A kind of method and device for deep removal of methanol from carbon four

A deep methanol removal technology, applied in extraction and purification/separation, organic chemistry, etc., can solve the problems of extraction tower blockage, high energy consumption, corrosion of tray support beams, etc., to reduce the degree of corrosion, reduce the amount of waste acid, treat fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

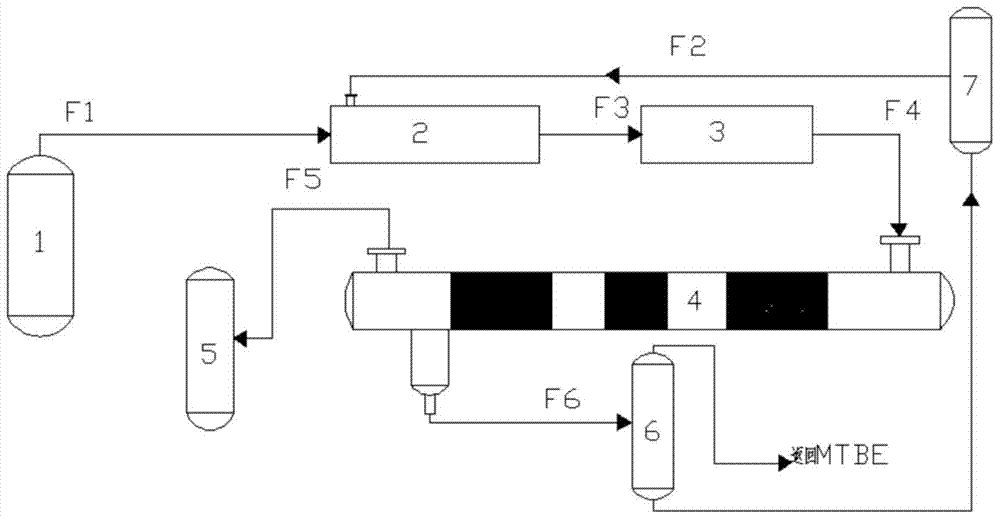

Embodiment 1

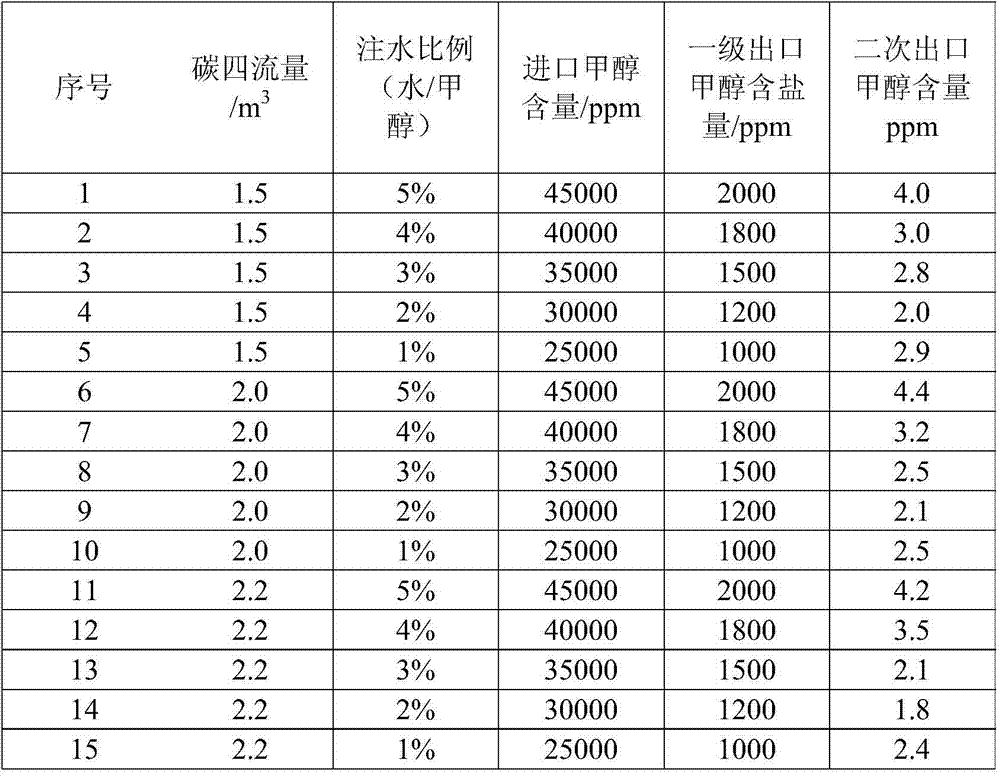

[0043] A refinery and petrochemical company in Shandong found that the content of methanol in C4 after ether was washed and extracted by a methanol washing tower was as high as 1000-3000ppm, which seriously affected the production of the alkylation unit. The C4 after the methanol washing tower is demethanolized. The combination form is microphase disperser 2 + microcyclone extractor 3 for complete extraction, and the first-level coalescence separation module is used for deep separation. The experimental scheme is shown in the following table 1 shows:

[0044] Table 1

[0045] C4 demethanol (after methanol washing tower) experiment record

[0046]

[0047] According to different methanol content, different desalted water inflows are proportioned to achieve the best extraction effect and minimum water consumption, reduce the processing capacity of the methanol recovery tower, and reduce energy consumption.

[0048] Experimental results prove that the content of methanol aft...

Embodiment 2

[0055] In order to compare the difference between whether there is complete extraction or not, the extraction part of this experiment uses the microphase disperser 2 alone, and the microcyclone 3 is short-circuited, and the carbon four after the water washing tower is demethanolized. The experimental scheme is shown in Table 3 below:

[0056] table 3

[0057] C4 demethanol (after methanol washing tower) experiment record table

[0058]

[0059]

[0060] The experimental results prove that the final separation effect cannot meet the separation accuracy requirements when the microphase disperser 2 is used alone for extraction.

Embodiment 3

[0062] In order to compare the difference between whether there is complete extraction or not, the extraction part of this experiment uses the micro-swirl flow extractor 3 alone, short-circuits the micro-phase disperser 2, and demethanolizes the C4 after the water washing tower. The experimental scheme is shown in Table 4 below:

[0063] Table 4

[0064] C4 demethanol (after methanol washing tower) experiment record

[0065]

[0066] The experimental results prove that the final separation effect cannot meet the separation precision requirement when the microphase disperser 3 is used alone for extraction.

[0067] The comparison of the three groups of experiments shows that in the process of demethanolization of C4, extraction and separation have the same effect on the treatment effect, and the best experimental effect is the complete extraction method of microphase disperser 2 + micro cyclone extractor 3, A modular deep separation device is used for complete extraction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com