Mercury-free catalyst used for acetylene hydrochlorination for synthesizing vinyl chloride, and preparation method and application thereof

A technology for the synthesis of vinyl chloride and mercury catalysts by hydrochlorination of acetylene, which is applied in the direction of hydrogen halide addition preparation, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., and can solve problems that are difficult to meet large-scale Industrial production needs, easy loss of metal salts, high cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

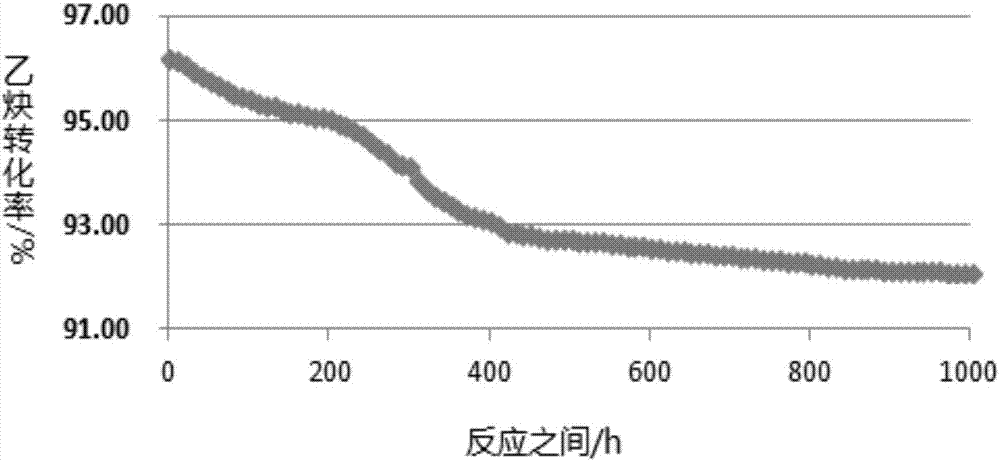

Image

Examples

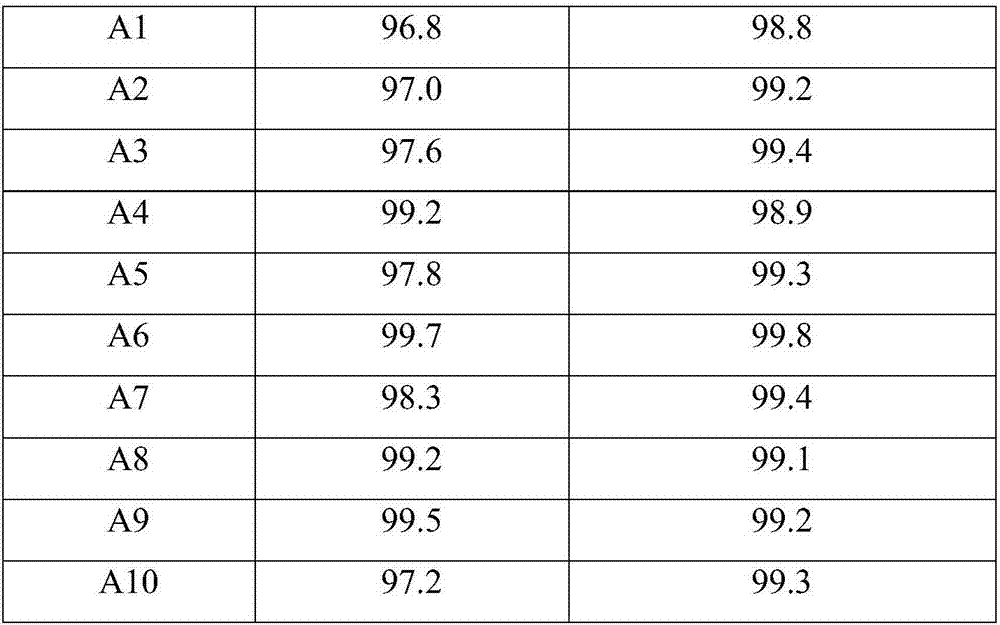

Embodiment 1

[0098] (1) Weigh 76.12g CuCl 2 2H 2 O and 8g N-Methylpyrrolidone are dissolved in the deionized water of 315.88g, obtain the impregnation solution containing copper chloride and N-Methylpyrrolidone;

[0099] (2) The specific surface area is 700 ~ 1500m 2 / g, the carbon tetrachloride adsorption value is 50~70%, and the granular activated carbon after the ash content is less than 6% is soaked in the above-mentioned prepared solution at room temperature, and the control soaking temperature is 70 ℃, the solution and activated carbon The volume ratio is 2:1, soak until the concentration of copper chloride in the solution is constant;

[0100] (3) filter the soaked activated carbon, dry it, and dry it with hydrogen chloride gas at 120°C to obtain the required catalyst A1;

[0101] (4) put C 2 h 2 Mixed gas with HCl (C 2 h 2 and HCl molar ratio of 1:1.1) into the first-stage tube reactor equipped with catalyst A1 for hydrochlorination reaction, the cooling temperature in the j...

Embodiment 2

[0104] (1) Weigh 58.5g CuCl 2 2H 2 0 and 12g 2-pyrrolidone 84g deionized water, obtain the impregnation solution containing copper chloride and 2-pyrrolidone;

[0105] (2) The specific surface area is 700 ~ 1500m 2 / g, the carbon tetrachloride adsorption value is 50~70%, the ash value is less than 6%. The granular activated carbon after pickling is soaked in the above-mentioned prepared solution at room temperature, and the control soaking temperature is room temperature, the volume of solution and activated carbon The ratio is 1.5:1, soak until the concentration of copper chloride in the solution is constant;

[0106] (3) filter the soaked activated carbon, dry it, and dry it with hydrogen chloride gas at 120°C to obtain the required catalyst A2;

[0107] (4) put C 2 h 2 Mixed gas with HCl (C 2 h 2 The molar ratio of HCl and HCl is 1:1.05) into the first-stage tube reactor equipped with catalyst A2 for hydrochlorination reaction, the reaction temperature is controlled ...

Embodiment 3

[0110] (1) Weigh 50.75g CuCl 2 2H 2 O and 6g N-methylcaprolactam are dissolved in 143.25g deionized water to obtain an impregnation solution containing copper chloride and N-methylcaprolactam;

[0111] (2) The specific surface area is 700 ~ 1500m 2 / g, the adsorption value of carbon tetrachloride is 50-70%, and the ash value is less than 6%. The granular activated carbon after pickling is soaked in the above-mentioned prepared solution at room temperature, and the soaking temperature is controlled to be 50°C. The volume ratio is 1:1, soak until the concentration of copper chloride in the solution is constant;

[0112] (3) Filter the soaked activated carbon, dry it, and dry it with hydrogen chloride gas at 150°C to obtain the required catalyst A3;

[0113] (4) put C 2 h 2 Mixed gas with HCl (C 2 h 2 and HCl molar ratio of 1:1.05) into the first-stage tube reactor equipped with catalyst A3 for hydrochlorination reaction, the cooling temperature in the jacket is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com