Preparation method of 2-nitro-4-methylsulfonylbenzoic acid

A technology of methylsulfonylbenzoic acid and methylsulfonyltoluene is applied in the field of preparation of 2-nitro-4-methylsulfonylbenzoic acid, and can solve the problems of small amount of three wastes, high production cost, large amount of three wastes and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

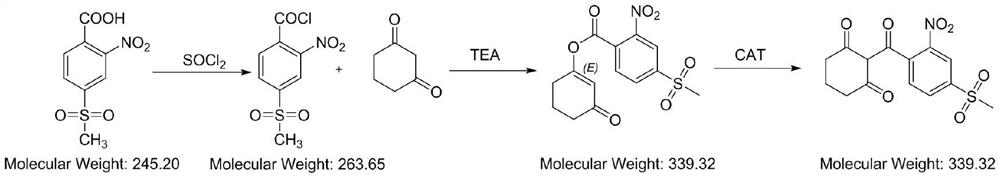

Image

Examples

Embodiment 1

[0044] 1) Nitrification reaction

[0045]First drop 1000kg of dichloromethane into the dissolution kettle, then drop into 170kg (1.0kmol) p-thiamphenicol toluene, stir, dissolve, and set aside; add 613kg (5kmol) of sulfuric acid with a mass fraction of 90wt% to the mixing acid kettle, and start the circulating water temperature control 20-30°C, slowly add 101.9kg (1.1kmol) of nitric acid dropwise, control the temperature at 20-50°C during the dropwise addition, and then cool down to 20-30°C for later use.

[0046] Simultaneously and continuously pump p-thiamphenyltoluene dichloromethane solution and sulfuric acid-nitric acid mixed acid solution into the tubular reactor, control the flow of the two solutions, keep the reaction temperature at 20-30°C, and receive the output material until nitration treatment Still, sampling detection p-thymphenyltoluene content is less than 0.5%, and the reaction ends.

[0047] The nitration treatment tank that receives the reaction discharge i...

Embodiment 2

[0057] 1) Nitrification reaction

[0058] First put 1600kg of dichloroethane into the dissolution kettle, then drop into 170kg (1.0kmol) p-thiamphenicol toluene, stir, dissolve, and set aside; add 871kg (8kmol) of sulfuric acid with a mass fraction of 90wt% to the mixed acid kettle, and open the circulating water control Temperature 10~20 ℃, slowly drop nitric acid 139kg (1.5kmol), control temperature 20~50 ℃ during dropwise, then cool down to 20~30 ℃ standby, the sulfuric acid that described mass fraction is 90wt% is the nitration treatment still. Apply sulfuric acid out.

[0059] Simultaneously and continuously pump p-thiamphenyltoluene dichloromethane solution and sulfuric acid-nitric acid mixed acid solution into the tubular reactor, control the flow of the two solutions, keep the reaction temperature at 10-20°C, and control the feed and output of the reactor. The material speed, the total material time is 2 hours, the output material is received into the nitration treatm...

Embodiment 3

[0069] 1) Nitrification reaction

[0070] First put 1200kg of chloroform into the dissolution kettle, then put in 170kg (1.0kmol) of p-thiamphenicol toluene, stir, dissolve, and set aside; add 80% sulfuric acid 735kg (6kmol) to the mixing acid kettle, and turn on the circulating water to control the temperature at 20-30°C , slowly add 92.6kg (1.0kmol) of nitric acid dropwise, control the temperature at 20-50°C during the dropwise addition, and then cool down to 20-30°C for later use;

[0071] Simultaneously and continuously pump p-thiamphenyltoluene dichloromethane solution and sulfuric acid-nitric acid mixed acid solution into the tubular reactor, control the flow of the two solutions, keep the reaction temperature at 20-30°C, and control the feed and output of the reactor. The material speed, the total material time is 3 hours, the output material is received into the nitration treatment tank, and when the content of p-thymphenyltoluene is less than 1%, the sample is qualifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com