Process for producing precipitated white carbon black from silicon tetrachloride

A technology for precipitating white carbon black and silicon tetrachloride, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of ineffective treatment, waste of the environment, narrow use range, etc., achieve simple production equipment and process control, and reduce processing The effect of small cost and investment scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

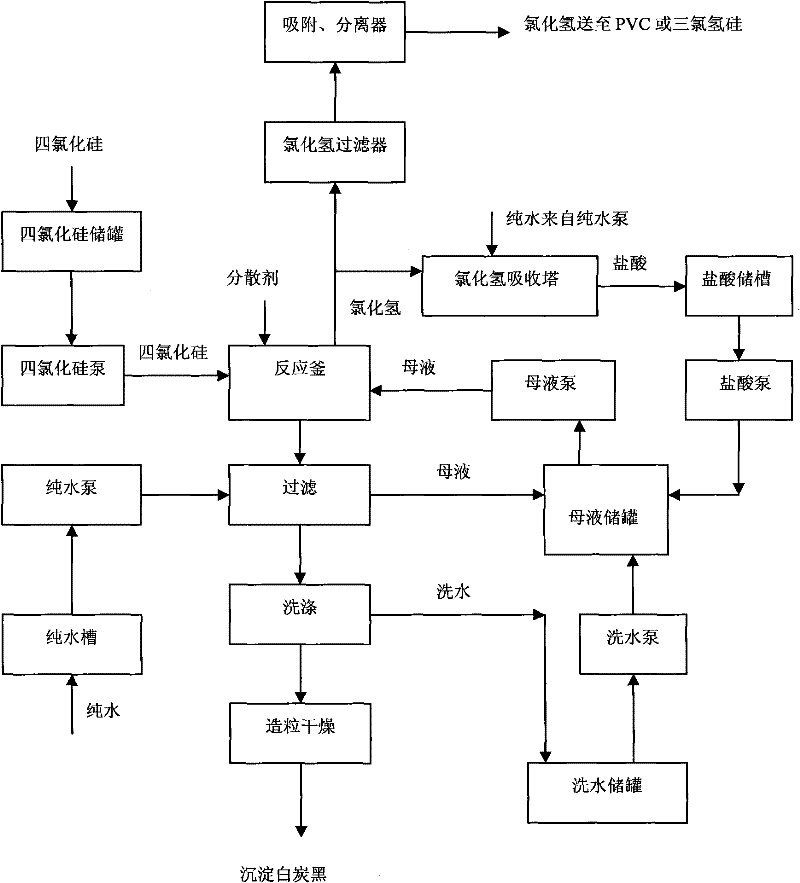

Method used

Image

Examples

Embodiment 1

[0015] Add 60L of hydrochloric acid solution with a mass concentration of 29% in the reaction kettle, add 3.6g of sodium dodecylbenzenesulfonate dispersant, stir well, and heat through steam in the jacket, and the temperature is controlled at 40°C. Slowly add silicon tetrachloride into the reaction kettle, and control the flow rate of silicon tetrachloride at 0.8m 3 / h, adjust the amount of cooling water at any time during the addition process, and control the temperature in the kettle at 41-45°C. After the hydrogen chloride gas produced in the reaction is treated by filtration, adsorption, separation and other devices, the qualified hydrogen chloride is sent to the PVC or trichlorosilane production device for use, and the unqualified hydrogen chloride is absorbed by water and then replenished to the mother liquid storage tank; continuous sampling during the reaction process Analyze the purity of hydrogen chloride, when the hydrogen chloride purity ≥ 95%, it can all be recover...

Embodiment 2

[0017] Add 60L of hydrochloric acid solution with a mass concentration of 31% in the reaction kettle, add 4.8g of hexadecyltrimethylammonium bromide dispersant, stir well, pass steam into the jacket for heating, and control the temperature at 38°C . Slowly add silicon tetrachloride into the reactor, and control the flow rate of silicon tetrachloride at 1.0m 3 / h, adjust the amount of cooling water at any time during the addition process, and control the temperature in the kettle at 36-40°C. After the hydrogen chloride gas produced in the reaction is treated by filtration, adsorption, separation and other devices, the qualified hydrogen chloride is sent to the PVC or trichlorosilane production device for use, and the unqualified hydrogen chloride is absorbed by water and then replenished to the mother liquid storage tank; continuous sampling during the reaction process Analyze the purity of hydrogen chloride, when the hydrogen chloride purity ≥ 95%, it can all be recovered, an...

Embodiment 3

[0019] Add 60L of hydrochloric acid solution with a mass concentration of 33% in the reaction kettle, add 7.2g of cetyltrimethylammonium bromide dispersant, stir well, pass steam into the jacket for heating, and control the temperature at 32°C . Slowly add silicon tetrachloride into the reactor, control the flow of silicon tetrachloride at 1.2m 3 / h, adjust the amount of cooling water at any time during the addition process, and control the temperature in the kettle at 28-34°C. After the hydrogen chloride gas produced in the reaction is treated by filtration, adsorption, separation and other devices, the qualified hydrogen chloride is sent to the PVC or trichlorosilane production device for use, and the unqualified hydrogen chloride is absorbed by water and then replenished to the mother liquid storage tank; continuous sampling during the reaction process Analyze the purity of hydrogen chloride, when the hydrogen chloride purity ≥ 95%, it can all be recovered, and when the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com