Manufacturing and processing method for synthetic polymer waterproof roll

A technology for synthesizing polymers and waterproofing membranes, which is applied to coatings and devices for coating liquid on the surface, etc. It can solve the problems of air holes in waterproofing membranes, reduced service life of waterproofing membranes, and uneven distribution of coatings on the surface of the carrier. Avoid porosity, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

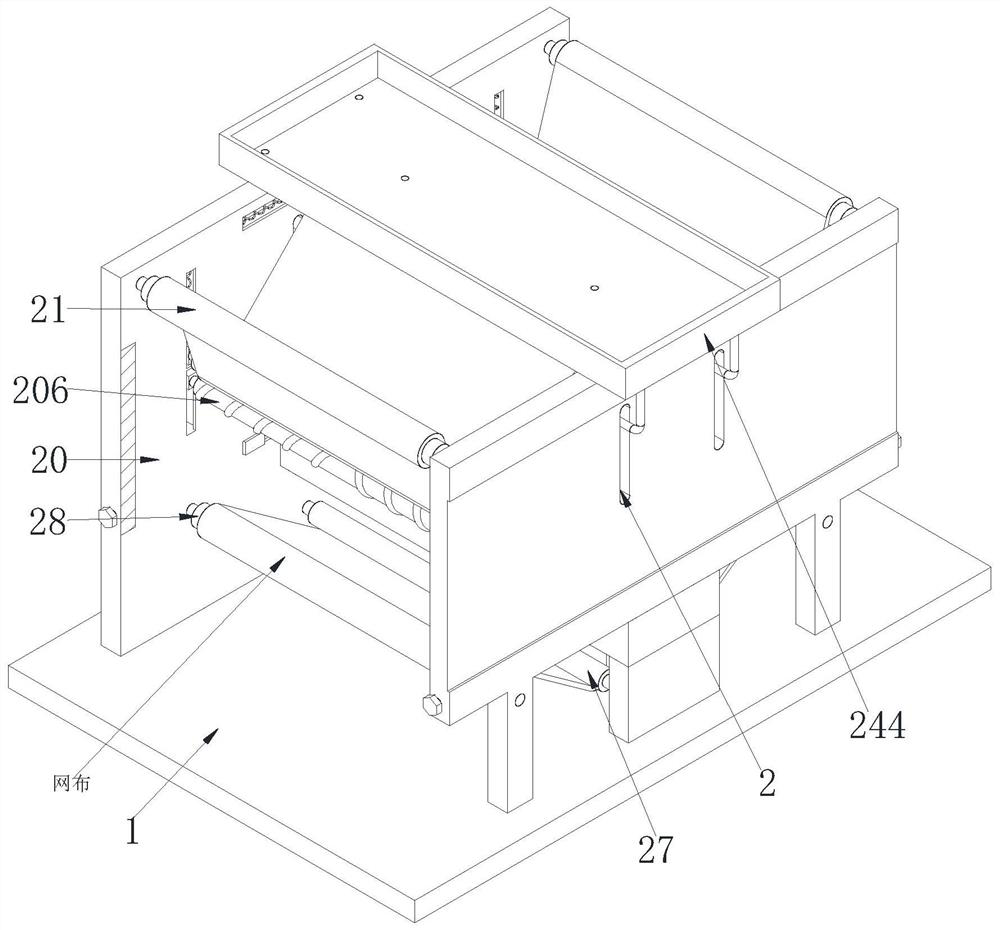

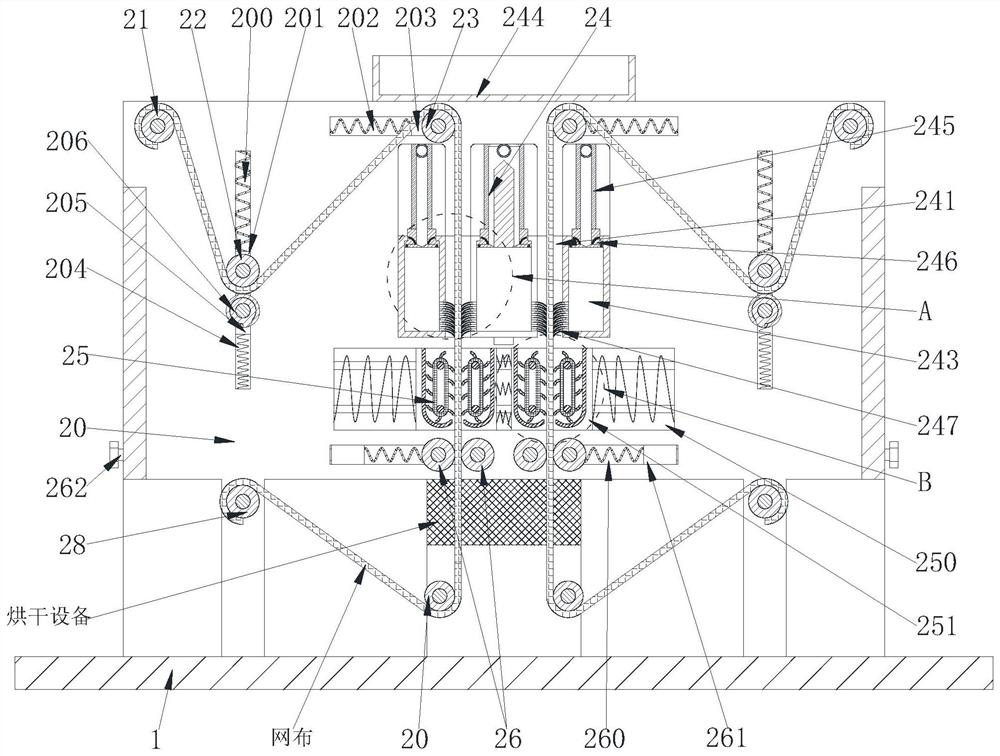

[0030] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0031] A method for manufacturing and processing a synthetic polymer waterproof membrane, which uses a manufacturing and processing equipment for a synthetic polymer waterproof membrane. The equipment for manufacturing and processing a synthetic polymer waterproof membrane includes a base 1 and a coating device 2. The specific methods of manufacturing synthetic polymer waterproof membranes by molecular waterproof membrane manufacturing and processing equipment are as follows:

[0032] Step 1. Preparatory work: debug the synthetic polymer waterproof membrane manufacturing and processing equipment of the present invention, and prepare the carrier mesh material and coating raw materials for making the waterproof membrane;

[0033] Step 2. Raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com