Channel type double-view-angle X-ray safety inspection device

A security inspection and X-ray technology, applied in the field of X-ray security inspection, can solve the problems of increasing equipment length, complex mechanical structure, loss of key information, etc., to achieve the effect of reducing the need for repeated inspections, strong anti-interference ability, and rich observation fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

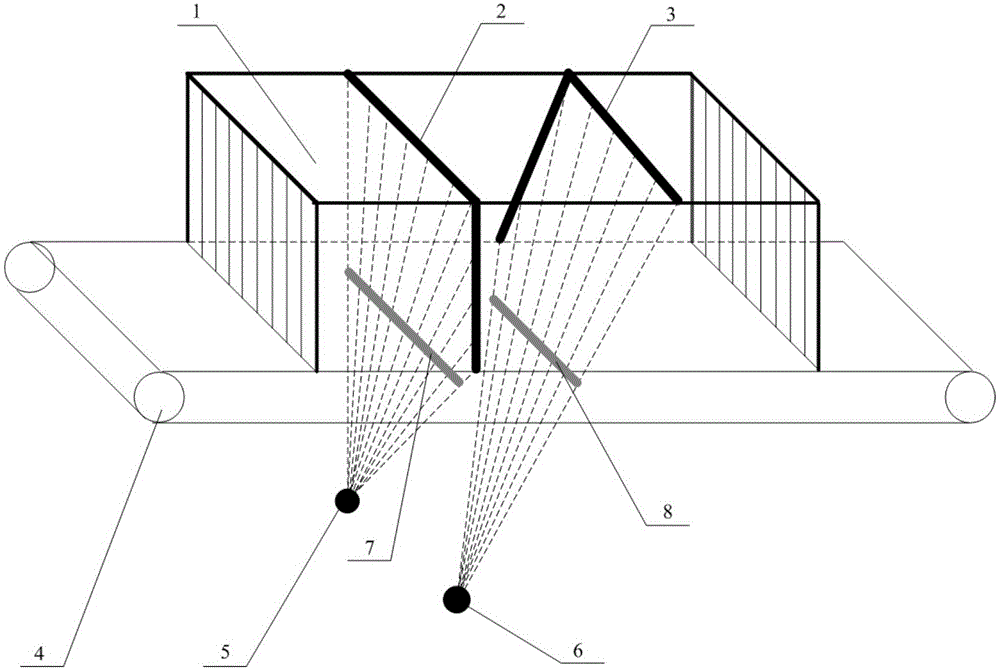

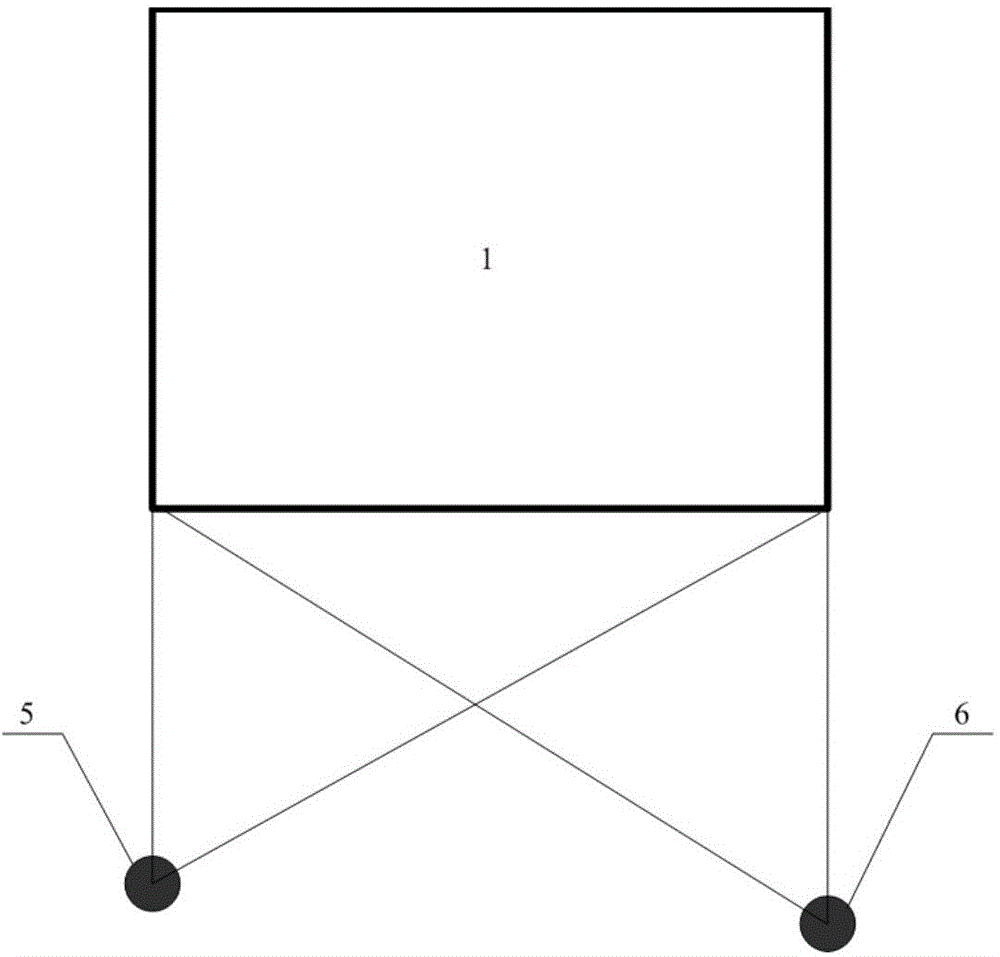

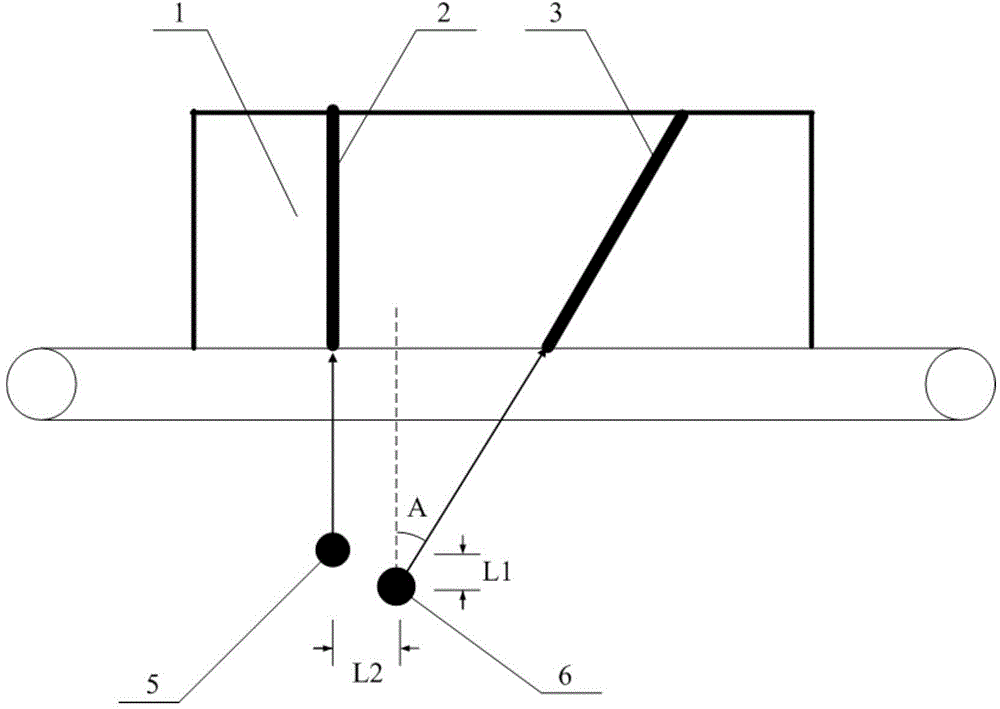

[0035] The specific implementation manner of the safety inspection device of the present invention will be described in detail below in conjunction with the accompanying drawings. refer to figure 1 As shown in , the safety inspection device of the present invention includes a conveying channel 1, a first X-ray source 5, a first detector 2, a second X-ray source 6, a second detector 3, a conveyor 4, system control and signal Processing circuit unit, comprehensive processing computer, lead door curtains at the entrances at both ends of the conveying channel, light sensors in the conveying channel, wherein the system control and signal processing circuit unit, comprehensive processing computer, lead door curtains at the entrances at both ends of the conveying channel, conveying The four components of the light sensor in the channel are traditional components of the security inspection equipment, so they are not included in the figure 1 Marked out.

[0036] refer to figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com