Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Reduce use value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

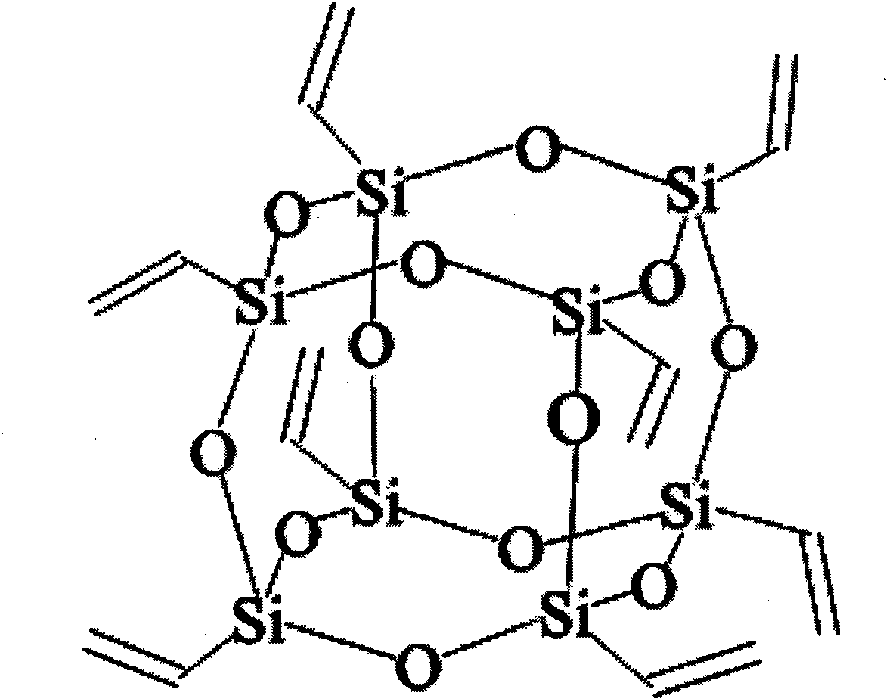

Acidproof, alkali-proof and hydrogen-sulphide-corrosion-resistant aflas composite

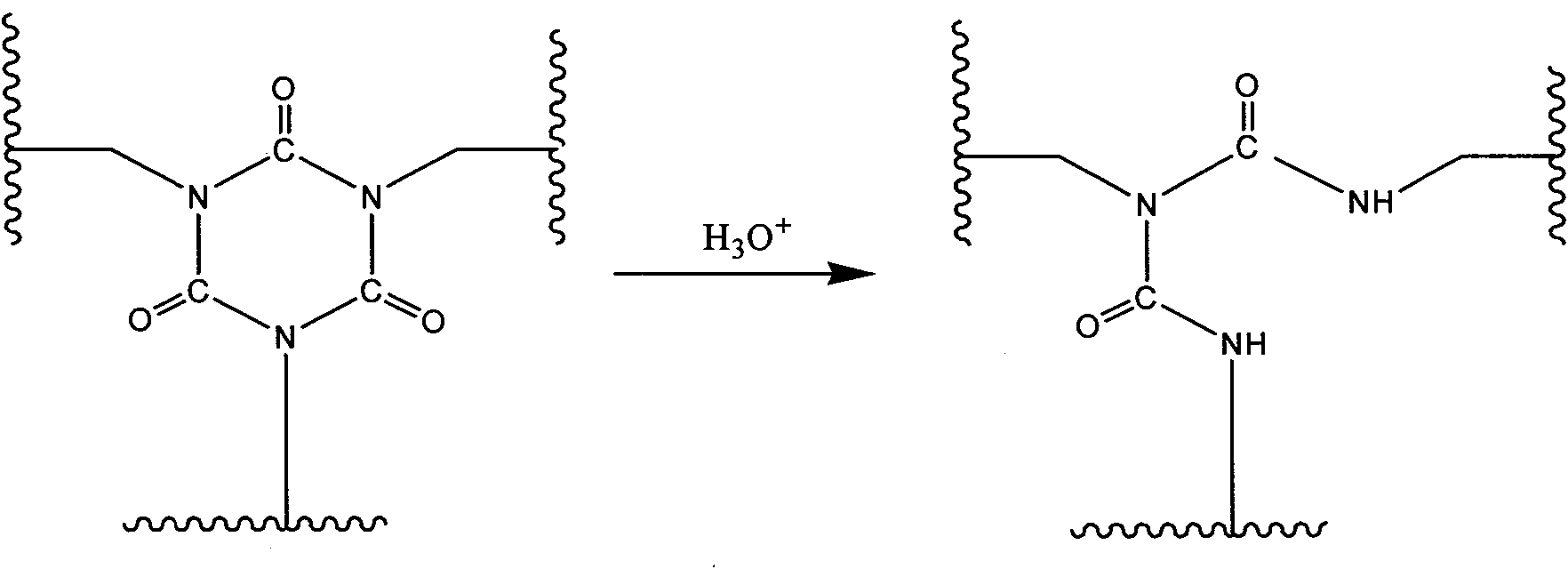

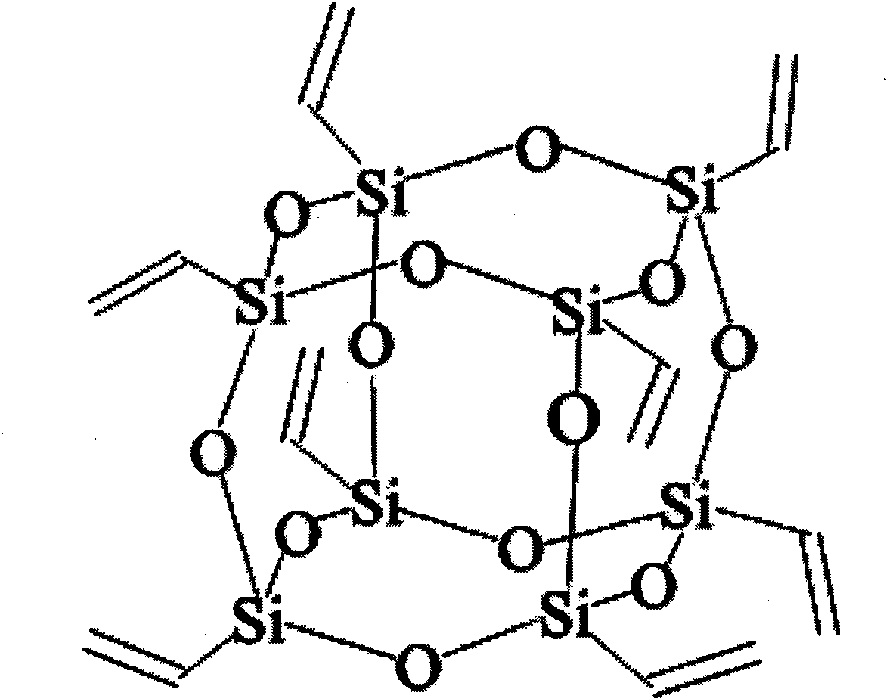

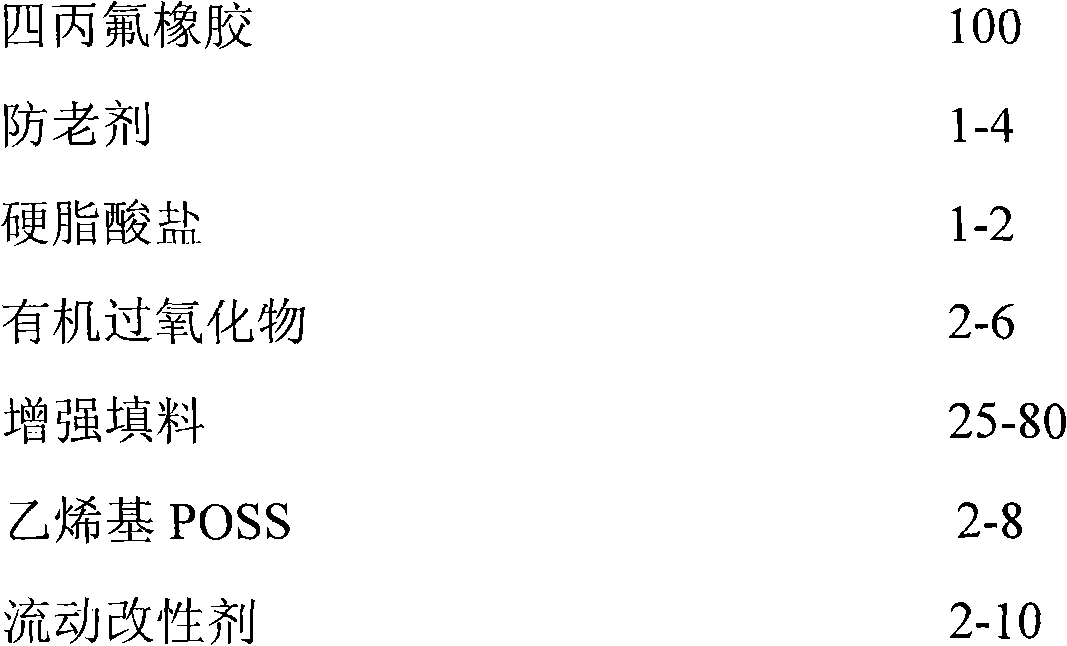

The invention relates to an acidproof, alkali-proof and hydrogen-sulphide-corrosion-resistant aflas composite. In the composite, aflas serves as main material, organic peroxide serves as a cross linking agent, vinyl polyphenyl silsesquioxane serves as an assistant cross-linking agent, hard carbon black serves as an enhanced filler, and resin serves as a flow modifier. The composite can be used for preparing rubber products used in an acid or alkali environment, especially in the hydrogen sulfide environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

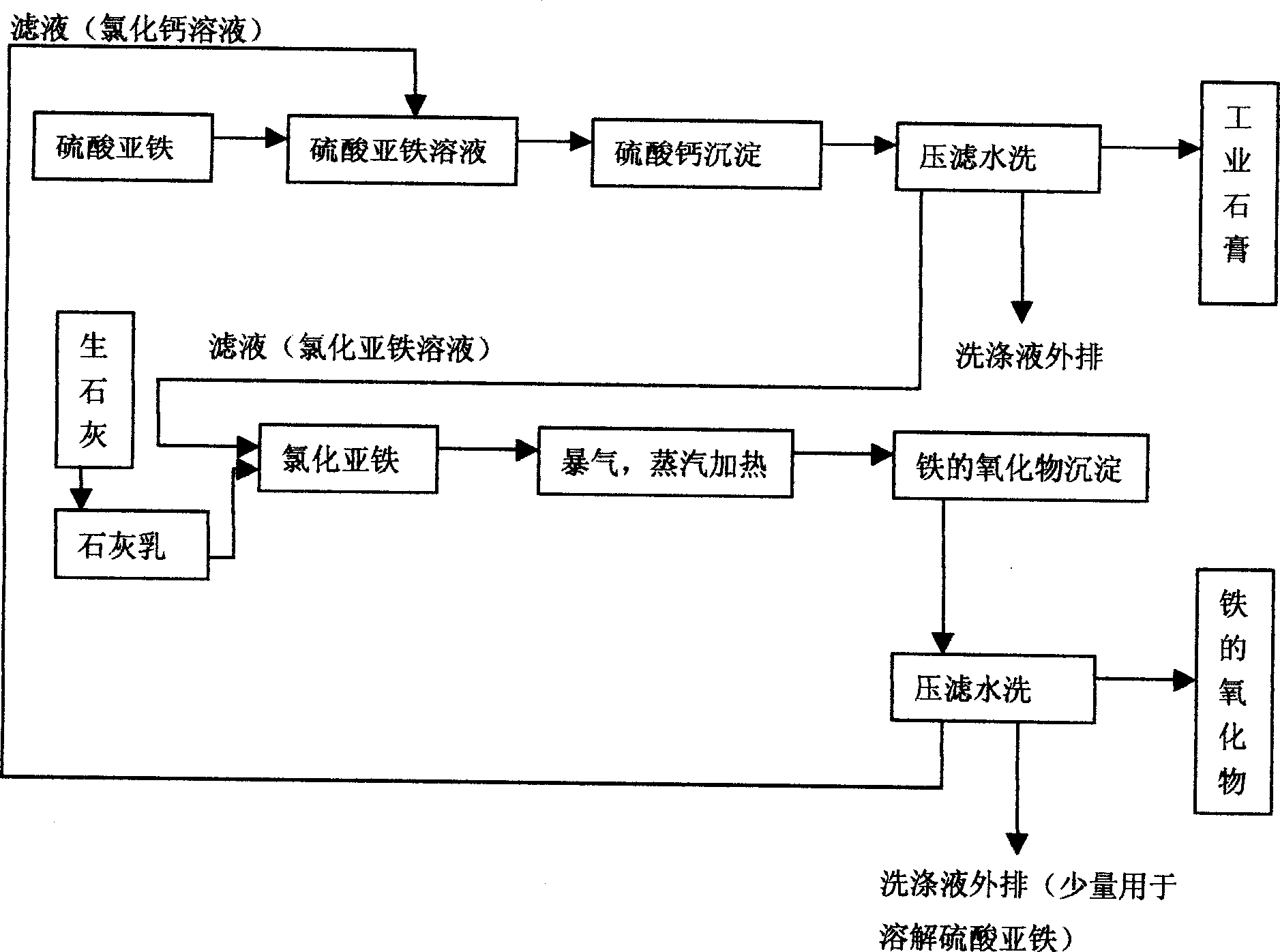

Comprehensively utilizing new process for ferrous sulfate

The technological process of utilizing ferrous sulfate comprehensively in preparing industrial gypsum and iron with lime as main material has the key point of bridging effect of calcium chloride. The technological process includes the steps of: dissolving ferrous sulfate in water, adding calcium chloride solution to produce calcium sulfate precipitate and ferrous chloride solution, filtering to separate calcium sulfate precipitate, adding lime milk into the filtrate and heating via stirring to produce ferric hydroxide precipitate, filtering, stoving the filter slag to obtain ferric oxide, and returning the filtrate. The obtained ferric oxide may be used in smelting iron, preparing iron oxide red, etc. The present invention has relatively low cost of utilizing ferrous sulfate.

Owner:刘应兵

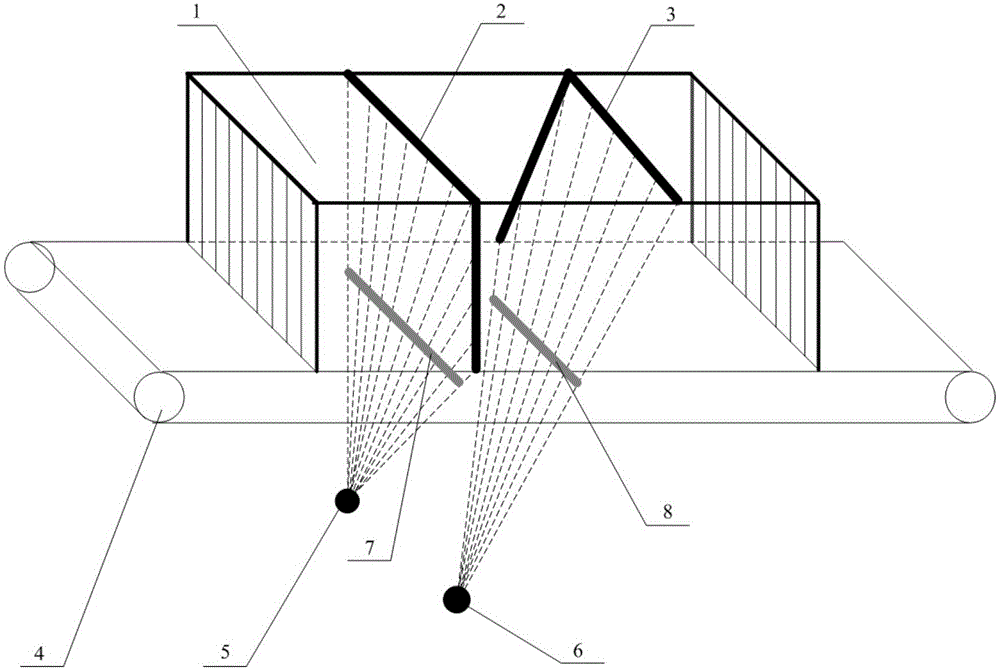

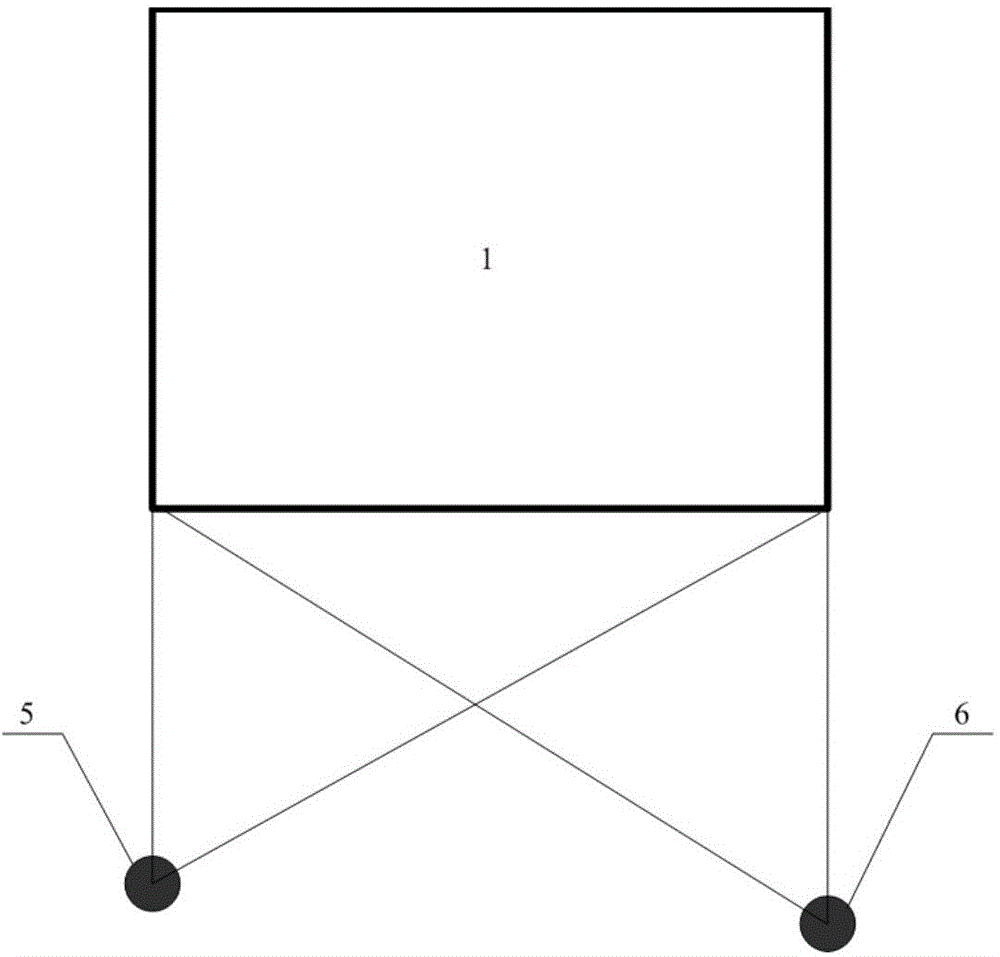

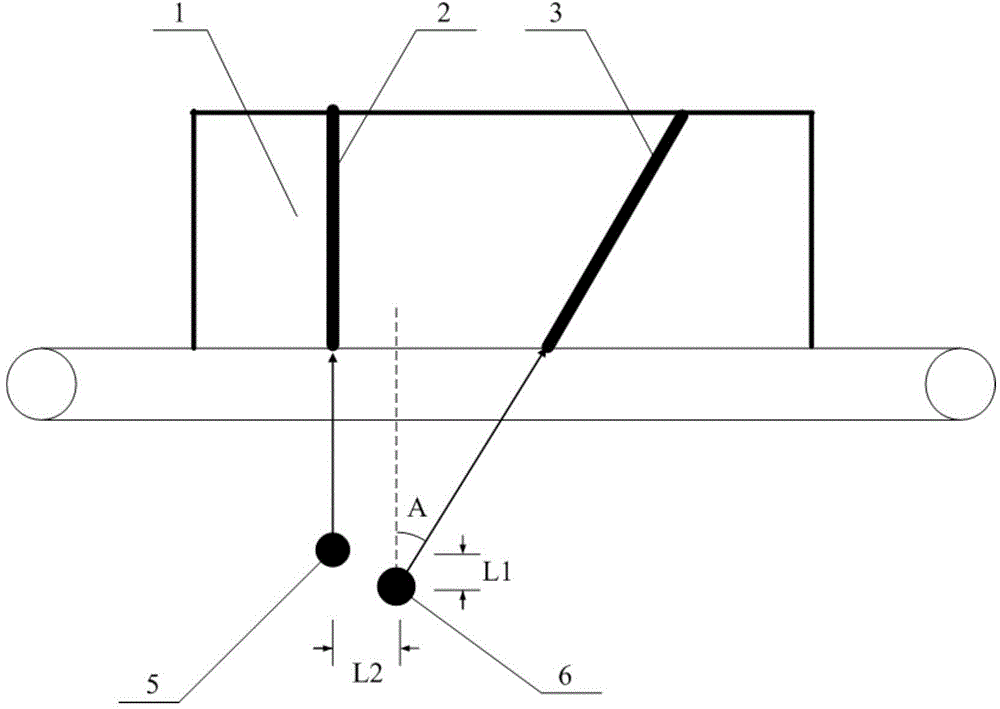

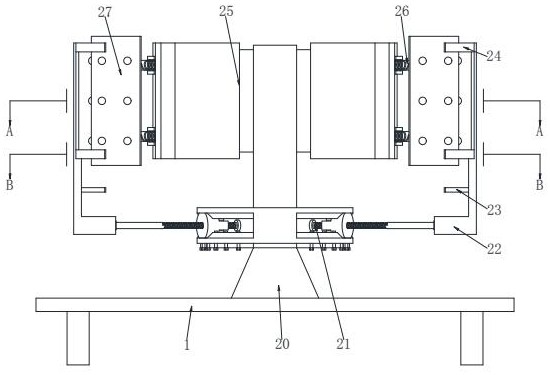

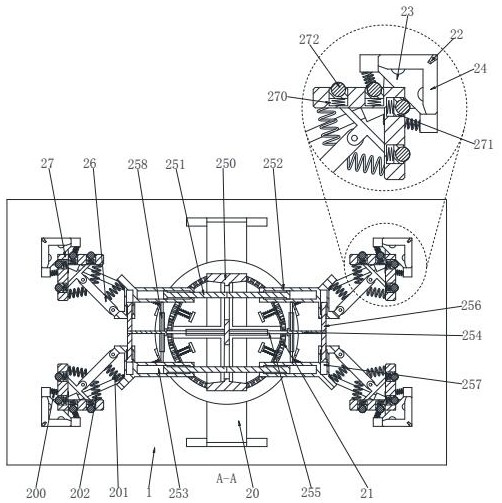

Channel type double-view-angle X-ray safety inspection device

InactiveCN105784733ARich field of viewReduce use valueMaterial analysis by transmitting radiationNuclear radiation detectionX-rayField of view

The invention discloses a channel type double-view-angle X-ray safety inspection device which comprises a conveying channel and double view angles. The double view angles are composed of two groups of X-ray sources and detectors, each group of X-ray source and detector forms an imaging system for one view angle, and the double view angles are a first view angle and a second view angle arranged around the conveying channel; the first view angle comprises a first X-ray source and a first detector; the second view angle comprises a second X-ray source and a second detector; the first X-ray source is located just under a side plate on one side of the conveying channel, and the second X-ray source is located just under a side plate on the other side of the conveying channel. The channel type double-view-angle X-ray safety inspection device has the advantages that view field of a security inspector is wider, the second view angle has more use values than a traditional side view angle, and no blind corner for imaging of a piece-shaped object occurs.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

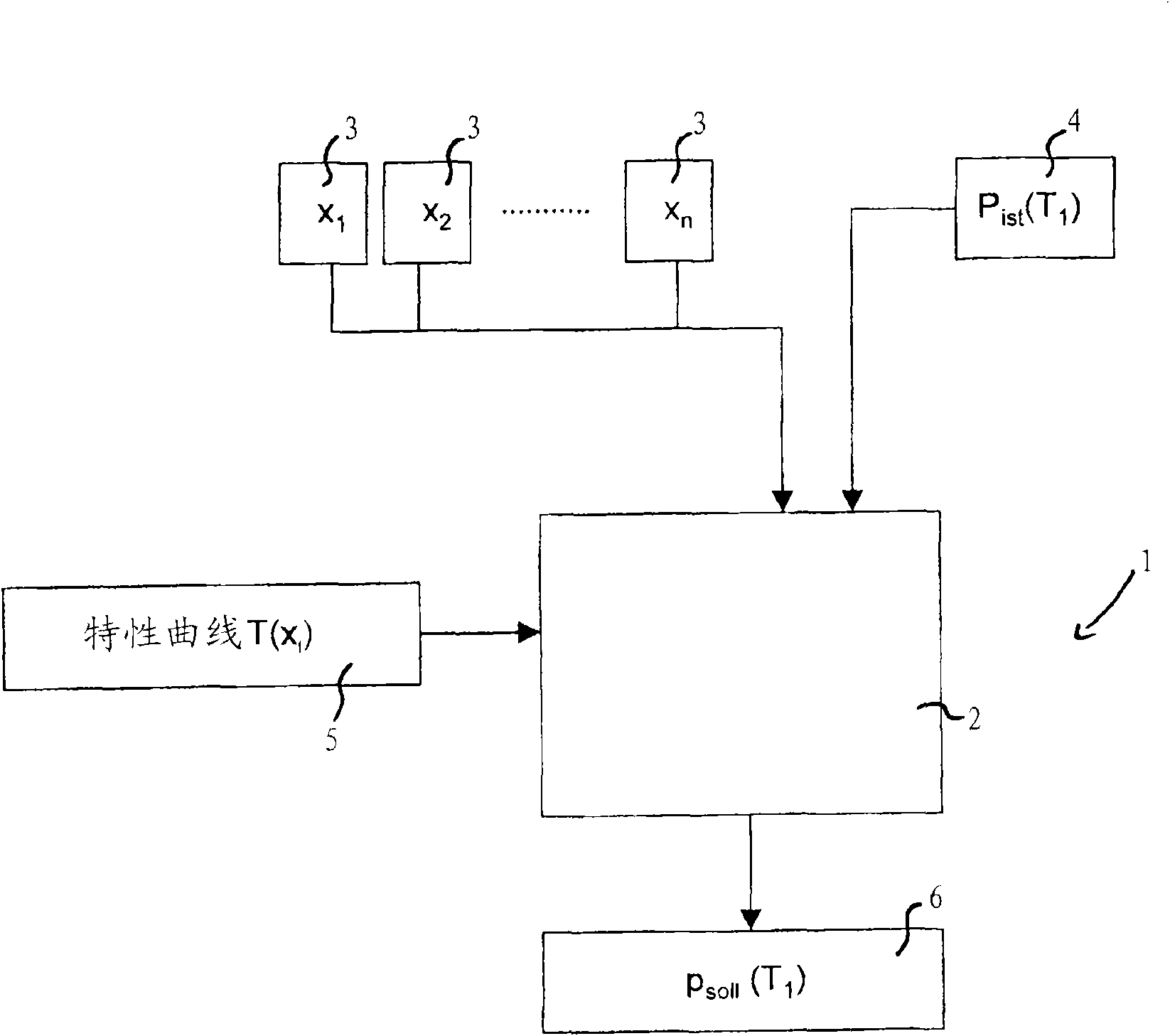

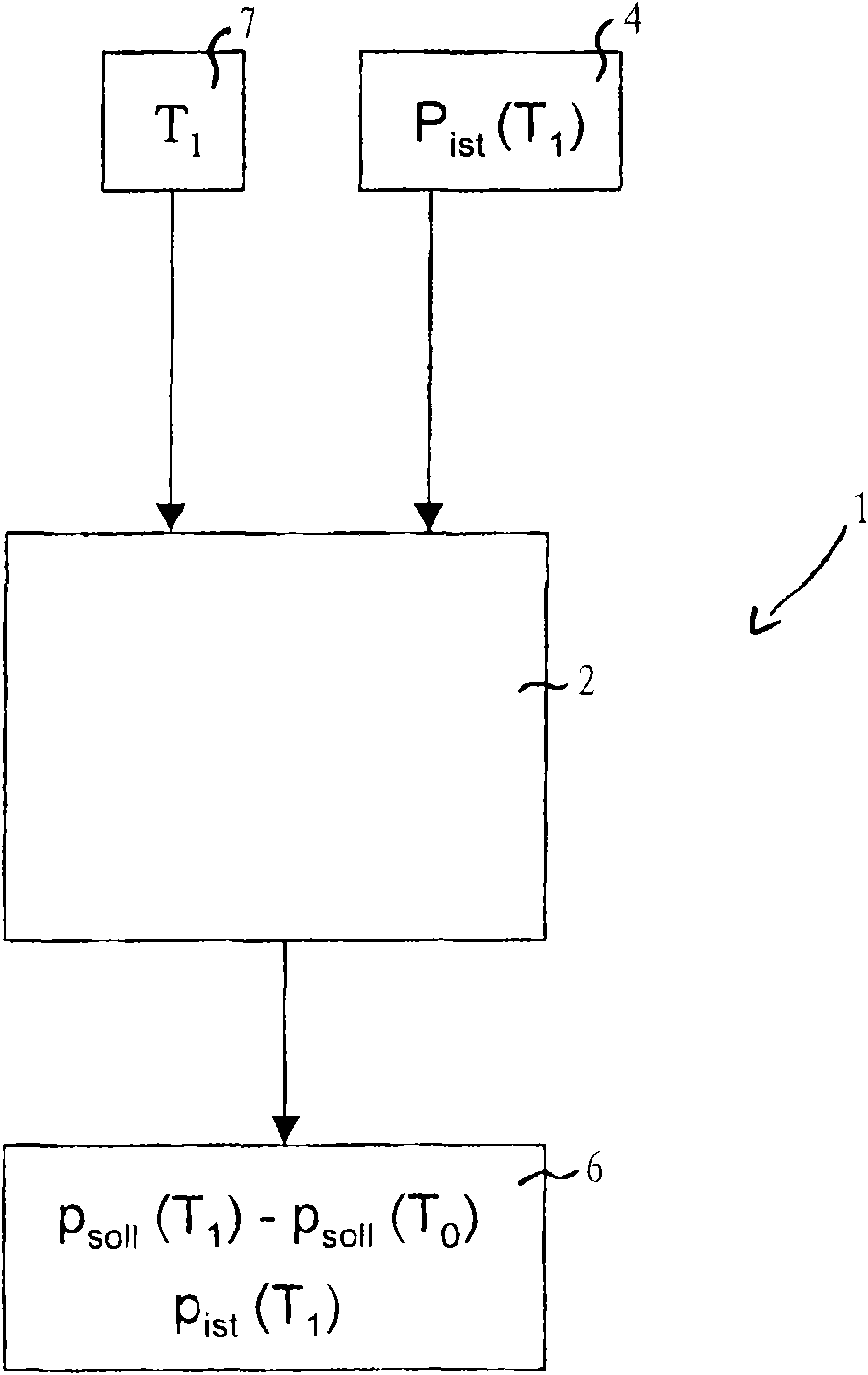

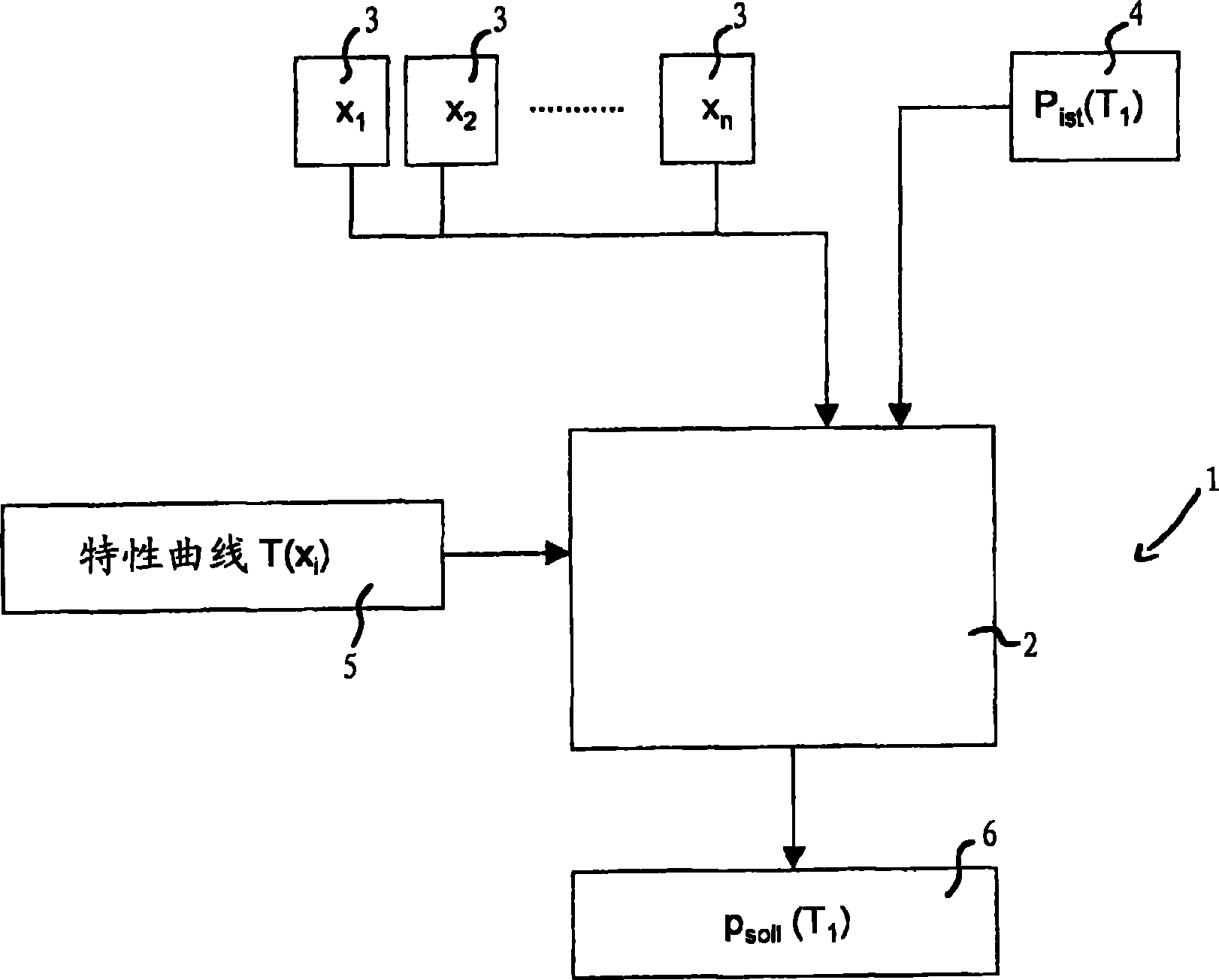

Device and method for automatically monitoring tire pressure

InactiveCN102529603AReduce use valueReduce Technology SpendingTyre measurementsEngineeringTire pressure

A method for automatically monitoring tire pressure in a vehicle encompasses indirectly determining the actual temperature in a vehicle tire, wherein the actual temperature is ascertained based on empirically determined families of characteristics as a function of parameters that describe environmental conditions, driving conditions and / or material properties of the vehicle tires.

Owner:GM GLOBAL TECH OPERATIONS LLC

Quail feed additive

InactiveCN102578395AImprove the immunityPrevention of quail coccidiosisAnimal feeding stuffAccessory food factorsDiseaseAnimal science

The invention relates to a quail feed additive comprising the following components in part by weight: 10-20 parts of aureomycin, 3-5 parts of bacitracin zinc, 15-20 parts of oxytetracycline, 5-15 parts of dinitolmide, 5-15 parts of L-calcium ascorbate, 10-20 parts of calcium propionate, 5-10 parts of anise oil, 20-30 parts of bentonite and 1-5 parts of lucerne meal. The quail feed additive is capable of preventing and treating various diseases which are easily produced in the production process of quails, and further has the effects of increasing appetite, promoting animal growth, boosting feed digestion and improving the immunity of organisms.

Owner:常熟市汇康食品厂

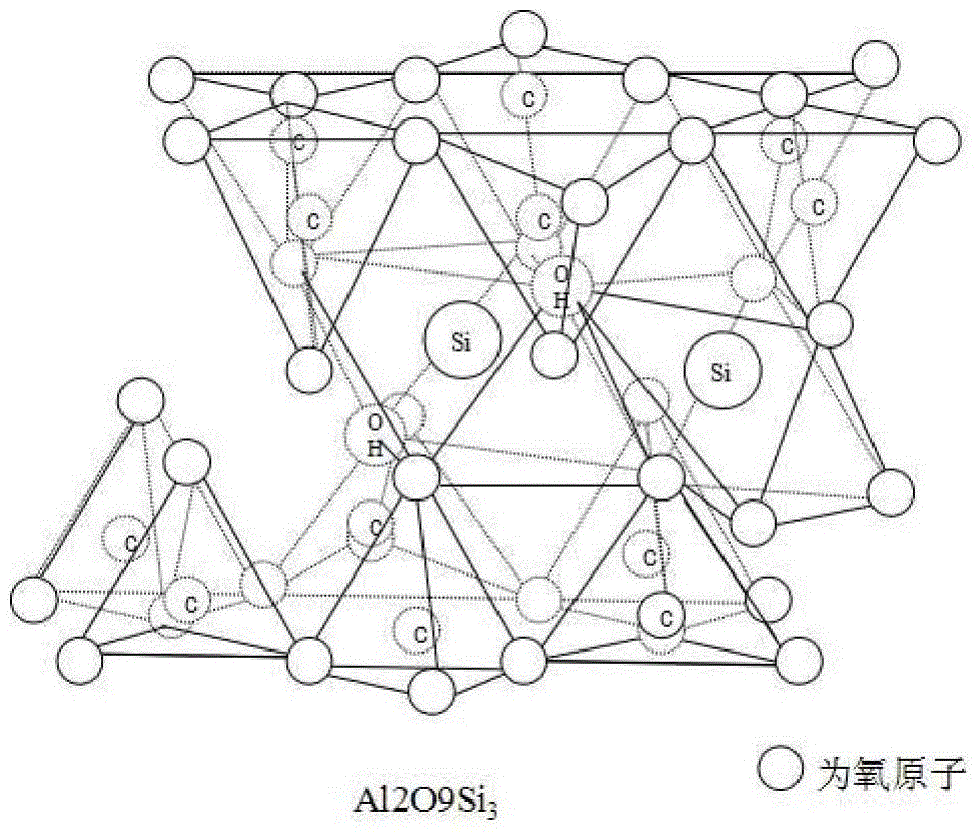

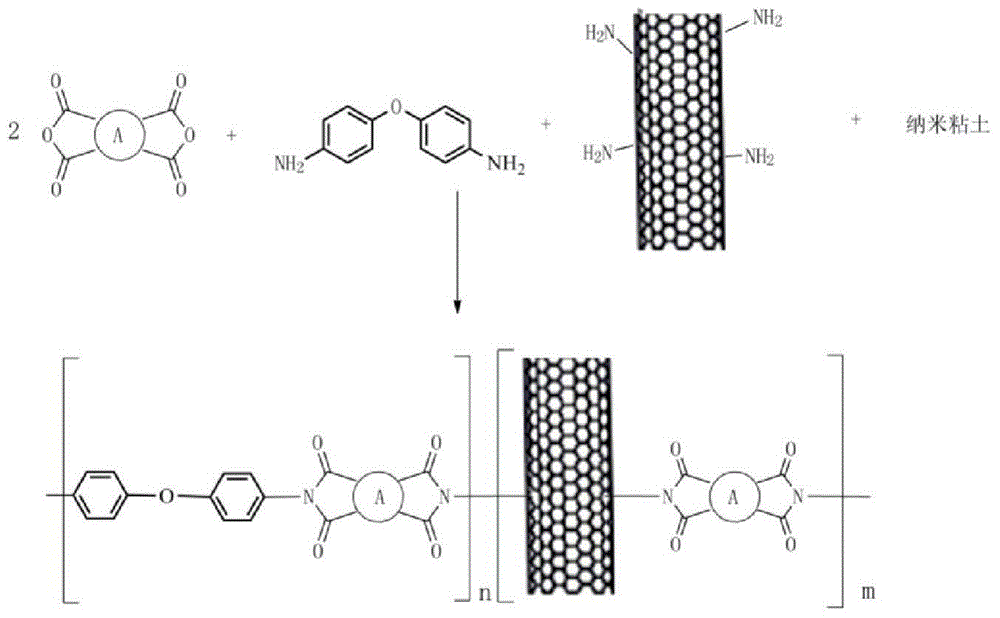

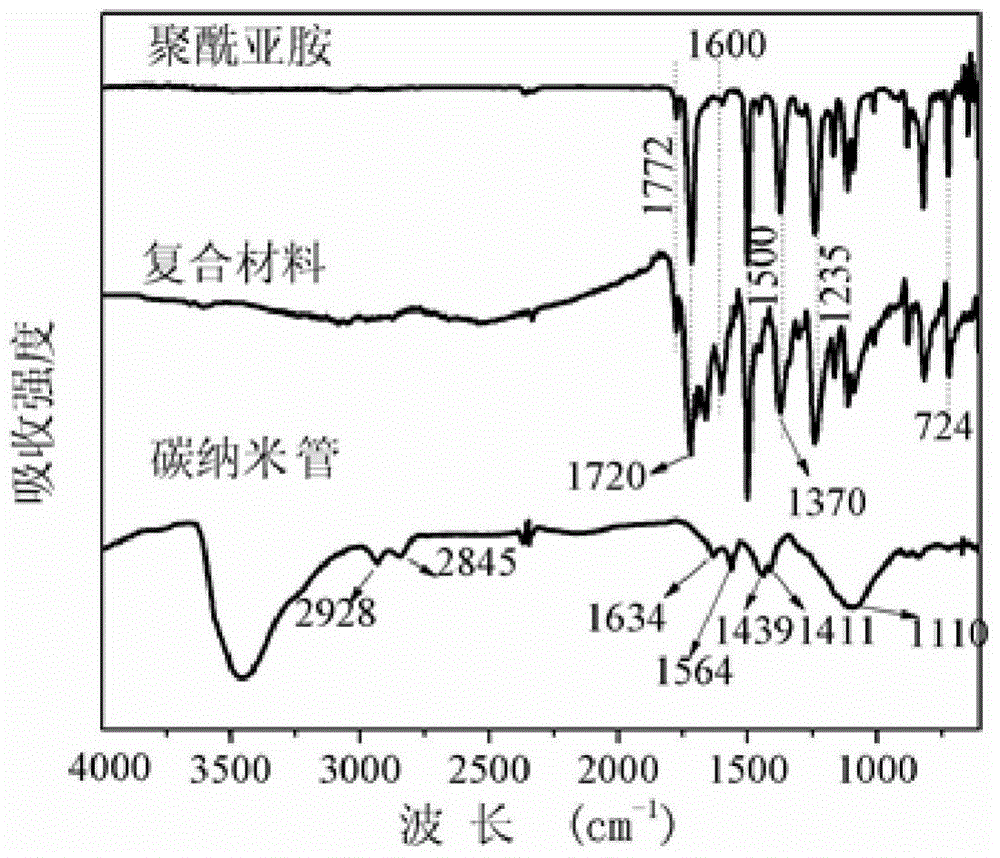

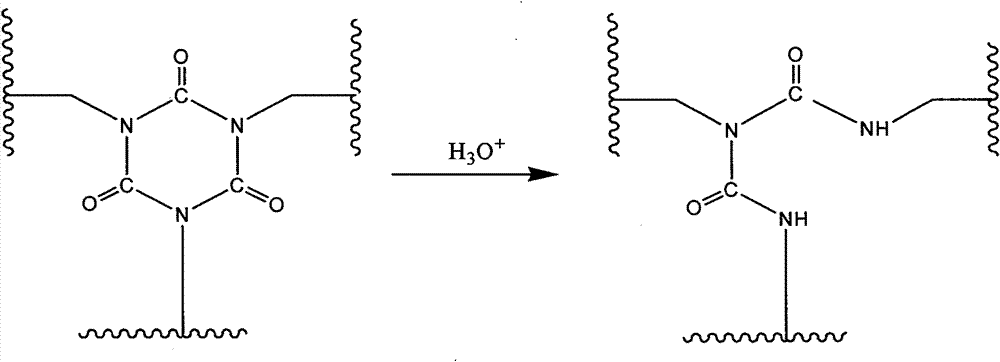

Polyimide composite material and preparation method and application thereof

InactiveCN104945902AOvercome the shortcomings of short service life and unsatisfactory radiation resistanceOvercome the disadvantages of being harmful to the human environmentDiaminodiphenyl etherCarbon nanotube

The invention discloses a polyimide composite material. Aminated carbon nanotube and diaminodiphenyl ether, which are used cooperatively as diamine, and another dianhydride monomer, namely PMDA (pyromellitic dianhydride) or BPDA (3,3',4,4'-biphenyltetracarboxylic anhydride), are polymerized to form polyamide acid; and during the process of forming a polyamide acid solution, nano-clay is added, and the composite material is formed by a hot-pressing technology after amidation of the system. The aminated carbon nanotube is directly bonded to the polyimide system through chemical bonding, but nano-clay is doped to the polyimide system through physical function. The aminated carbon nanotube-bonded and nano-clay-doped polyimide material obtained by the above method has good thermal neutron shielding property. The invention also discloses a preparation method of the above aminated carbon nanotube-bonded and nano-clay-doped polyimide material and its application in neutron radiation shield.

Owner:SOUTHEAST UNIV

Method for preparing donkey feed

The invention discloses a method for preparing a donkey feed. The donkey feed comprises 20-30 parts of bean pulp, 20-30 parts of corn, 10-20 parts of wheat berry, 30-40 parts of cornstalks, 30-40 parts of sweet potato vines, 30-40 parts of sugarcane stalks, 4-6 parts of bacitracin zinc, 7-11 parts of zoalene, 7-12 parts of L-calcium ascorbate, 13-16 parts of calcium propionate, 18-26 parts of bentonite, 1-3 parts of fish oil, 0.05-0.08 part of protease, 0.05-0.07 part of cellulose, 0.2-0.4 part of composite minerals and 6-8 parts of a traditional Chinese medicine extracting solution. The preparation method comprises the following steps: cutting the cornstalks, the sweet potato vines and the sugarcane stalks into fragments according to a proportion, then conveying the fragments into a pulverizer together with the bean pulp, the corn and the wheat berry to be crushed into powder, mixing the powder with other component raw materials, conveying the mixture into a pelletizer to be pelletized, bagging and sealing.

Owner:LIUZHOU HUASHENG TECH

Wood composite material containing paulownia

InactiveCN101090937AGrow fastBest strength/weight ratioFibreboardWood working apparatusPaulowniaMaterials science

Owner:HUBER ENGINEERED WOODS

Pig feed additive

InactiveCN104381687ALong retention periodImprove the immunityAnimal feeding stuffNeutral proteaseAnimal science

The invention discloses a pig feed additive. The pig feed additive comprises 0.5-0.7 part of chitosan, 0.3-0.4 part of glucose oxidase, 1-3 parts of neutral protease, 0.09-0.12 part of cellulase, 0.1-0.3 part of compound vitamin, 3-5 parts of compound bacterial agent, 8-11 parts of calcium L-ascorbate, 10-13 parts of calcium propionate, 1-3 parts of fish oil, 0.2-0.4 part of compound mineral and 6-8 parts of traditional Chinese medicine extracting solution. The pig feed additive has the beneficial effects that by adding the traditional Chinese medicine extracting solution, insect pests can be effectively killed, the immunities of pigs can be improved and the weights of the pigs are increased by about 12% on average.

Owner:LIUZHOU HUASHENG TECH

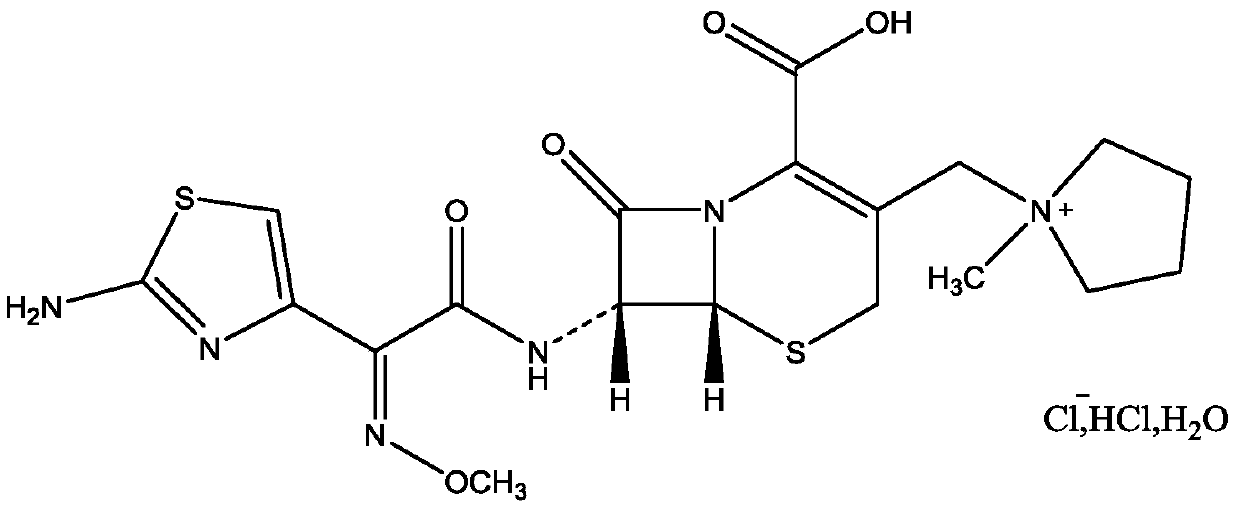

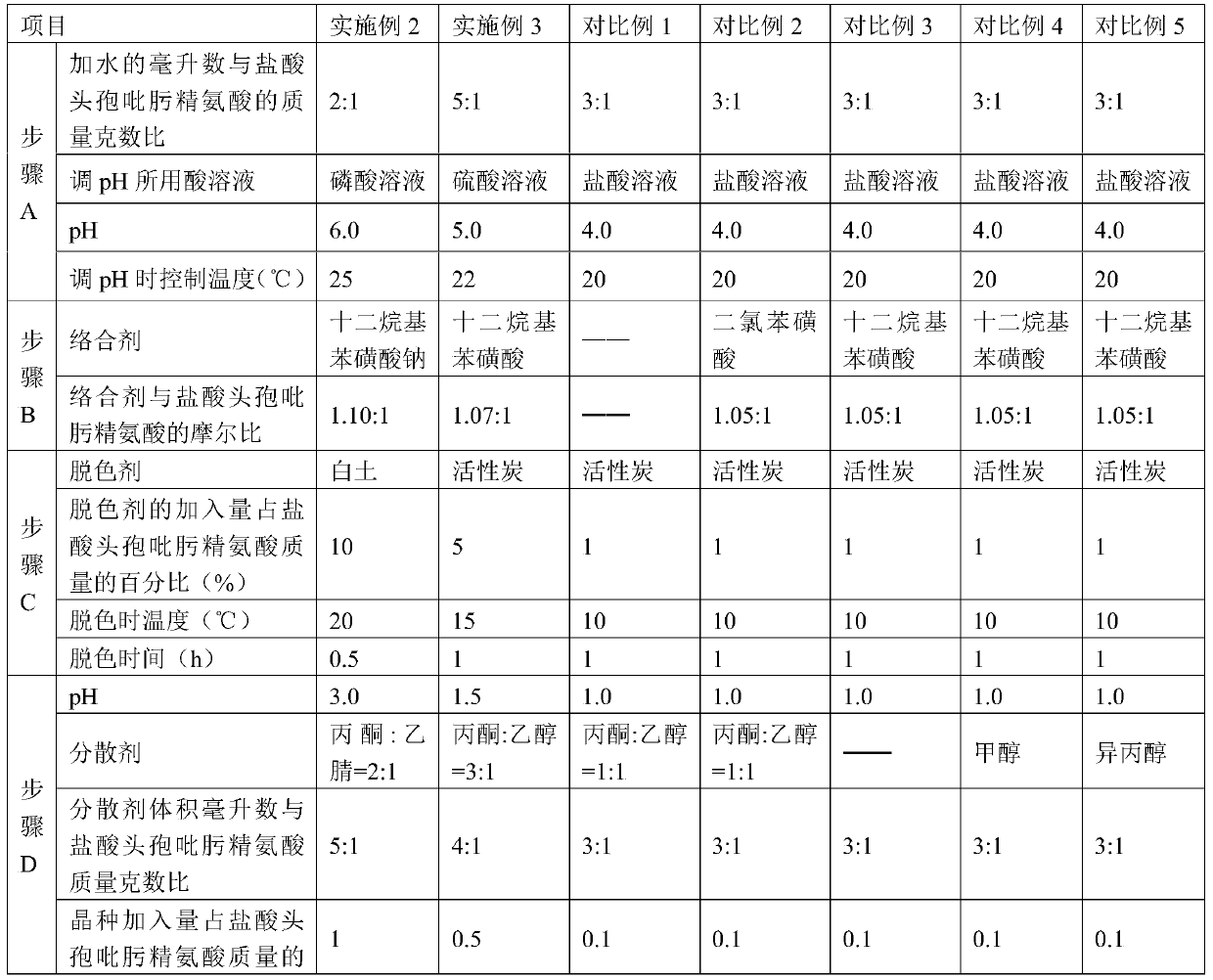

Purification method of cefepime dihydrochloride

ActiveCN109776572AIncrease contentLess impuritiesOrganic chemistryCefepime hydrochloridePurification methods

The invention discloses a purification method of cefepime dihydrochloride, and belongs to the field of chemical pharmacy. The method comprises the following steps: cefepime dihydrochloride arginine istaken as a raw material, a complexing agent is added in the dissolving solution of the cefepime dihydrochloride arginine for decoloration; and a dispersant and a crystallization agent are added intothe decolorated solution for crystallization, so as to finally obtain the cefepime dihydrochloride. The purification method can enable the cefepime dihydrochloride arginine which does not meet the quality standard to be fully recycled, therefore the prepared cefepime dihydrochloride has the advantages of high content, less impurities and high stability; and the preparation method is simple, energy-saving and environmental-friendly, thereby being suitable for large-scale industrial production.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

Processing method for producing walnut oil

InactiveCN105087145AFully retain the original nutrientsHigh freezing pointFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesWater vapor

The invention discloses a processing method for producing walnut oil. The processing method comprises the steps of airing, grinding, heat preservation, cake preparation, stewing, squeezing and filtering and specially comprises the steps of taking shelled walnut kernels; airing the shelled walnut kernels to obtain dried walnut kernels; grinding in a grinder, sealing the ground walnut kernels in a container, and carrying out heat preservation at the temperature of 55+ / -5 DEG C for 2 hours; preparing cakes, putting the cakes in a food steamer for stewing by virtue of vapor; and after stewing, squeezing to obtain crude walnut oil; and precipitating the crude walnut oil for 36-48 hours and then filtering to obtain finished walnut oil. According to the invention, the walnut oil is intense and soft in taste, is beneficial to body health if used for a long time due to high monounsaturated fatty acid, and has high nutritive value and health effect.

Owner:饶世柱

Anti-blue light high-definition polyester film and manufacturing method thereof

ActiveCN108192124AImprove film forming performanceImprove mechanical propertiesCoatingsChemistryAging property

The invention discloses an anti-blue light high-definition polyester film and a manufacturing method thereof. The anti-blue light high-definition polyester film is based on a blue light softening material, and the blue light softening material is specifically a stabilization-modified and hydrogen-hardened polyester optical film with thickness of 0.03 mm to 0.05 mm thick and is further laminated with a rosin-based, UV-cured and stabilized polyester acrylate film layer with a thickness of 0.01 mm to 0.02 mm. The anti-blue light high-definition polyester film adopts a polyester optical film as asubstrate, and has the advantages of one-time processing and molding, stable chemical property, strong anti-aging property, surface scratch resistance, long service life, and can reduce damages of high-energy blue light to human eyes.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

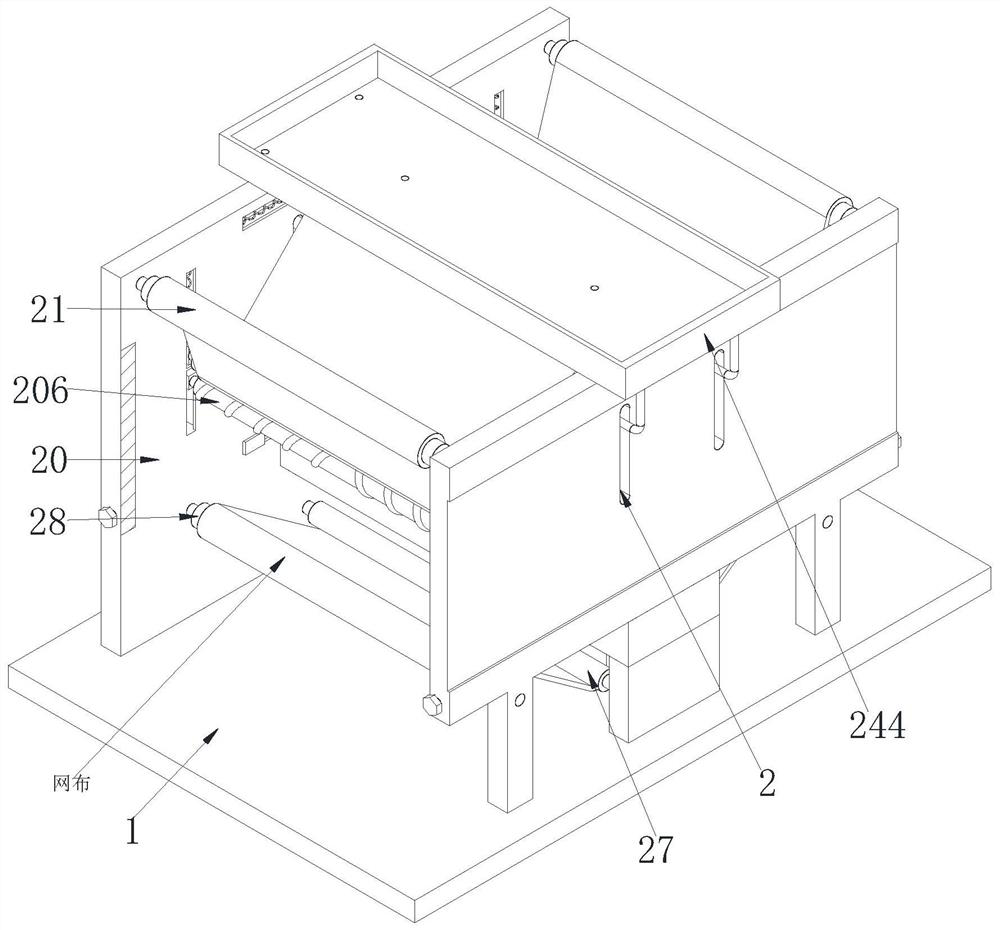

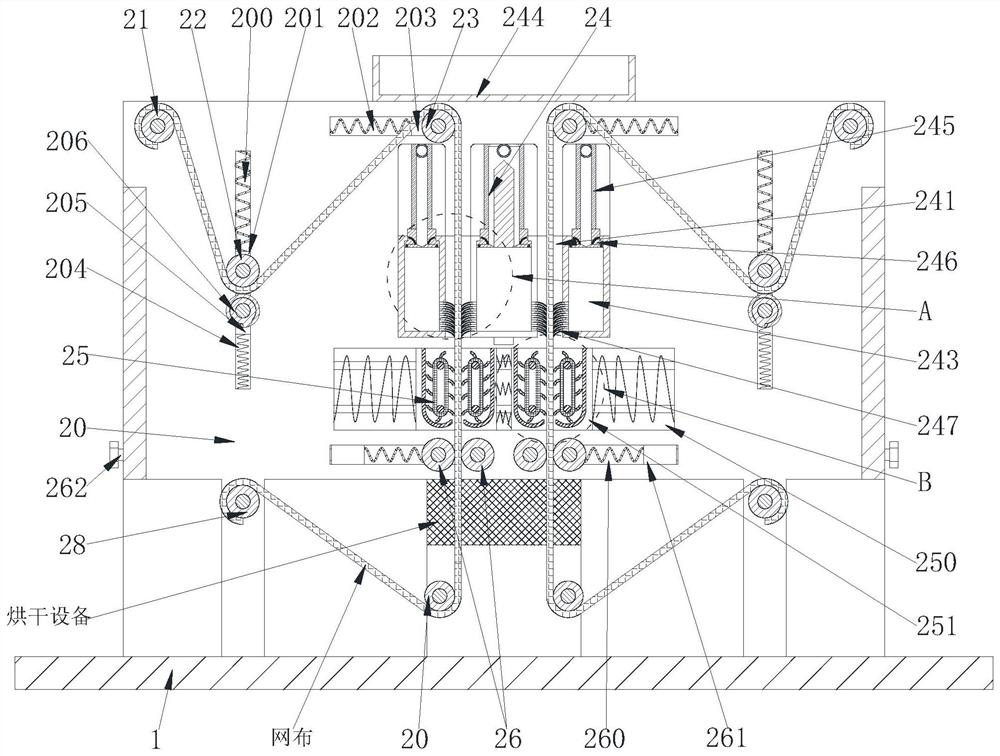

Manufacturing and processing method for synthetic polymer waterproof roll

ActiveCN112156945AUniform thicknessAvoid the problem of air holesLiquid surface applicatorsCoatingsEngineeringSynthetic Polymeric Macromolecules

The invention relates to a manufacturing and processing method for synthetic polymer waterproof roll. The manufacturing and processing method uses synthetic polymer waterproof roll manufacturing and processing equipment, the synthetic polymer waterproof roll manufacturing and processing equipment comprises a base and a coating device, and the upper surface of the base is provided with the coatingdevice. According to the manufacturing and processing method for synthetic polymer waterproof roll, the following problems existing currently when the synthetic polymer waterproof roll is manufacturedand processed can be solved: the existing waterproof roll manufacturing equipment directly dries the carrier after the surface of the carrier is coated with a coating, as a result, the prepared waterproof roll is easy to cause uneven distribution of the coating on the surface of the carrier, the service life of the waterproof roll is shortened due to the fact that a position with thinner coatingis worn quickly and the position with thicker coating is worn slowly, coatings on the two faces of the carrier cannot be completely fused, air holes are formed in the surface of the formed waterproofroll, and the using effect of the waterproof roll is affected.

Owner:WEIFANG JUSHENG WATERPROOF MATERIAL

Method for forming mullite-based ceramic cylinder reinforced composite wear-resistant steel plate

The invention relates to a method for forming a mullite-based ceramic cylinder reinforced composite wear-resistant steel plate. The method comprises the following technological processes that firstly, sillimanite and iron composite powder is prepared, according to the matching ratio, the sillimanite and iron composite powder comprises, by weight, 80 percent of sillimanite power and 20 percent of Fe powder, the sillimanite power and the Fe powder are evenly mixed and are pressed into a round-head cylindrical precast block in a round-head cylindrical closed-type extruding die, under the constant pressure, the round-head cylindrical precast block is sintered for two hours at the temperature of 1750 DEG C to form mullite, and round-head mullite-based composite material cylinders are obtained; secondly, plain carbon steel is taken as a matrix steel plate, the periphery of the matrix steel plate is manufactured to a reaction tank by using refractory bricks and box sealing mud, round heads of the round-head mullite-based composite material cylinders are placed on the surface of the steel plate upwards, certain gaps are reserved between the round-head mullite-based composite material cylinders, a steel plate with round blind holes in the surface is used for pressing the round heads of the round-head mullite-based composite material cylinders, the round-head mullite-based composite material cylinders are preheated at the temperature of 300 DEG C, then molten steel is cast in the gaps of the round-head mullite-based composite material cylinders, the molten steel, the cylinders and the steel plate are welded together in a casting mode, and the mullite-based ceramic cylinder reinforced composite wear-resistant steel plate is formed. The method is high in interface bonding strength and excellent in wear-resisting property.

Owner:陈威

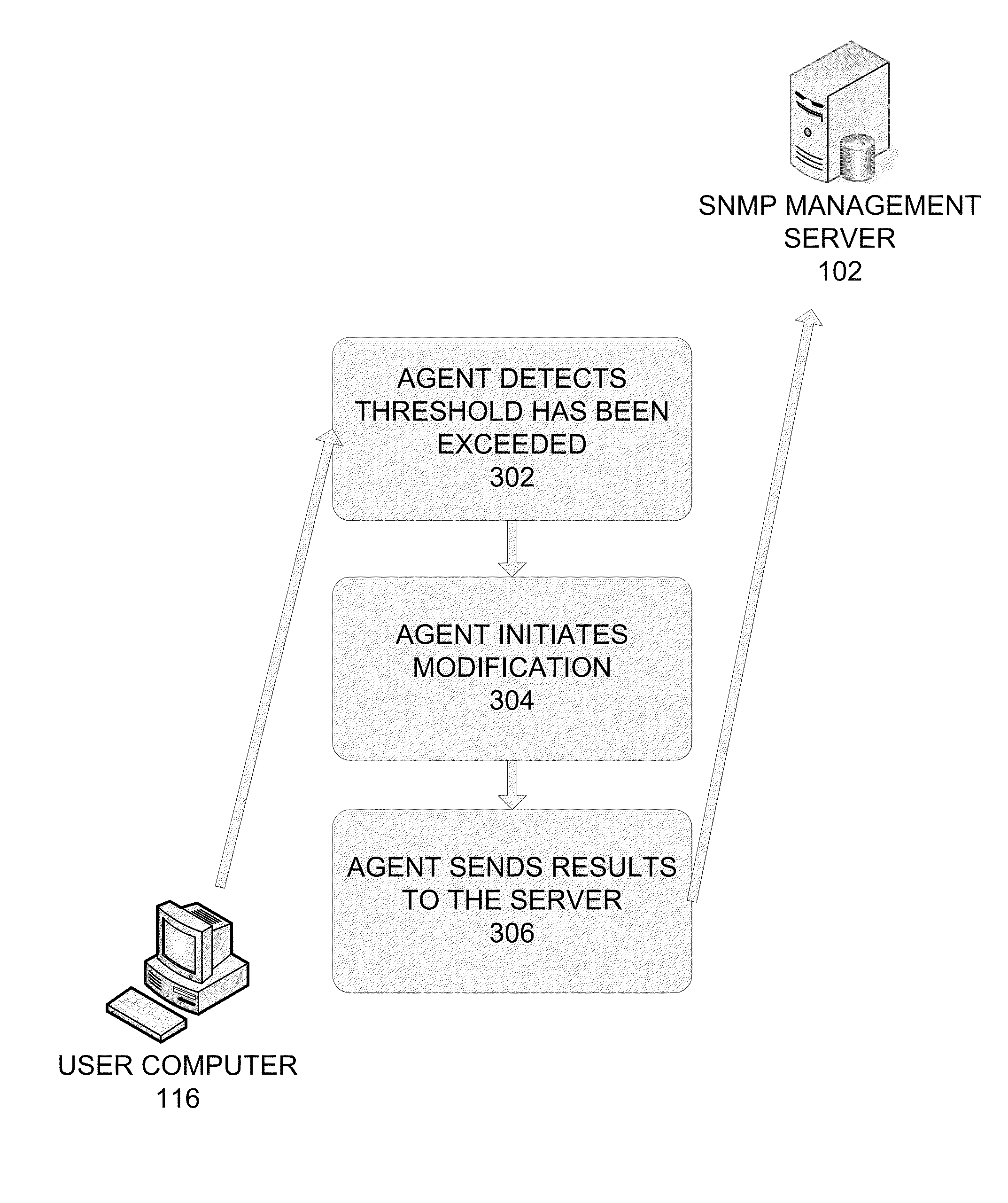

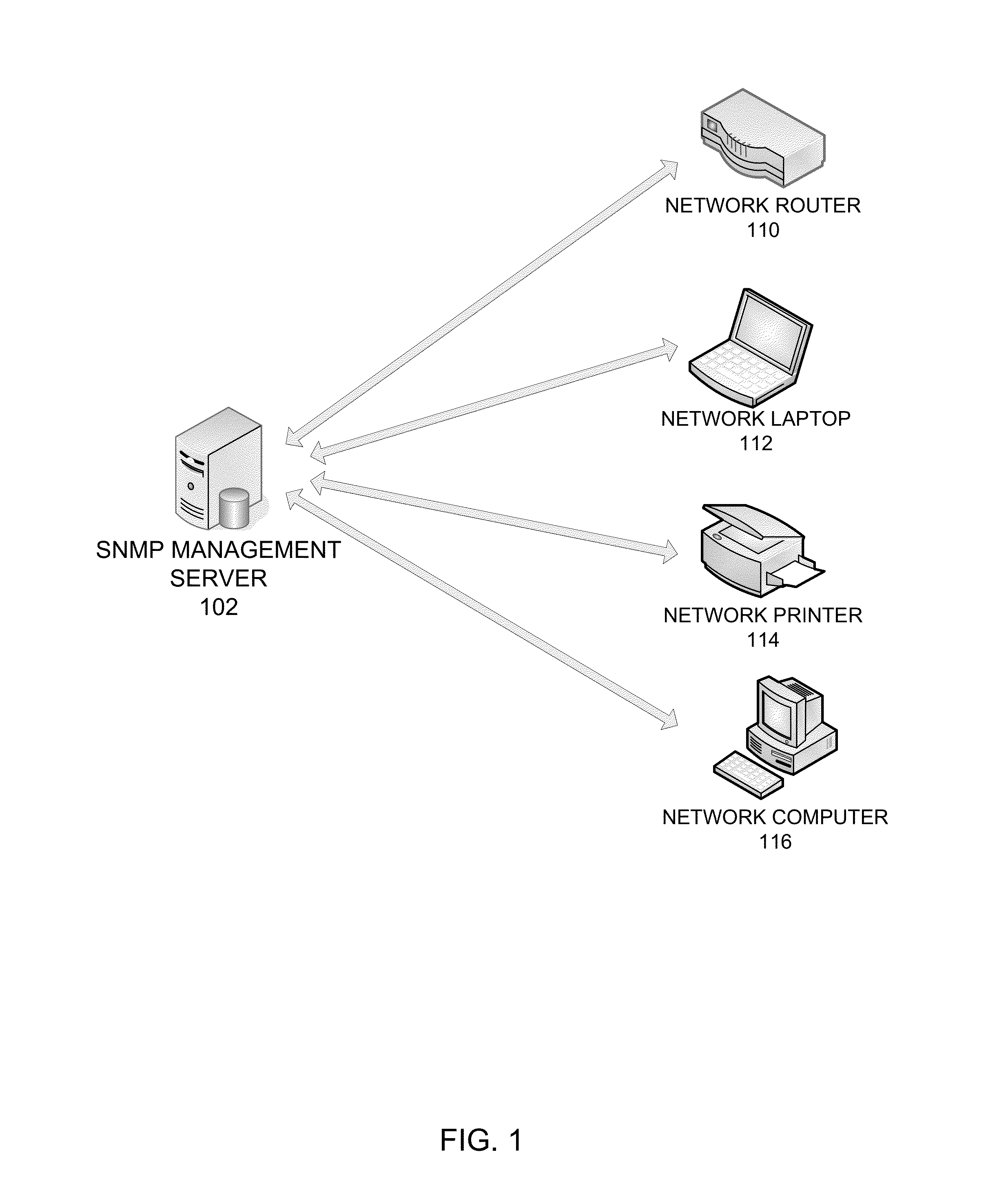

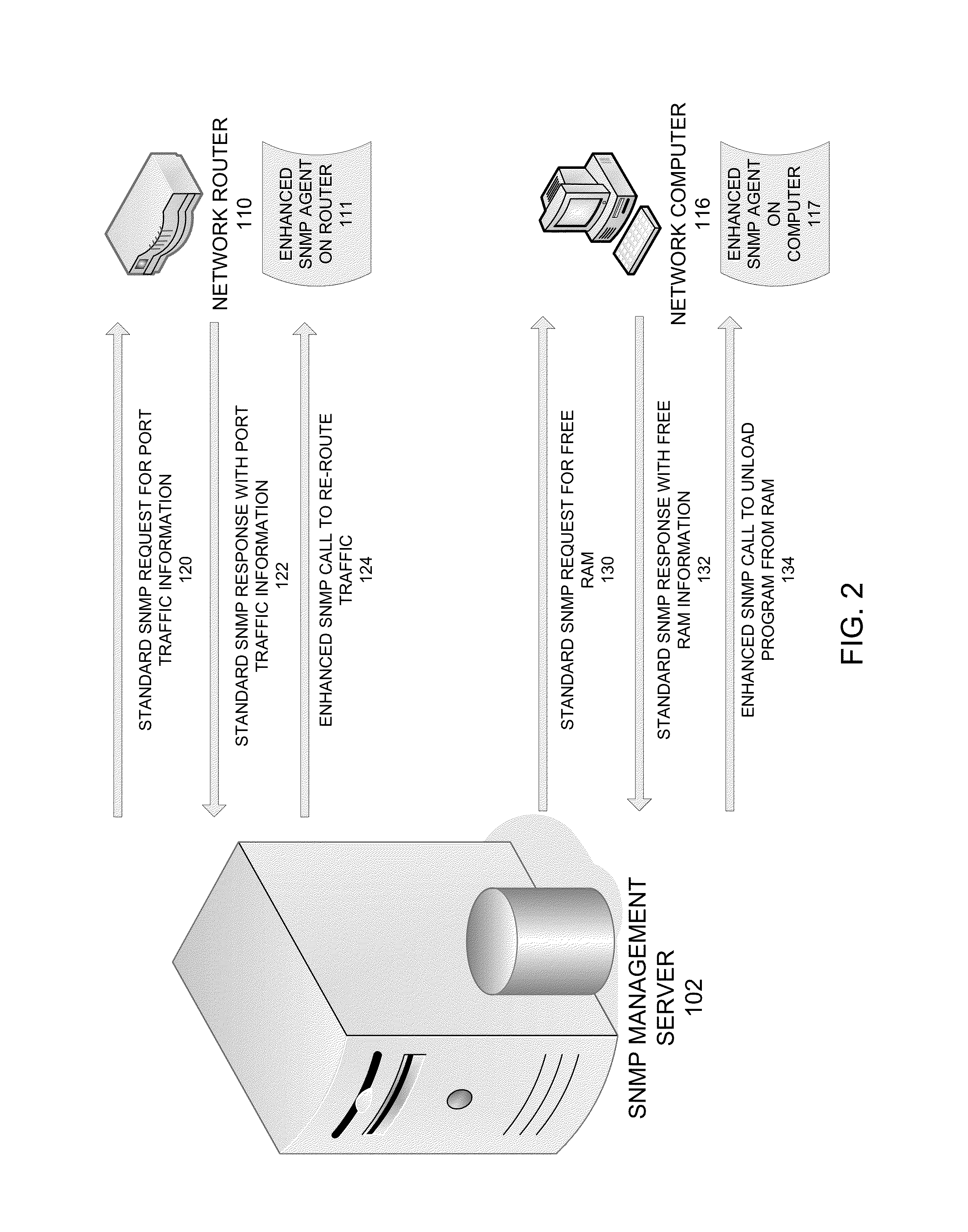

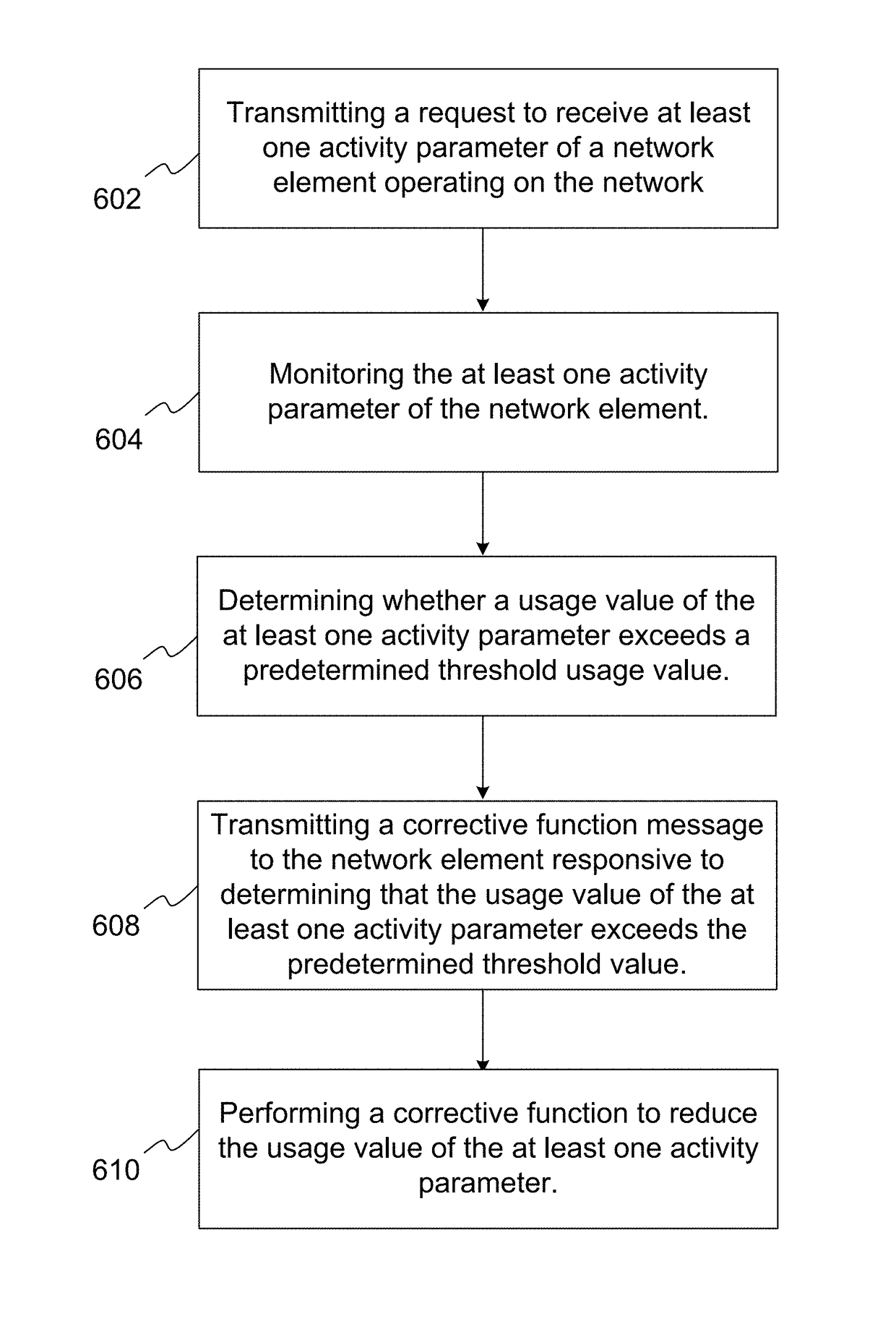

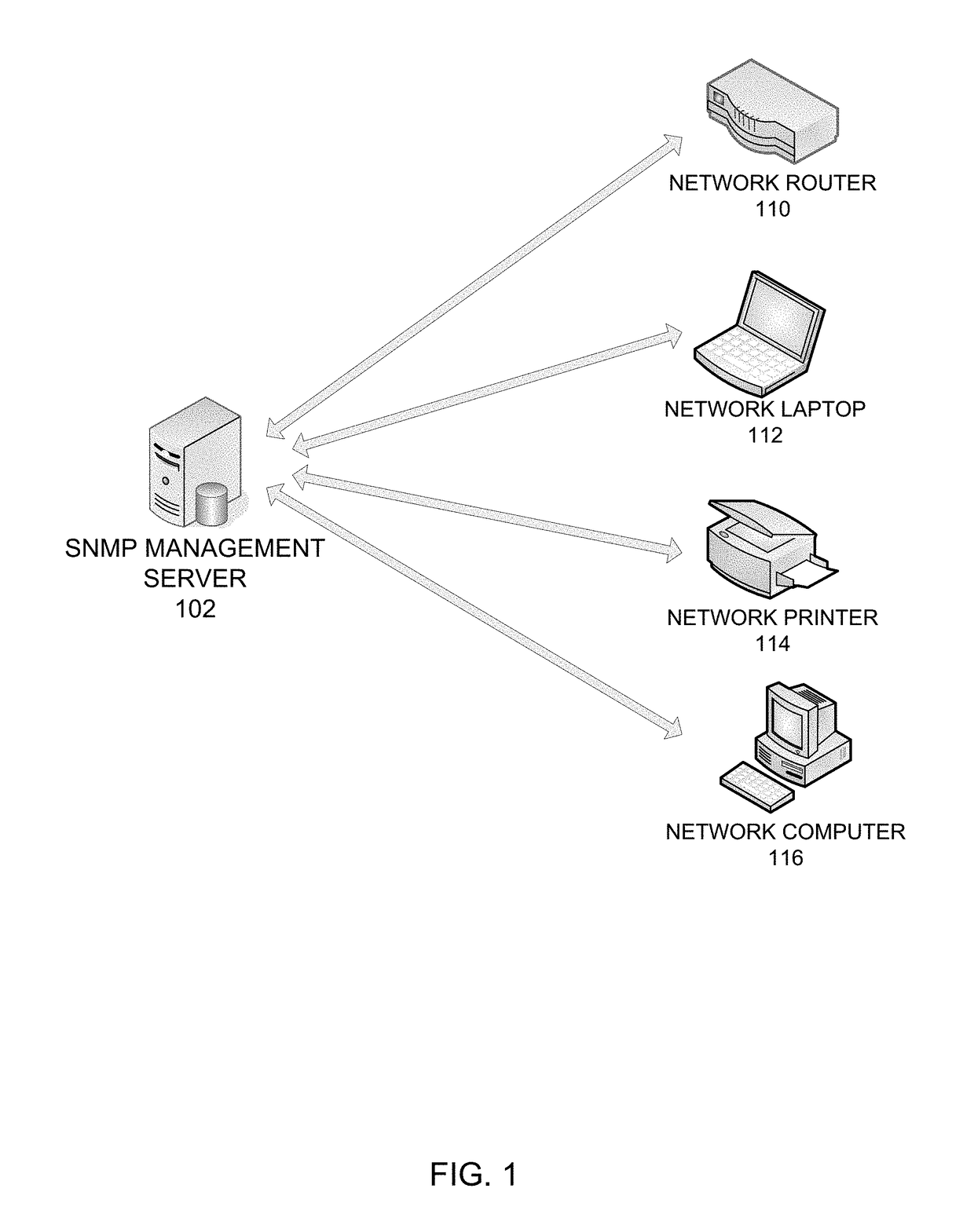

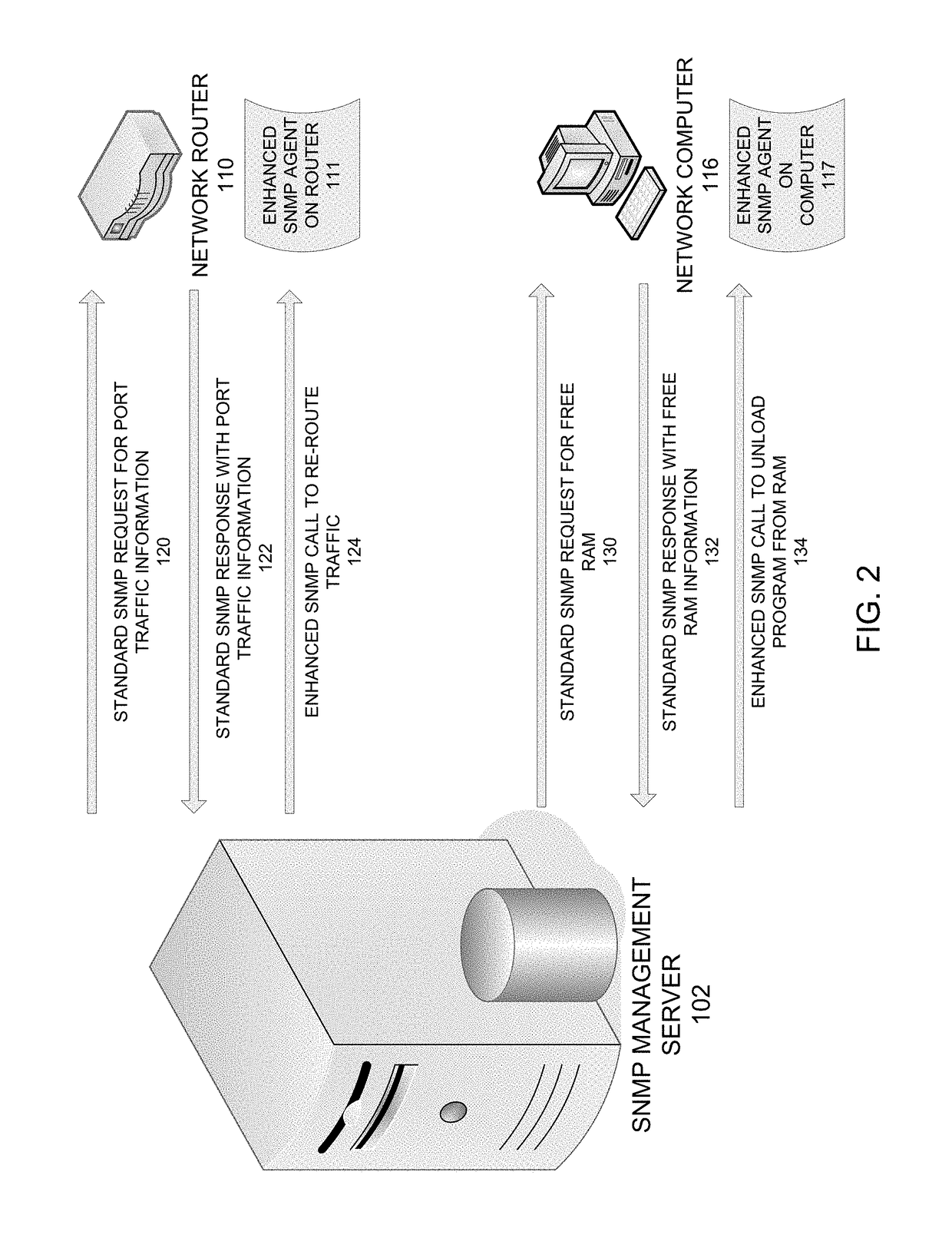

Managing a network element operating on a network

ActiveUS8825845B1Reduce use valueDigital computer detailsData switching networksDistributed computingNetwork element

Disclosed are an apparatus and method of managing network elements operating on a network. One example method may include transmitting a request to receive at least one activity parameter of a network element operating on the network and monitoring the at least one activity parameter of the network element. The method may include determining whether a usage value of the at least one activity parameter exceeds a predetermined threshold usage value and transmitting a corrective function message to the network element responsive to determining that the usage value of the at least one activity parameter exceeds the predetermined threshold value. The method may further include performing a corrective function to reduce the usage value of the at least one activity parameter.

Owner:IBM CORP

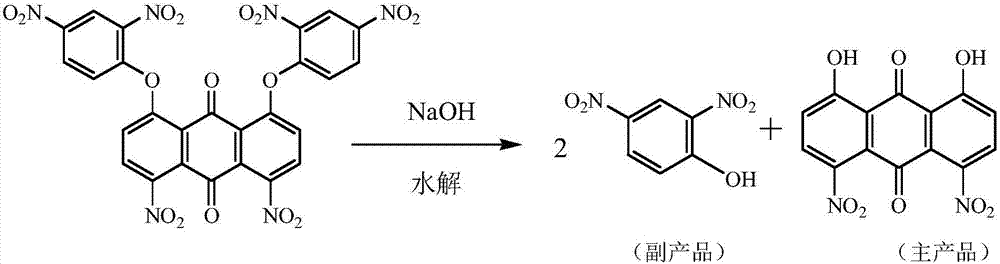

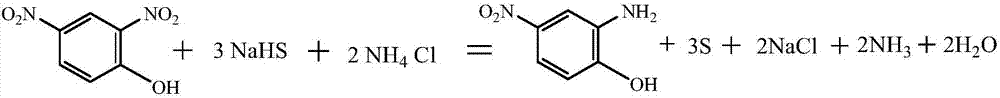

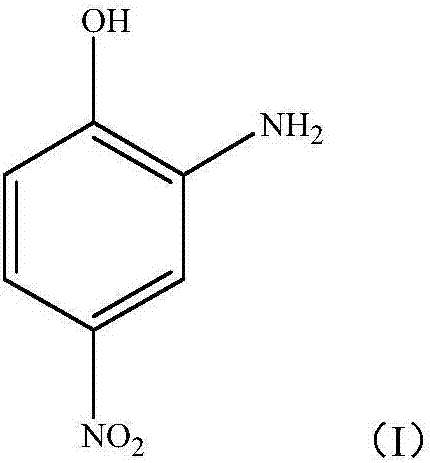

Method for preparing 2-amino-4-nitrophenol by using disperse blue 2BLN byproduct

ActiveCN107253914AReduce dosageIncrease dosageOrganic compound preparationAmino-hyroxy compound preparationChemical industrySodium hydrosulfide

The invention belongs to the technical field of chemical industry, and more specifically relates to a method for preparing 2-amino-4-nitrophenol by using a disperse blue 2BLN byproduct. The method comprises the following steps: A) adjusting the pH value of mother liquor in a hydrolysis reaction step during a disperse blue 2BLN preparation process to 2.2-3.0, filtering the material to obtain a 2,4-dinitro phenol crude product; B) adding water in the crude product obtained in the step A) for beating, using sodium sulfhydrate for reduction in an ammonium chloride buffer system; C) using liquid chromatogram for controlling a reaction terminal point of the step B), adding sodium chloride for salting-out after arriving the terminal point, cooling the material and filtering the material to obtain a 2-amino-4-nitrophenol crude product; D) dissolving the crude product in the step C) in water, heating the material and filtering the material while hot; E) acidifying the crude product, cooling the material and performing suction filtration on the material, and washing the material; and F) drying a filter cake.

Owner:青岛海湾集团有限公司

Acidproof, alkali-proof and hydrogen-sulphide-corrosion-resistant aflas composite

The invention relates to an acidproof, alkali-proof and hydrogen-sulphide-corrosion-resistant aflas composite. In the composite, aflas serves as main material, organic peroxide serves as a cross linking agent, vinyl polyphenyl silsesquioxane serves as an assistant cross-linking agent, hard carbon black serves as an enhanced filler, and resin serves as a flow modifier. The composite can be used for preparing rubber products used in an acid or alkali environment, especially in the hydrogen sulfide environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of horse feed additive

The invention relates to a preparation method of a horse feed additive. The horse feed additive comprises 5-9 parts of bacitracin zinc, 10-14 parts of L-calcium ascorbate, 4-6 parts of calcium propionate, 18-26 parts of bentonite, 1-3 parts of fish oil, 0.07-0.09 part of protease, 0.06-0.08 part of cellulase, 0.3-0.5 part of complex mineral and 10-15 parts of traditional Chinese medicine extracting solution. The diseases and pests can be effectively controlled and the resistance of horses can be improved by adding the traditional Chinese medicine extracting solution, so that the weights of the horses are increased by about 12% on average.

Owner:兰梅

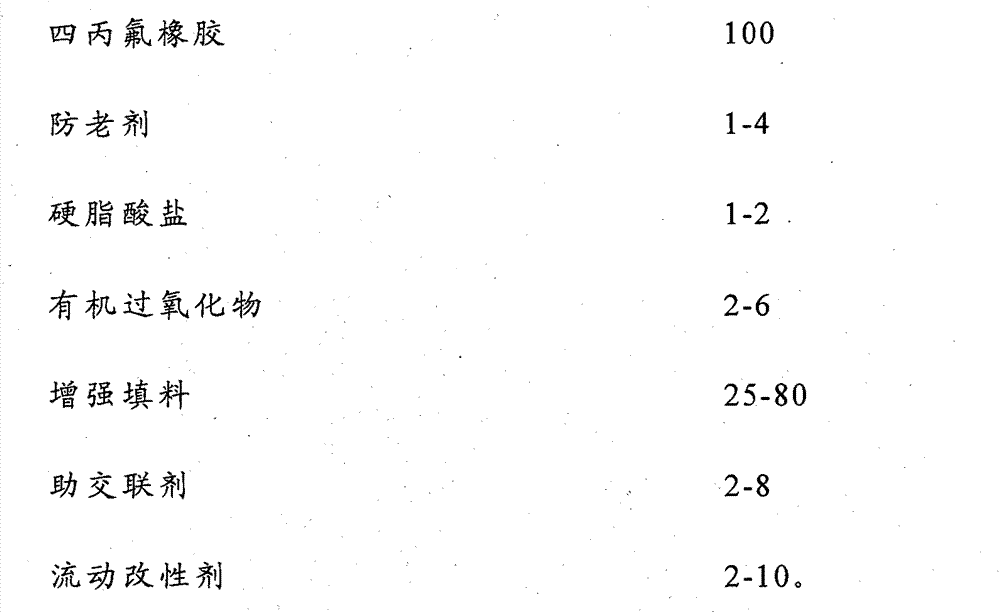

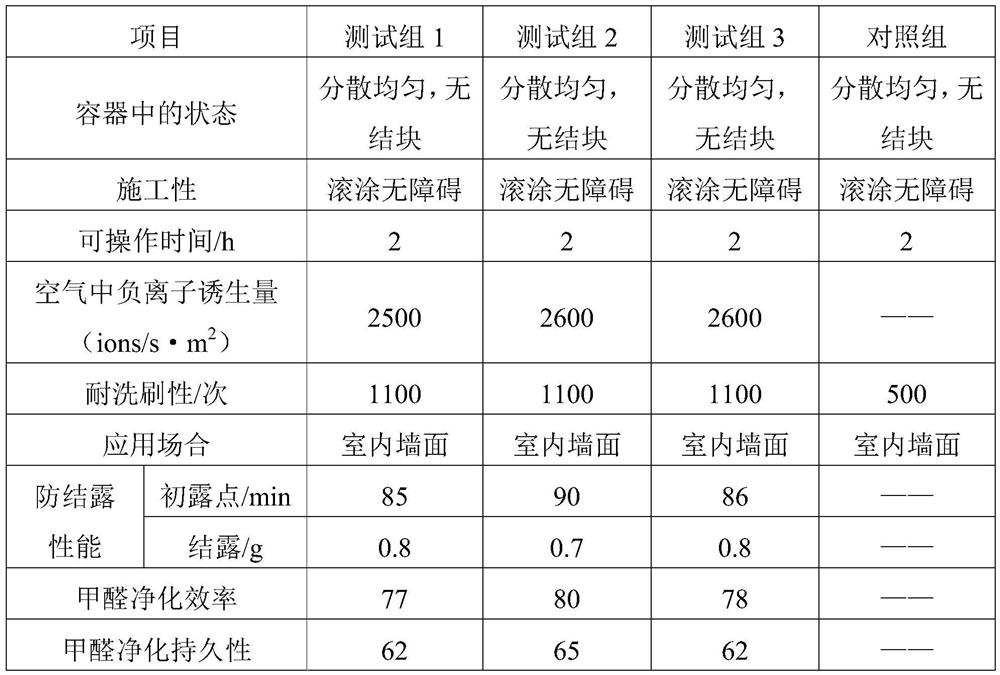

Light weight high-strength anti-condensation dry powder coating and preparation method thereof

InactiveCN111718607ALow costReduce use valuePowdery paintsCement coatingsCalcium silicateWaste material

The invention relates to a light-weight high-strength anti-condensation dry powder coating and a preparation method thereof. The light-weight high-strength anti-condensation dry powder coating comprises the following components in parts by weight: 15-25 parts of calcium silicate board sanding waste, 15-25 parts of food-grade ash calcium powder, 3-5 parts of special-grade white cement and 3-5 partsof an anion carrier material. Compared with the prior art, a large amount of sanding waste powder in the calcium silicate board industry is used, the negative ion carrier material is added, and the product has the advantages of being environmentally friendly, low in cost, light in weight, high in strength, good in anti-condensation performance, capable of releasing negative ions and purifying airand the like.

Owner:SHANGHAI CIMIC HEALTHY ENVIRONMENT TECH CO LTD

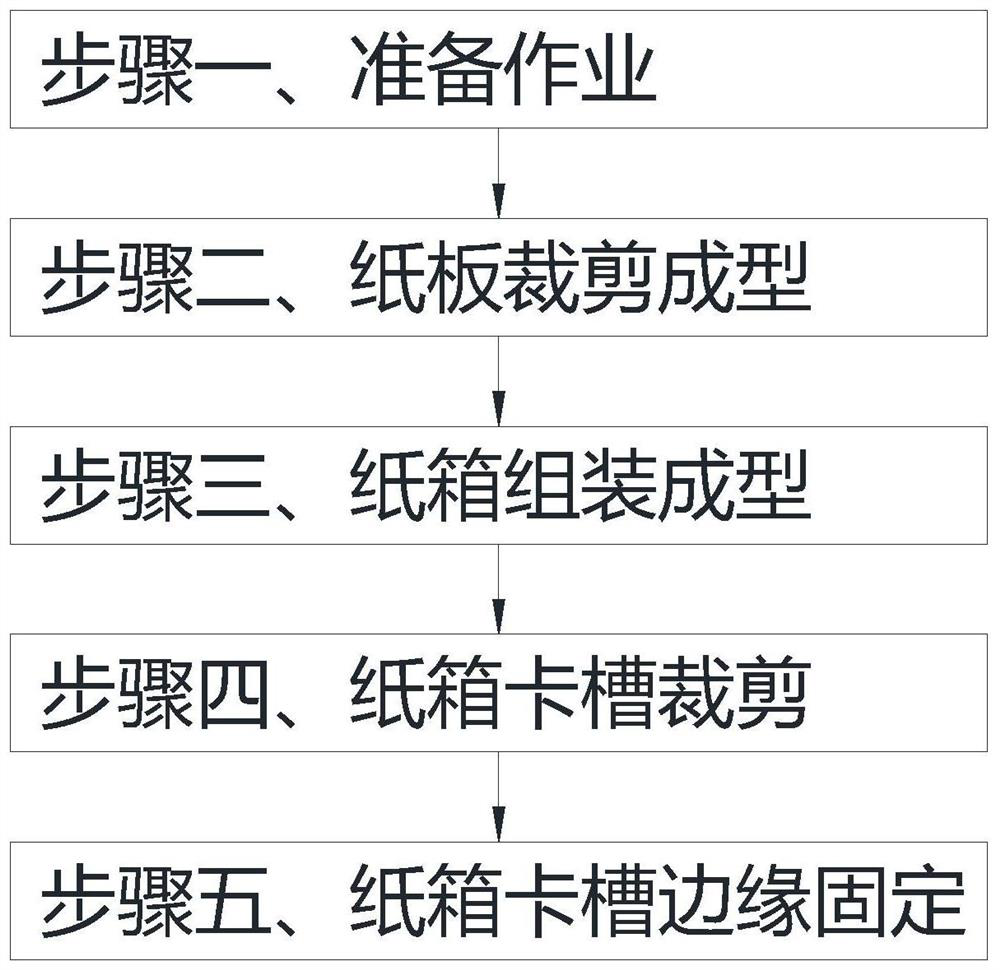

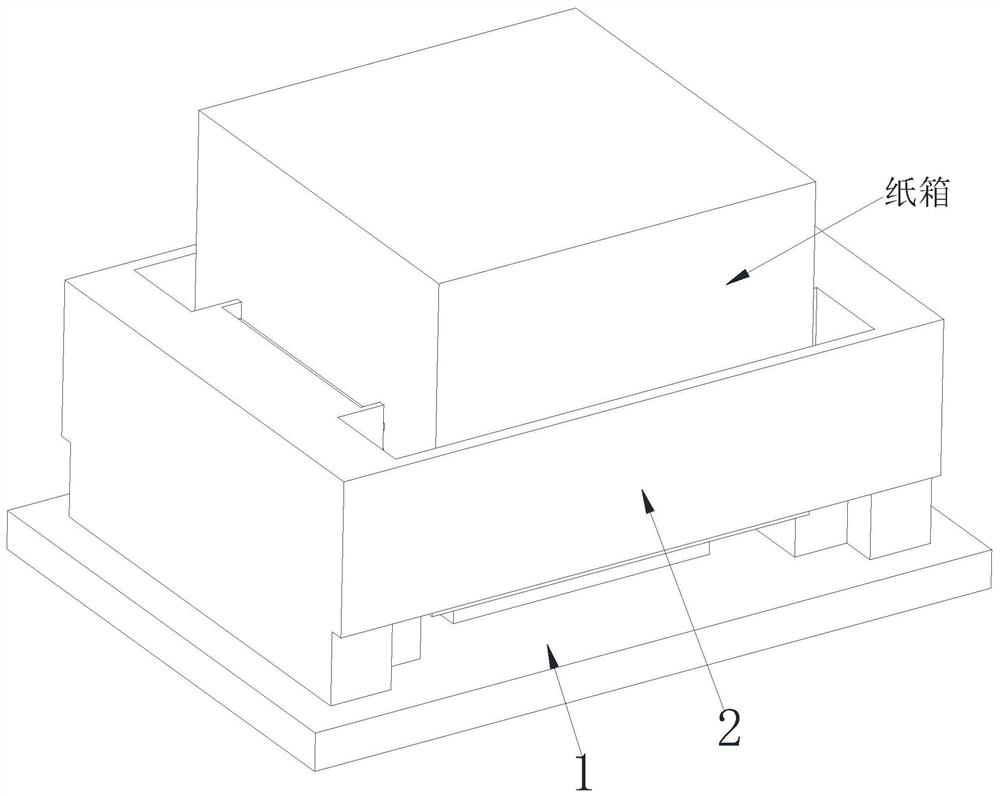

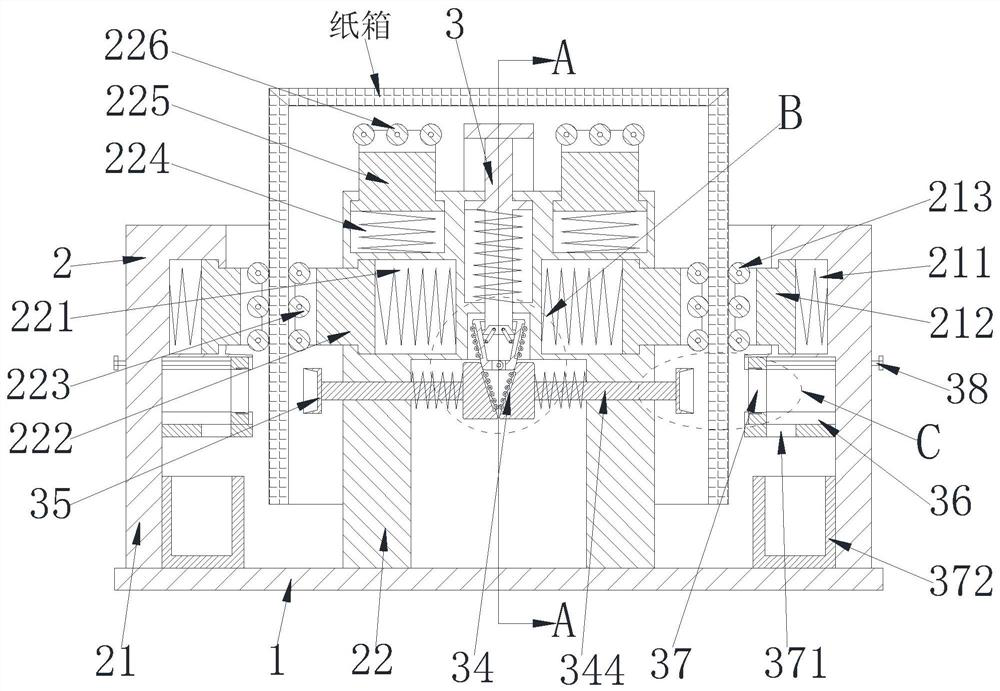

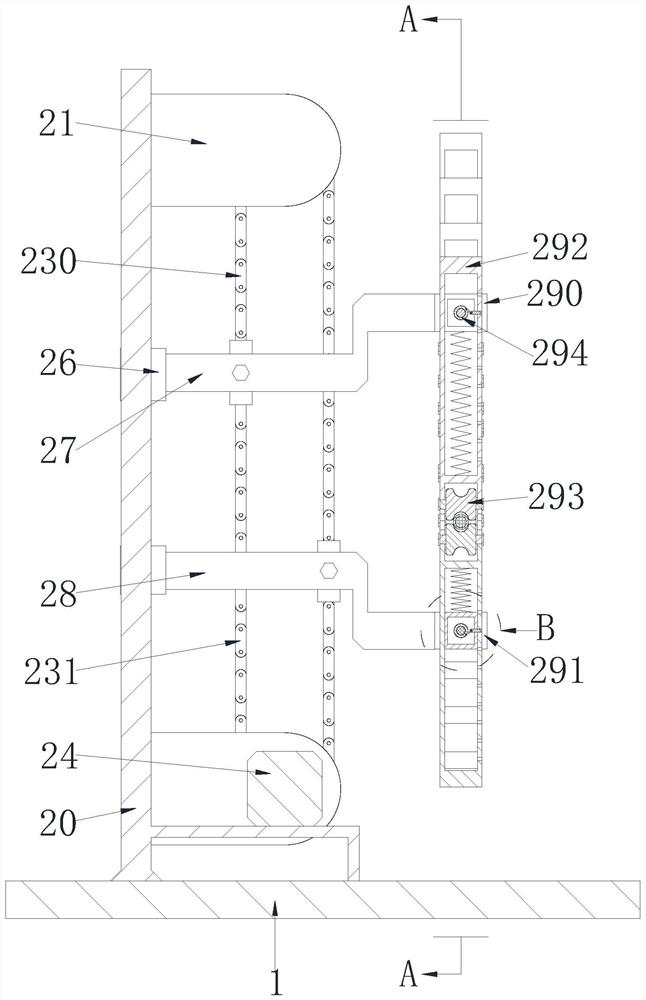

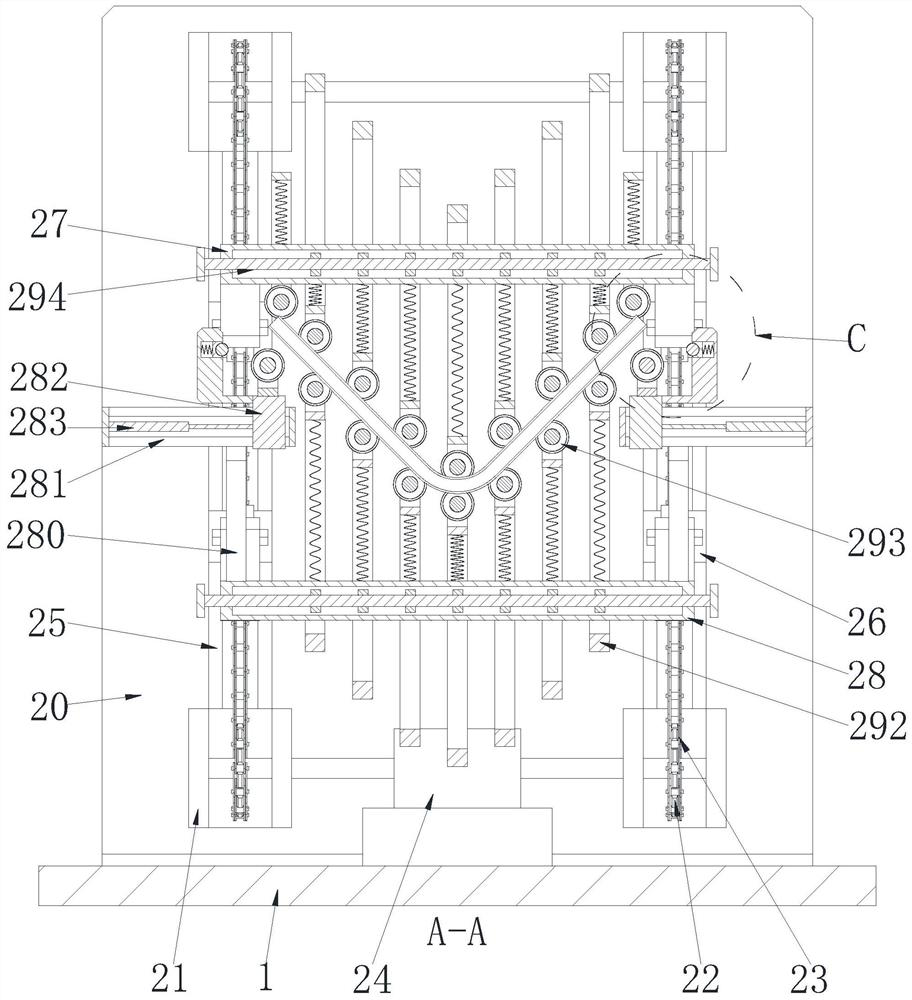

Manufacture and processing method for packaging paper box

ActiveCN111716815AFix damageReduce use valueBox making operationsPaper-makingKnife bladesManufacturing engineering

The invention relates to a manufacture and processing method for a packaging paper box. The method adopts manufacturing and processing equipment of the packaging paper box. The manufacturing and processing equipment of the packaging paper box comprises a base, an auxiliary unit and a slotting unit, wherein the auxiliary unit is disposed on the upper surface of the base, and the slotting unit is formed in the middle of the auxiliary unit. The method disclosed by the invention can solve problems existing at present when two opposite sides of the paper box are slotted: when the slotted paper boxis placed, a placement position cannot be effectively adjusted, thus clamping groove positions opened in side faces of the paper box are not aligned and the paper box is damaged due to uneven force bearing on two sides during carrying of the paper box; and a flat-opening blade is used as a slotting blade for two sides of the paper box, the paper box is extruded at first when the paper box is cut by the blade and then the clamping grooves is formed by cutting, thus press marks occur on edges of slots of the paper boxes, deformation and wrinkles appear easily at the slots during carrying of thepaper box, and use values of the paper box are thus reduced.

Owner:威海先优包装科技有限公司

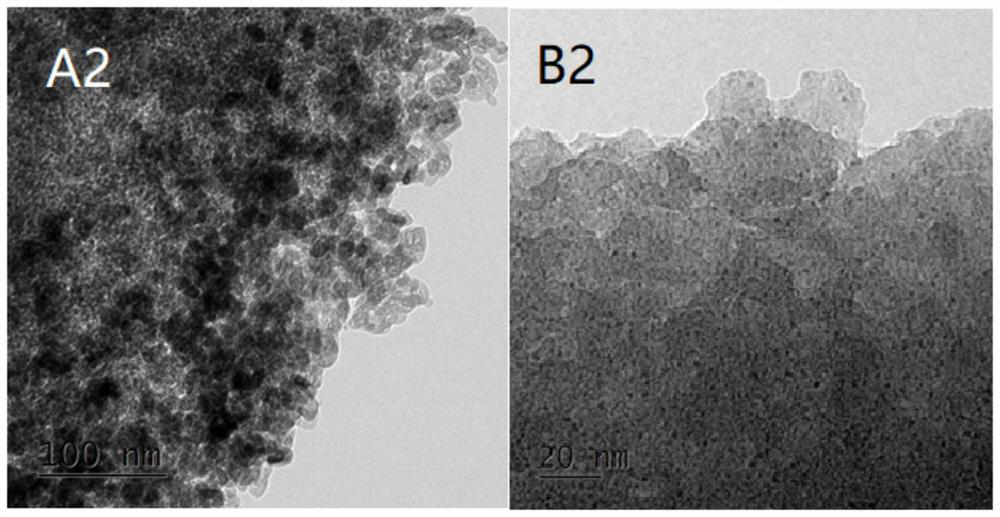

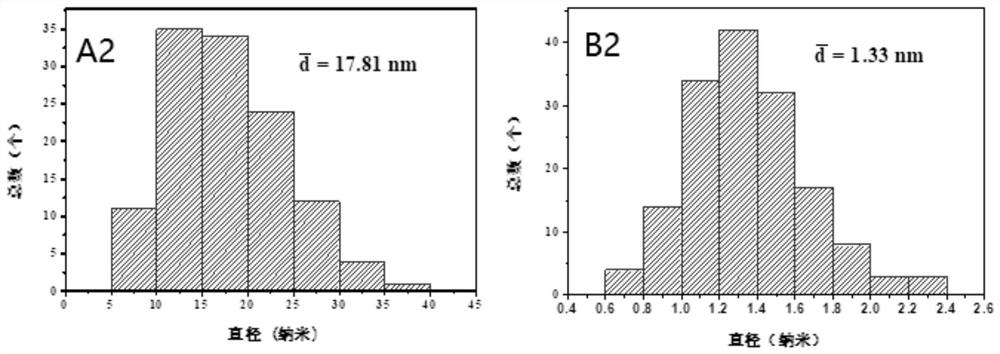

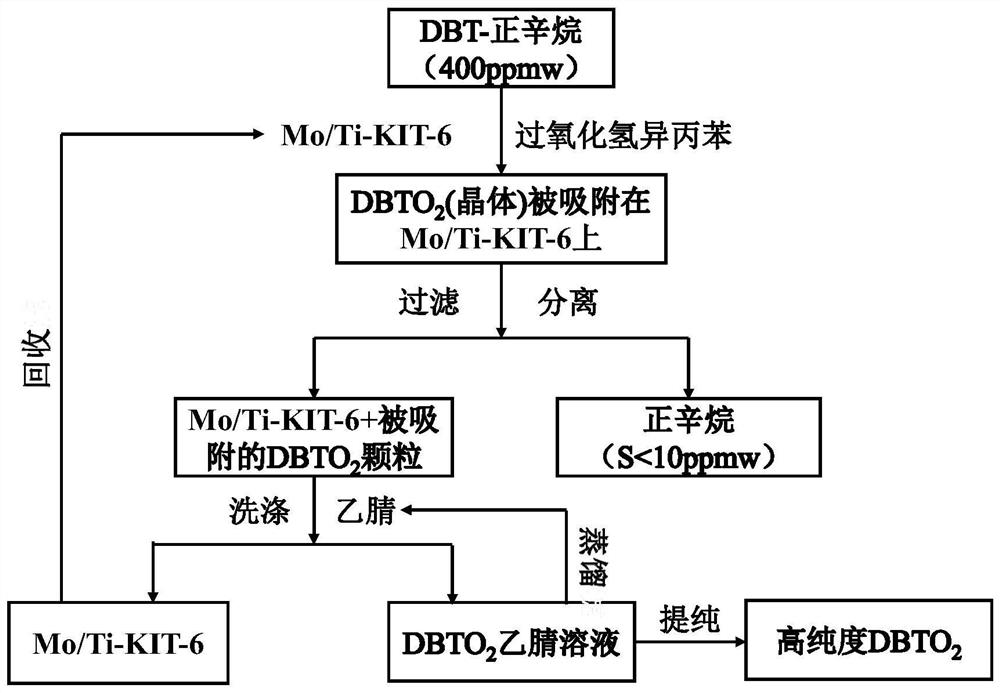

Three-dimensional ordered mesoporous molybdenum-based catalyst as well as preparation method and application thereof

PendingCN112705244ALarge specific surface areaHigh catalytic activityMolecular sieve catalystsRefining with oxygen compoundsMolecular sieveSimple Organic Compounds

The invention discloses a three-dimensional ordered mesoporous molybdenum-based catalyst as well as a preparation method and application thereof. The catalyst comprises a mesoporous molecular sieve, wherein sub-nano molybdenum trioxide particles are loaded on the mesoporous molecular sieve. The preparation method comprises the following steps: preparing a precursor solution of the three-dimensional ordered mesoporous molybdenum-based catalyst, and then sequentially carrying out hydrothermal reaction and calcination. The three-dimensional ordered mesoporous molybdenum-based catalyst provided by the invention has the advantages of large specific surface area, strong adsorption capacity, strong catalytic activity, good stability and the like, can be widely used for removing sulfur-containing organic compounds in petroleum products, can realize rapid and effective removal of sulfur-containing organic compounds in petroleum products, shows very excellent oxidative desulfurization activity, and has high use value and good application prospects. The preparation method of the three-dimensional ordered mesoporous molybdenum-based catalyst has the advantages of simple process, convenience in operation, usage of cheap and easily available raw materials, low cost and the like, can realize large-scale batch preparation, and is beneficial to industrial utilization.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

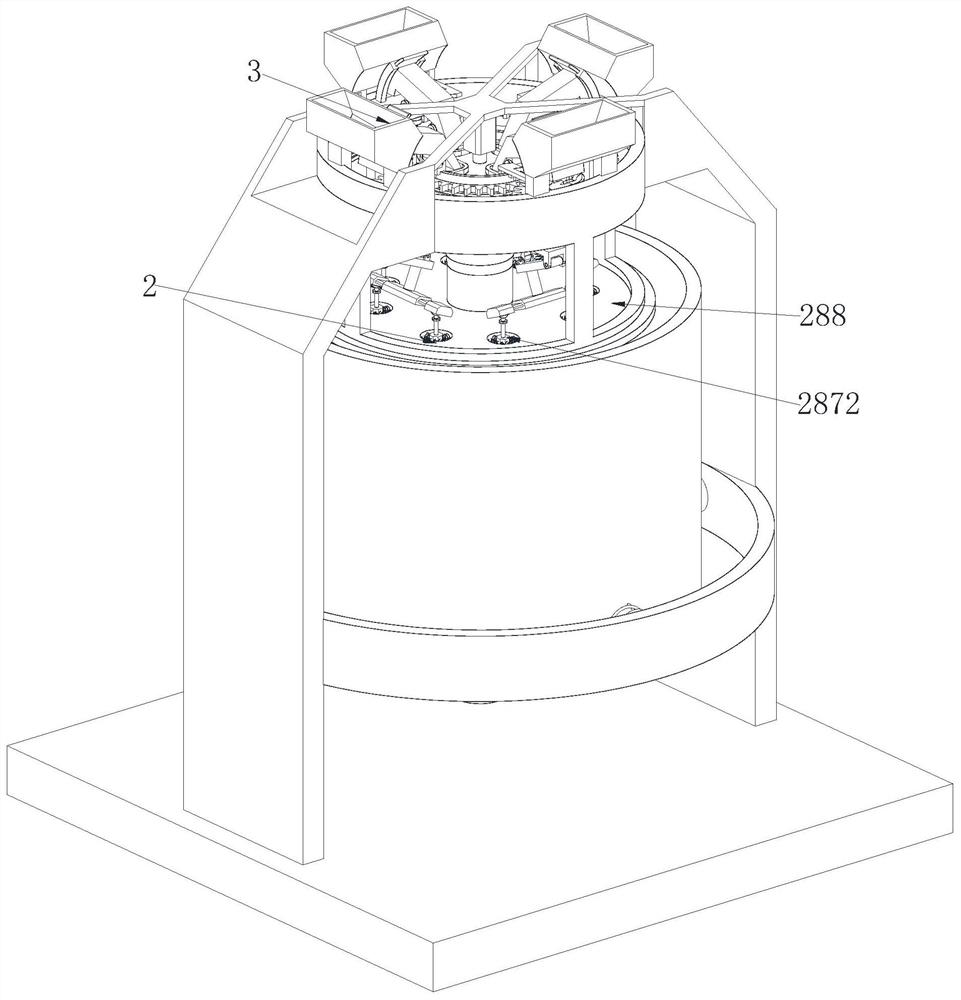

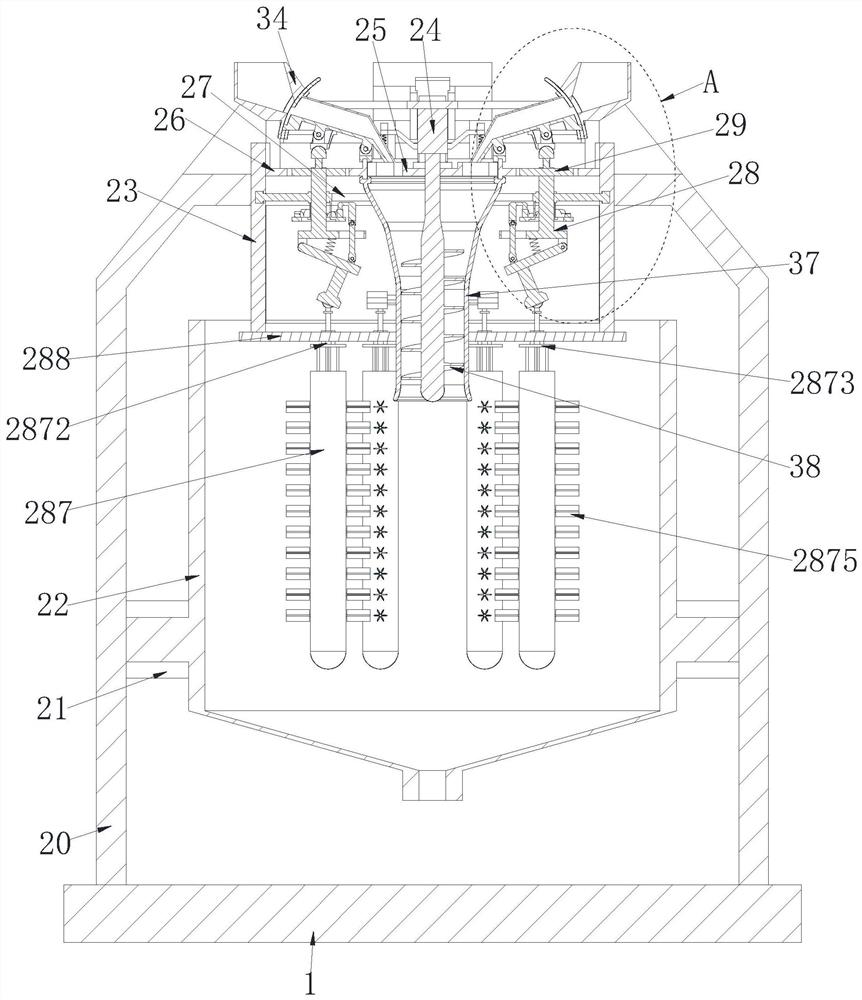

Preparation method of polymer cement waterproof mortar

ActiveCN112919857AStir wellLow efficiencySolid waste managementCement mixing apparatusPolymer sciencePolymer chemistry

The invention relates to a preparation method of polymer cement waterproof mortar, which applies preparation equipment of the polymer cement waterproof mortar.The preparation equipment of the polymer cement waterproof mortar comprises a base, a stirring device and a feeding device, wherein the stirring device is arranged on the upper surface of the base, and the feeding device is arranged above the stirring device. The invention can solve the following problems in the prior art: raw materials of mortar are put into existing stirring equipment in proportion for stirring, the stirring equipment needs longer time to uniformly stir the raw materials of the mortar in the stirring equipment due to the large input amount of the raw materials in the stirring process of the raw materials of the mortar, the use efficiency of the mortar is reduced, and the construction period is prolonged; and the stirring treatment mode of mortar raw materials is too simple, all the raw materials of the mortar are difficult to fully and uniformly mix, the prepared mortar is common in quality and low in use value, and the safety of buildings is influenced.

Owner:浙江天造环保科技有限公司

Managing a network element operating on a network

ActiveUS9755887B1Reduce use valueDigital computer detailsData switching networksReal-time computingNetwork element

Disclosed are an apparatus and method of managing network elements operating on a network. One example method may include transmitting a request to receive at least one activity parameter of a network element operating on the network and monitoring the at least one activity parameter of the network element. The method may include determining whether a usage value of the at least one activity parameter exceeds a predetermined threshold usage value and transmitting a corrective function message to the network element responsive to determining that the usage value of the at least one activity parameter exceeds the predetermined threshold value. The method may further include performing a corrective function to reduce the usage value of the at least one activity parameter.

Owner:IBM CORP

Horse feed additive

The invention provides a horse feed additive. The horse feed additive comprises 5-9 parts of bacitracin zinc, 10-14 parts of L-calcium ascorbate, 4-6 parts of calcium propionate, 18-26 parts of bentonite, 1-3 parts of fish oil, 0.07-0.09 part of protease, 0.06-0.08 part of cellulase, 0.3-0.5 part of complex mineral and 10-15 parts of traditional Chinese medicine extracting solution. The diseases and pests can be effectively controlled and the resistance of horses can be improved by adding the traditional Chinese medicine extracting solution, so that the weights of the horses are increased by about 12% on average.

Owner:兰梅

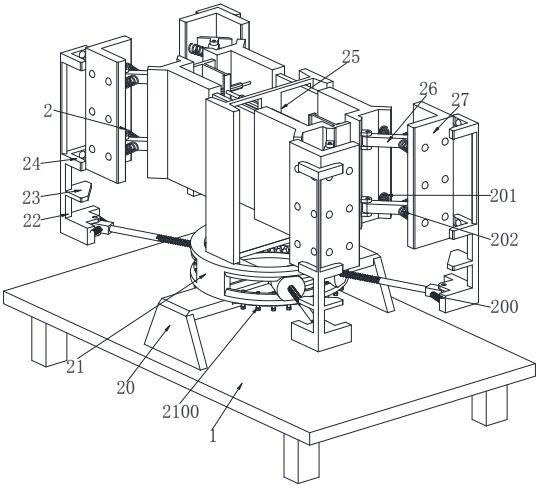

A high and low voltage power distribution cabinet assembly equipment and assembly method

ActiveCN113258487BReduce production efficiencyLabor intensiveSwitchgearLow voltageMechanical engineering

The invention relates to an assembly device and an assembly method for a high and low voltage power distribution cabinet, comprising a base and an assembly device, and the upper surface of the base is provided with an assembly device. The present invention can solve the current existing problems: the existing assembly equipment for the assembly of power distribution cabinets needs to be manually assisted by a large number of staff for the splicing and assembly of each board of the power distribution cabinet, while the power distribution cabinet The production is often in large quantities, which not only brings greater labor intensity to the staff, but also reduces the production efficiency of the power distribution cabinet; Adjustment at any time, it is still impossible to automatically align up, down, left, right, front, and rear between the panels of the power distribution cabinet being assembled, and it is difficult to accurately align the interconnected panels manually. In this way, the use value of the assembled power distribution cabinet will be reduced accordingly.

Owner:新沂市中振电器科技有限公司

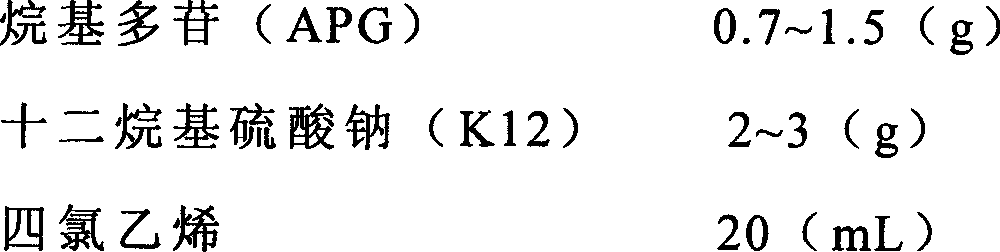

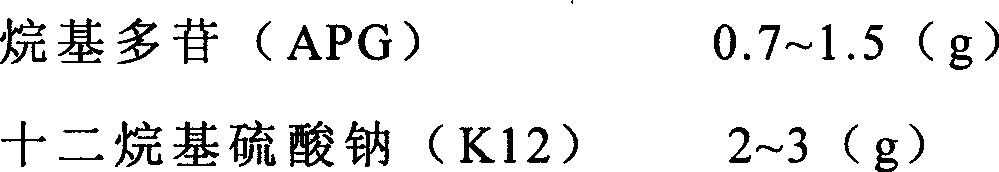

Auroral remover for wool fabric

The invention relates to an auroral remover for wool fabric and belongs to the technical field of spinning. The auroral remover consists of a canned spray agent A and a canned spray agent B. Alkyl polyglycoside in the spray agent A is an ampholytic surfactant; lauryl sodium sulfate in the spray agent A is an anionic surfactant; alkyl polyglycoside and lauryl sodium sulfate have good effects of wetting, permeating and foaming, can effectively permeate into hardened textile, yarns and fibers after being used for garments, and allow dirt to be stripped from the fibers. Alkyl polyglycoside has good compatibility and a synergistic effect with lauryl sodium sulfate. Tetrachloroethylene in the spray agent A enters the textile by the synergistic action of alkyl polyglycoside and lauryl sodium sulfate, and exerts a decontamination effect by the action of mechanical external forces such as gentle brushing and kneading. Petroleum ether in the spray agent B has dissolution and volatilization effects on oil stripped from the fabric, and acetic acid in the spray agent B has a color fixation effect. The auroral remover is short in production flow, low in cost, pollution-free, convenient to use, green, environment-friendly, and not required to be cleaned.

Owner:WUHAN TEXTILE UNIV

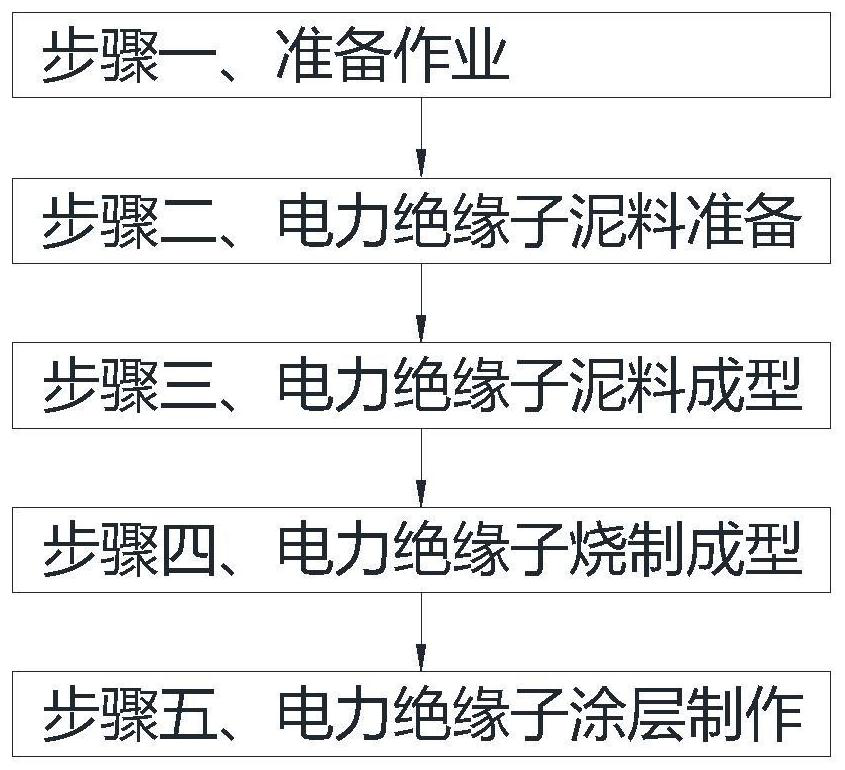

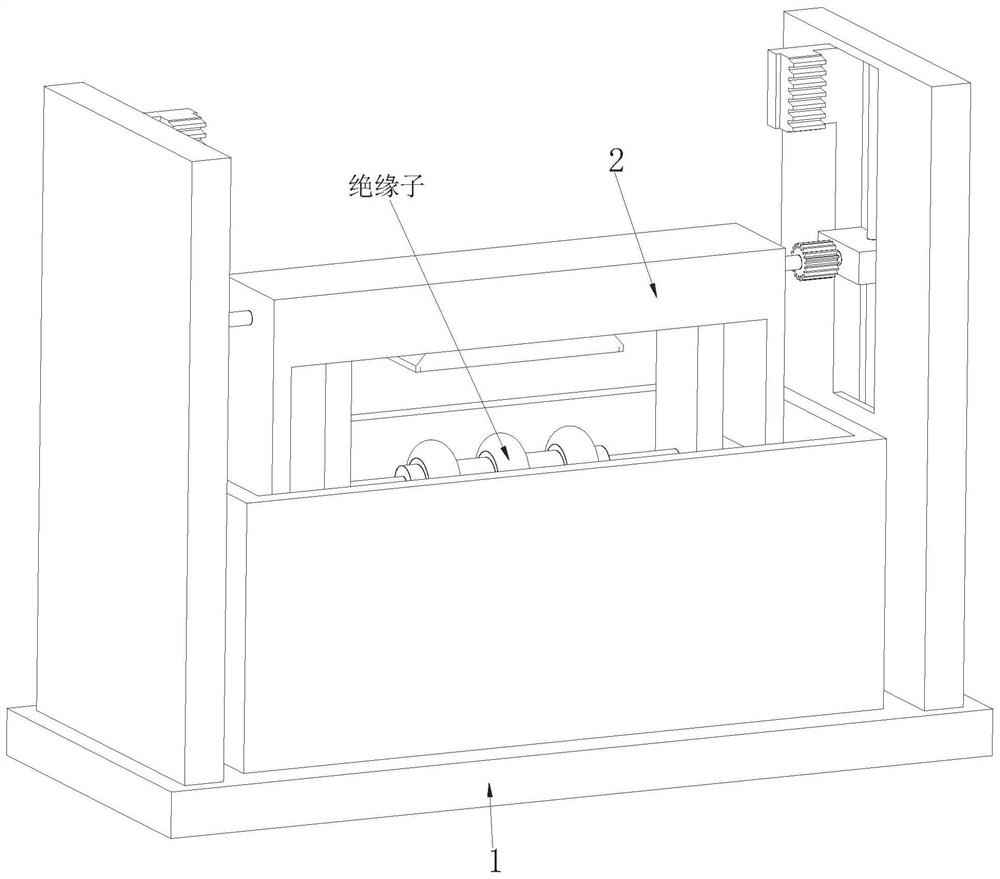

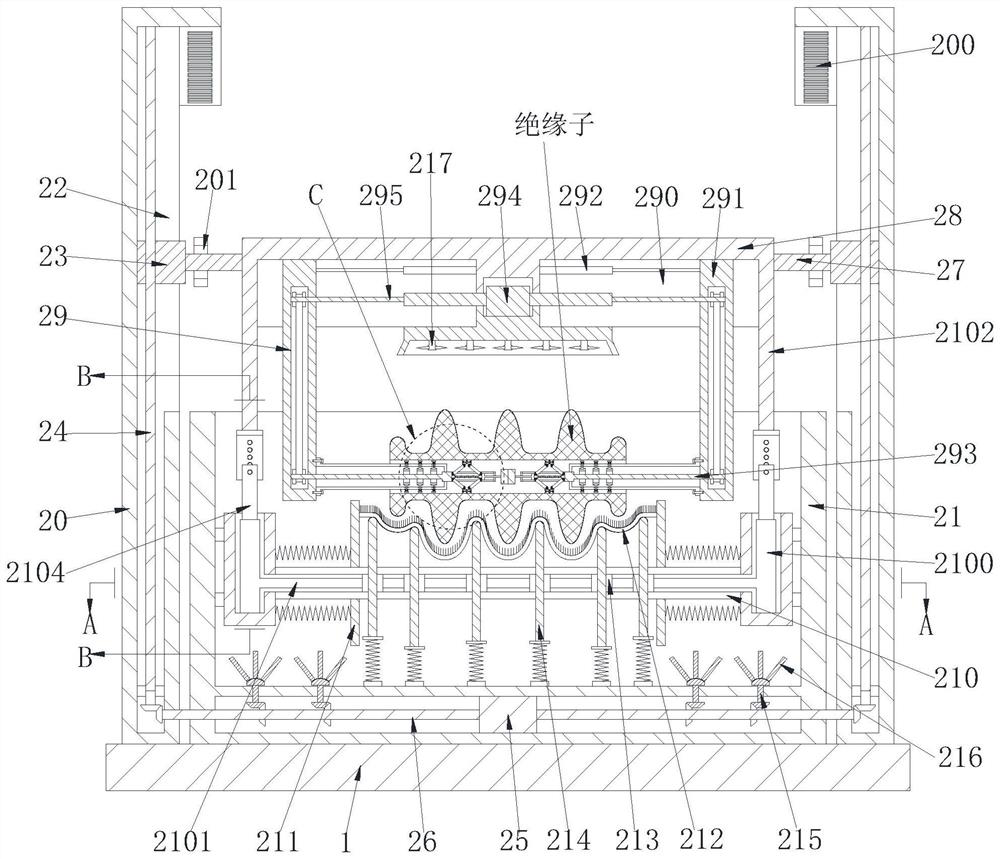

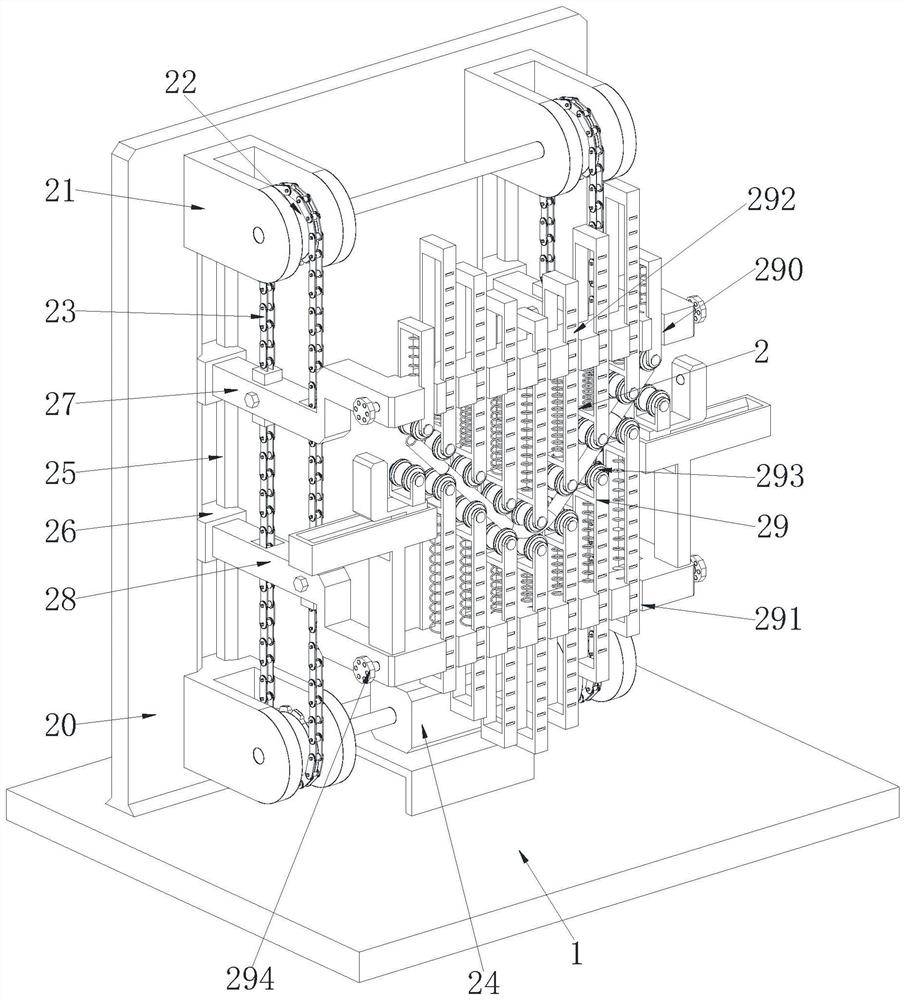

Method for manufacturing surface coating of electric power insulator

ActiveCN112967853AReduced service lifeLiquidInsulatorsCeramic materials productionPhysical chemistryDip-coating

The invention relates to a method for manufacturing a surface coating of an electric power insulator. The method uses manufacturing equipment of the surface coating of the electric power insulator, the manufacturing equipment of the surface coating of the electric power insulator comprises a base and a coating device, and the coating device is arranged on the upper surface of the base. The problems existing when the coating is manufactured on the surface of the electric power insulator at present can be solved, specifically, the insulator is only put into a dip coating groove for coating once, then taken out, placed and dried for dip coating, the coating has certain flowability, however, according to an existing dip-coating mode, the coating attached to the surface of the insulator is not evenly attached due to the flowing reason; and the surface of the insulator is not brushed no matter in dip-coating or spray-coating, and when the surface of the insulator is in a dry state, bubbles are easily generated when the coating is attached to the surface of the insulator, so that the effect of attaching the coating to the surface of the insulator is poor.

Owner:醴陵市永诚电瓷电器有限公司

Pale-red jasmine-flower-fragrance diarrhea-preventing bean curd sheets and preparation method thereof

InactiveCN105918487AImprove the compatibility effectImprove efficacyCheese manufactureFood scienceDiarrheaHerb

The invention discloses pale-red jasmine-flower-fragrance diarrhea-preventing bean curd sheets. The pale-red jasmine-flower-fragrance diarrhea-preventing bean curd sheets are prepared from the following materials: soybeans, red adzuki beans, jasmine flowers, bighead atractylodes rhizomes, aucklandia roots, Chinese alyxia herb, pilose gerbera herb, raspberry roots, common evolvulus herb, dried orange peels, liquorice roots, Chinese trumpetcreeper roots and safflower extract. The bean curd sheets prepared by the invention are rich and balanced in nutrition; and the Chinese herbal medicine preparations added therein are capable of increasing nutritive values of the bean curd sheets, and have very good effects of reducing diarrhea rates of the consumers. The bean curd sheets are pale red in outer surfaces, and have faint refreshing fragrance of the jasmine flowers; thus, the bean curd sheets are relatively good in appearance conditions and more attractive compared with traditional bean curd sheets which have single yellowish-white color. Moreover, technological matches of the preparation method are scientific and rational, so that material utilization ratios are greatly improved. Compared with traditional production methods, the production cost of the preparation method disclosed by the invention is saved by about 25% when bean curd sheets of the same yields and qualities are produced; thus, the bean curd sheets and the preparation method thereof have very good promotional values.

Owner:ANHUI HONGHUA FOOD

Plastic-coated elbow manufacturing, forming and bending machine

InactiveCN113458205AGood bending effectReduced bending efficiencyMetal-working feeding devicesMetal working apparatusEngineeringStructural engineering

The invention relates to a plastic-coated elbow manufacturing, forming and bending machine which comprises a base and a bending device, and the bending device is arranged on the upper surface of the base. According to the plastic-coated elbow manufacturing, forming and bending machine, a bending unit can be adjusted at any time according to the actually needed shapes of metal pipes within the bending angle range and the bending radian range of the metal pipes of the same specification, other bending dies do not need to be replaced, after adjustment is conducted every time, the shape formed by a bending sliding frame is fixed through a positioning branch chain, and therefore, the bending efficiency can be effectively improved for the metal pipes which are bent into different shapes; and limiting rollers arranged on an upper supporting rod can guarantee that the two ends of the metal pipes and the bending unit are always located on the same horizontal line when the metal pipes are bent, and a position correcting roller arranged on a lower supporting rod is used in cooperation with a position correcting supporting block, so that the distances between the two ends of the metal pipes and the middle position of the bending unit can be kept the same, and in this way, the bending effect of the metal pipes can be better.

Owner:李龙

Mint-fragrance bean curd sheets for preventing and treating cough

InactiveCN105918486APromote leachingReduce harmful ingredientsCheese manufactureFood scienceNutritive valuesMedicine

The invention discloses mint-fragrance bean curd sheets for preventing and treating cough. The mint-fragrance bean curd sheets for preventing and treating the cough are prepared from the following materials: soybeans, green peas, mint leaves, liquorice roots, rhizomes of willowleaf swallowwort, astragalus roots, beef omasum, olives, luffa blossoms, apricot kernels, cyrtomium, caulis perllae and gardenia jasminoides root extract. The bean curd sheets prepared by the invention are rich and balanced in nutrition; and the Chinese herbal medicine preparations added therein are capable of increasing nutritive values of the bean curd sheets, and have very good effects of reducing cough rates of the consumers. The bean curd sheets are pale green in outer surfaces, and have faint refreshing fragrance of the mint leaves; thus, the bean curd sheets are relatively good in appearance conditions and more attractive compared with traditional bean curd sheets which have single yellowish-white color. Moreover, technological matches of the preparation method are scientific and rational, so that material utilization ratios are greatly improved. Compared with traditional production methods, the production cost of the preparation method disclosed by the invention is saved by about 25% when bean curd sheets of the same yields and qualities are produced; thus, the bean curd sheets and the preparation method thereof have very good promotional values.

Owner:ANHUI HONGHUA FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com