A non-precious metal mercury-free catalyst for acetylene hydrochlorination and its preparation method and application

A technology of acetylene hydrochlorination and non-precious metals, which is applied in the field of non-precious metal mercury-free catalysts and their preparation, which can solve the problems of high cost and difficult large-scale industrial production, loss of catalyst active components, fast reaction speed, etc., and achieve good catalytic stability , single-pass conversion rate reduction, and the effect of reducing the amount of waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Weigh 17.05g CuCl 2 2H 2 O, 2.67 g NH 4 Cl and 5.76 g 85% H 3 PO 4 Dissolve in 43g of deionized water to prepare CuCl 2 , NH 4 Cl and H 3 PO 4 The solution;

[0052] (2) Set the specific surface area to 700-1300m 2 / g, the carbon tetrachloride adsorption value is 55-65%, and the ash value is less than 6%. The granular activated carbon after pickling is soaked in the above-mentioned prepared solution at room temperature, and the volume ratio of the control solution to the activated carbon is 0.5:1. , soak for 2 hours;

[0053] (3) Dry the soaked activated carbon and dry it with hydrogen chloride gas at 100°C to obtain the required catalyst A1.

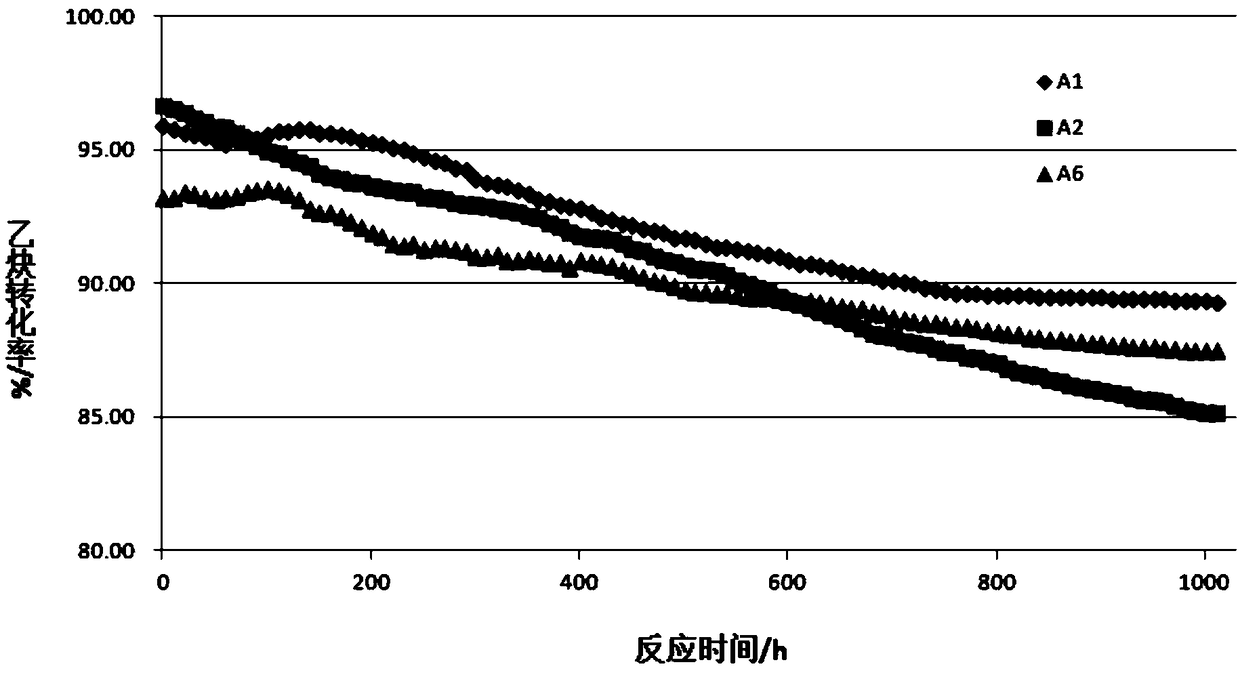

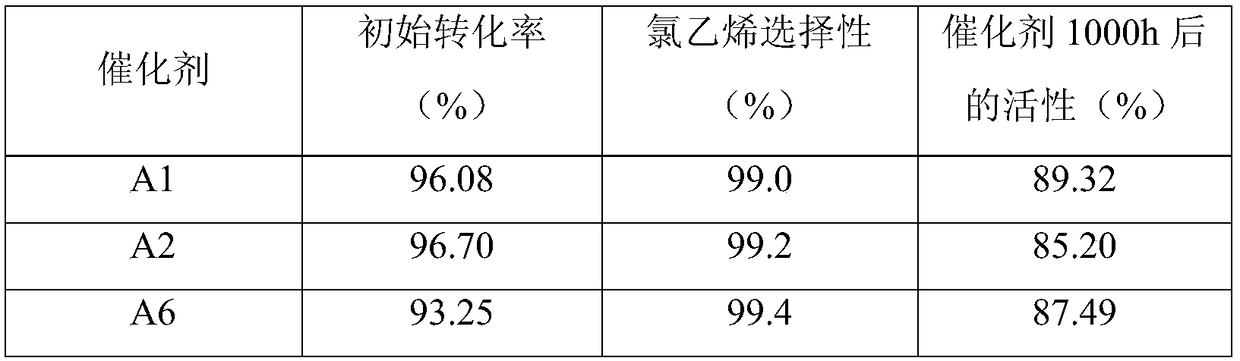

[0054] (4) The above-mentioned catalyst is loaded into the tube reactor, and the C 2 h 2 Mixed gas with HCl (C 2 h 2 and HCl molar ratio of 1:1.05) for hydrochlorination reaction, control the reaction temperature at 80°C, and the acetylene space velocity at 20h -1 , the reaction gauge pressure is 0.1MPa, the in...

Embodiment 2

[0056] (1) Weigh 17.05g CuCl 2 2H 2 O, 1.07 g NH 4 Cl and 9.2 g 85% H 3 PO 4 Dissolve in 80g of deionized water to prepare CuCl 2 , NH 4 Cl and H 3 PO 4 The solution;

[0057] (2) Set the specific surface area to 700-1300m 2 / g, the carbon tetrachloride adsorption value is 55~65%, the granular activated carbon after pickling is less than 6% is soaked in the above-mentioned prepared solution, and the control soaking temperature is 40 ℃, the volume ratio of solution and activated carbon is less than 6%. 1:1, soak for 10 hours;

[0058] (3) Dry the soaked activated carbon and dry it with hydrogen chloride gas at 150° C. to obtain the required catalyst A2.

[0059] (4) The above-mentioned catalyst is loaded into the tube reactor, and the C 2 h 2 Mixed gas with HCl (C 2 h 2 The molar ratio of HCl and HCl is 1:1) for hydrochlorination reaction, the temperature of the reaction is controlled at 100°C, and the space velocity of acetylene is 50h -1 , the reaction gauge pr...

Embodiment 3

[0061] (1) Weigh 17.05g CuCl 2 2H 2 O, 6.42 g NH 4 Cl and 6.92 g 85% H 3 PO 4 Dissolve in 100g of deionized water to prepare CuCl 2 , NH 4 Cl and H 3 PO 4 The solution;

[0062] (2) Set the specific surface area to 700-1300m 2 / g, the carbon tetrachloride adsorption value is 55~65%, and the granular activated carbon after pickling is less than 6% is soaked in the above-mentioned prepared solution, and the control soaking temperature is 60 ℃, and the volume ratio of solution and activated carbon is: 1.5:1, soak for 5 hours;

[0063] (3) Dry the soaked activated carbon and dry it with hydrogen chloride gas at 200°C to obtain the desired catalyst A3.

[0064] (4) The above-mentioned catalyst is loaded into the tube reactor, and the C 2 h 2 Mixed gas with HCl (C 2 h 2 The molar ratio of HCl and HCl is 1:1.03) for hydrochlorination reaction, the temperature of the reaction is controlled at 120°C, and the space velocity of acetylene is 40h -1 , the reaction gauge pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com