System for preparing liquid SO2 from concentrated waste acid

A SO2, liquid technology, applied in the field of concentrated waste acid to liquid SO2 system, can solve the problems of unstable gas combustion, large heat of gasification, corrosion of waste heat boilers, etc., to achieve the effect of easy further processing, sufficient energy recovery, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

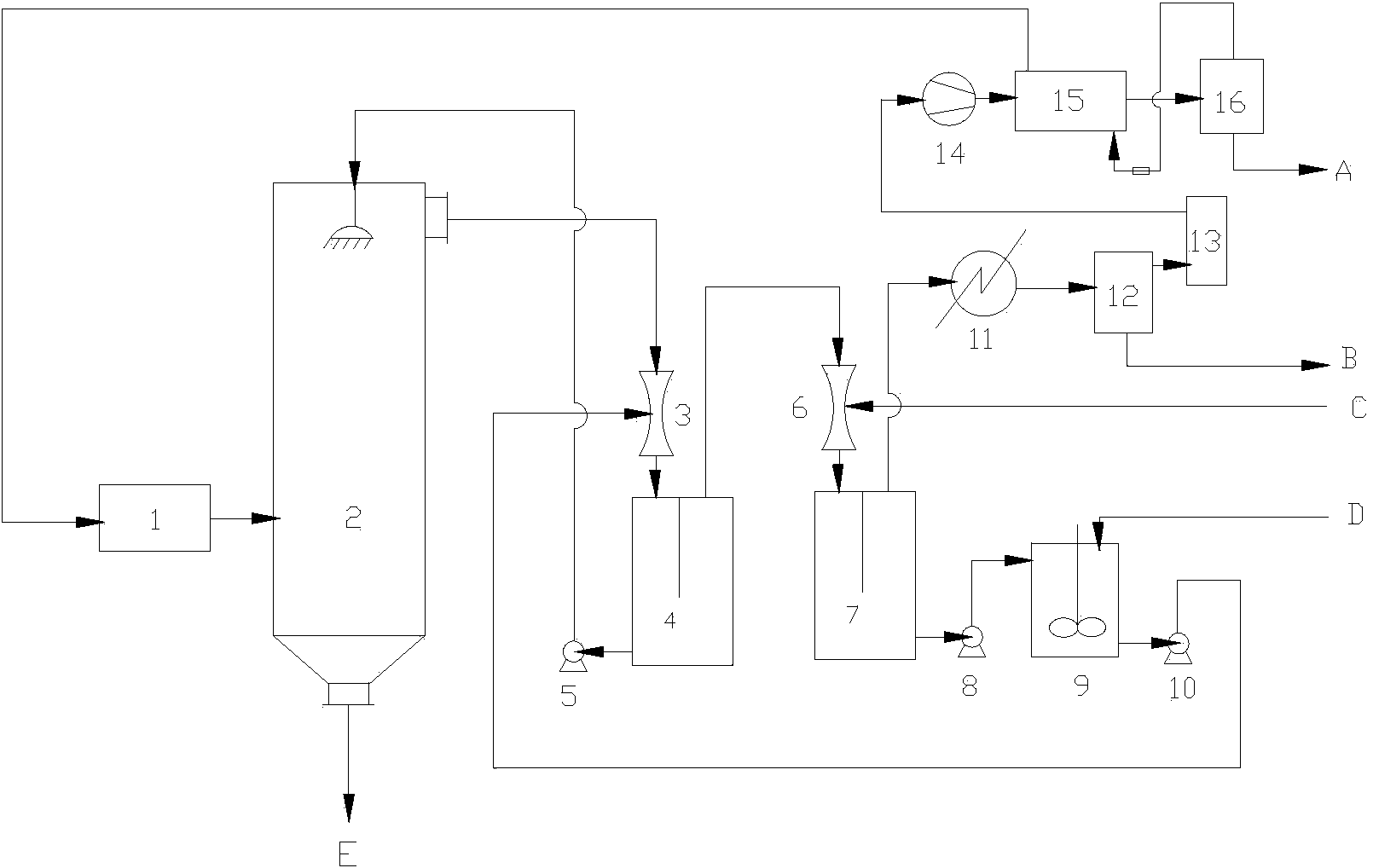

[0039] refer to figure 1 , a concentrated waste acid to liquid SO 2 The system uses sulfur as a reducing agent to reduce concentrated waste acid to produce SO 2 Gas, the unreacted waste acid with high solid content is further sent to gasification and decomposition under an inert atmosphere, the sulfur element in the waste acid is recovered, and the solid phase slag in the waste acid is separated; the prepared concentrated SO 2 The gas is dried by dehydration, pressurized and cooled to obtain liquid SO 2 ; Including temperature control gasification decomposition system, redox reaction system, heat energy recovery system, sulfur dissolving system, dehydration drying system and compression separation system.

[0040] The temperature-controlled gasification and decomposition system is composed of an electric heating device 1 and a gasification chamber 2;

[0041] The redox reaction system is composed of a Venturi reaction mixer 3, a reaction separator 4 and a high-solid waste a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com