Polyimide composite material and preparation method and application thereof

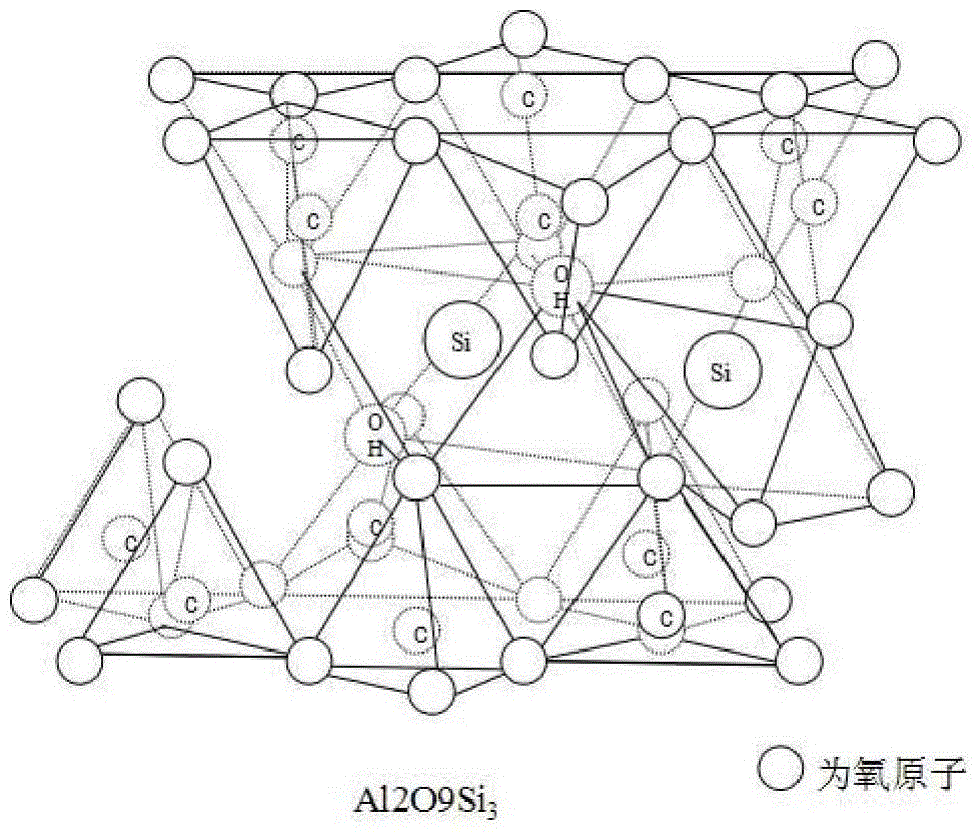

A composite material and polyimide technology, applied in the field of polyimide composite materials, can solve the problems of toxic heavy metal ions, poor mechanical properties and heat resistance, and unsatisfactory radiation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

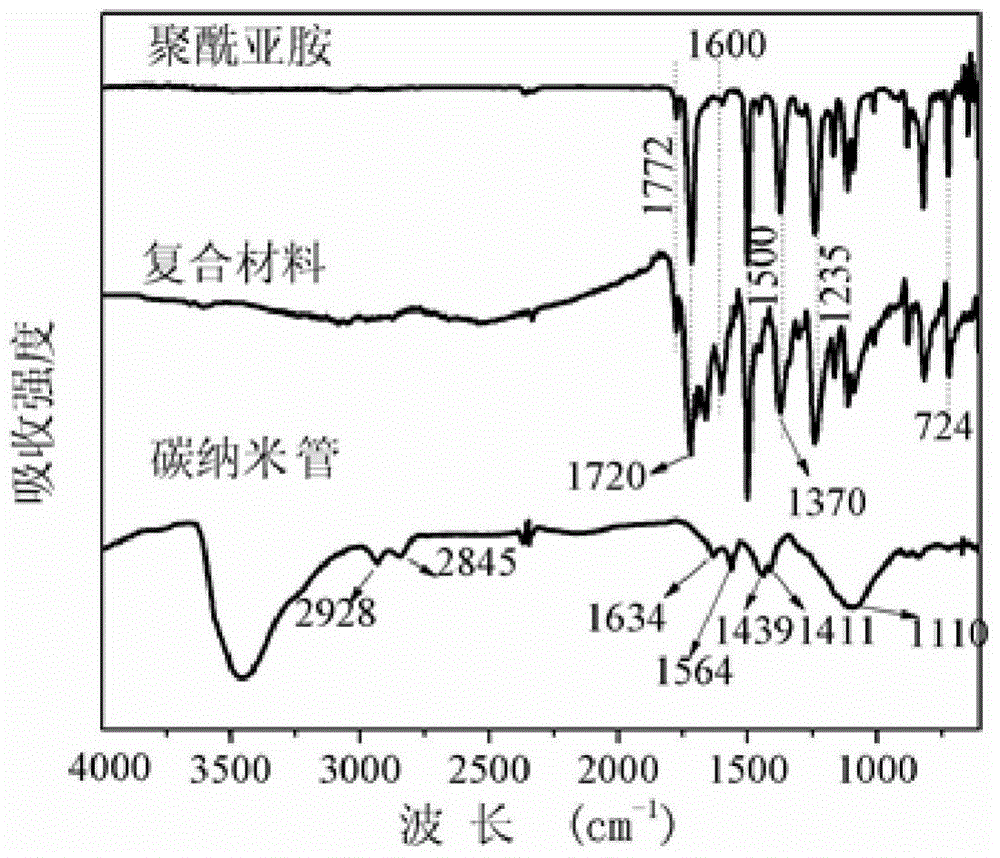

Examples

preparation example Construction

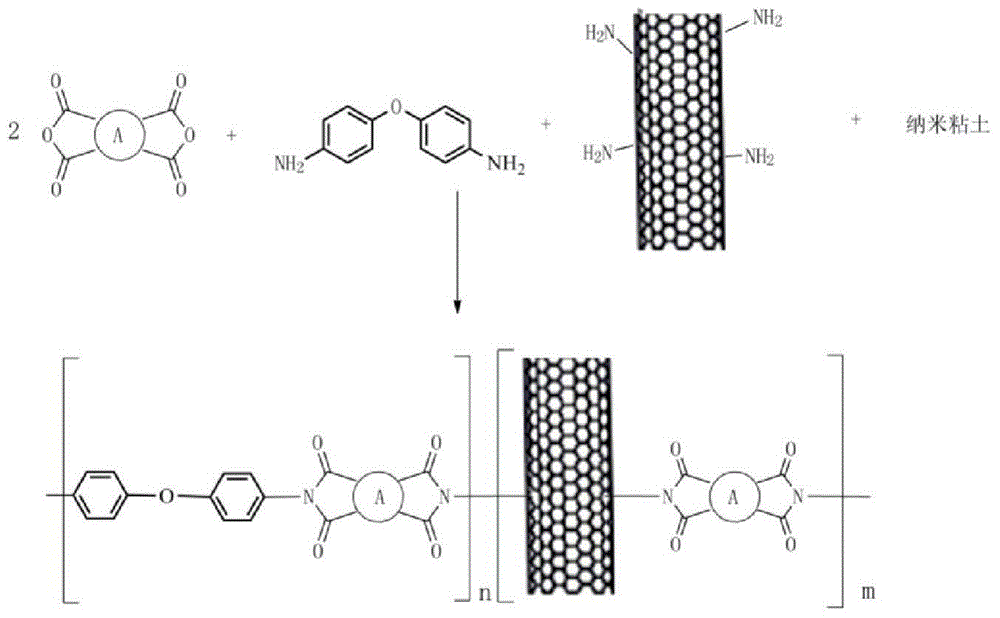

[0043] The preparation method of the polyimide composite material bonded by aminated carbon nanotubes of the present invention, the steps are:

[0044] 1. Recrystallize ODA, PMDA or BPDA with ethanol and acetic anhydride respectively, and seal them for storage.

[0045] 2. Remove the water in N,N'-dimethyl-2-pyrrolidone by vacuum distillation, and store the redistilled NMP in a desiccator.

[0046] 3. Dissolve M g of ODA in X g redistilled NMP. Magnetic or mechanical stirring.

[0047] 4. Add aminated carbon nanotubes (amination rate a) Y g to the system, and ultrasonically disperse evenly after stirring, then add dried nanoclay Z g to the system, and ultrasonically disperse the system for another 2 hours.

[0048] 5. Add N g of PMDA or BPDA to the system in batches. Let it react completely. Wherein when the dianhydride monomer is PMDA: M / 200+Ya / 16=N / 218; when the dianhydride monomer is BPDA: M / 200+Ya / 16=N / 294. Furthermore, (M+N+Y+Z) / (M+N+Y+X+Z)=0.1, that is, the solid co...

Embodiment 1

[0053] Embodiment 1: the preparation of the polyimide composite film whose mass content of aminated carbon nanotube is 5%, the mass fraction of nanoclay is 15%, the size is 5 × 5 × 1 cm, and the dianhydride monomer is PMDA , its preparation steps are:

[0054] (1) Recrystallize an appropriate amount of PMDA and ODA with acetic anhydride and ethanol, respectively. And a certain amount of polar solvent N-methylpyrrolidone (NMP) was distilled under reduced pressure.

[0055] (2) Add 15.2817g (0.0764mol) of diamine to a 500ml three-necked flask equipped with mechanical stirring, and add 400ml of distilled solvent NMP. After the diamine was dissolved by mechanical stirring, 2g of aminated carbon nanotubes (amination rate of 0.45wt%) was firstly added, and after the dispersion was uniform, 6g of dried nanoclay was added, and ultrasonically dispersed. 16.7183 g (0.0767 mol) of dianhydride were slowly added in portions. The reaction was stirred at room temperature for 5 hours to ob...

Embodiment 2

[0057] Embodiment 2: the mass content of aminated carbon nanotube is 10%, the mass fraction of nanoclay is 10%, the size is 5 * 5 * 1cm, and the dianhydride monomer is the preparation of the polyimide composite film of PMDA , its preparation steps are:

[0058] (1) Recrystallize an appropriate amount of PMDA and ODA with acetic anhydride and ethanol, respectively. And a certain amount of polar solvent N-methylpyrrolidone (NMP) was distilled under reduced pressure.

[0059] (2) Add 15.2523g (0.0762mol) of diamine into a 500ml three-necked flask equipped with mechanical stirring, and add 400ml of distilled solvent NMP. After the diamine was dissolved by mechanical stirring, 4g of aminated carbon nanotubes (amination rate of 0.45wt%) was added first, and after being uniformly dispersed, 4g of oven-dried nanoclay was added, and ultrasonically dispersed. 16.7477 g (0.0768 mol) of dianhydride were slowly added in portions. The reaction was stirred at room temperature for 5 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com