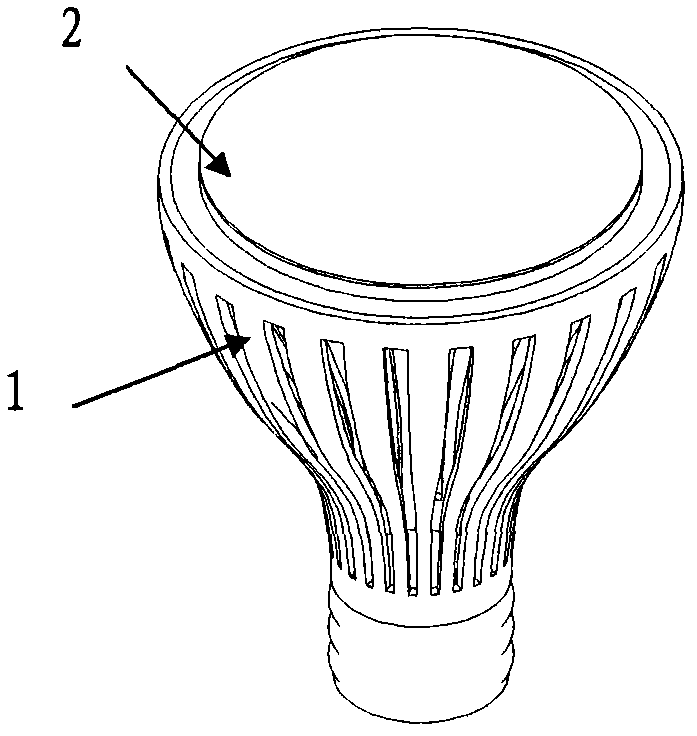

[0031] The following will describe in more detail the specific embodiments of the LED lamp module of the present invention, which is made by directly bonding LEDs with conductive adhesive lines and the three-dimensional heat dissipation support lamp carrier.

[0032] However, those skilled in the art can obviously understand that these implementation modes are only some preferred embodiments of the present invention, and do not limit the present invention and its protection scope in any way. Those of ordinary skill in the art can make some obvious changes and modifications on the condition of understanding the basic idea of the present invention, and these all belong to the scope of the present invention. The scope of the invention is limited only by the claims.

[0033] According to a preferred embodiment of the present invention, a three-dimensional heat dissipation supporting lamp carrier of an LED lamp module is provided. figure 1 It is a schematic diagram of a metal th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com