Comprehensively utilizing new process for ferrous sulfate

A ferrous sulfate and process technology, applied in the new technology field of comprehensive utilization of ferrous sulfate, can solve the problems of large energy consumption, reduced environmental pollution, limited amount of ferrous sulfate, etc., and achieves large equipment investment, poor economic benefits, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

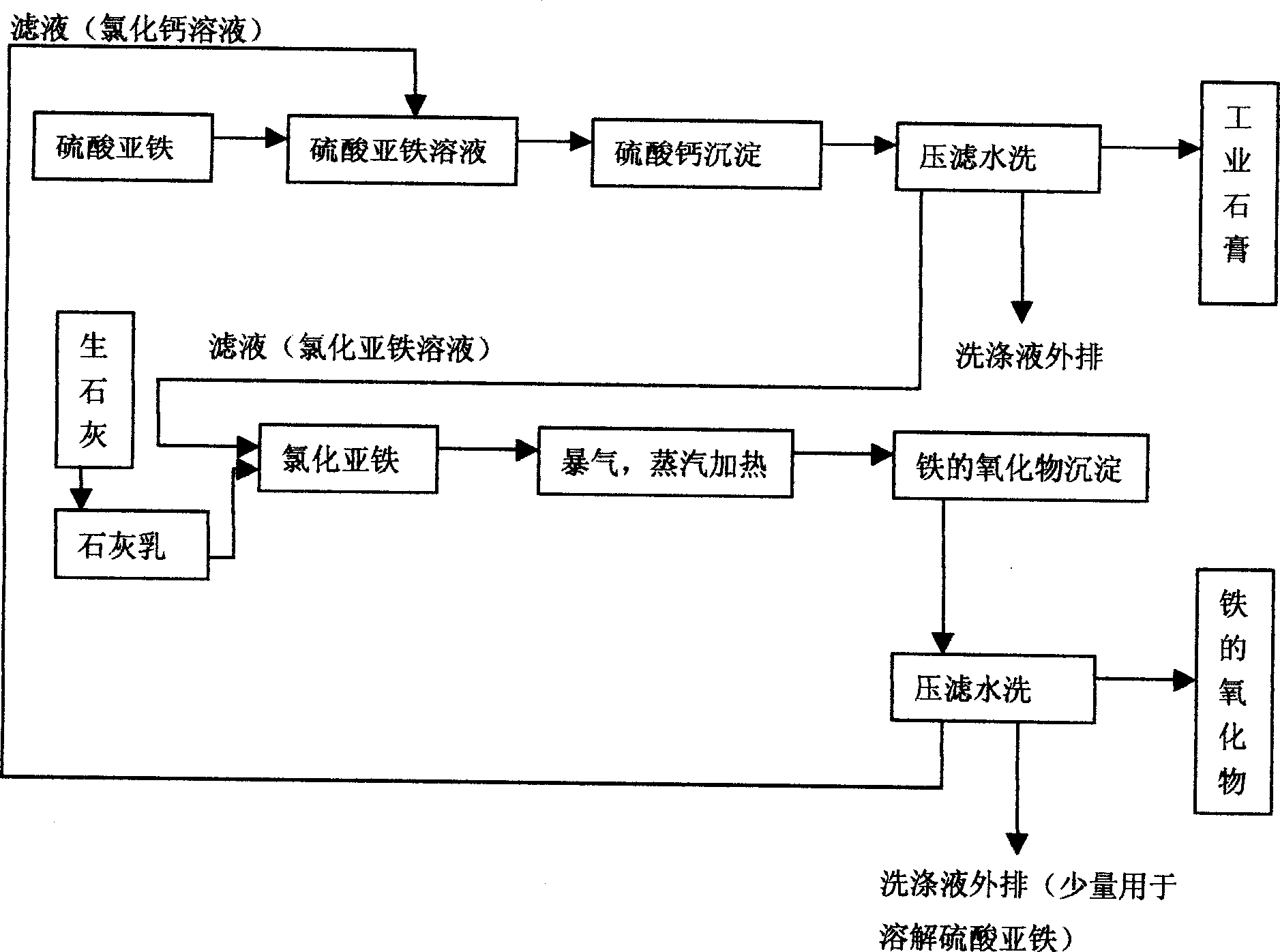

Method used

Image

Examples

Embodiment 1

[0056] Weigh FeSO by-product of titanium dioxide plant 4 ·7H 2 1000 grams of O (95% content) is put into a plastic bucket, add a small amount of water to become semi-fluid, slowly pour CaCl2 (concentration 300 grams per liter) solution 1300 milliliters in the bucket, fully stir for 2 hours, filter; (FeCl 2 Solution) preservation, the filter residue (1) is washed and exposed to the sun until dry; Weigh 209 grams of quicklime (calcium oxide content is 91%) in an aluminum bucket, add an appropriate amount of water to make it milky, and the above filtrate Slowly pour into this milk of lime, stir with compressed air, keep stirring for 48 hours, filter; the filtrate (CaCl 2 solution) was retained, and the filter residue (2) was washed with water and then exposed to the sun until dry.

[0057] After weighing filter residue (1) is 570 grams, CaSO 4 2H 2 O content is 97%, filter residue (2) 290 grams, Fe 2 o 3 The content is 90%, meeting the raw material requirements for ironmak...

Embodiment 2

[0059] Weigh FeSO from titanium dioxide factory 4 ·7H 2 O 1000 grams, place plastic barrel, add a small amount of tap water, partly dissolve into semi-flowing state; The filtrate (CaCl 2 solution) are all poured into the plastic barrel, and then add the CaCl in the example 1 2 (concentration 300 g / L) solution 30 ml, stirred for 3 hours and then filtered, the filter residue (1) was washed with water and then dried in an oven at 80°C; the filtrate was placed in an aluminum bucket and a small amount of quicklime was added to adjust the pH value to 3, and the precipitate was filtered off , add 209 grams of quicklime to the filtrate, stir vigorously with compressed air, and place the aluminum bucket in the sun for 48 hours, then filter, and the filter residue (2) is dried in an oven at 80°C after being washed with water, and the filtrate is used To process the next batch of ferrous sulfate.

[0060] Obtain filter residue (1) after drying——572 grams of gypsum, CaSO 4 2H 2 O con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com