Method for forming mullite-based ceramic cylinder reinforced composite wear-resistant steel plate

A mullite-based, reinforced composite technology is applied in the field of surface engineering, which can solve the problems of low interface bonding strength and poor wear resistance, and achieve the effects of excellent wear resistance, low price and improved use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Best practice:

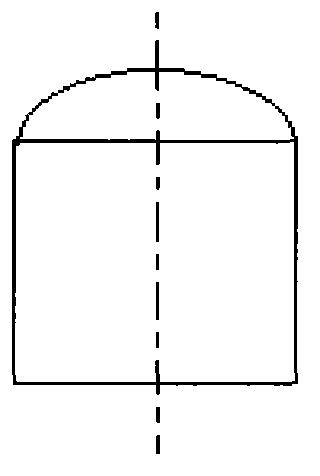

[0014] Step 1, preparing composite powder of sillimanite and iron, the ratio is: sillimanite powder accounts for 80%wt, its particle size is 200-300 mesh, Fe powder 20%wt, its particle size is 200 mesh. After mixing, it is pressed into a round cylindrical closed extrusion die with a diameter of 15mm to form a round cylindrical prefabricated block, and sintered at 1750°C for 2 hours at normal pressure to form mullite, or in a graphite mold with a pressure of 50MPa and sintered at 1750°C for 1 hours to form, to get figure 1 Round-ended mullite-based composite cylinders are shown.

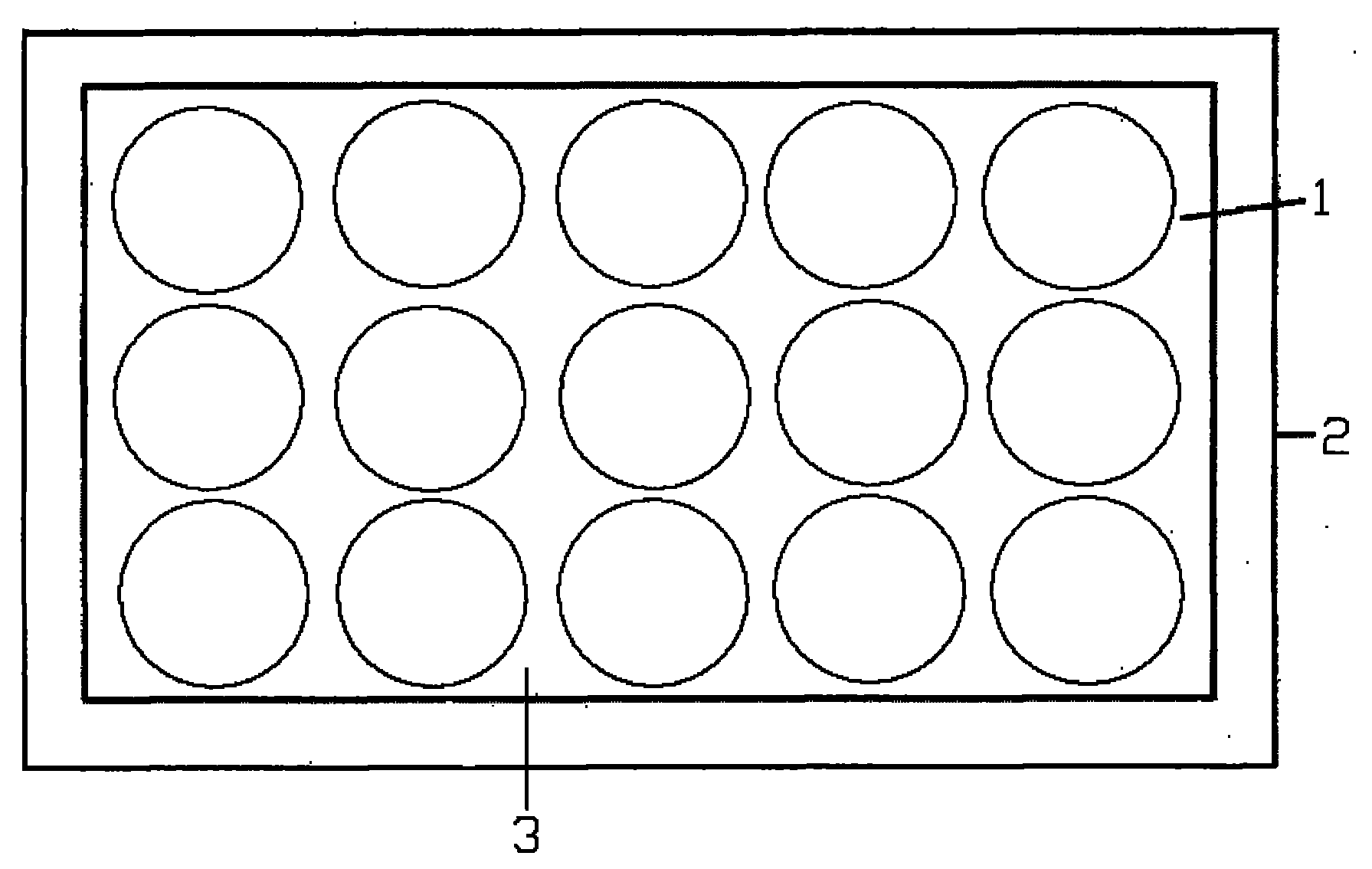

[0015] Step two, such as figure 2 As shown, ordinary carbon steel is taken as the base steel plate, and the base steel plate is surrounded by refractory bricks and sealing mud to make a reaction pool, and the round heads of mullite-based composite cylinders with round heads are placed on the surface of the steel plate. Leave a gap of 5 mm between each other, use a steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com