Light weight high-strength anti-condensation dry powder coating and preparation method thereof

A technology of dry powder coating and production method, applied in powder coatings, cement coatings, coatings and other directions, can solve the problems of difficult long-term storage, poor breathing ability, easy to generate condensation, etc., and achieve good anti-condensation performance and strong breathing ability. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

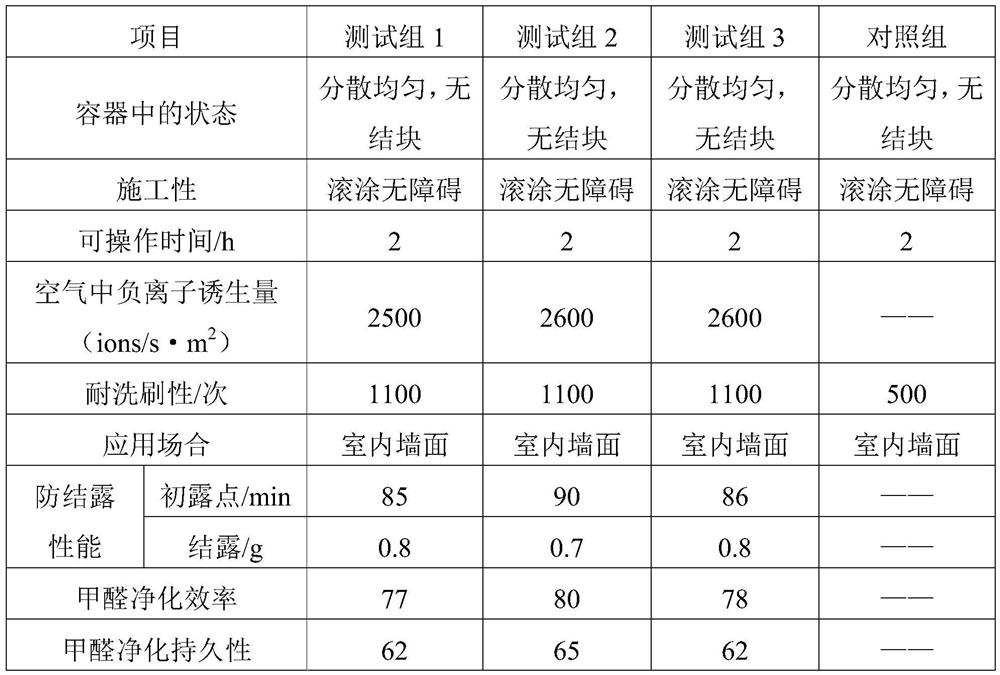

Examples

Embodiment 1

[0036] A method for making a lightweight high-strength anti-condensation dry powder coating, comprising the following steps:

[0037] (1) Material preparation: Weigh 20kg of calcium silicate board sanding waste, 20kg of food grade ash calcium powder, 4kg of super white cement, 4kg of negative ion carrier material, 8kg of diatomite, 8kg of attapulgite, 6kg of ultrafine powder, and talcum powder 4kg, quartz powder 7kg, heavy calcium 8kg, cellulose ether 1.5kg, dispersible latex powder 0.8kg, thixotropic lubricant 0.25kg, solid dispersant 0.15kg, defoamer 0.07kg, starch ether 0.07kg.

[0038] (2) Put food-grade gray calcium powder and super white cement into the mixer;

[0039] (3) input calcium silicate board sanding waste, then input cellulose ether, dispersible latex powder, thixotropic lubricant, solid dispersant, defoamer and starch ether;

[0040] (4) Put in diatomite, attapulgite, superfine powder, quartz powder, negative ion carrier material and heavy calcium, and fully ...

Embodiment 2

[0043] A method for making a lightweight high-strength anti-condensation dry powder coating, comprising the following steps:

[0044] (1) Material preparation: Weigh 15kg of calcium silicate board sanding waste, 25kg of food grade ash calcium powder, 3kg of super white cement, 5kg of negative ion carrier material, 10kg of diatomite, 5kg of attapulgite, 8kg of superfine powder, and talcum powder 3kg, quartz powder 5kg, heavy calcium 10kg, cellulose ether 2kg, dispersible latex powder 0.5kg, thixotropic lubricant 0.1kg, solid dispersant 0.2kg, defoamer 0.05kg, starch ether 0.1kg.

[0045] (2) Put food-grade gray calcium powder and super white cement into the mixer;

[0046] (3) input calcium silicate board sanding waste, then input cellulose ether, dispersible latex powder, thixotropic lubricant, solid dispersant, defoamer and starch ether;

[0047] (4) Put in diatomite, attapulgite, superfine powder, quartz powder, negative ion carrier material and heavy calcium, and fully mix...

Embodiment 3

[0050] A method for making a lightweight high-strength anti-condensation dry powder coating, comprising the following steps:

[0051] (1) Material preparation: Weigh 25kg of calcium silicate board sanding waste, 15kg of food grade ash calcium powder, 5kg of super white cement, 3kg of negative ion carrier material, 5kg of diatomite, 10kg of attapulgite, 5kg of superfine powder, and talcum powder 5kg, quartz powder 10kg, heavy calcium 5kg, cellulose ether 1kg, dispersible latex powder 1kg, thixotropic lubricant 0.5kg, solid dispersant 0.1kg, defoamer 0.1kg, starch ether 0.05kg.

[0052] (2) Put food-grade gray calcium powder and super white cement into the mixer;

[0053] (3) input calcium silicate board sanding waste, then input cellulose ether, dispersible latex powder, thixotropic lubricant, solid dispersant, defoamer and starch ether;

[0054] (4) Put in diatomite, attapulgite, superfine powder, quartz powder, negative ion carrier material and heavy calcium, and fully mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com