Three-dimensional ordered mesoporous molybdenum-based catalyst as well as preparation method and application thereof

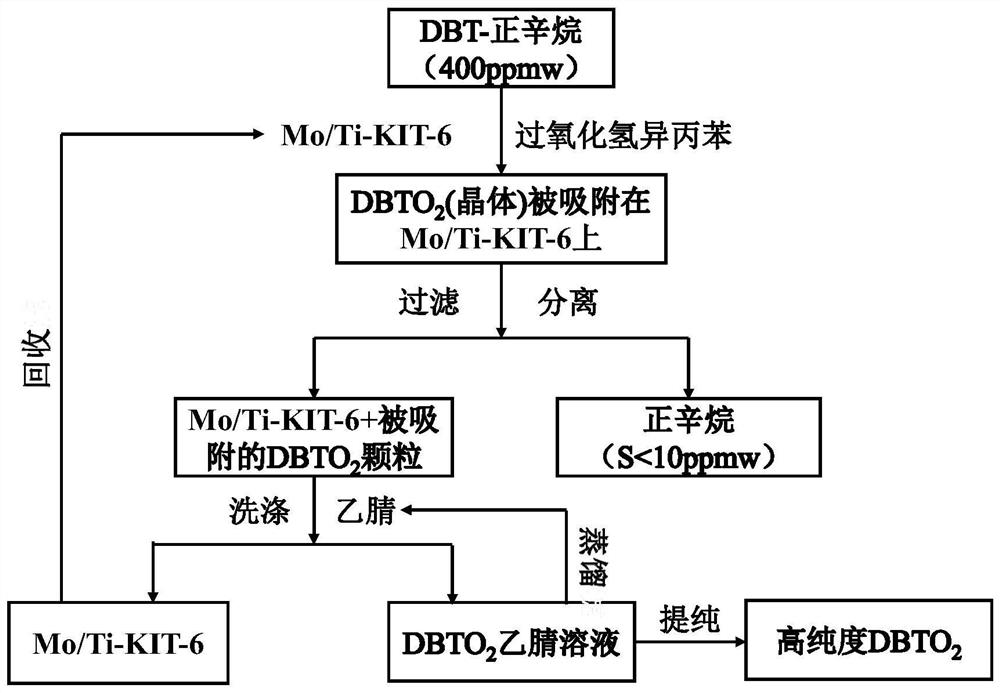

A molybdenum-based catalyst, a three-dimensional ordered technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems that limit the wide industrial application of molybdenum-based catalysts, difficult to remove sulfur-containing organic compounds, and molybdenum trioxide particles. Easy to aggregate and other problems, to achieve the effects of excellent oxidative desulfurization activity, efficient catalytic oxidation of target pollutants, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A three-dimensional ordered mesoporous molybdenum-based catalyst comprises mesoporous molecular sieves, and subnano-scale molybdenum trioxide particles are loaded on the mesoporous molecular sieves.

[0049] In this embodiment, in the three-dimensional ordered mesoporous molybdenum-based catalyst, the mass of molybdenum trioxide particles is 9.84% of the mass of the mesoporous molecular sieve.

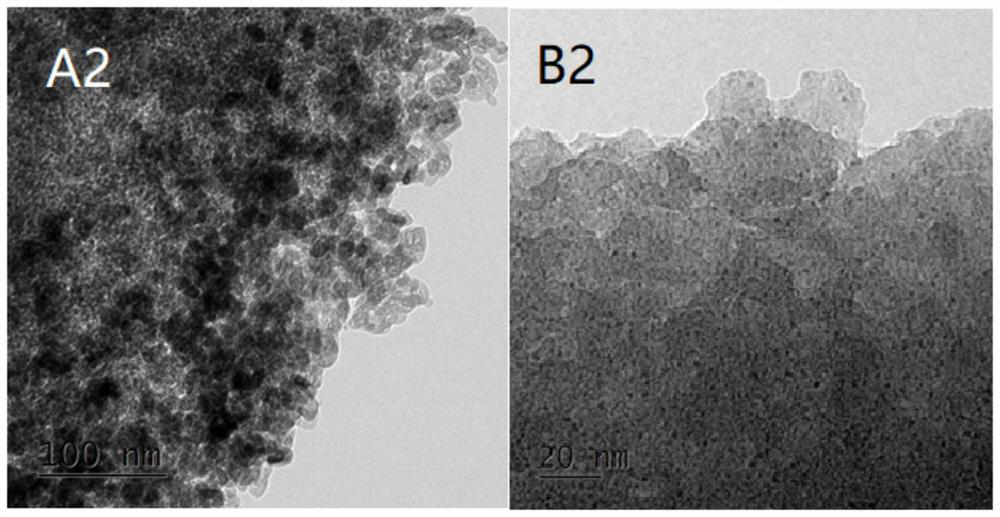

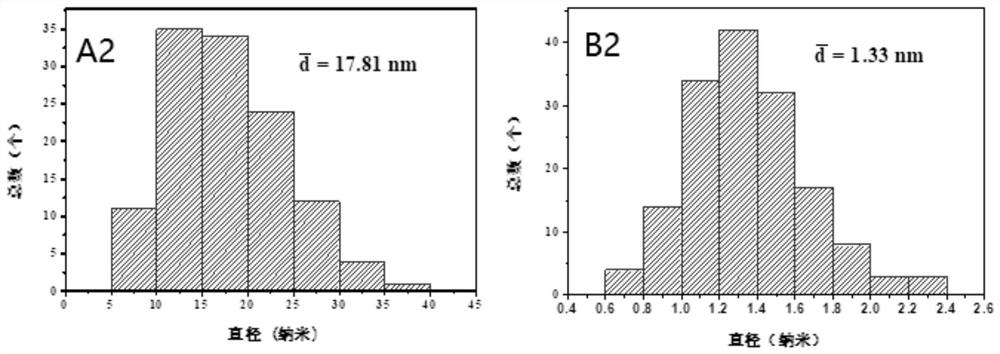

[0050] In this embodiment, the mesoporous molecular sieve is KIT-6, and the specific surface area of the mesoporous molecular sieve is 1155m 2 / g, pore volume 0.9cm 3 / g, the pore size is 3.10nm; the particle size of molybdenum trioxide particles is 0.8nm~2.4nm.

[0051] In this example, the specific surface area of the three-dimensional ordered mesoporous molybdenum-based catalyst is 978.47m 2 / g.

[0052] A preparation method of the three-dimensional ordered mesoporous molybdenum-based catalyst in the above-mentioned present embodiment, comprising the following steps: ...

Embodiment 2

[0057] A three-dimensional ordered mesoporous molybdenum-based catalyst comprises a mesoporous molecular sieve, the mesoporous molecular sieve is doped with titanium dioxide, and the titanium dioxide-doped mesoporous molecular sieve is loaded with subnano-scale molybdenum trioxide particles.

[0058] In this embodiment, in the three-dimensional ordered mesoporous molybdenum-based catalyst, the mass of molybdenum trioxide particles is 9.80% of the mass of the mesoporous molecular sieve, and the mass of titanium dioxide is 5% of the mass of the mesoporous molecular sieve.

[0059] In this embodiment, the mesoporous molecular sieve is KIT-6, and the specific surface area of the mesoporous molecular sieve is 1155m 2 / g, pore volume 0.9cm 3 / g, the pore size is 3.10nm; the particle size of molybdenum trioxide particles is 0.8nm~2.4nm.

[0060] In this example, the specific surface area of the three-dimensional ordered mesoporous molybdenum-based catalyst is 978.47m 2 / g.

[...

Embodiment 3

[0066] A method for preparing a three-dimensional ordered mesoporous molybdenum-based catalyst is basically the same as that in Example 2, the only difference being that the calcining temperature in Example 3 is 300°C.

[0067] The three-dimensional ordered mesoporous molybdenum-based catalyst (Mo / KIT-6-Ti) prepared in Example 3 is numbered C1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com