Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Reduce waste acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and preparation method and application thereof

ActiveCN106944151AEasy to prepareLow costPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsSolventActive carbon

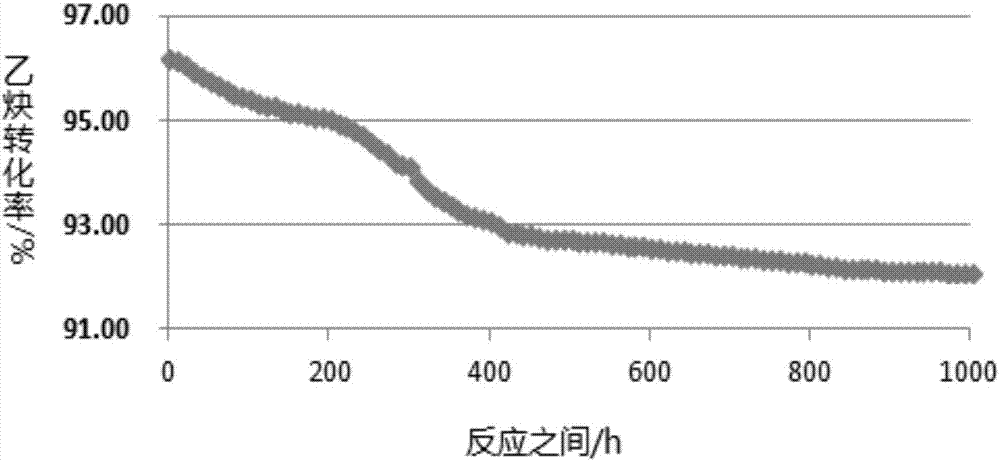

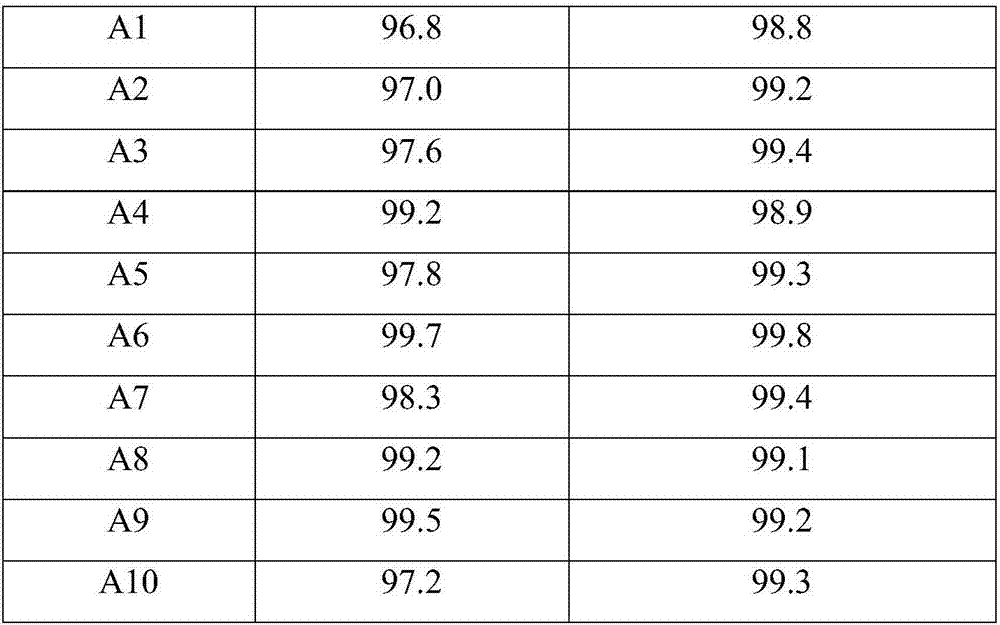

The invention relates to a mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, dissolving alkali metal salt and an amide solvent in water to prepare a mixed solution; 2, adding active carbon into the mixed solution obtained in step 1, and dipping the active carbon; and 3, filtering the active carbon obtained in step 2, draining the filtered active carbon, and heating and drying the drained active carbon to obtain the catalyst. The concentration of raw gas on the surface of the catalyst is increased through using the synergism of the alkali metal salt and the amide solvent and the adsorbing and dissolving ability of the amide solvent to raw materials comprising acetylene and hydrogen chloride, and the amide solvent is a high-polarity aprotic polar solvent, and has a polarization effect on reactants, so the reaction efficiency is further improved, the low temperature activity of the catalyst is high, and the selectivity and the stability are good.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

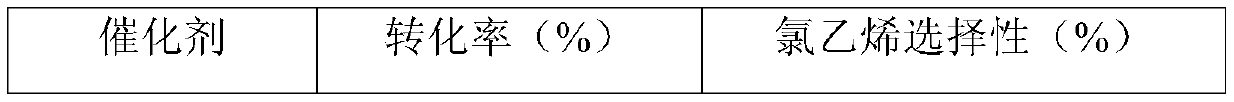

Non-noble metal mercury-free catalyst for acetylene hydrochlorination reaction, preparation method and application thereof

ActiveCN106492869AEmission reductionImprove catalytic stabilityPreparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsPhosphateReaction temperature

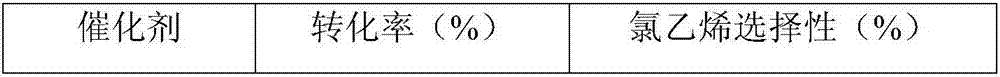

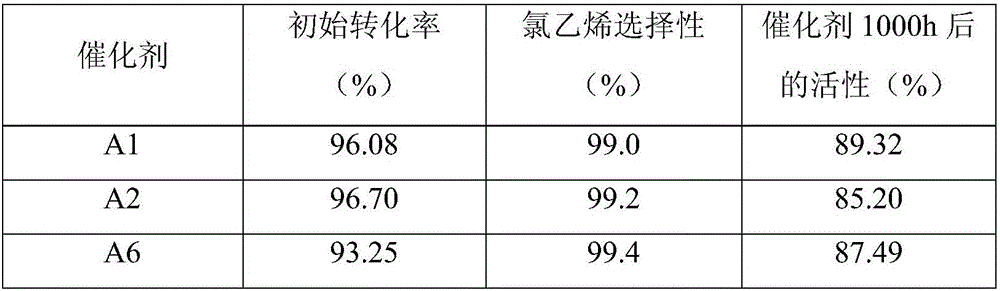

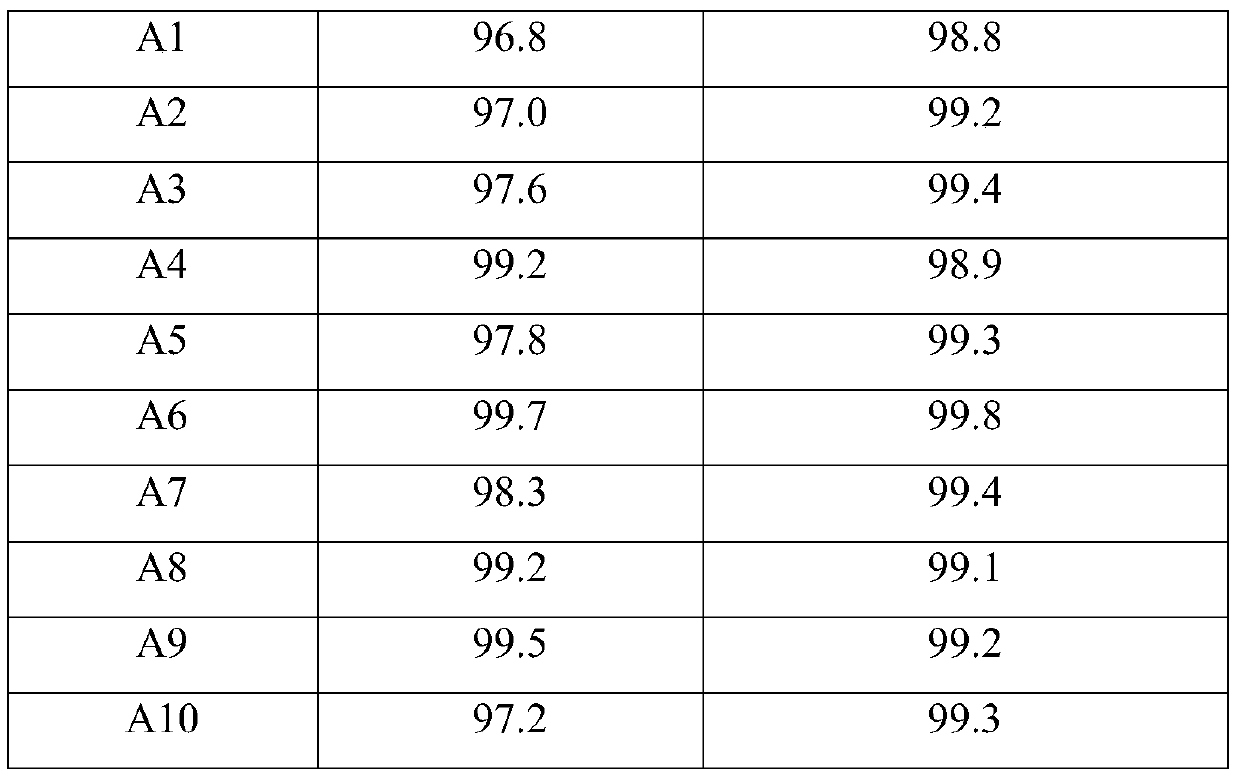

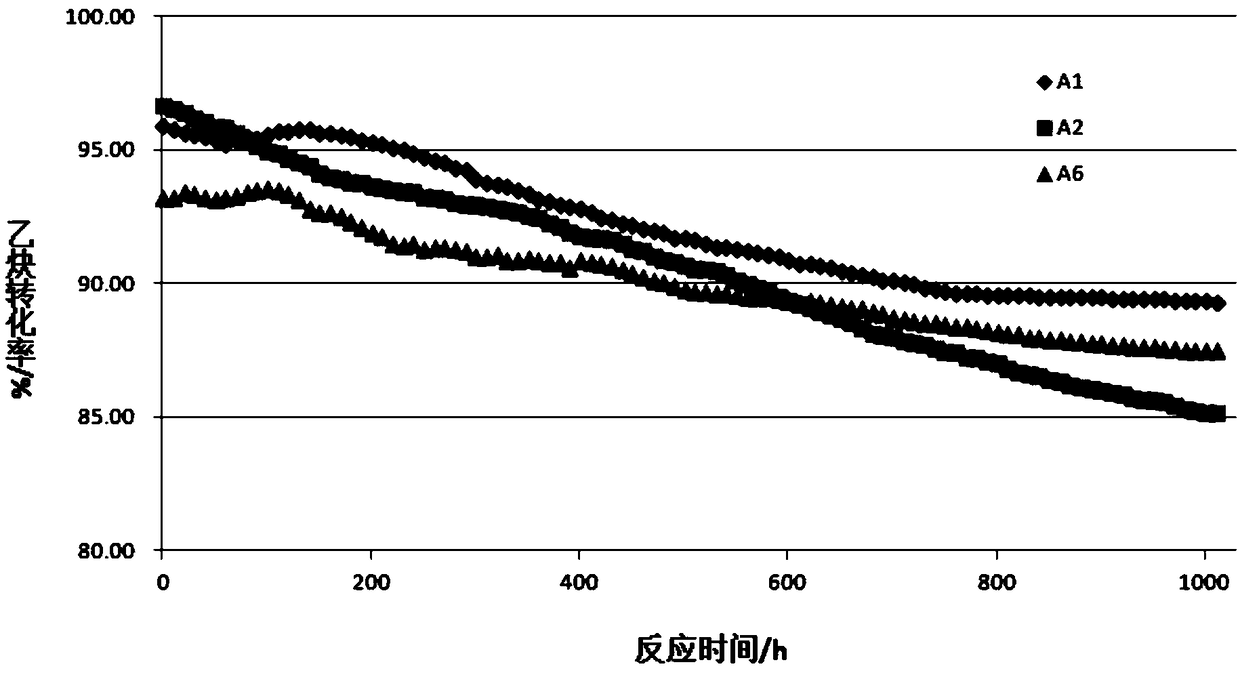

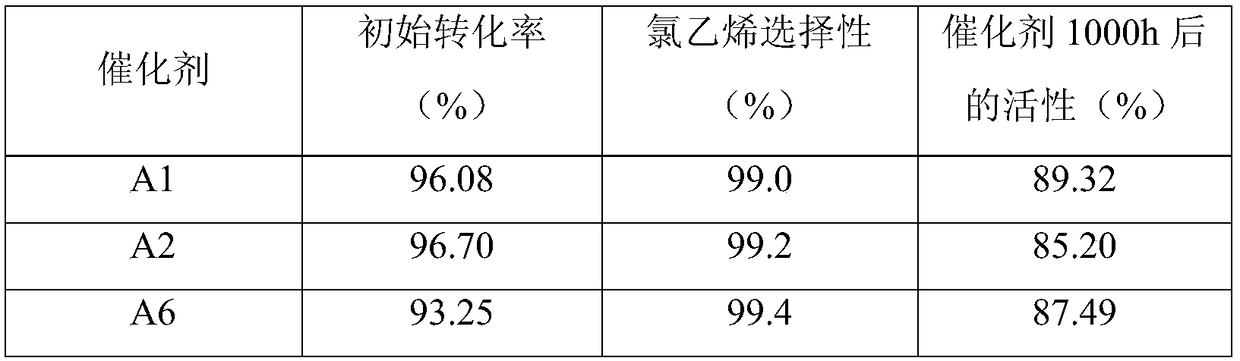

The invention relates to a non-noble metal mercury-free catalyst for acetylene hydrochlorination reaction, a preparation method and application thereof. The preparation method comprises the steps of: 1) preparing a mixed solution of a copper salt, an ammonium salt and phosphoric acid, or a mixed solution of a copper salt, an ammonium salt and phosphate; 2) adding activated carbon into the mixed solution obtained in step 1 for soaking; 3) spin-drying the soaked activated carbon, and conducting heating and drying to obtain the catalyst. Through the synergistic effect of multiple components, the catalyst prepared by the method provided by the invention acquires good catalytic stability and high low-temperature activity, and under a reaction temperature of 130DEG C and the existing mercury catalyst running pressure condition and feeding intensity, more than 96% of conversion per pass and more than 99% of vinyl chloride selectivity can be obtained. As the technical conditions of the catalyst for acetylene hydrochlorination reaction are similar to those of the existing mercury catalyst, renovation of existing equipment is unnecessary, and the mercury catalyst can be replaced easily on the existing equipment.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

Process for synthesizing quinclorac by oxidizing reaction

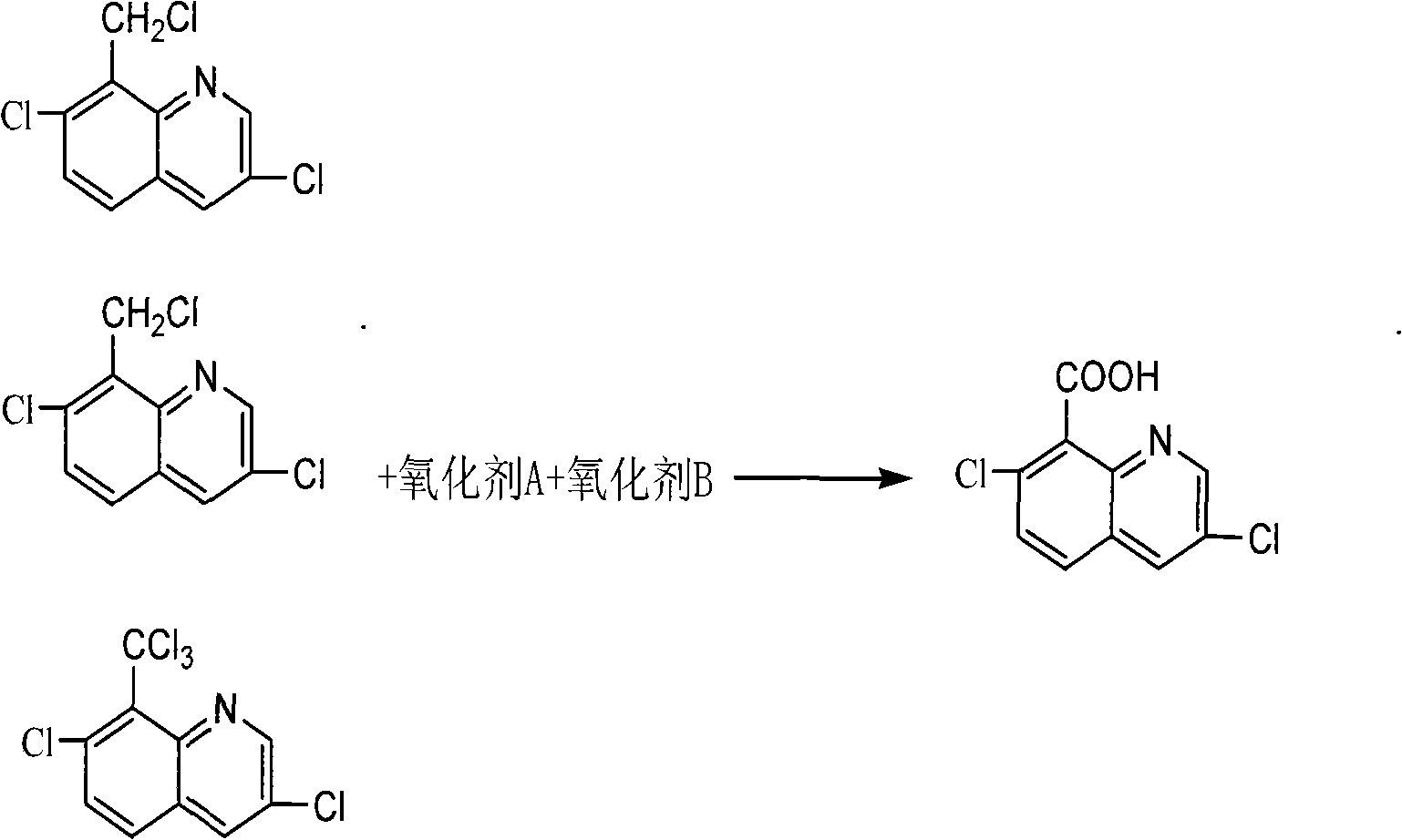

The invention provides an oxidizer used in the di-chlorine quinoline acid synthesis technology, which can effectively improve the problems that the time of the oxidation operation is long, the production capacity is limited, and the generated waste acid is not easy to be processed in the prior art. The oxidizer is oxyacid of chlorine, bromine and iodine and salts thereof, and peroxide. The invention further provides a novel method for synthesizing di-chlorine quinoline acid oxo by utilizing the novel oxidizer.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

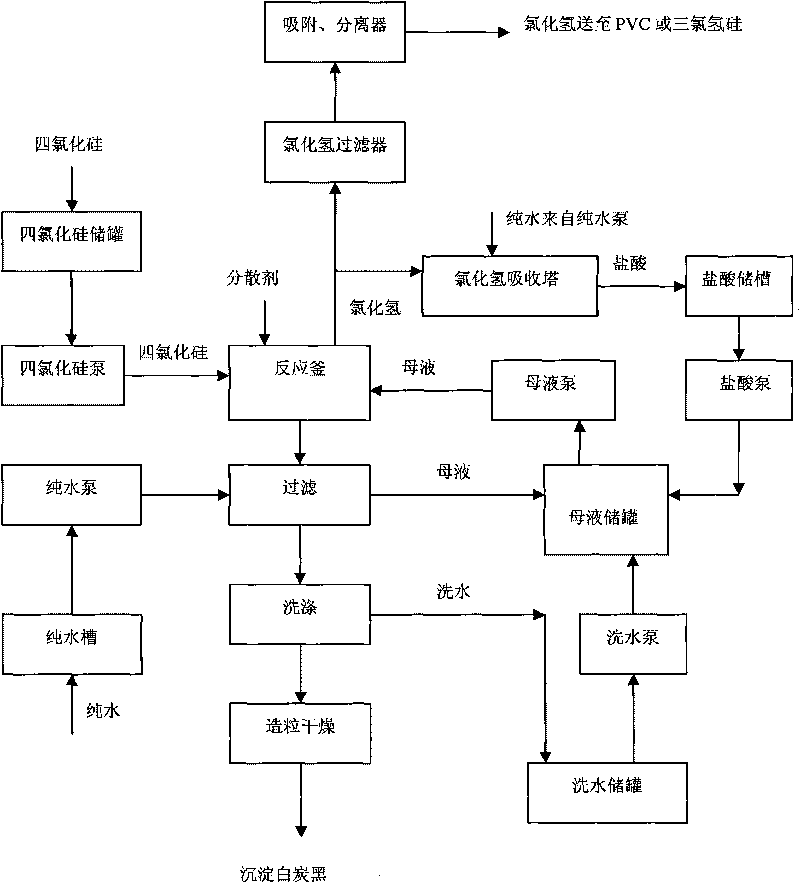

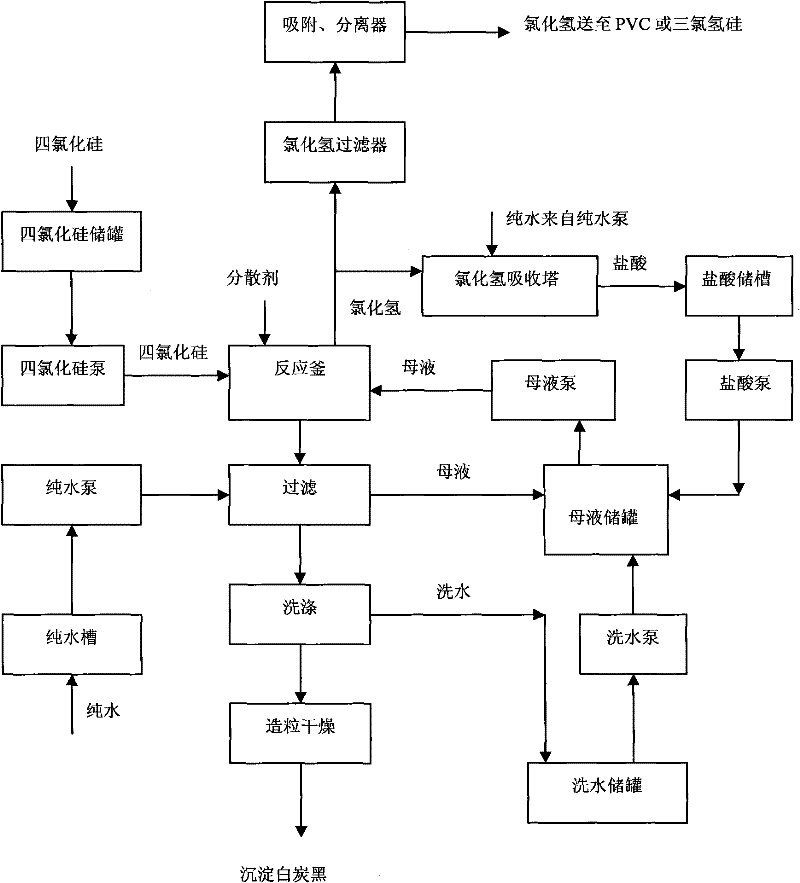

Process for producing precipitated white carbon black by silicon tetrachloride

InactiveCN101734667AIncrease porositySolve the pollution of the environmentSilicaHydrideRaw material

The invention belongs to a process for preparing white carbon black and in particular relates to a process for producing precipitated white carbon black by silicon tetrachloride. The process comprises the following steps: adding the silicon tetrachloride into 29 to 33 mass percent hydrochloric acid aqueous solution which contains a dispersant, controlling the temperature to between 28 and 45 DEG C for reaction to generate silica sol and chlorine hydride gas, standing and ageing the silica sol to form colloidal white flocculent sediment, filtering, separating and washing the sediment, and pelletizing and drying the sediment to obtain the precipitated white carbon black. The process has short flow, relatively simple production equipment and process control, and available raw materials, effectively utilizes the silicon tetrachloride, totally reclaims the product chlorine hydride, reduces the processing expense, the amount of waste acid and the environmental pollution, and has low production cost, wide application and large market capacity.

Owner:昊华宇航化工有限责任公司

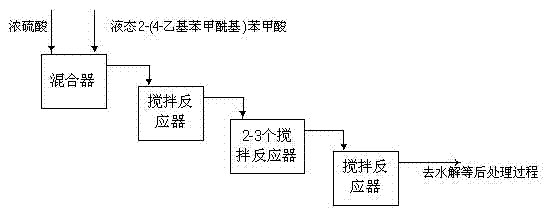

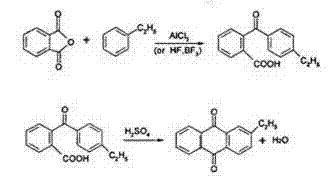

Method for preparing 2-ethylanthraquinone by continuous 2-(4-alkylbenzoyl)benzoic acid ring-closing reaction

InactiveCN103360229AEasy to operateReduce labor intensityOrganic compound preparationQuinone preparationBenzoic acidAnthraquinones

The invention discloses a method for preparing 2-ethylanthraquinone by continuous 2-(4-alkylbenzoyl)benzoic acid ring-closing reaction, which comprises the following steps: mixing liquid 2-(4-alkylbenzoyl)benzoic acid and room-temperature concentrated sulfuric acid in a mixer in a mass-volume ratio of 1:1.5-1:2.5, wherein the mixing temperature is room temperature to 100 DEG C, and the retention time of the mixture in the mixer is 1-10 minutes; connecting the mixer with a stirring reactor, and carrying out ring-closing reaction, wherein the temperature of the stirring reactor is 100-140 DEG C, and the retention time of the reaction materials in the reactor is 5-30 minutes; and directly hydrolyzing the liquid after reaction, extracting, and distilling to obtain the 2-ethylanthraquinone. The detailed method is disclosed in the specification. The process is simple to operate and easy to control, lowers the labor intensity, improves the working environment, reduces the equipment investment, lowers the waste acid quantity, and enhances the product yield by 5-10% as compared with the existing production technique; and the product quality is good.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Wet flue gas desulfurization method

ActiveCN101612515AReduce processing costsShort processDispersed particle separationSulphate IonFlue gas

The invention discloses a wet flue gas desulfurization method comprising the steps: obtaining absorption liquid with sulphite by using an alkaline absorbing agent which is in contact with flue gas to absorb SO2 in the flue gas in a desulfurizing tower; reacting the obtained absorption liquid containing sulphite with sulphuric acid; transmitting the SO2 precipitated by the reaction to an acid preparation system to prepare the sulphuric acid; and obtaining a solid settling matter of sulphate by soil-liquid collecting reaction. The wet flue gas desulfurization method can use sulphuric acid in waste acid to treat the absorption liquid, shortens a treating process and saves a large amount of device investment and operation cost, and the SO2 absorbed from the flue gas enters the acid preparation system again, therefore, resources can be recycled.

Owner:JINLONG COPPER

2-naphthalenesulfonic acid, sodium naphthalene sulfonate and preparation thereof

InactiveCN101372466AImprove conversion rateReduce salt contentSulfonic acid preparationSulfonateSulfite salt

The invention relates to 2-naphthalene sulfonic acid, 2-sodium naphthalene sulfonate and a preparation technology thereof. The technical proposal is as follows: naphthalene and a little amount of anhydrous sodium sulfate are added to a reactor containing sulfuric acid with the concentration of 98% according to the mol ratio of the naphthalene to sulfuric acid being 1:0.1-0.5, and heated while stirring until the naphthalene and the anhydrous sodium sulfate are completely dissolved; SO3 gas is fed into the reactor within 1-3h for sulfonation reaction at the temperature of 120-180 DEG C; and then at the temperature of 150-180 DEG C, the naphthalene and the SO3 in the mixture obtained from the sulfonation reaction are blown away by compressed nitrogen gas when the mixture is stirred, so as to prepare the 2-naphthalene sulfonic acid. In addition, the prepared 2-naphthalene sulfonic acid can be added to a neutralization pot, and sodium sulfite solution with the concentration of 5%-15% which is preheated to 80-90 DEG C is added to the neutralization pot by a measuring tank, so the 2-naphthalene sulfonic acid and sodium sulfite solution can have neutralization reaction; crystallization and separation are carried out to obtain the 2-sodium naphthalene sulfonate. The preparation technology has the advantages of full utilization of the existing resources, high naphthalene conversion rate, good product quality, little environmental pollution, low cost and high economic benefits.

Owner:WUHAN UNIV OF SCI & TECH

Method for producing 5-n-butyl-2-benzoglioxaline methyl carbamate

InactiveCN101245049AReduce generationSimplify operating proceduresOrganic chemistryChemical recyclingAcetic anhydrideMethyl carbamate

The invention pertains to a preparation method of 5-n-butyl-2-benzimidazole methyl formate, that is, parbendazole, and includes five reaction steps of acetylation, nitrification, hydrolysis, reduction and ring formation; n-butyl aniline is taken as the raw material, acetic anhydride is firstly used for acetylation, nitric acid is then used for nitrification, potassium hydroxide solution is used for hydrolysis, after that, Pd / C is used for the reduction to form 4-n-butyl-o-phenylenediamine, finally a ring closing agent of methyl formate cyanamide is used for ring closing, thus preparing the 5-n-butyl-2-benzimidazole methyl formate. The technique adopts p-n-butyl aniline which is cheap and easy to obtain as the raw material, the acetylation and the nitrification are completed in a same reactor, thus simplifying operation procedure and reducing production cost. The acetic anhydride is adopted as an acetylation reagent for protecting amino group, the reaction conditions are mild, and the acetic acid and the excessive acetic anhydride which are generated by the reaction can be used as a solvent and a dehydrating agent, thus reducing the amount of the waste acid. Palladium carbon is adopted as a catalyst for the reduction of the amino group, and the catalyst can be recycled and is characterized by high conversion rate, green and clean properties.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

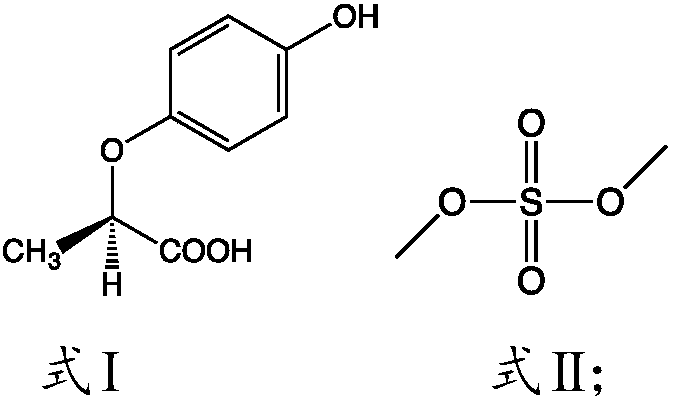

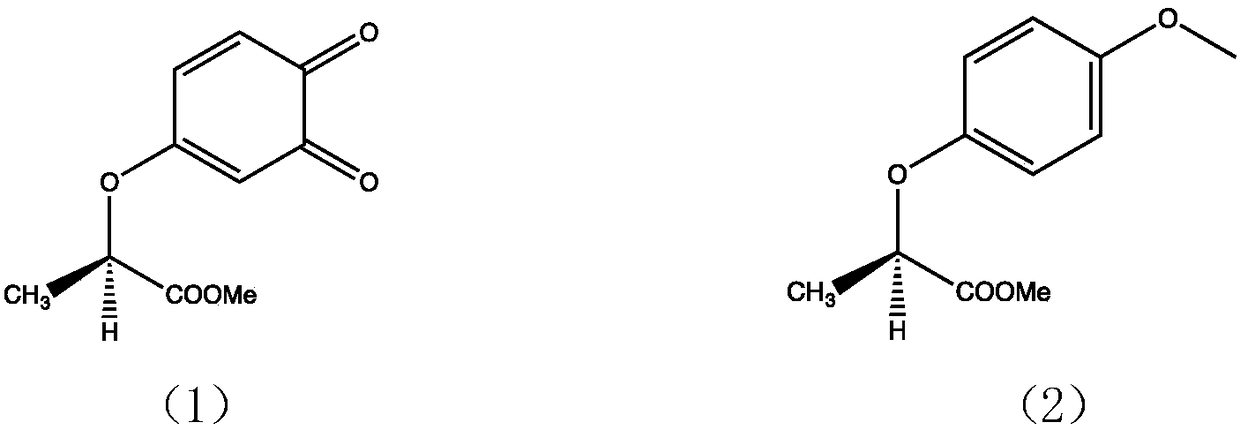

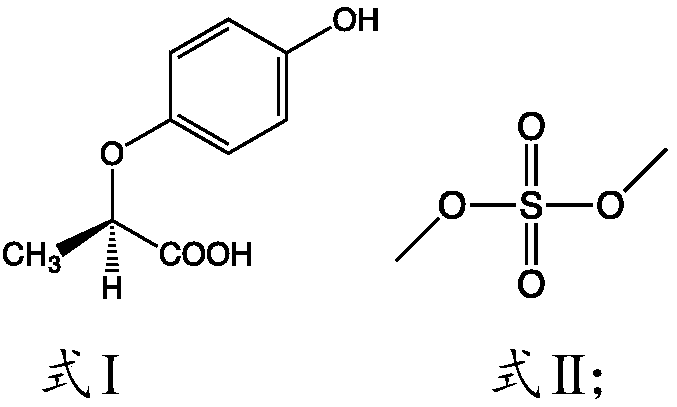

Method for preparing methyl R-(+)-2-(4-hydroxyphenoxy)propionate

InactiveCN108129303AImprove the problem of low conversion rateReduce processing costsOrganic compound preparationOrganic chemistry methodsReaction rateRates reactions

The first problem to be improved in the invention is to provide a method for preparing methyl R-(+)-2-(4-hydroxyphenoxy)propionate. Dimethyl sulfate and water, methanol and sulfuric acid generated during an esterification reaction continuously catalyze the reaction, so the esterification conversion rate is improved to above 99.5%, and the average esterification yield of the whole process is about99%; and no catalyst is excessively added in the reaction process, and a reaction system is sealed, so the environment is protected. The reaction rate of methanol in the system is high, and the methanol can be repeatedly used, so the problem of low conversion rate of pure methanol when reacted under the action of the catalyst is improved, the yield is increased, and the cost is reduced. An alkali-washed mother liquor can be recycled to solve the problem of high COD of alkali washing wastewater during dehydration, so the wastewater treatment cost is reduced. Experiments in the invention show that the average yield of the method is 99%, and the purity of the product is 99% or more.

Owner:SUZHOU KAIYUAN MINSHENG SCI & TECH CORP

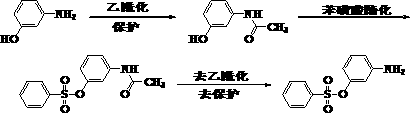

Novel method for post-processing vat yellow GCN

The invention provides a novel method for post-processing vat yellow GCN to greatly reduce the amount of waste acid. A crude product of vat yellow GCN is added into a solvent tetrachloroethylene, stirred, heated to 120 DEG C, subjected to a backflow reaction for 6 hours, cooled to the room temperature and then filtered, and the residue naphthaline in a filter cake is cleaned in multiple times by using rationed tetrachloroethylene; the filter cake in which the naphthaline is removed is added into a hydrochloric acid solution to remove copper, stirred, added with sodium chlorate, heated to 70-90 DEG C, thermally insulated for 2 hours, filtered while being hot, washed to neutral state and dried, the pre-processed vat yellow GCN dry product is added into a sulfuric acid concentrated solution, stirred, heated to 130-150 DEG C and reacted for 2-4 hours, a sample is taken and observed by using a microscope, if a crystal becomes transparent, then the crystal transformation is completed, the mixture is cooled to the room temperature, added with water to separate the material and filtered in a suction manner, the filter cake is washed with water to the neutral state, reacts in a sodium hypochlorite solution again at 70-80 DEG C for 2 hours and filtered, and the filter cake is washed to the neutral state and dried to obtain the vat yellow GCN dry product.

Owner:上海华元实业有限公司

Continuous synthesis method of m-acetamido phenol

ActiveCN108358806ARapid responseReduce the amount of materialOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsPhenol

The invention discloses a continuous synthesis method of m-acetamido phenol. The method comprises the following steps: respectively preparing two solutions from m-aminoacetanilide, sulfuric acid, sodium nitrite and the like, respectively continuously pumping the solutions into a tubular reactor by a metering pump at a preset flow velocity, performing diazotization and hydrolysis reactions, and cooling, extracting, drying and desolventizing the obtained reaction product to obtain the product, wherein the diazotization reaction and the hydrolysis reaction are completed in the same tubular reactor. The method has the characteristics of sufficient sources and low price of raw materials, high safety in the synthesis process, high product yield, less pollution of three wastes, and high industrialization values.

Owner:JIANGSU D I A N CHEM CO LTD

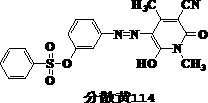

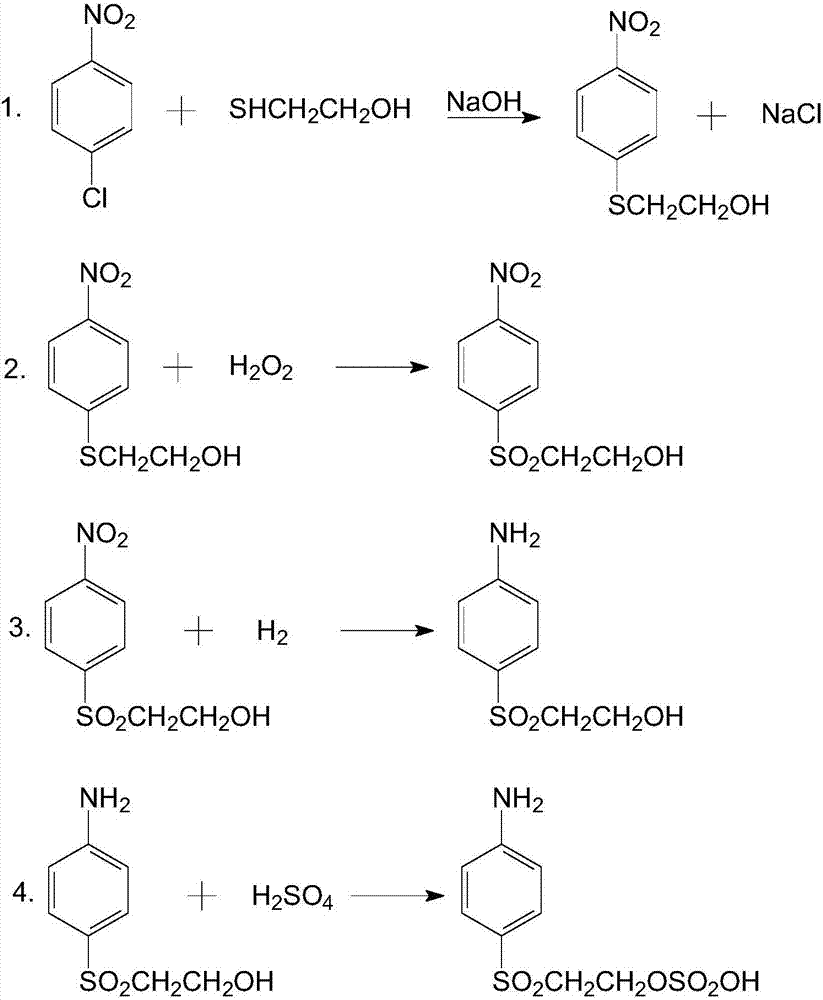

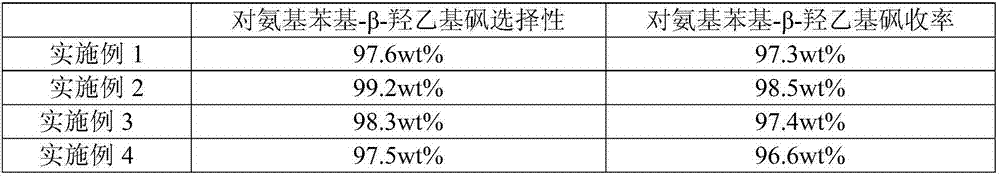

Preparing methods of p-aminophenyl-beta-hydroxyethylsulfonyl and p-minophenyl-beta-hydroxyethylsulfonyl sulphonate

InactiveCN108003073AReduce manufacturing costLow costOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsSocial benefitsAdjuvant

The invention relates to preparing methods of p-aminophenyl-beta-hydroxyethylsulfonyl and p-minophenyl-beta-hydroxyethylsulfonyl sulphonate. The preparing methods both comprise the steps that p-aminophenyl-beta-hydroxyethylsulfonyl and hydrogen are used as raw materials, modified framework nickel is used as a hydrogen-adding catalyst, a catalytic hydrogenation reaction is conducted in a solvent toobtain reduction liquid, and modified framework nickel and the solvent in the reduction liquid are separated and removed to obtain p-minophenyl-beta-hydroxyethylsulfonyl sulphonate; according to modified framework nickel, nickel is used as a framework, and modified framework nickel is prepared from, by mass, 75-95 parts of Ni, 3-15 parts of Al and 2-10 parts of metal adjuvant; the metal adjuvantcomprises the combination of any one or at least two of Mo, Cu and Cr. The yield can reach 94% or above; preparation of p-minophenyl-beta-hydroxyethylsulfonyl sulphonate is a continuous production technology, the technology is simplified, the production efficiency is high, the quality is stable, the production cost is low, and the economic benefit and social benefit are obvious.

Owner:广东众和高新科技股份公司

After-treatment clean process for purifying vat blue 66 dye

InactiveCN104341797AReduce waste acidRealize cleaner production processOrganic dyesSulfur-trioxide/sulfuric-acidAfter treatmentOlivine

The invention relates to an after-treatment clean process for purifying vat blue 66 dye. The clean process comprises the steps: levigating a vat blue 66 crude product, filtering the levigated vat blue 66 by adopting a 300-mesh sieve, adding he filtered vat blue 66 in a sulfuric acid concentrated solution, wherein the weight ratio of the vat blue 66 crude product and the sulfuric acid concentrated solution is 1: (13-15), and the concentration of the sulfuric acid concentrated solution is 70 to 75 percent by weight; heating the mixed solution to 70 to 90 DEG C, stirring and insulating the mixed solution for 4 to 6 hours, when the vat blue 66 crude product is stirred and insulated in the sulfuric acid concentrated solution, the color of the mixed solution is turned from dark blue to olivine, cooling the mixed solution to the temperature of 50 DEG C after the mixed solution is thermally insulated, stirring the mixed solution for 4 to 8 hours, filtering the mixed solution, washing filter cake by utilizing the70% to 75% sulfuric acid concentrated solution or the sulfuric acid solution which is identical in the concentration, adding water to the filter cake, pulping the filter cake, heating the pulp to the temperature of 80 DEG C, preserving the pump for 0.5 to 1 hour, and drying the filter cake at the temperature of 90 DEG C to obtain a vat blue 66 dye dry product. The sulfuric acid concentrated solution with the concentration of 70 to 75 percent is obtained by after-processing the sulfuric acid concentrated mother solution obtained by purifying the vat blue 66. The invention provides the after-treatment clean production process of the vat blue 66.

Owner:上海华元实业有限公司

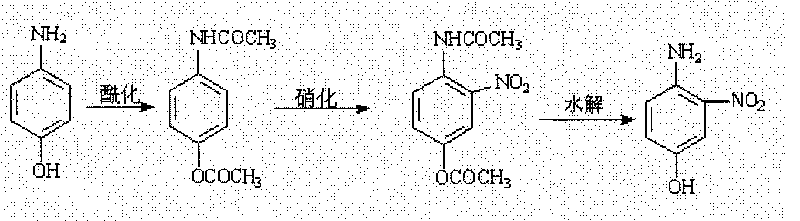

Process of preparing 4-amino-3-nitro phenol

ActiveCN101066929AReduce dosageReduce generationOrganic compound preparationAmino-hyroxy compound preparationAcetic anhydrideNitrobenzene

The present invention belongs to the field of fined chemical intermediate synthesizing technology, and is process of preparing 4-amino-3-nitro phenol. The process of preparing 4-amino-3-nitro phenol includes the following three steps: acetylation of p-aminophenol as material with acetic anhydride, the subsequent nitration with nitric acid, and final hydrolysis of 4-acetoxy-2-acetamino nitrobenzene with sodium hydroxide. The present invention has simple operation and low cost.

Owner:溧阳常大技术转移中心有限公司

Method for decreasing waste acid content in titanium dioxide production

ActiveCN105293574AReduce waste acidReduce post-processing costsTitanium dioxideDioxide titaniumMaterials science

The invention discloses a method for decreasing the waste acid content in titanium dioxide production. Sulfur trioxide and 55% sulfuric acid are adopted to be premixed with titanium concentrate for an acidolysis reaction in the rutile-type titanium dioxide production process through a sulfuric acid method, and then the method for decreasing the waste acid content in titanium dioxide production is achieved.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

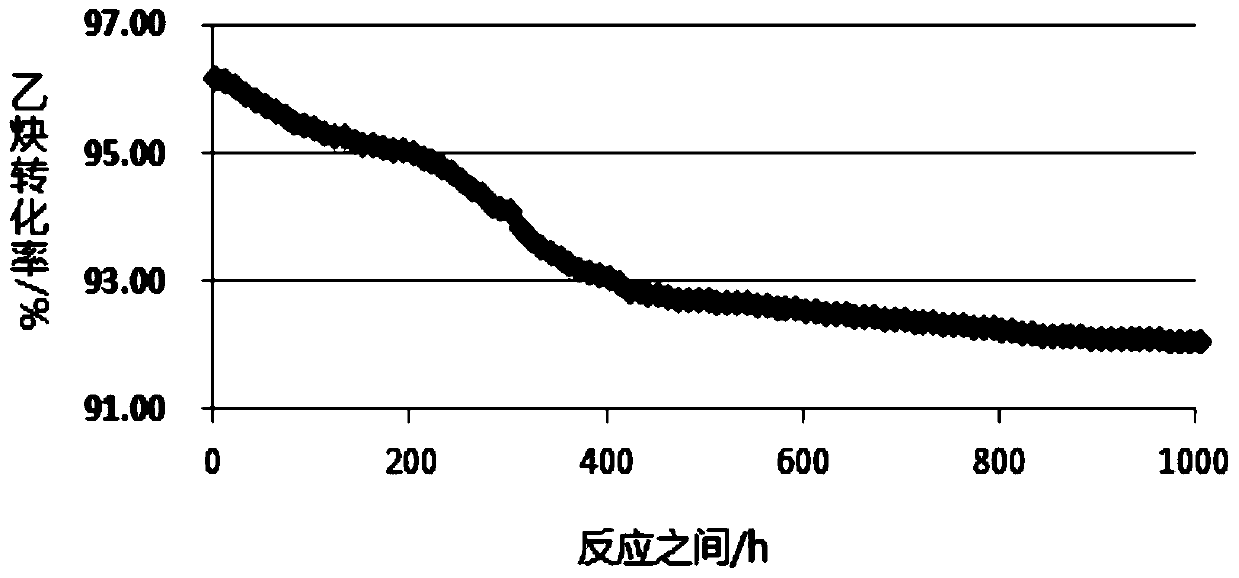

A kind of mercury-free catalyst for the synthesis of vinyl chloride by acetylene hydrochlorination and its preparation method and application

ActiveCN106944151BEasy to prepareLow costPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystActivated carbon filtration

The invention relates to a mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, dissolving alkali metal salt and an amide solvent in water to prepare a mixed solution; 2, adding active carbon into the mixed solution obtained in step 1, and dipping the active carbon; and 3, filtering the active carbon obtained in step 2, draining the filtered active carbon, and heating and drying the drained active carbon to obtain the catalyst. The concentration of raw gas on the surface of the catalyst is increased through using the synergism of the alkali metal salt and the amide solvent and the adsorbing and dissolving ability of the amide solvent to raw materials comprising acetylene and hydrogen chloride, and the amide solvent is a high-polarity aprotic polar solvent, and has a polarization effect on reactants, so the reaction efficiency is further improved, the low temperature activity of the catalyst is high, and the selectivity and the stability are good.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

A non-precious metal mercury-free catalyst for acetylene hydrochlorination and its preparation method and application

ActiveCN106492869BEmission reductionImprove catalytic stabilityPreparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsPhosphatePhosphoric acid

The invention relates to a non-noble metal mercury-free catalyst for acetylene hydrochlorination reaction, a preparation method and application thereof. The preparation method comprises the steps of: 1) preparing a mixed solution of a copper salt, an ammonium salt and phosphoric acid, or a mixed solution of a copper salt, an ammonium salt and phosphate; 2) adding activated carbon into the mixed solution obtained in step 1 for soaking; 3) spin-drying the soaked activated carbon, and conducting heating and drying to obtain the catalyst. Through the synergistic effect of multiple components, the catalyst prepared by the method provided by the invention acquires good catalytic stability and high low-temperature activity, and under a reaction temperature of 130DEG C and the existing mercury catalyst running pressure condition and feeding intensity, more than 96% of conversion per pass and more than 99% of vinyl chloride selectivity can be obtained. As the technical conditions of the catalyst for acetylene hydrochlorination reaction are similar to those of the existing mercury catalyst, renovation of existing equipment is unnecessary, and the mercury catalyst can be replaced easily on the existing equipment.

Owner:ZHONGKE YIGONG XIAMEN CHEM TECH

Method for preparing 2-alkylanthraquinone with microchannel continuous reactor

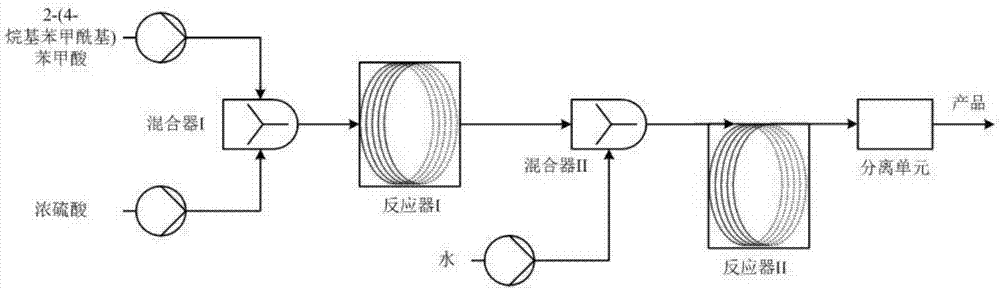

InactiveCN107879915AImprove airtightnessImprove securityOrganic compound preparationPreparation from carboxylic acid anhydridesChemical synthesisBenzoic acid

The invention belongs to the field of chemical synthesis, and particularly relates to a method for preparing 2-alkylanthraquinone with a microchannel continuous reactor. The synthesis is carried out in a microchannel reactor, and the method comprises the following steps: (1) catalyzing phthalic anhydride and alkylbenzene by using AlCl3 as a catalyst, and performing a Friedel-Crafts acylation reaction to generate 2-(4-alkyl benzoyl) benzoic acid; and (2) continuously reacting the 2-(4-alkyl benzoyl) benzoic acid with concentrated sulfuric acid through a mixer I, a reactor I, a mixer II, a reactor II and a separation unit of the microchannel reactor to generate the 2-alkylanthraquinone in a closed loop mode. Compared with a traditional intermittent reaction, the microchannel reaction adoptedin the method has the advantages of relatively good microchannel airtightness, high safety, little pollution and simple operation; the product has a yield increased by 5-10 percent in comparison withthat of an existing production process, and has high quality.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Piperonal preparation method

The invention relates to a preparation method of piperonal. The specific steps are: mix water, glyoxylic acid and sulfuric acid in proportion, add piperonyl cyclocyclone dropwise at a temperature of 0-5°C, stir at a high speed for 5-8 hours, add After diluting with 80-100ml of water, filter with suction to obtain solid 3,4-dimethoxymandelic acid, and the filtrate is the mother liquor containing dilute sulfuric acid; the mass ratio of water, glyoxylic acid, and sulfuric acid is 1.5-1.7:10- 11:10‑11; take 30%‑70% dilute sulfuric acid mother liquor, add solid 3,4‑dimethoxymandelic acid to it, then add 80 mL of dichloromethane, add 3% dilute nitric acid 18‑1 dropwise at 20°C 20mL, heated, and reacted for 1-3 hours until the reaction was complete; layers were separated, washed, concentrated and distilled under reduced pressure to obtain the product piperonal.

Owner:江西科美香料有限公司

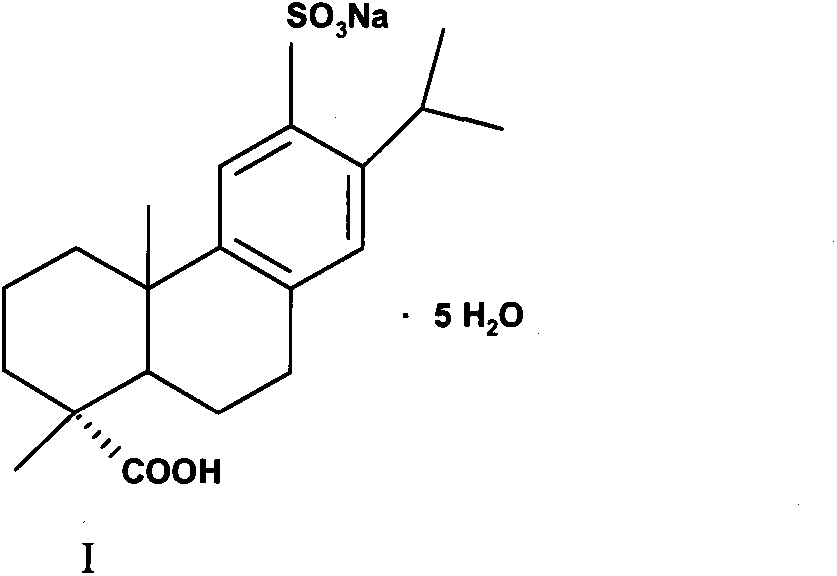

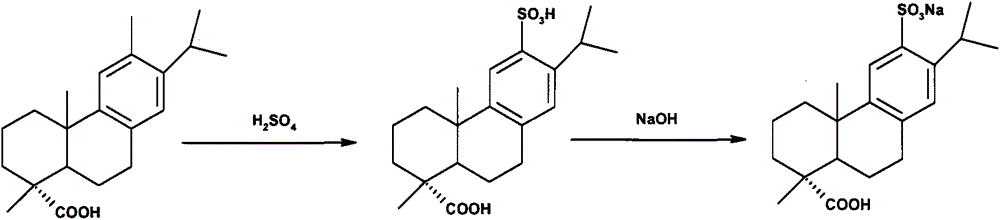

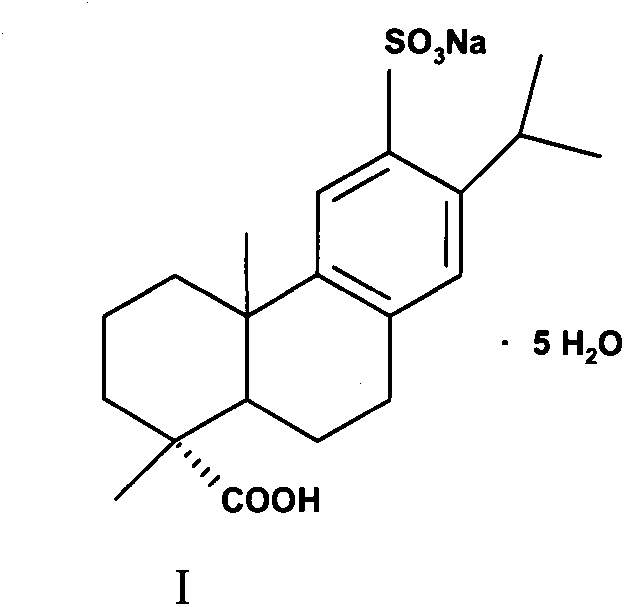

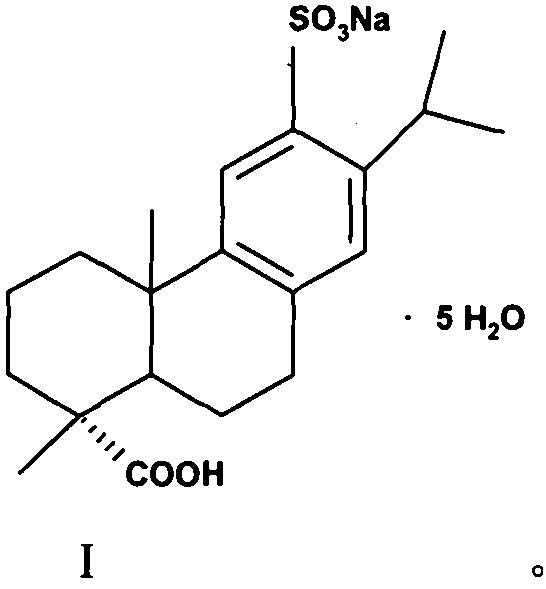

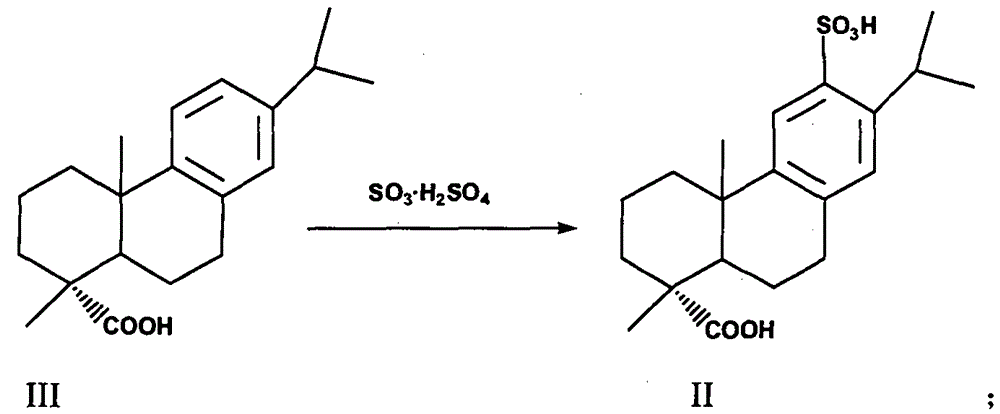

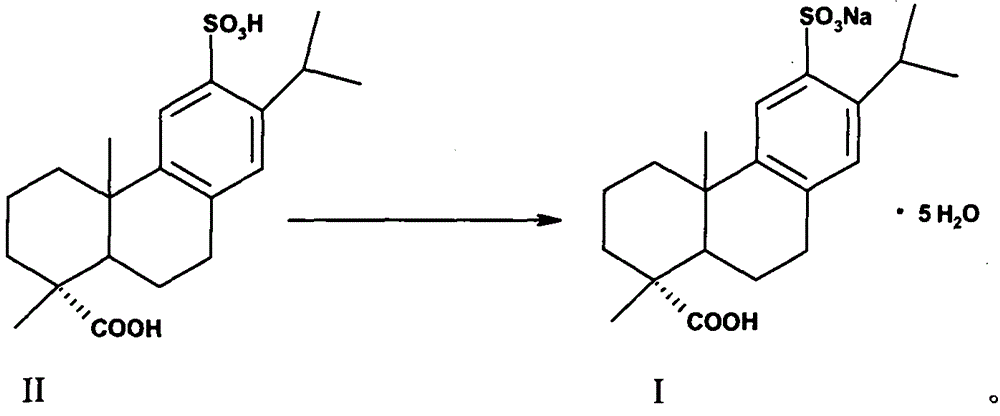

Method for preparing ecabet sodium

ActiveCN104086465AWeak alkalineFast sulfonationSulfonic acids salts preparationState of artSodium salt

The invention discloses a method for preparing ecabet sodium. The method disclosed by the invention is characterized by comprising the following steps of carrying out sulfonation reaction on dehydroabietic acid (formula III) as a starting material and fuming sulfuric acid to obtain 12-sulfonic dehydroabietic acid (formula II) and enabling the compound shown as the formula II and a sodium-forming agent to form a sodium salt in a solvent system at least containing water to obtain ecabet sodium. By virtue of the method disclosed by the invention, the deficiencies of the prior art are overcome and the method has the advantage of high sulfonation yield and high selectivity in sodium salt forming, simple operation, safety and environment friendliness and is suitable for industrial production.

Owner:CHONGQING KANGLE PHARMA

A kind of preparation method of ecabet sodium

ActiveCN104086465BWeak alkalineFast sulfonationSulfonic acids salts preparationState of artSodium salt

The invention discloses a preparation method of ecabet sodium, which is characterized in that: the method of the invention uses dehydroabietic acid (formula III) as a starting material, and carries out sulfonation reaction with oleum to obtain 12-sulfonic acid Base dehydroabietic acid (formula II), the compound of formula II and a sodium forming agent form a sodium salt in at least an aqueous solvent system to obtain ecabet sodium. The method of the invention overcomes the disadvantages of the prior art, and has the advantages of high sulfonation yield, high selectivity for sodium salt formation, simple operation, safety and environmental protection, and is suitable for industrial production.

Owner:CHONGQING KANGLE PHARMA

Method utilizing hydrogen chloride gas method to prepare zirconium oxychloride

InactiveCN105819504ALow costHigh zirconium contentZirconium compoundsFiltrationZirconium oxychloride

The invention discloses a method for preparing zirconium oxychloride by a hydrogen chloride gas method. The process steps of the method are: S1, taking zirconium oxychloride leaching solution and putting it into a reaction kettle; When the acidity of the zirconia leaching solution increases to a set value, stop feeding the hydrogen chloride gas; S3, heat to dissolve the crystallization material completely, and when the temperature drops to the set temperature, suction filter; S4, rinse with dilute hydrochloric acid to obtain zirconium oxychloride crystals. The beneficial effects of the present invention are: 1) The hydrogen chloride gas is passed into the zirconium oxychloride solution to increase the acidity of the solution to achieve the purpose of crystallization, and at the same time reduce the increase in the amount of liquid in the system and reduce the amount of waste acid; at the same time, it improves the utilization of equipment 2) The concentration process, an important part of the current zirconium oxychloride production process, is omitted, and a large amount of steam is no longer consumed. A single ton of zirconium oxychloride crystals saves about 6 tons of steam, effectively reducing production costs.

Owner:LOMON BILLIONS GRP CO LTD

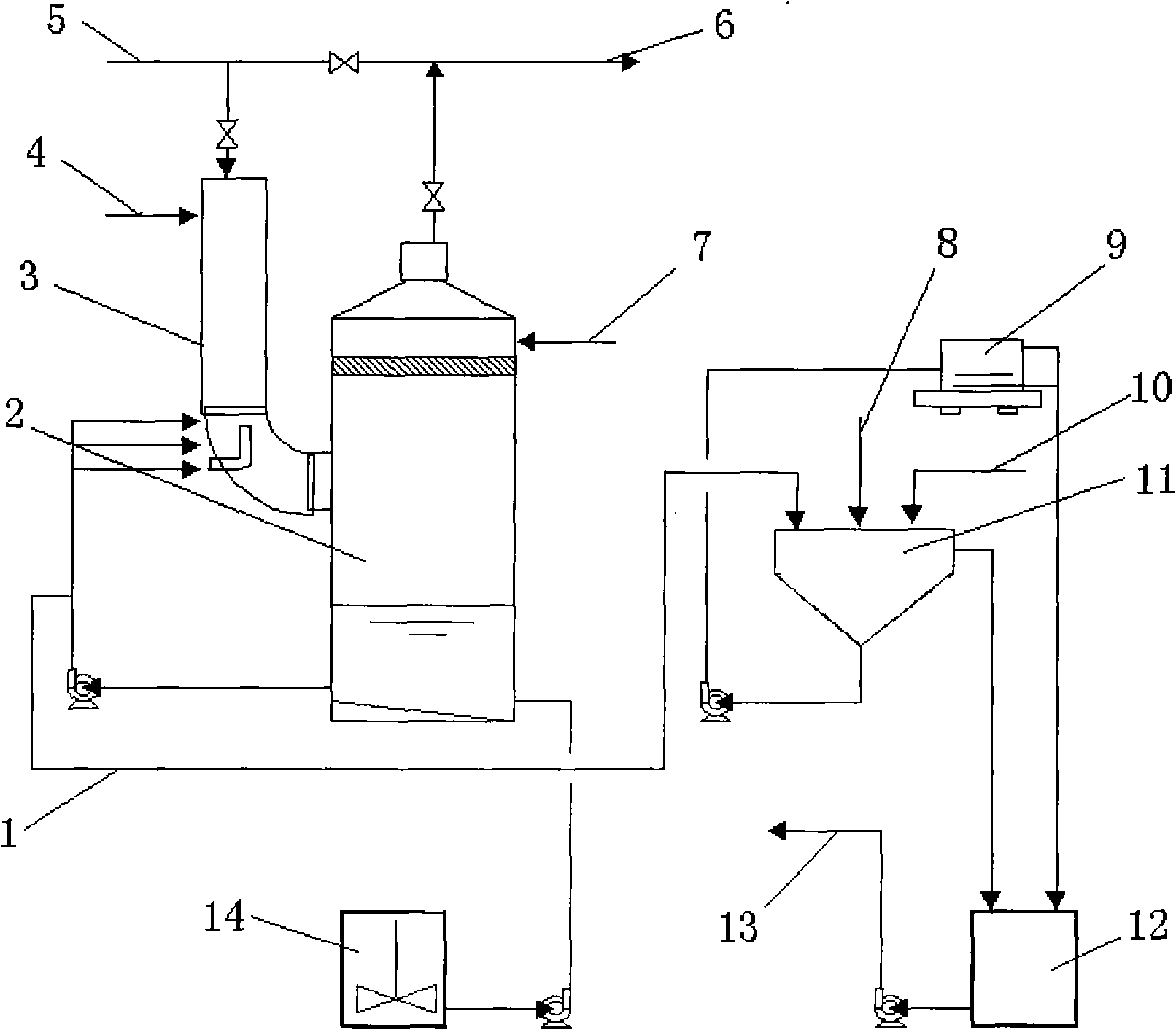

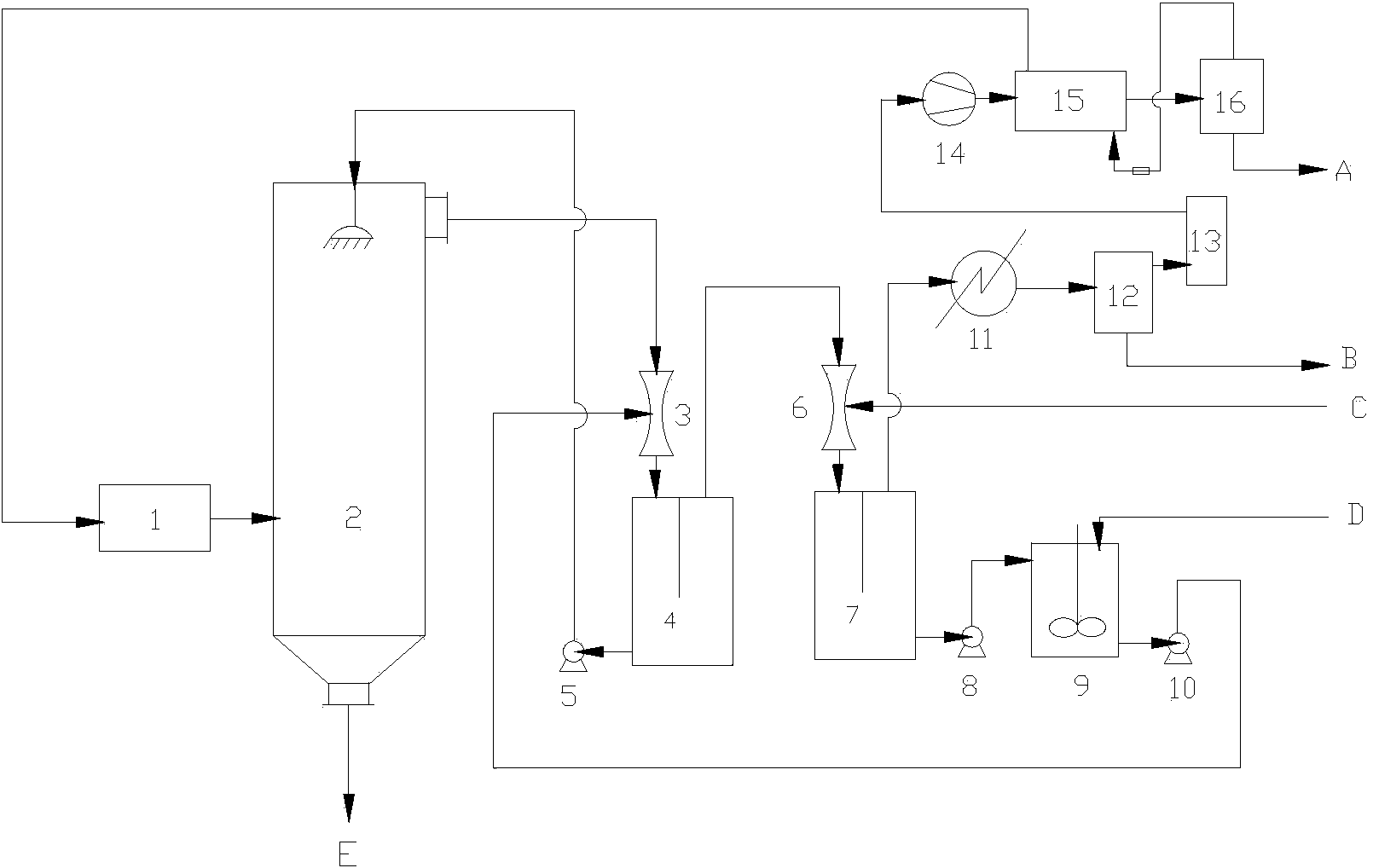

System for preparing liquid SO2 from concentrated waste acid

InactiveCN104016308AReduce consumptionIncrease productionSolidificationLiquefactionThermal energySlag

The invention relates to a system for preparing liquid SO2 from concentrated waste acid, belonging to the fields of waste acid treatment and liquid SO2 production. Sulfur is used as a reducer to reduce the concentrated waste acid to prepare SO2 gas, and the unreacted high-solid-content waste acid is gasified and decomposed in an inert atmosphere, thereby recovering the sulfur element in the waste acid and separating the solid-phase slag in the waste acid; and the prepared concentrated SO2 gas is dehydrated and dried, and is subjected to pressure cooling separation to obtain the liquid SO2. The system for preparing liquid SO2 from concentrated waste acid comprises a temperature-control gasification and decomposition system, an oxidation-reduction reaction system, a heat recovery system, a sulfur melting system, a dehydration and drying system and a compression separation system. By adding the sulfur to initiate the oxidation-reduction reaction, the amount of waste acid entering the gasification chamber is greatly lowered, thereby effectively lowering the heat consumption of gasification; the SO2 yield is greatly enhanced, and the SO2 concentration is high; the energy source is sufficiently recovered, so the energy consumption is low; and the system has the advantages of small pollution and no waste gas emission.

Owner:山东钧策科技服务有限公司

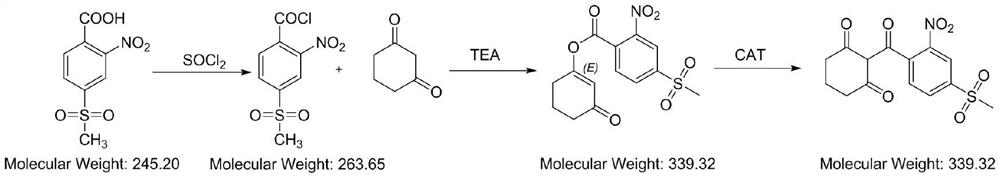

Preparation method of 2-nitro-4-methylsulfonylbenzoic acid

ActiveCN111808000ARealize applicationReduce dosageOrganic chemistryOrganic compound preparationBenzoic acidNitration

The invention relates to a preparation method of 2-nitro-4-methylsulfonylbenzoic acid. Based on a nitric acid oxidation scheme, p-methylsulfonyltoluene is dissolved into a chloroalkane solvent, nitricacid is dropwise added into sulfuric acid with the mass fraction of 80-90wt%, a chloroalkane solution of p-methylsulfonyltoluene and a mixed acid solution are simultaneously and continuously added into a reaction system for a nitration reaction, the sulfuric acid is repeatedly used after the nitration reaction material liquid is treated, the sulfuric acid can be used both in the nitration reaction and the oxidation reaction, the sulfuric acid in the oxidation reaction can be repeatedly used, the total molar yield of the 2-nitro-4-methylsulfonylbenzoic acid can achieve more than 90%, and the content is more than 99%. By means of the method, the amount of waste acid in production of 2-nitro-4-methylsulfonylbenzoic acid can be reduced by 90% or above, the use amount of vanadium pentoxide isreduced by 90% or above, three wastes are greatly reduced, the process is safe and environmentally friendly, the amount of the three wastes is small, and the method is suitable for industrial large-scale production.

Owner:JIANGSU FENGSHAN GROUP

Process of preparing 4-amino-3-nitro phenol

ActiveCN101066929BSimplify operating proceduresLow costOrganic compound preparationAmino-hyroxy compound preparationAcetic anhydrideNitration

The present invention belongs to the field of fined chemical intermediate synthesizing technology, and is process of preparing 4-amino-3-nitro phenol. The process of preparing 4-amino-3-nitro phenol includes the following three steps: acetylation of p-aminophenol as material with acetic anhydride, the subsequent nitration with nitric acid, and final hydrolysis of 4-acetoxy-2-acetamino nitrobenzenewith sodium hydroxide. The present invention has simple operation and low cost.

Owner:溧阳常大技术转移中心有限公司

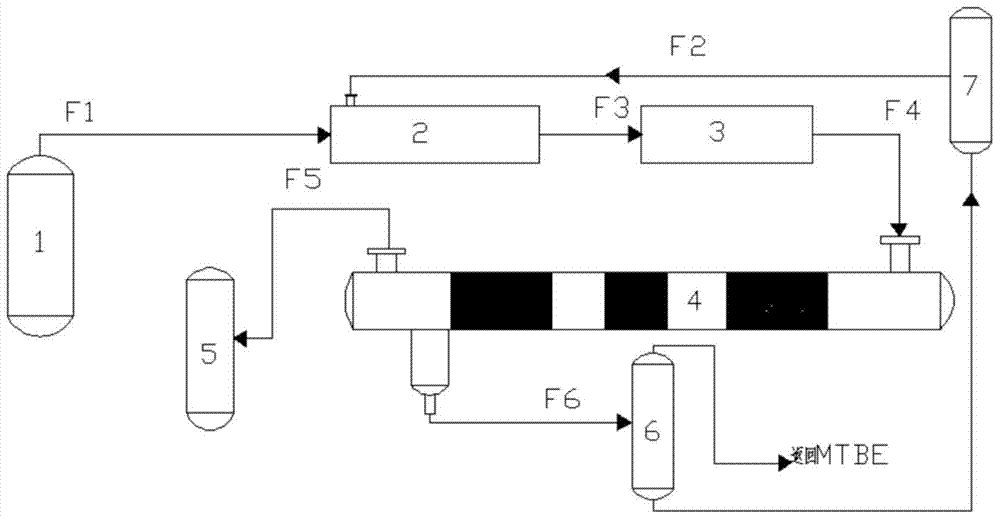

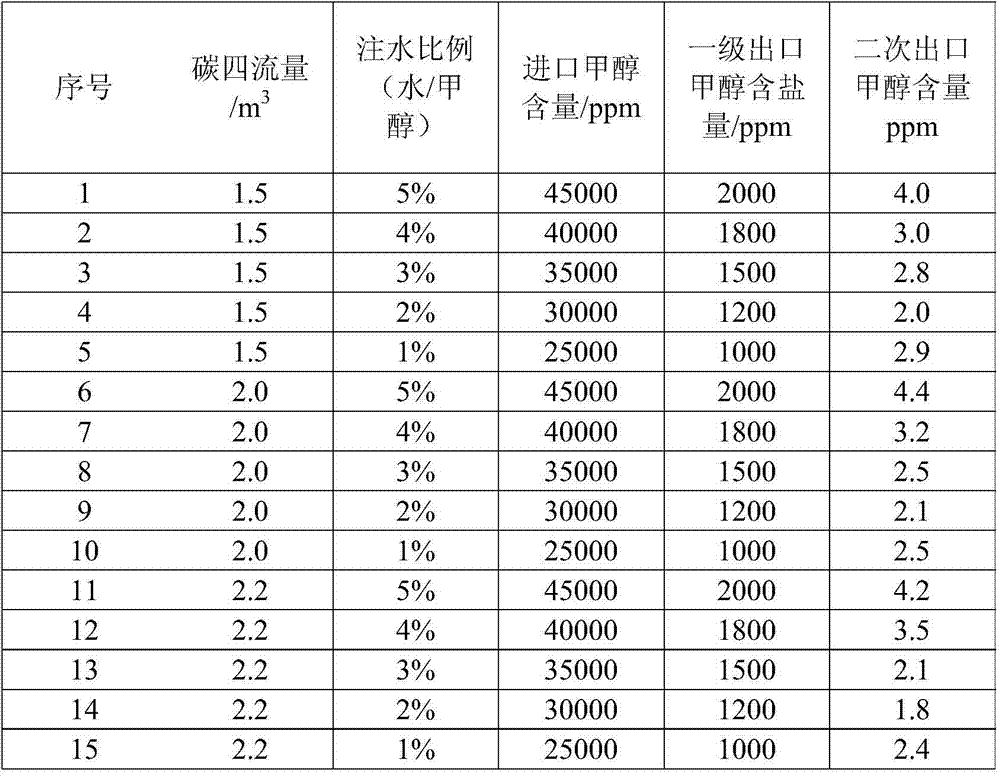

A kind of method and device for deep removal of methanol from carbon four

ActiveCN105016949BReduce lossReduce water consumptionExtraction purification/separationAzeotropic distillationCoalescer

The invention relates to a method and device for deep demethanolization of C4. The demethanolization treatment of C4 extracted from the top of the azeotropic distillation tower is divided into three steps: firstly, the pre-distribution extraction of C4 is carried out by using microphase distribution technology; The C4 and the extract after the final extraction fully enter the modular deep separation device for deep separation of C4 and the extract; the C4 after demethanolization enters the subsequent production device, and the extract returns to the methanol recovery tower for further extraction. Recycle. The present invention also provides a set of devices for realizing the method, including an extraction device and a separation device; the extraction device is divided into a microphase disperser and a micro-swirl flow extraction device; the separation device is a coalescence separation module and a corrugated plate enhanced sedimentation, water bag, Boundary meter and several other parts. The method of the invention has high processing speed and high efficiency, and the methanol content in the treated C4 is not more than 5 ppm, thereby improving the performance of the C4 follow-up deep processing device.

Owner:SHANGHAI MISU ENVIRONMENTAL PROTECTION TECHCO LTD +1

Process for producing precipitated white carbon black from silicon tetrachloride

The invention belongs to a preparation process of white carbon black, in particular to a process for producing precipitated white carbon black from silicon tetrachloride. Add silicon tetrachloride to the hydrochloric acid aqueous solution with a mass concentration of 29-33% containing a dispersant, control the temperature at 28-45°C to react to generate silica sol and hydrogen chloride gas, and the silica sol will form colloidal White flocculent precipitate, the precipitate is separated by filtration, washed, granulated and dried to obtain precipitated white carbon black. The present invention has short process flow, relatively simple production equipment and process control, and easy-to-obtain raw materials; silicon tetrachloride is effectively utilized, and the product hydrogen chloride is completely recovered, thereby reducing treatment costs, reducing the amount of waste acid, and reducing environmental pollution; The production cost is low, the application is extensive, and the market capacity is large.

Owner:昊华宇航化工有限责任公司

A system for producing liquid SO2 from concentrated waste acid

InactiveCN104016308BReduce consumptionIncrease productionSolidificationLiquefactionThermal energySlag

Owner:山东钧策科技服务有限公司

A method for reducing the amount of waste acid in the production of titanium dioxide

ActiveCN105293574BReduce waste acidReduce post-processing costsTitanium dioxideSulfur trioxideTitanium

The invention discloses a method for decreasing the waste acid content in titanium dioxide production. Sulfur trioxide and 55% sulfuric acid are adopted to be premixed with titanium concentrate for an acidolysis reaction in the rutile-type titanium dioxide production process through a sulfuric acid method, and then the method for decreasing the waste acid content in titanium dioxide production is achieved.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

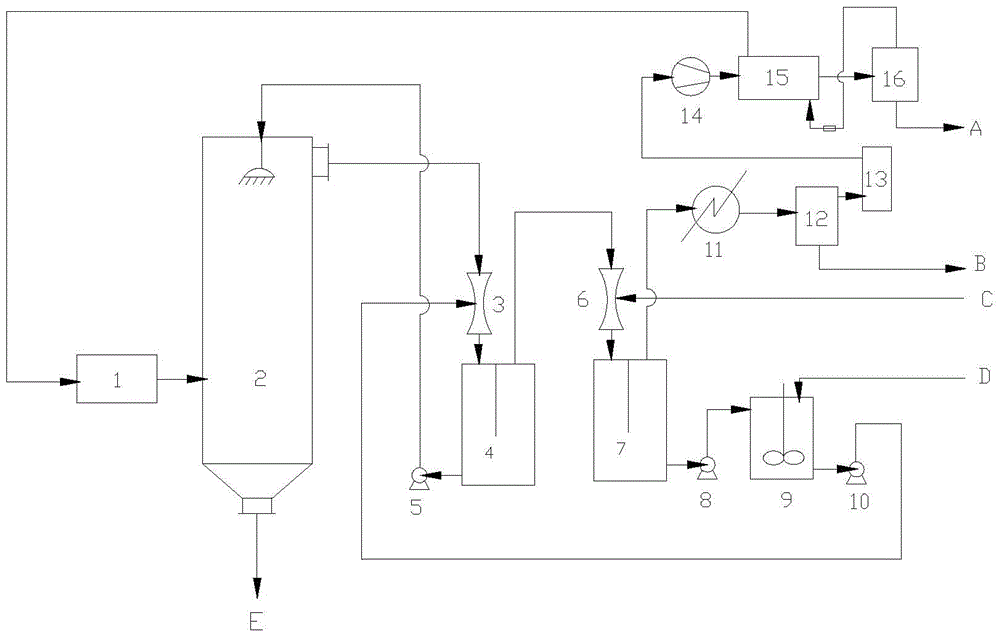

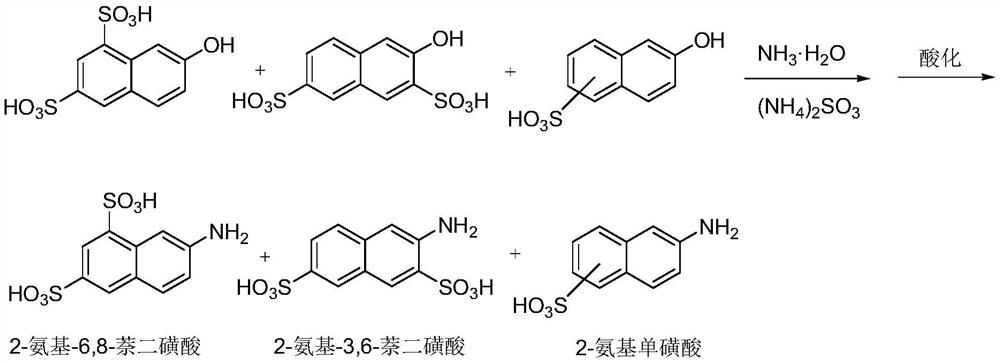

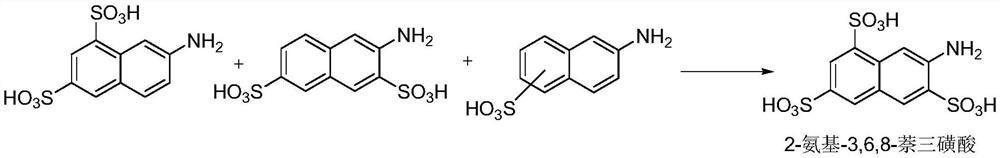

A kind of preparation technology of 2-aminonaphthalenesulfonic acid mixture

ActiveCN108623502BIncrease profitSimple processSulfonic acid preparationOleumAminonaphthalenesulfonic acids

The invention discloses a preparation technology for a 2-sulfonaphtine mixture. The preparation technology comprises the following steps: enabling 2-naphthol to be subjected to sulfonation in sulfuricacid of which the mass fraction is 98-100% and fuming sulphuric acid of which the mass fraction of the sulfuric acid is 105%, to obtain sulfonation liquid of a mixture containing 2-hydroxyl-6,8-naphthalene disulfonic acid, 2-hydroxyl-3,6-naphthalene disulfonic acid and 2-naphthol monosulfonic acid, adding ammonia water to the sulfonation liquid for regulating an ammonia value, adding ammonium sulfite for catalytic-aminolysis, and adding dilute sulphuric acid for acidizing, to obtain a mixture of 2-amino-6,8-naphthalene disulfonic acid, 2-amino-3,6-naphthalene disulfonic acid and 2-amino monosulfonic acid, namely the 2-sulfonaphtine mixture. The mixture is capable of sulfonating in 115% of the fuming sulphuric acid so as to obtain 2-amino-3,6,8-naphthalene trisulfonic acid. The preparationtechnology is capable of greatly improving the utilization ratio of the 2-naphthol.

Owner:SHANDONG CHUANGLAN YAOSHI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com