Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Reduce electrostatic force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

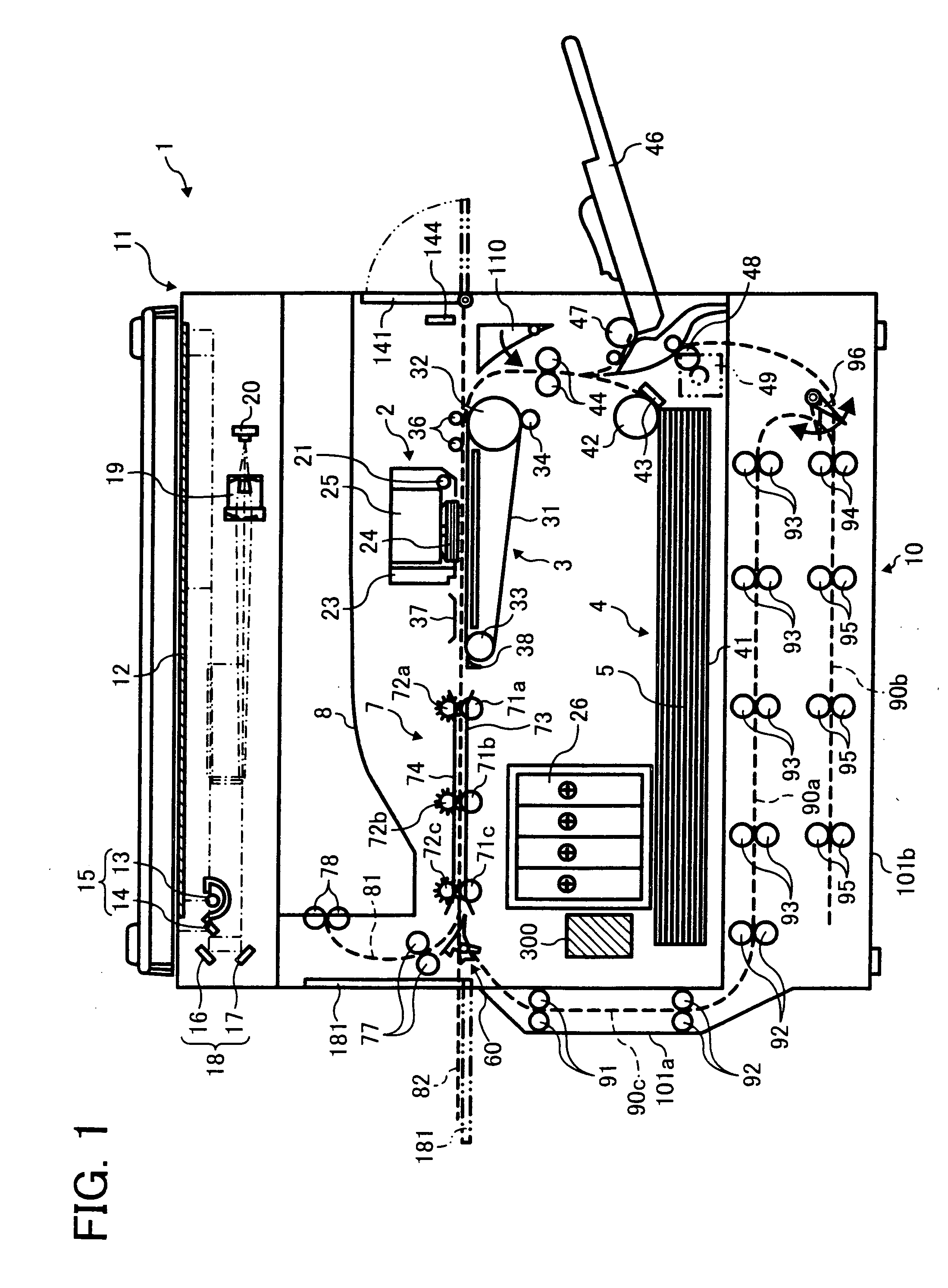

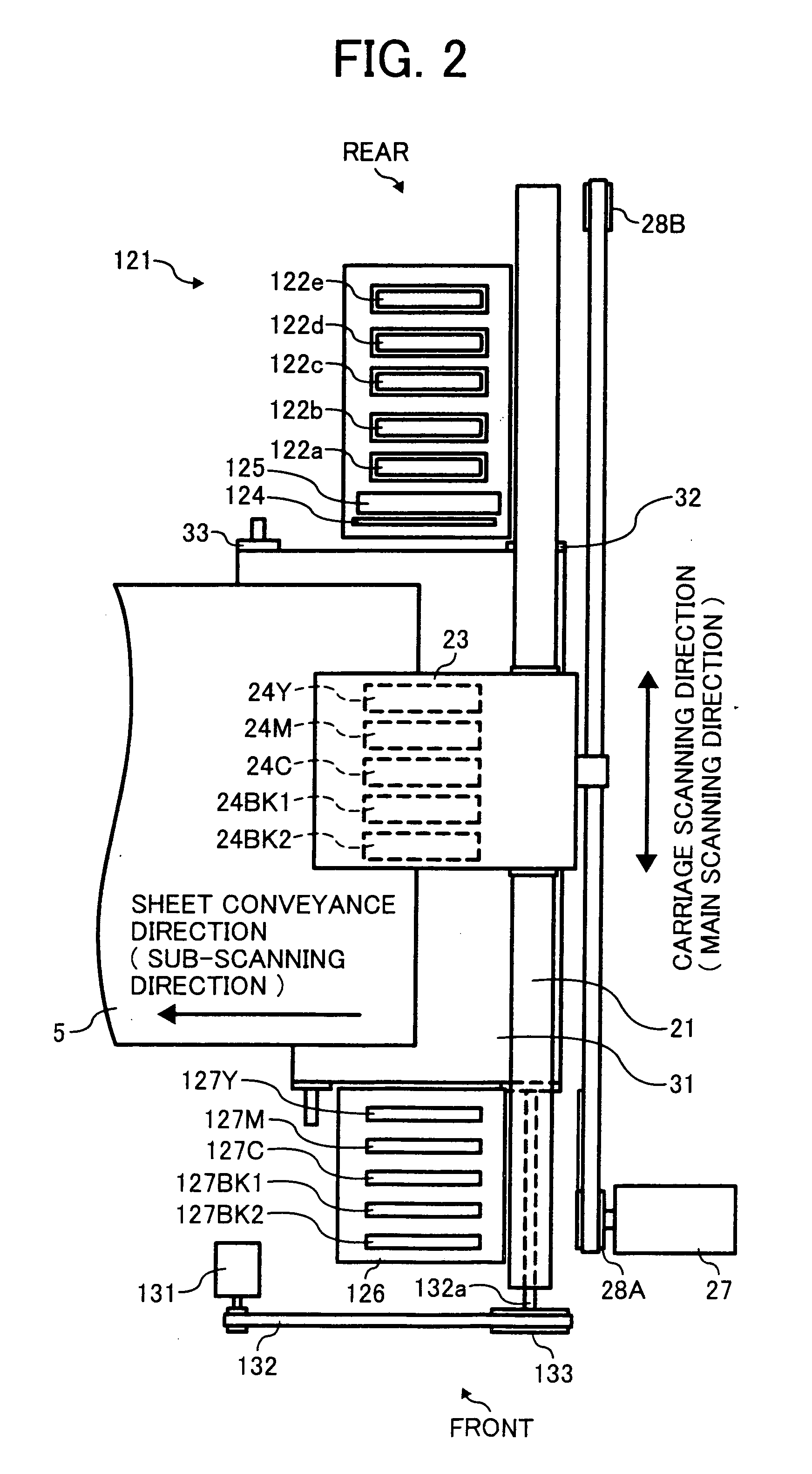

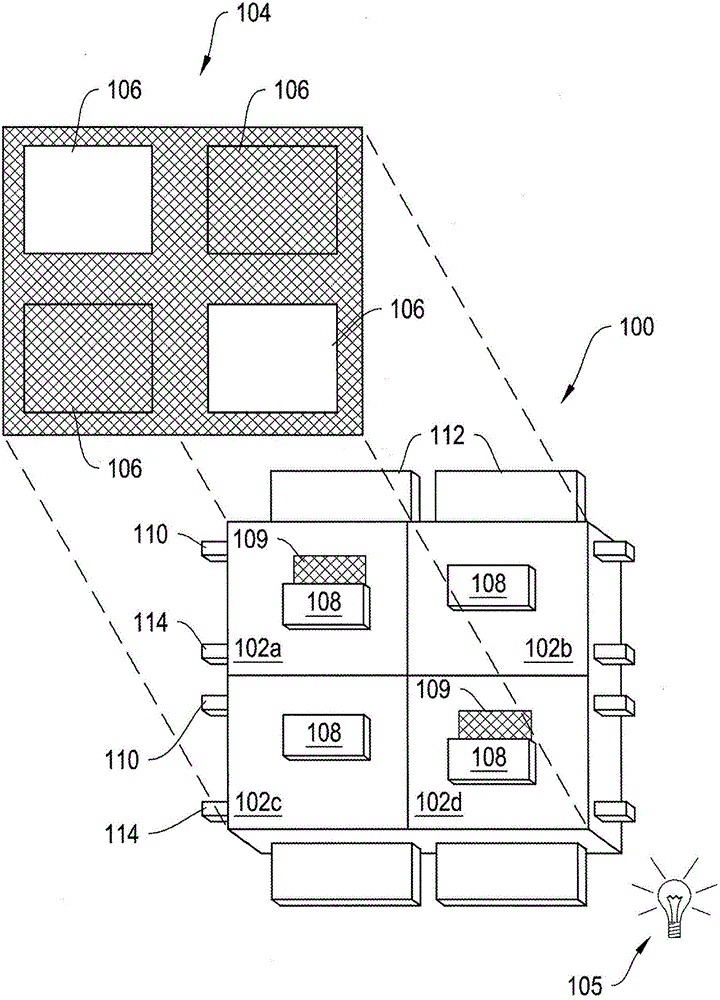

Image forming apparatus including an electrostatic conveyance apparatus capable of stably conveying a recording medium

InactiveUS20070120936A1Reduce electrostatic forceReduce bias voltageOther printing apparatusEngineeringVoltage variation

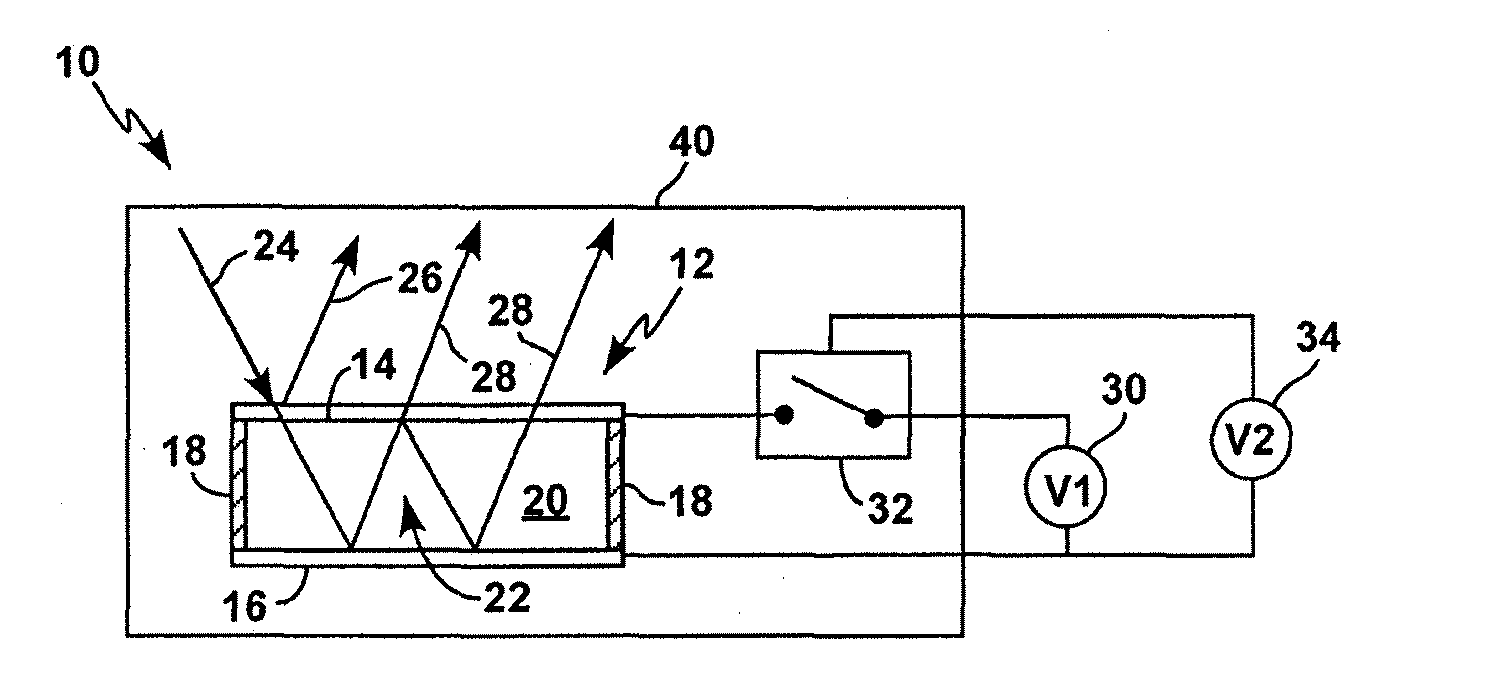

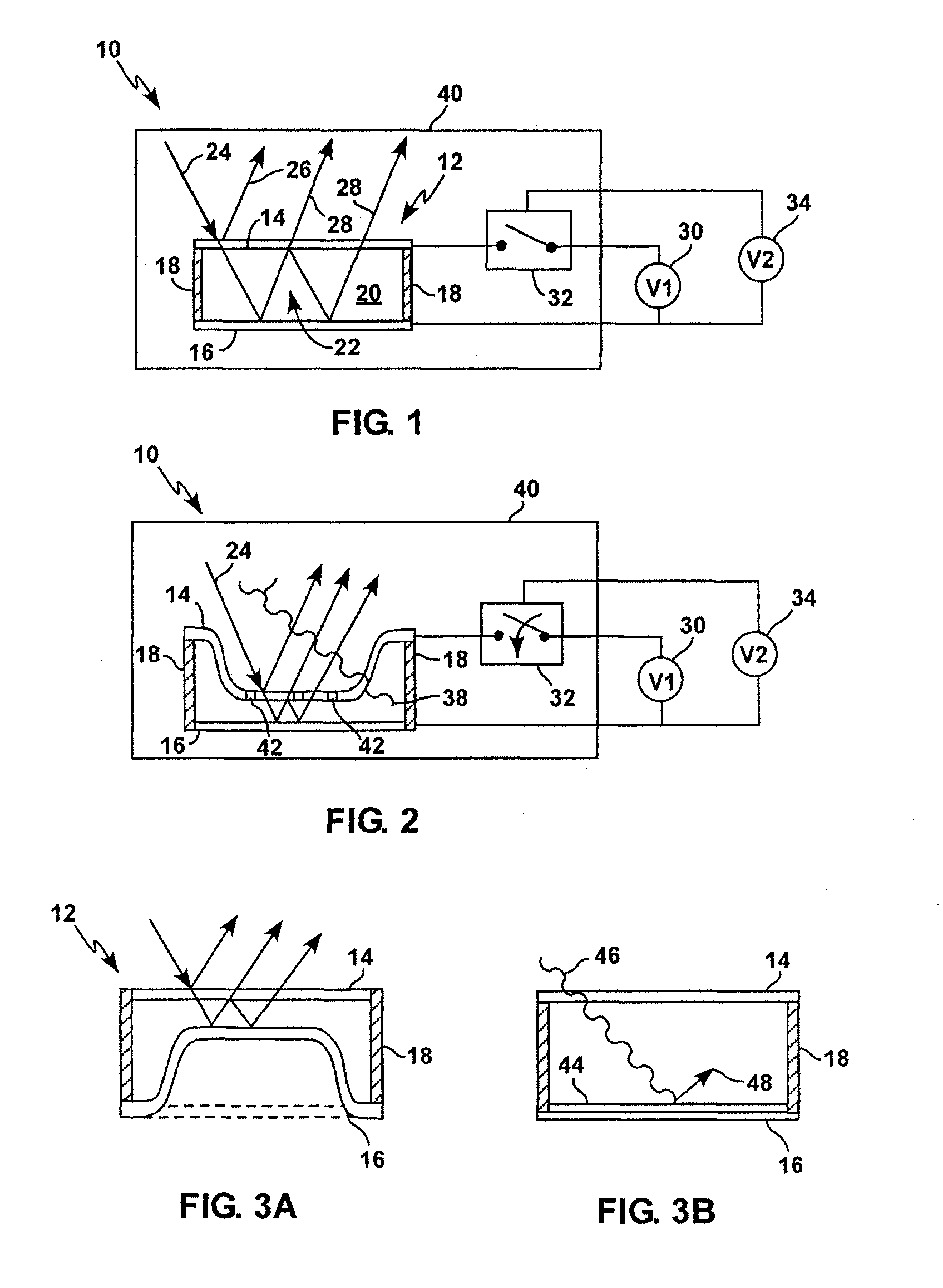

An image forming apparatus, which uses an electrostatic force to hold a recording medium during conveyance, includes a rotary belt, an image forming mechanism, a driving mechanism, a contact member in contact with the rotary belt, a charging mechanism and a controller. The controller may cause the contact member to be held in contact with the rotary belt, may cause the bias voltage to vary so as to reduce the electrostatic force during a time other than the image forming operation by the image forming mechanism, and may cause the driving mechanism to drive the rotary belt when the contact member is held in contact with the rotary belt.

Owner:RICOH KK

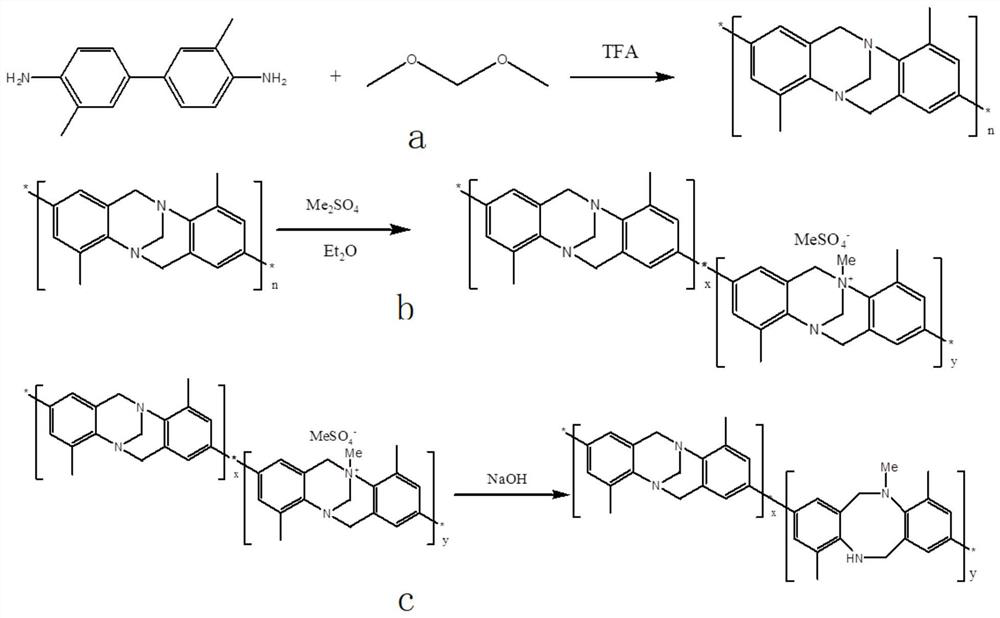

Ionic conductive polymer diaphragm for lithium-sulphur battery, and preparation method and application thereof

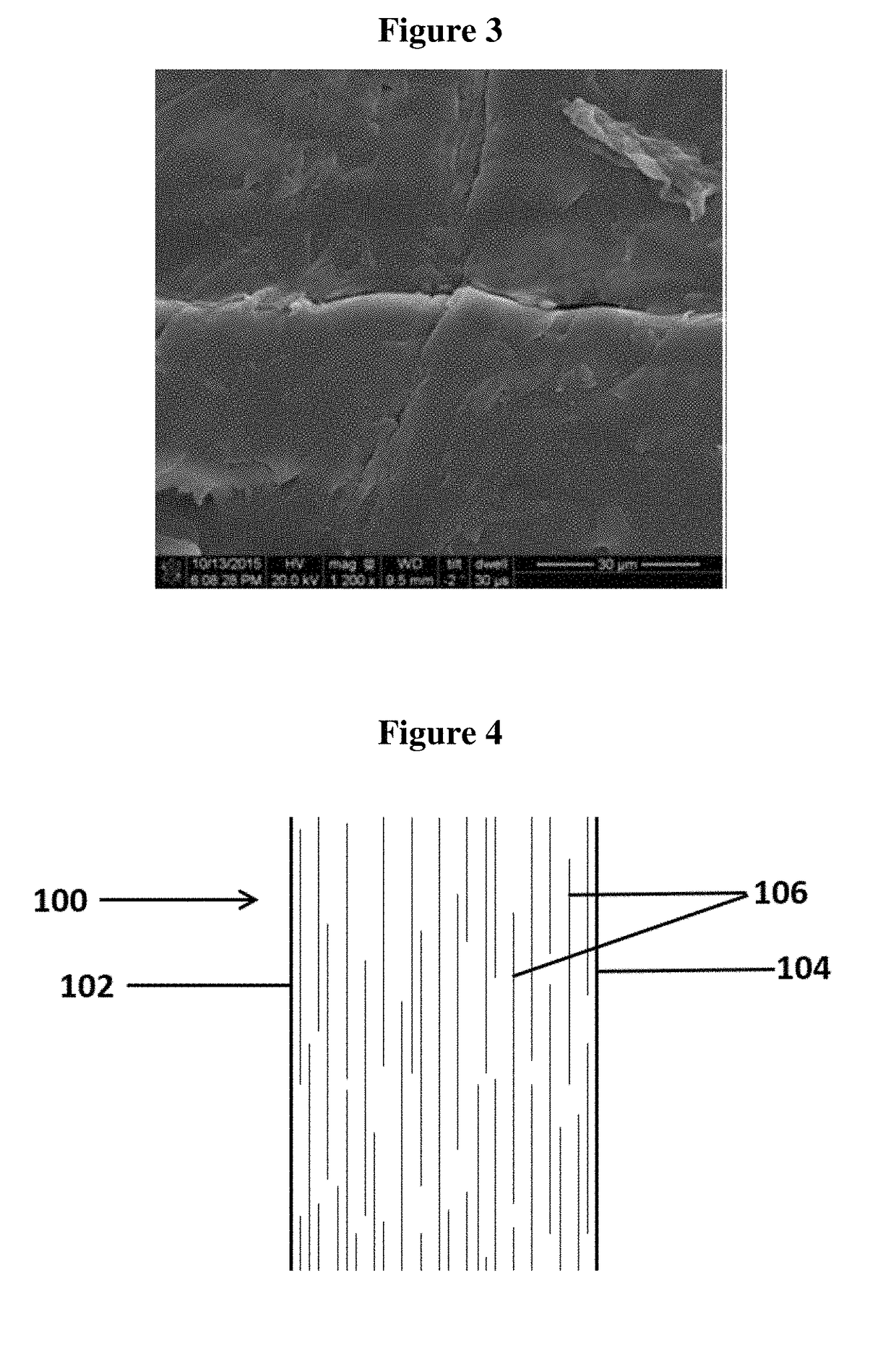

InactiveCN105845965AHigh conductanceReduce electrostatic forceCell seperators/membranes/diaphragms/spacersLi-accumulatorsCyclic processUltrasound attenuation

The invention discloses an ionic conductive polymer diaphragm for a lithium-sulphur battery, and a preparation method and application thereof. The diaphragm is mainly composed of a battery diaphragm and an ionic conductive polymer layer attached to the surface of the battery diaphragm. The diaphragm disclosed by the invention has lithium ion permselectivity and has good blocking effect to multi-sulphur anions; the lithium ion mobility of the polymer diaphragm is close to 1; the shuttling effect of the lithium-sulphur battery in a cyclic process can be effectively reduced; attenuation of the lithium-sulphur battery is inhibited; simultaneously, the effect of reducing side reaction due to shuttling of multi-sulphur anions can be realized; impedance is prevented from being further increased; and an effective method is provided for application of the lithium-sulphur battery.

Owner:NINGBO LIANHUA ENVIRONMENTAL SCI & TECH

Powder for ceramic tile dry press forming and preparation method thereof

The invention relates to powder for ceramic tile dry press forming and a preparation method thereof. The powder is particles with smooth surface and flowability, which are obtained by performing spray drying on a slurry prepared from a polyvinyl-alcohol-containing ceramic raw material; and the water content of the powder is less than or equal to 1%. The preparation method of the powder for ceramic tile dry press forming comprises the following steps: A. slurry preparation: adding 0.01-0.02% of polyvinyl alcohol into a ceramic slurry, wherein the water content of the ceramic slurry is 35-38%, and the fineness of the ceramic slurry is: after 200g of the ceramic slurry passes through a 250-mesh screen, the screen residue is 3-10g; and b. performing spray pulverization to obtain the powder. The powder for ceramic tile dry press forming has the advantages of smooth particle surface, high binding property, low electrostatic force among particles, and favorable flowability. In addition, the invention also provides a preparation method of the dry powder for ceramic tile dry press forming; according to the method, a low water content of dry powder particles can still be obtained after the water amount is increased; and the continuous production of the dry powder particles can also be ensured.

Owner:FOSHAN DONGPENG CERAMIC +3

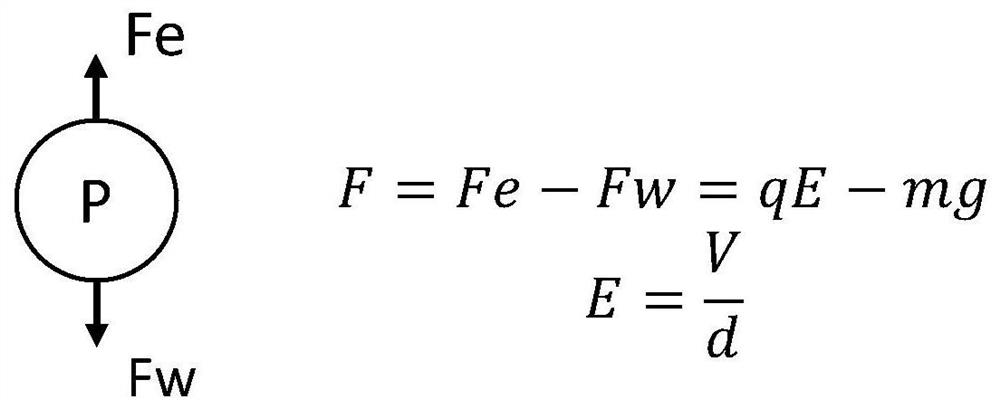

Air bearing designs to reduce external van der waals and electrostatic forces

InactiveUS7023664B2Reduce electrostatic forceReduce van der Waals forcesRecord information storageFluid-dynamic spacing of headsAir bearingAir bearing surface

A slider for a disk drive has an air bearing surface that opposes a rotatable disk of recordable media. The air bearing surface includes one or more interior cavities to reduce van der Waals and electrostatic forces that attract the slider to the disk.

Owner:WESTERN DIGITAL TECH INC

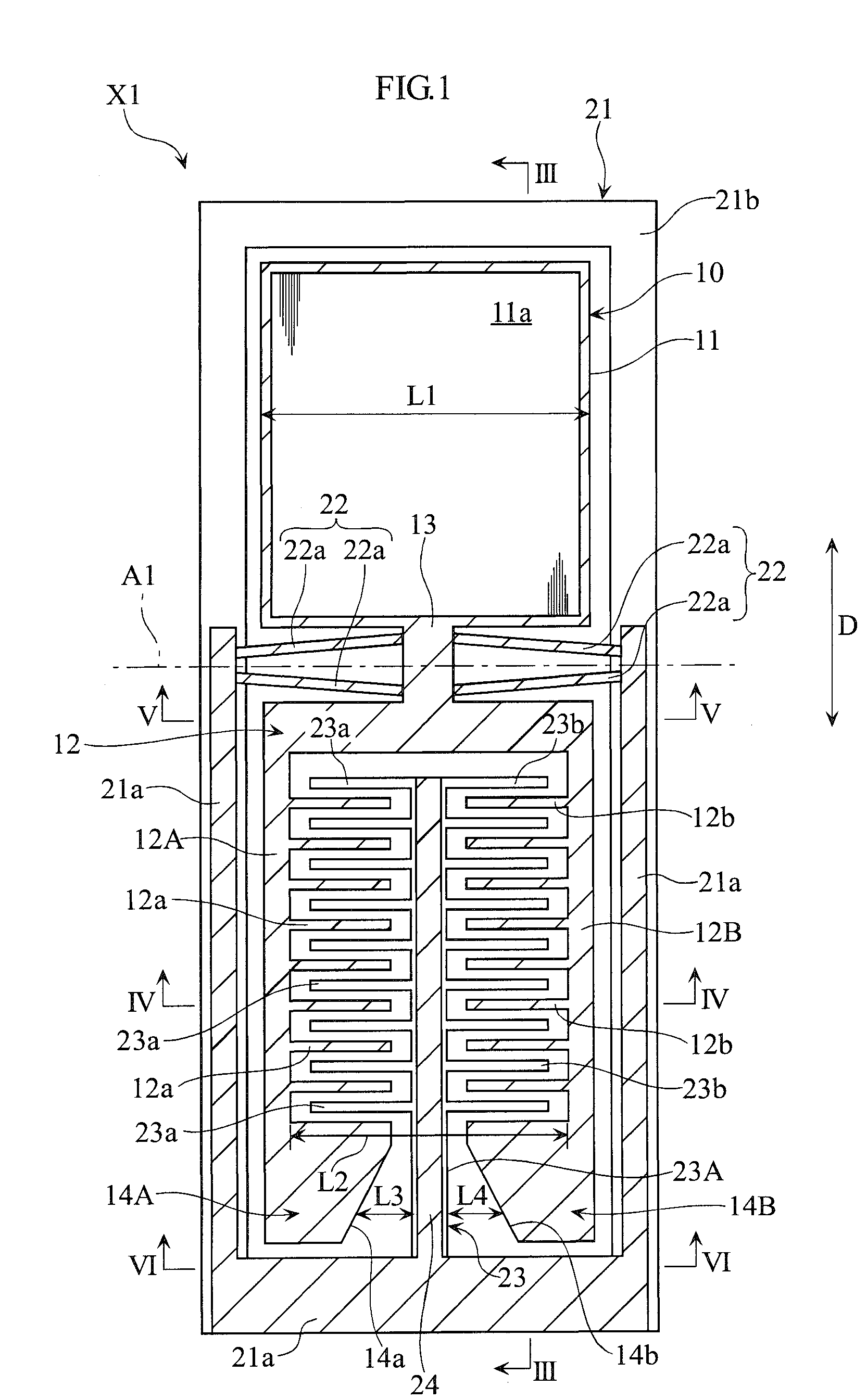

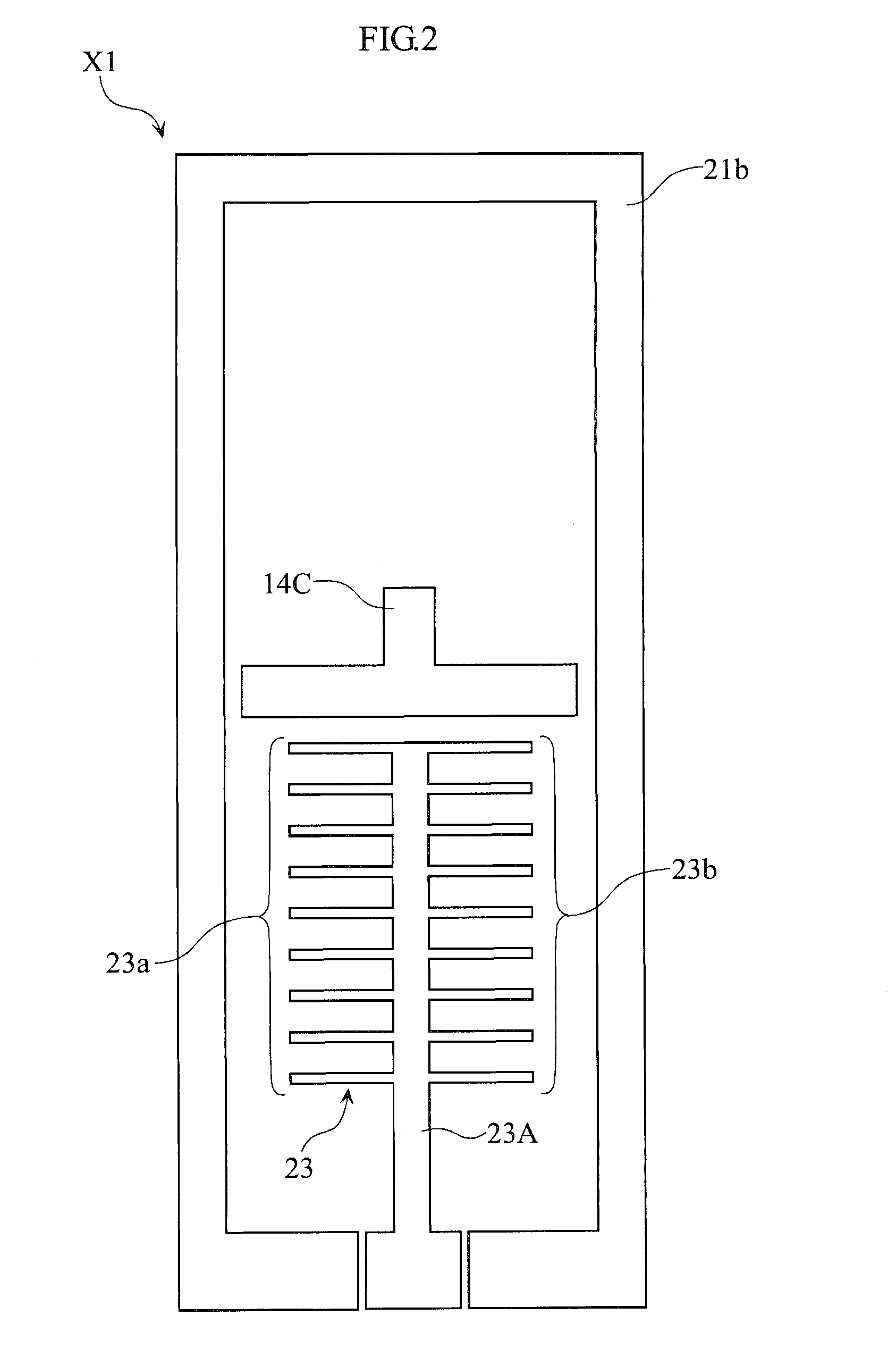

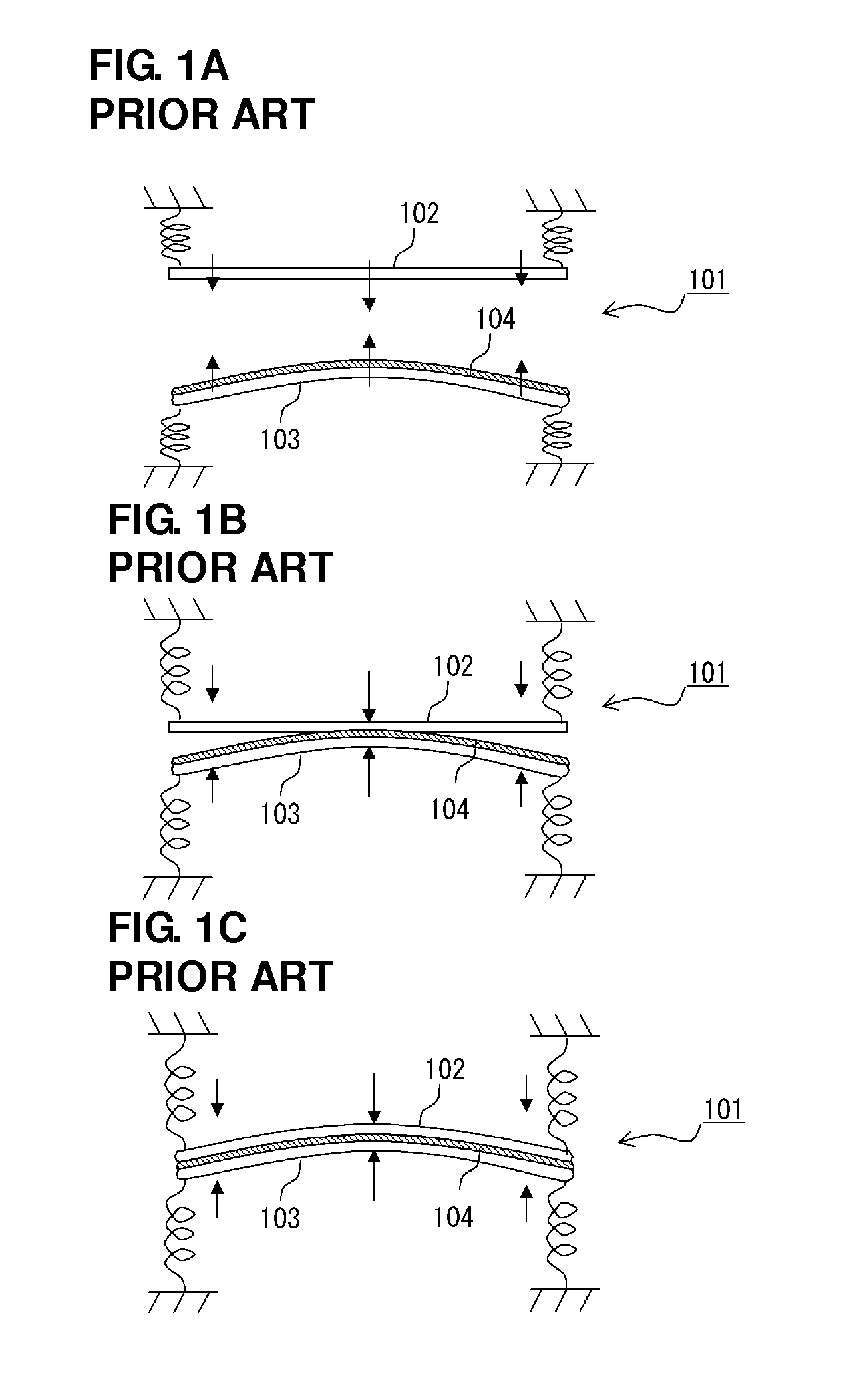

Micro-oscillation element and array of micro-oscillation elements

ActiveUS20090001847A1Easily causedReduce electrostatic forceElectrostatic generators/motorsPiezoelectric/electrostrictive devicesEngineeringMechanical engineering

A micro-oscillation element includes a base frame, an oscillating portion, and a link portion connecting the base frame and the oscillating portion to each other. The oscillating portion has a movable functional portion, a first driving electrode connected to the movable functional portion, and a weight portion joined to the first driving electrode. The link portion defines an axis of the oscillating motion of the oscillating portion. The second driving electrode, fixed to the base frame, generates driving force for the oscillating motion in cooperation with the first driving electrode.

Owner:FUJITSU LTD

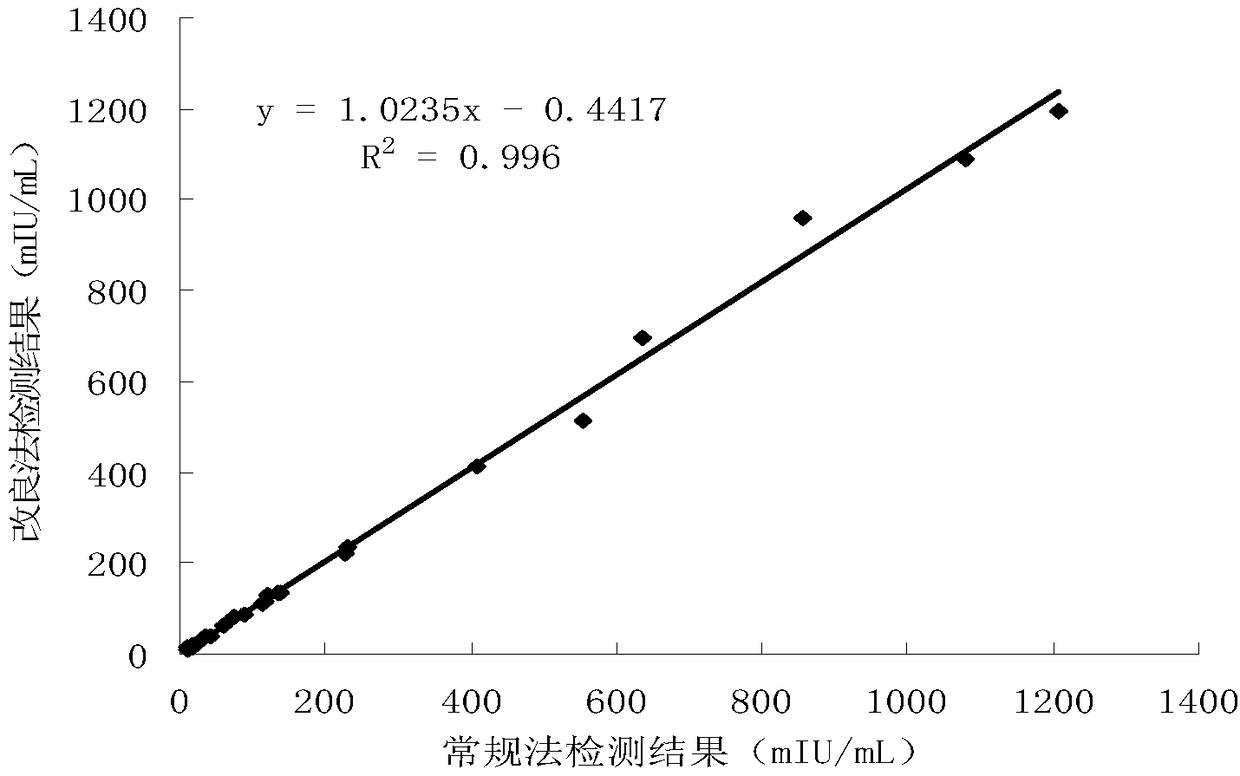

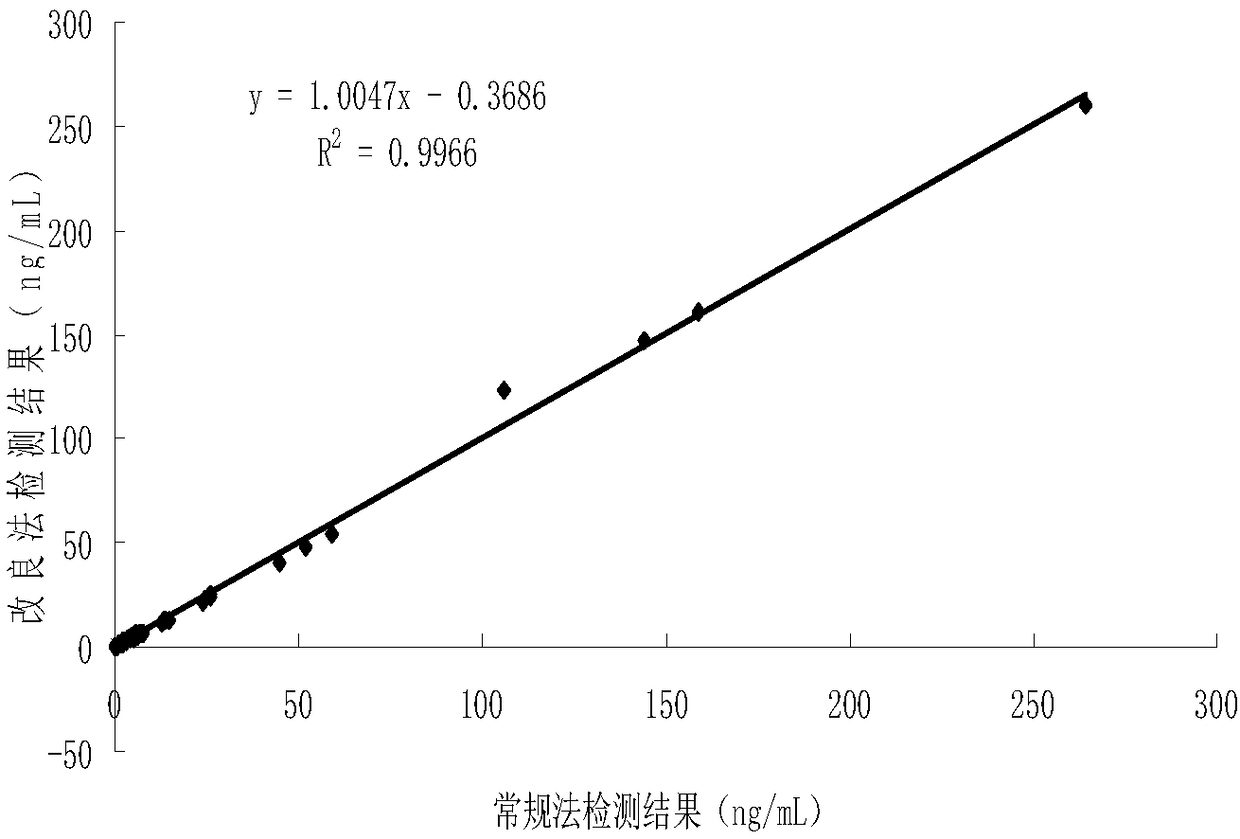

Improved experimental buffer solution and application thereof

ActiveCN108490166AReduce non-specific reactionsSuitable ionic strengthBiological testingAntigenLow affinity

The invention discloses an improved experimental buffer solution. The improved experimental buffer solution comprises a basic experimental buffer solution, sodium chloride and a dissociation agent, wherein the dissociation agent is at least one selected from the group consisting of 8-anilinonaphthalene-1-sulfonate, thimerosal, sodium salicylate and sodium trichloroacetate. The invention also discloses the application of the improved experimental buffer solution. The improved experimental buffer solution provided by the invention can effectively reduce electrostatic force, promote the dissolution and dissociation of non-specific immunoreactive or non-specifically adsorbed low-affinity protein ligands, and reduce the non-specific binding of antigens and antibodies; and the improved experimental buffer solution can promote the dissociation of non-specific immunoreactive or non-specifically adsorbed protein ligands under the action of the dissociation agent, so non-specific reactions of immunoassay are reduced, and detection resolution, accuracy and precision are improved.

Owner:GUANGZHOU FENGHUA BIOENG

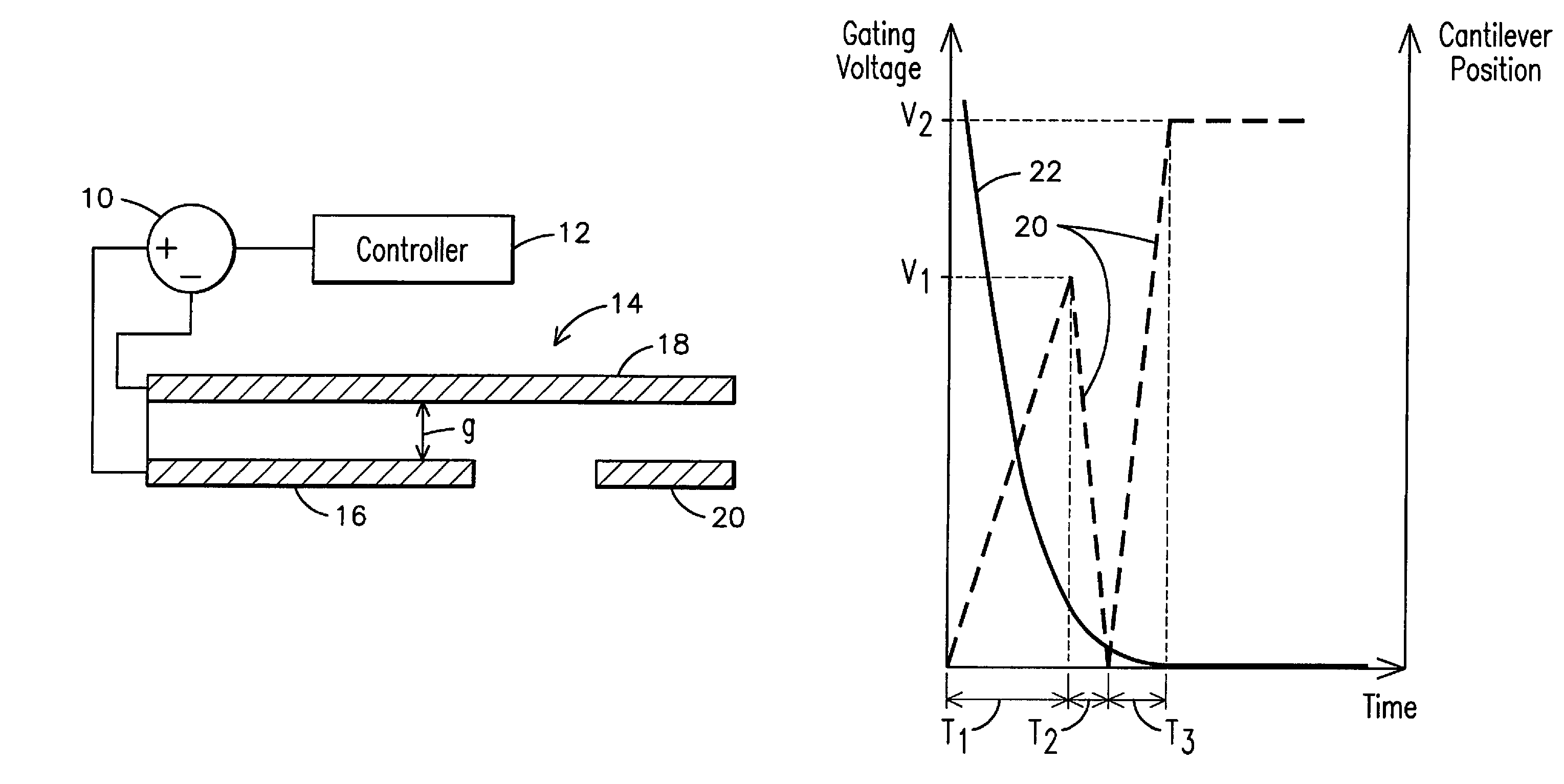

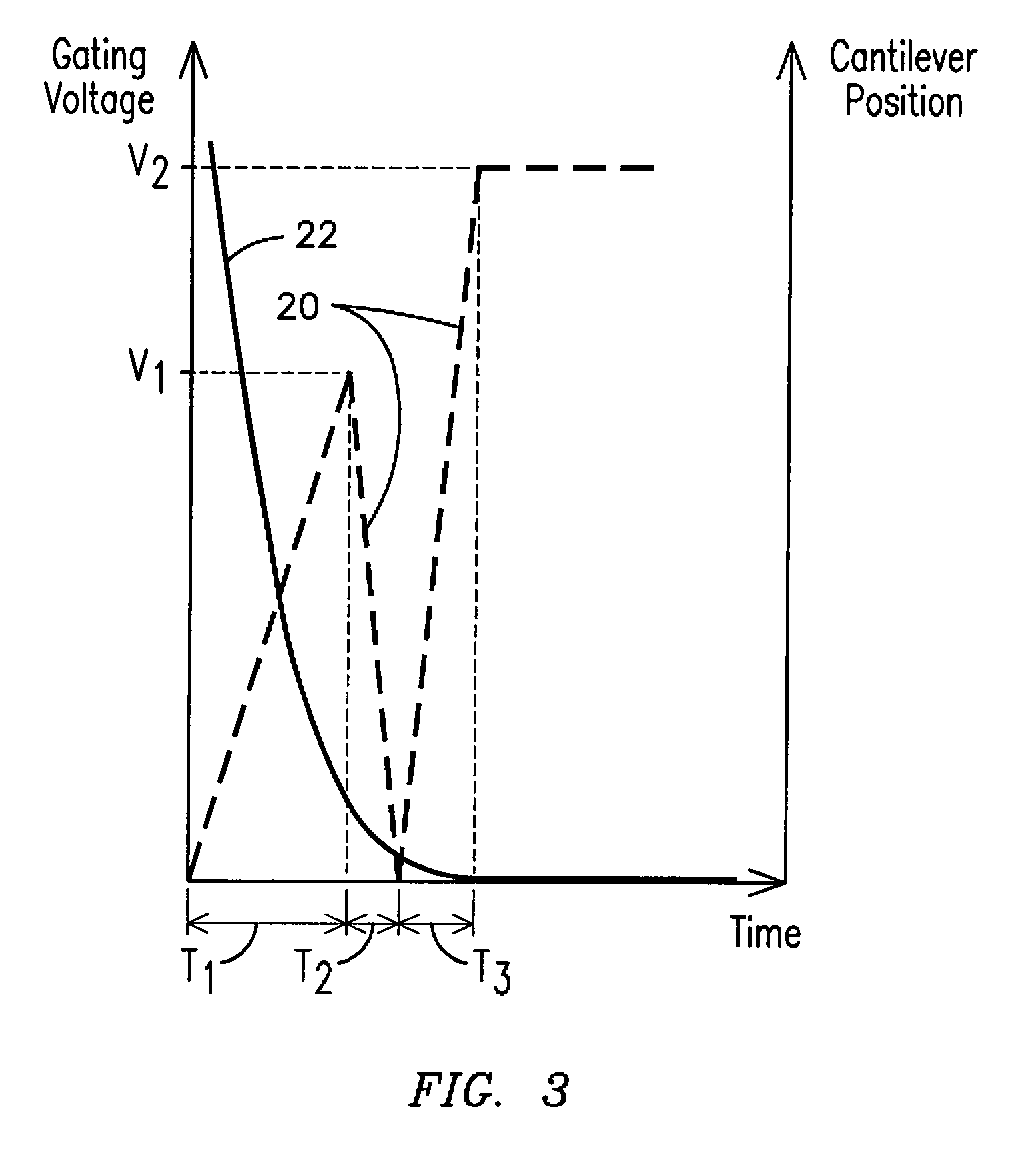

Gating voltage control system and method for electrostatically actuating a micro-electromechanical device

ActiveUS7473859B2Reduce forceSufficient accelerationContact mechanismsElectrostatic/electro-adhesion relaysElectricityControl system

Owner:GENERAL ELECTRIC CO

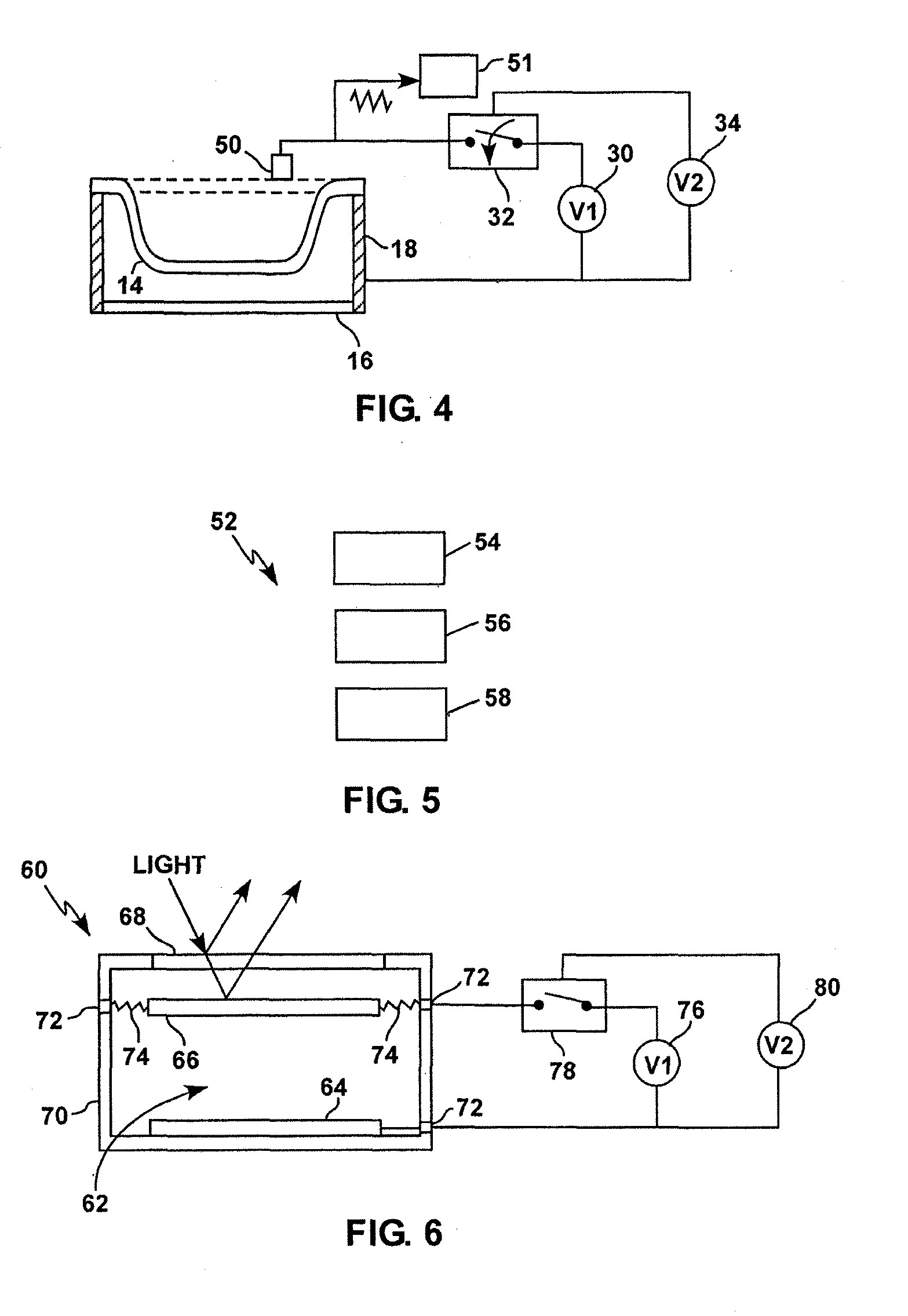

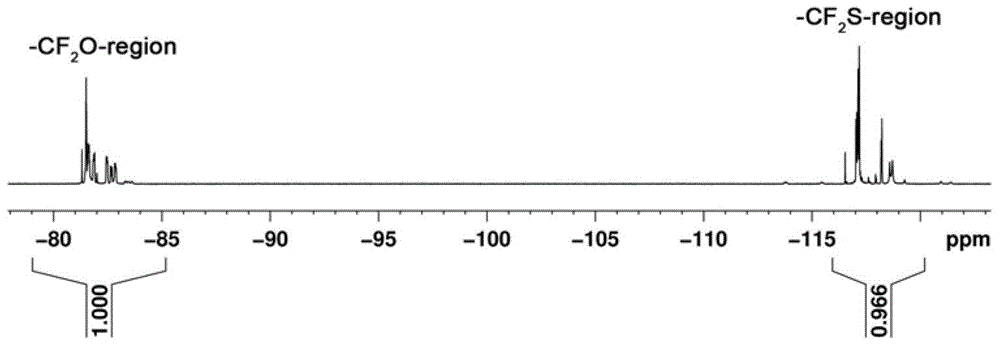

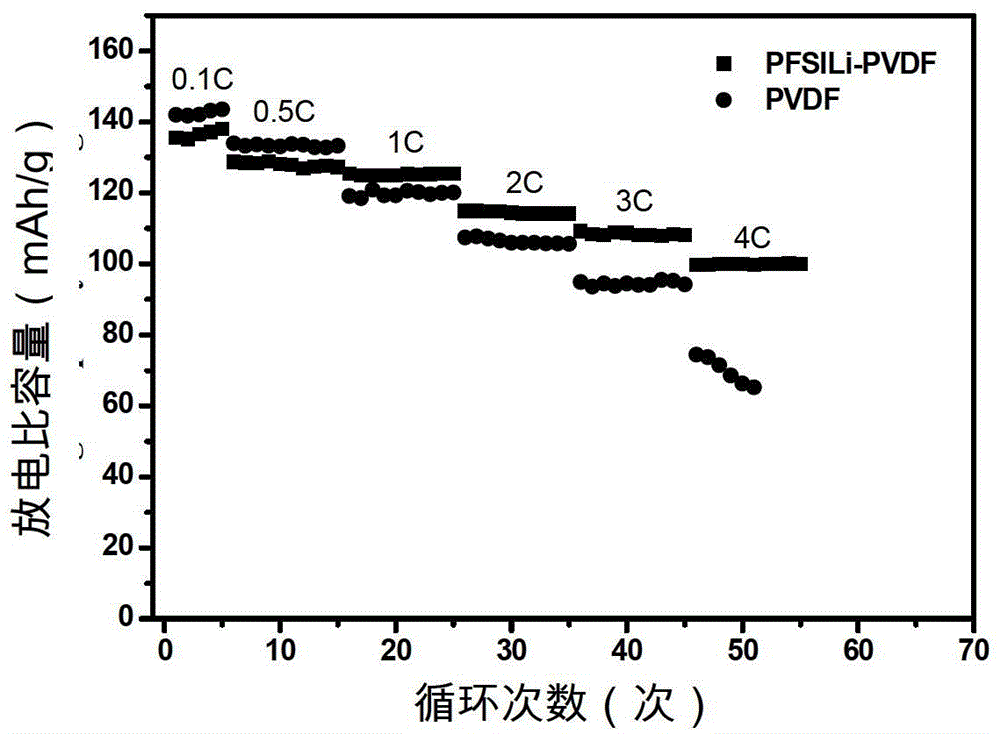

Conductive adhesive for lithium ion battery positive pole, lithium ion battery positive pole and preparation method of conductive adhesive

InactiveCN104282909AImprove adhesionImprove ionic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesBattery chargeAdhesive

The invention provides a conductive adhesive for a lithium ion battery positive pole. The adhesive comprises a fluorine-containing sulfimide lithium ion polymer. An ionic polymer main chain of the conductive adhesive comprises a superacid structure containing -SO2N-Li+SO2-, and the lithium ion can be effectively dissociated, so that the lithium ion conductivity is improved, and the battery capacity and battery charging and discharging cycle ratio under large-current charging and discharging are improved. Meanwhile, the electrochemical performance of the lithium ion battery taking the adhesive as a positive pole adhesive is stable, and the lithium ion battery is difficultly degraded along with the charging and discharging cycle, so that the service life of the battery is effectively prolonged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

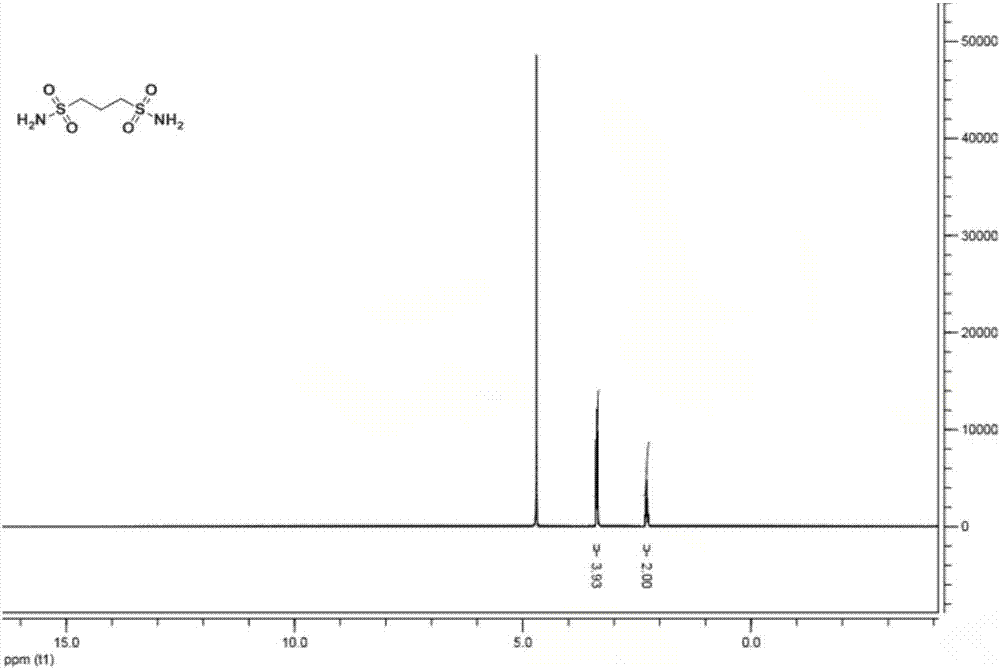

Preparation method of high-performance lithium salt

InactiveCN107987035AHigh yieldHigh purityOrganic chemistrySecondary cellsLithium hydroxideSulfonyl fluoride

The invention provides a preparation method of high-performance lithium salt, and belongs to the technical field of lithium salt for a battery. The preparation method comprises the following steps ofA, using vinyl sulfonyl fluoride or 1,3-propane bi-sulfonyl fluoride as the raw material, leading ammonia gas to bubble, adding diethyl ether, and acting at the temperature of 5 to 10 DEG C, so as toobtain sulfonyl amide or 1,3-propane bisulfonyl amide; B, adding the product obtained in step A into lithium hydroxide, and reacting at the temperature of 50 to 60 DEG C, so as to obtain the high-performance lithium salt, wherein the high-performance lithium salt contains the high-performance lithium salt and the high-performance lithium salt with substituted perfluoroalkyl. The preparation methodhas the advantages that the preparation method is simple; a wholly novel preparation method for the lithium salt of the battery is provided; the yield rate of the product is high, the purity is high,and the property is good after the high-performance lithium salt is applied to the battery.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

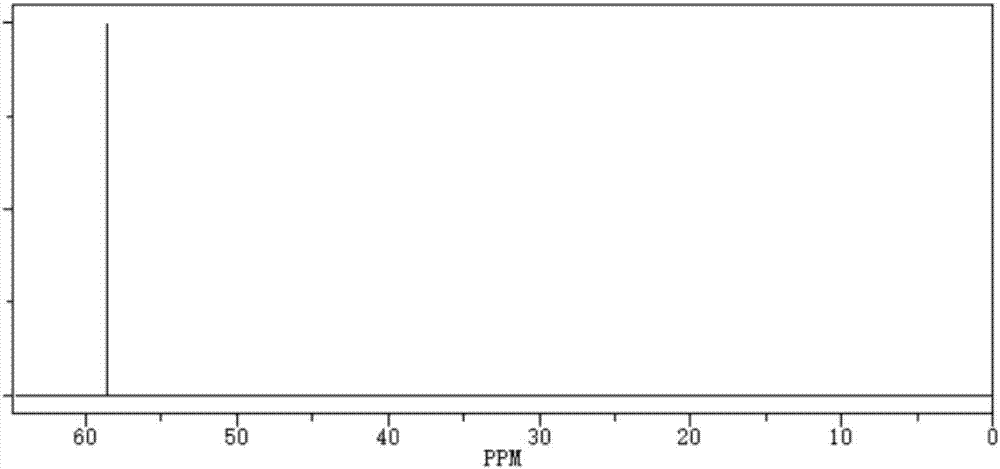

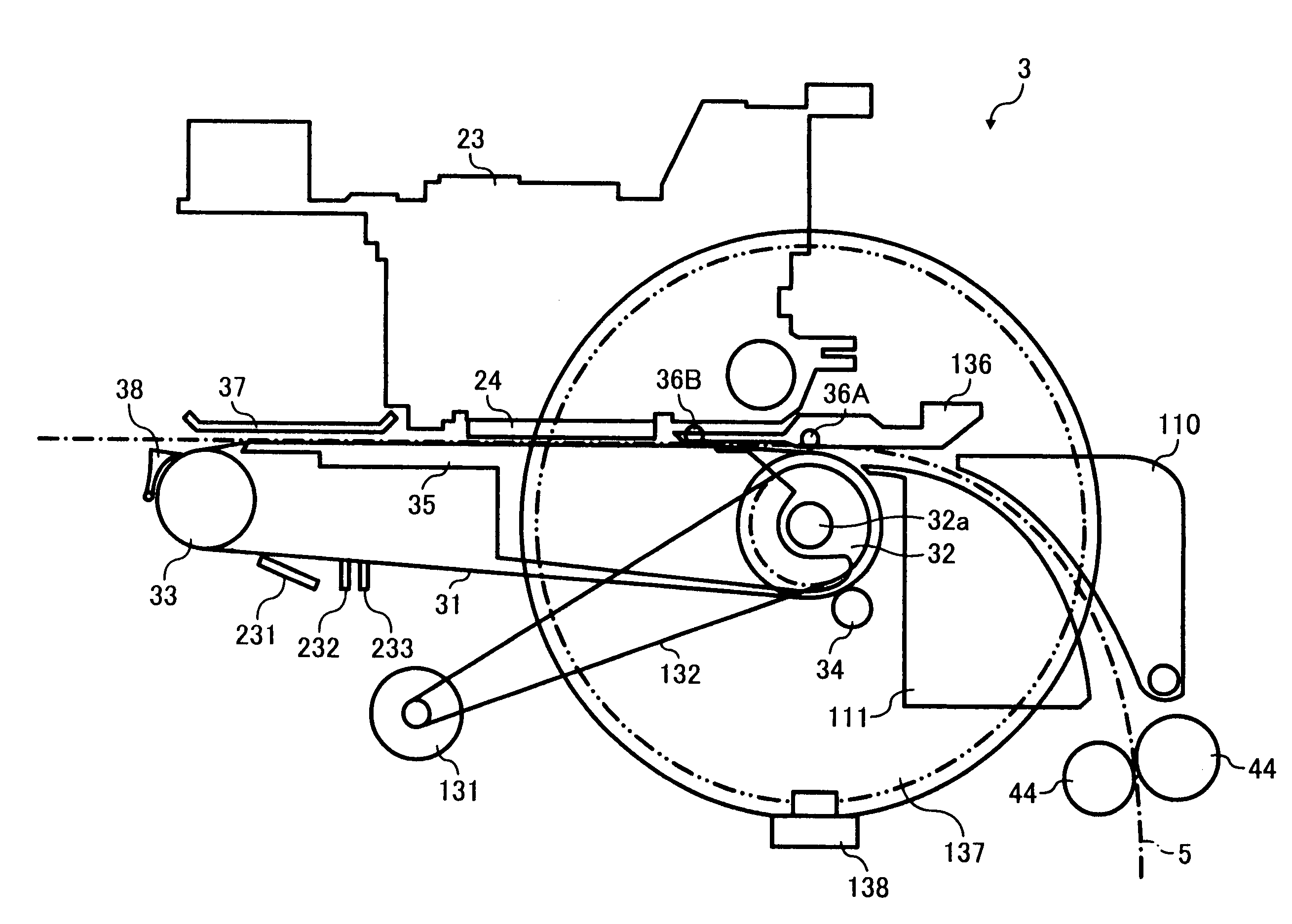

Image forming apparatus including an electrostatic conveyance apparatus capable of stably conveying a recording medium

InactiveUS7758180B2Reduce electrostatic forceReduce bias voltageOther printing apparatusVoltage variationMechanical engineering

An image forming apparatus, which uses an electrostatic force to hold a recording medium during conveyance, includes a rotary belt, an image forming mechanism, a driving mechanism, a contact member in contact with the rotary belt, a charging mechanism and a controller. The controller may cause the contact member to be held in contact with the rotary belt, may cause the bias voltage to vary so as to reduce the electrostatic force during a time other than the image forming operation by the image forming mechanism, and may cause the driving mechanism to drive the rotary belt when the contact member is held in contact with the rotary belt.

Owner:RICOH KK

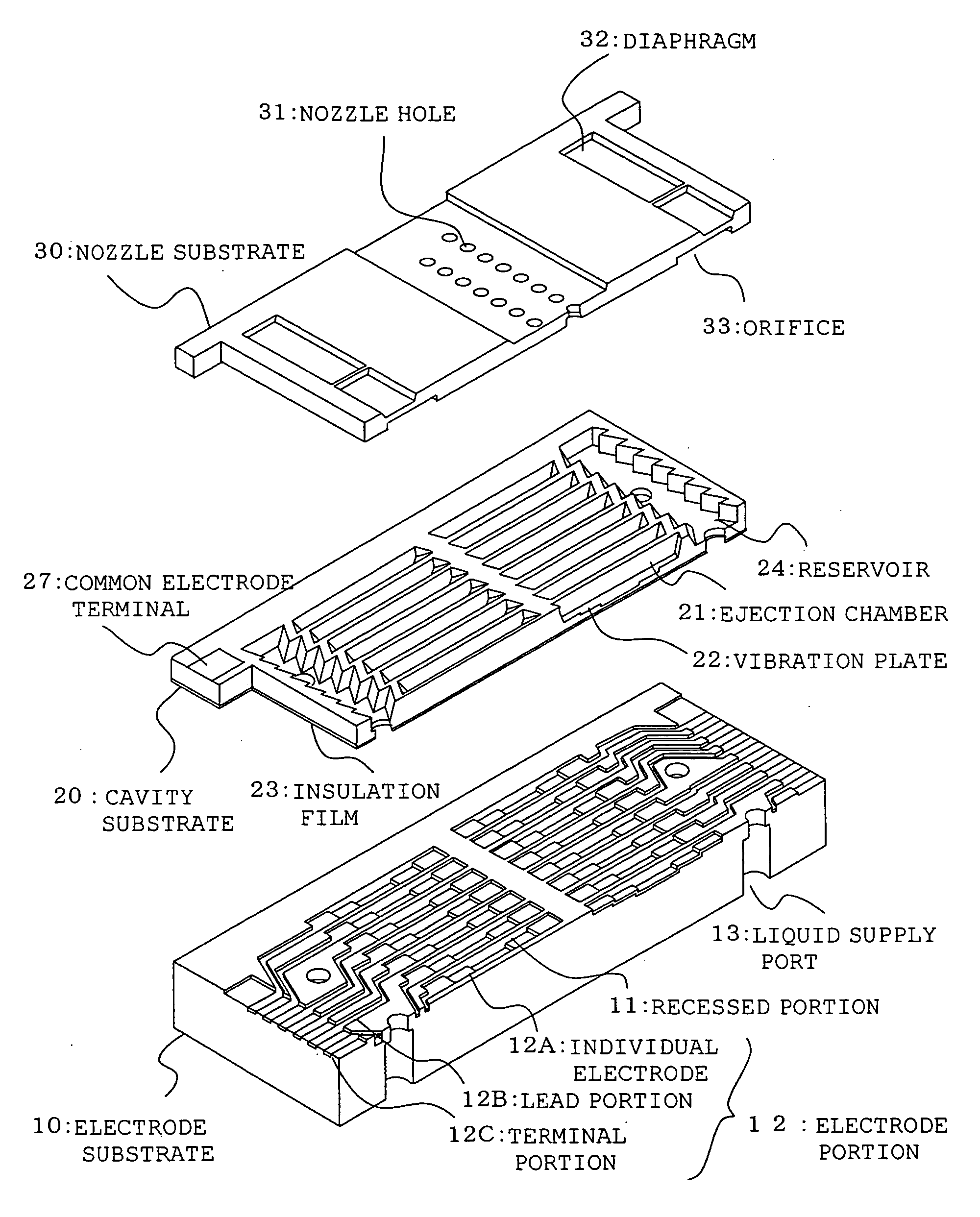

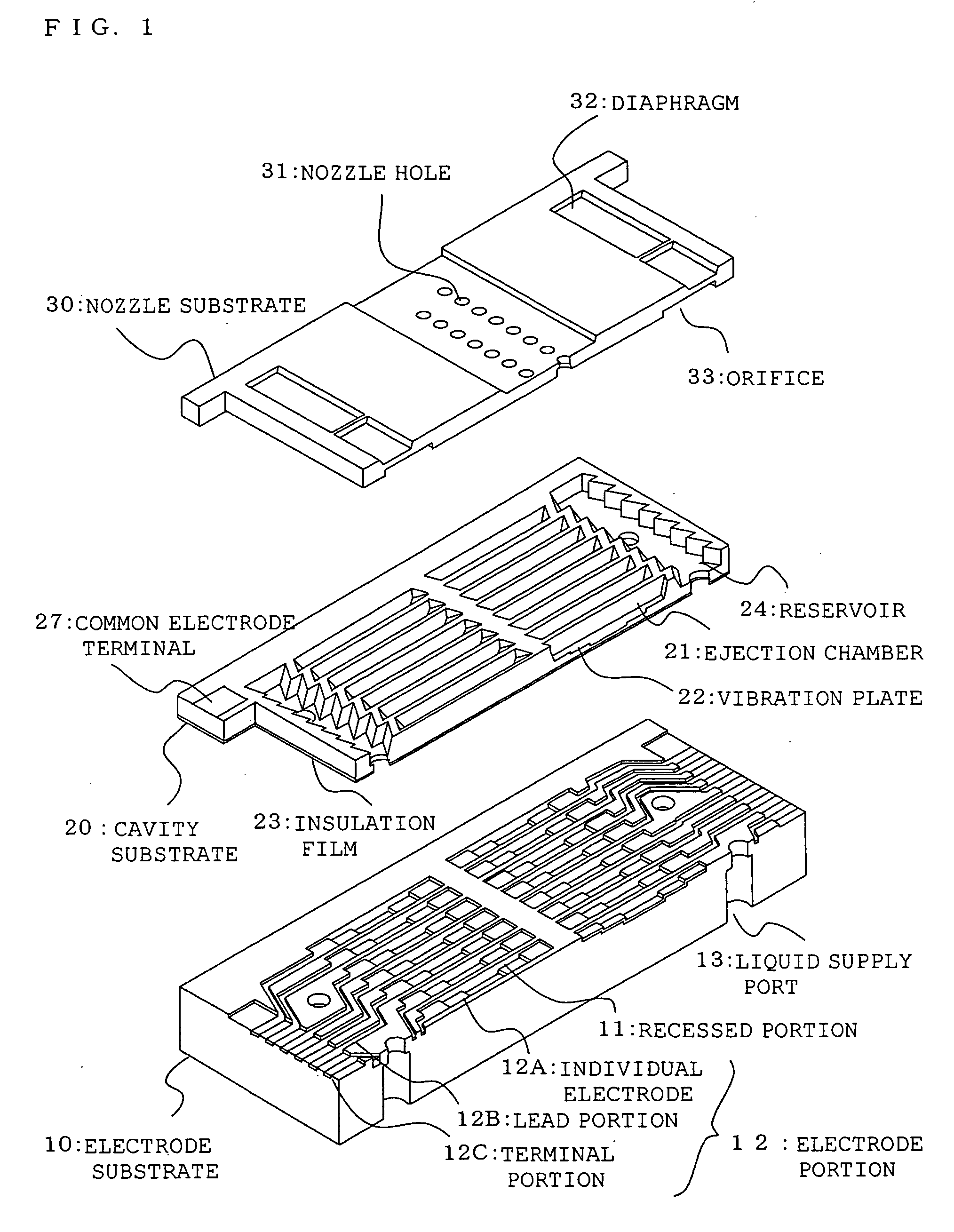

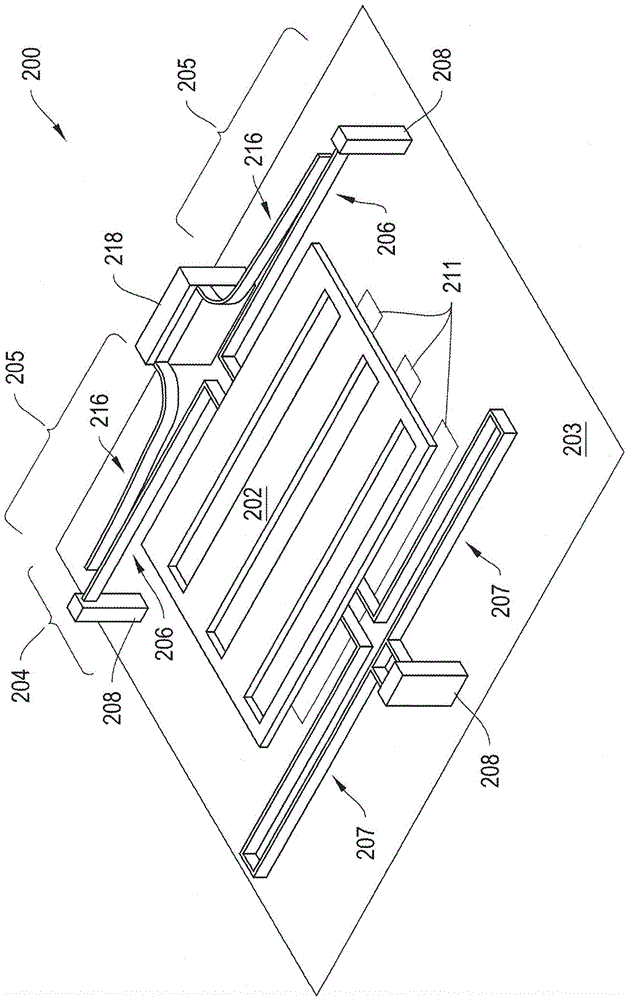

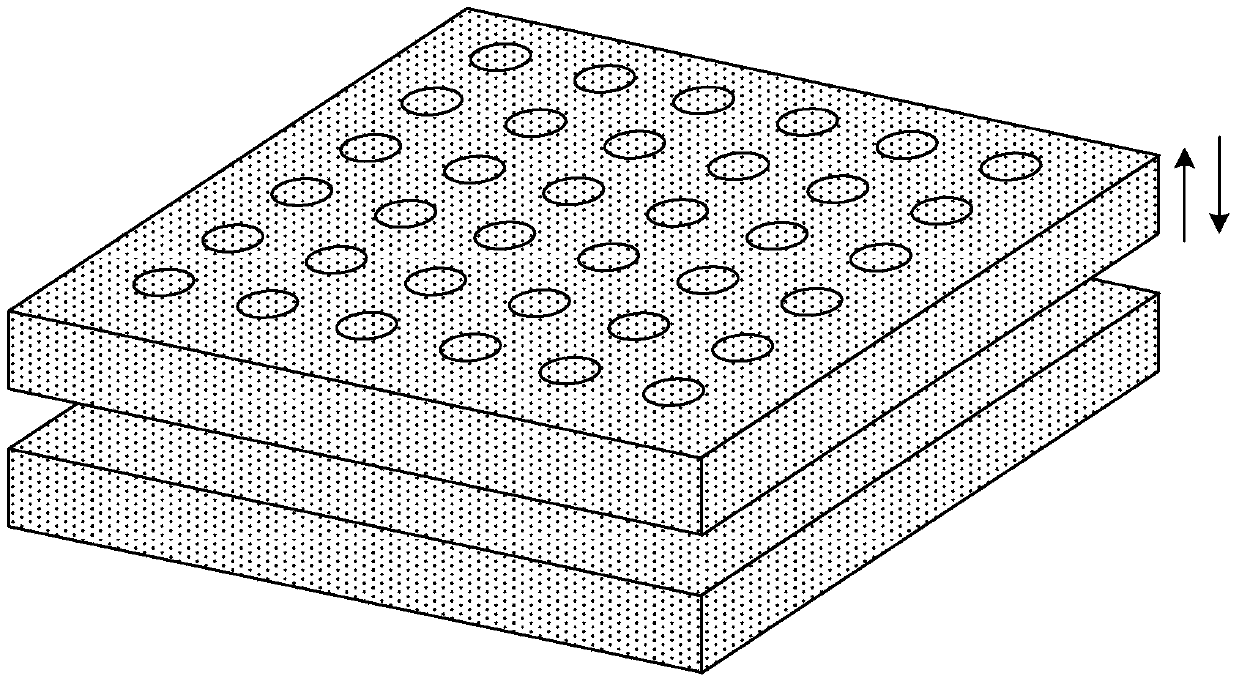

Electrostatic actuator, liquid droplet ejection head, liquid droplet ejection device and electrostatic driving device as well as methods of manufacturing them

InactiveUS20070176997A1Guaranteed uptimeReduce the driving voltageMechanical recordingRecord information storageElectrostatic actuatorEngineering

An electrostatic actuator, a liquid droplet ejection head, and a liquid droplet ejection device which have a good response and are driven by a small drive voltage includes a vibration plate as a sheet-shaped movable electrode and an individual electrode acting as a rectangular fixed electrode confronting the vibration plate and having stepped portions or an inclined portion in a long side direction with respect to the vibration plate, wherein the thickness of the vibration plate is reduced according to an order by which the vibration plate is made to abut against the individual electrode by electrostatic attracting force generated between the vibration plate and the individual electrode. Methods of manufacturing the above devices are also disclosed.

Owner:SEIKO EPSON CORP

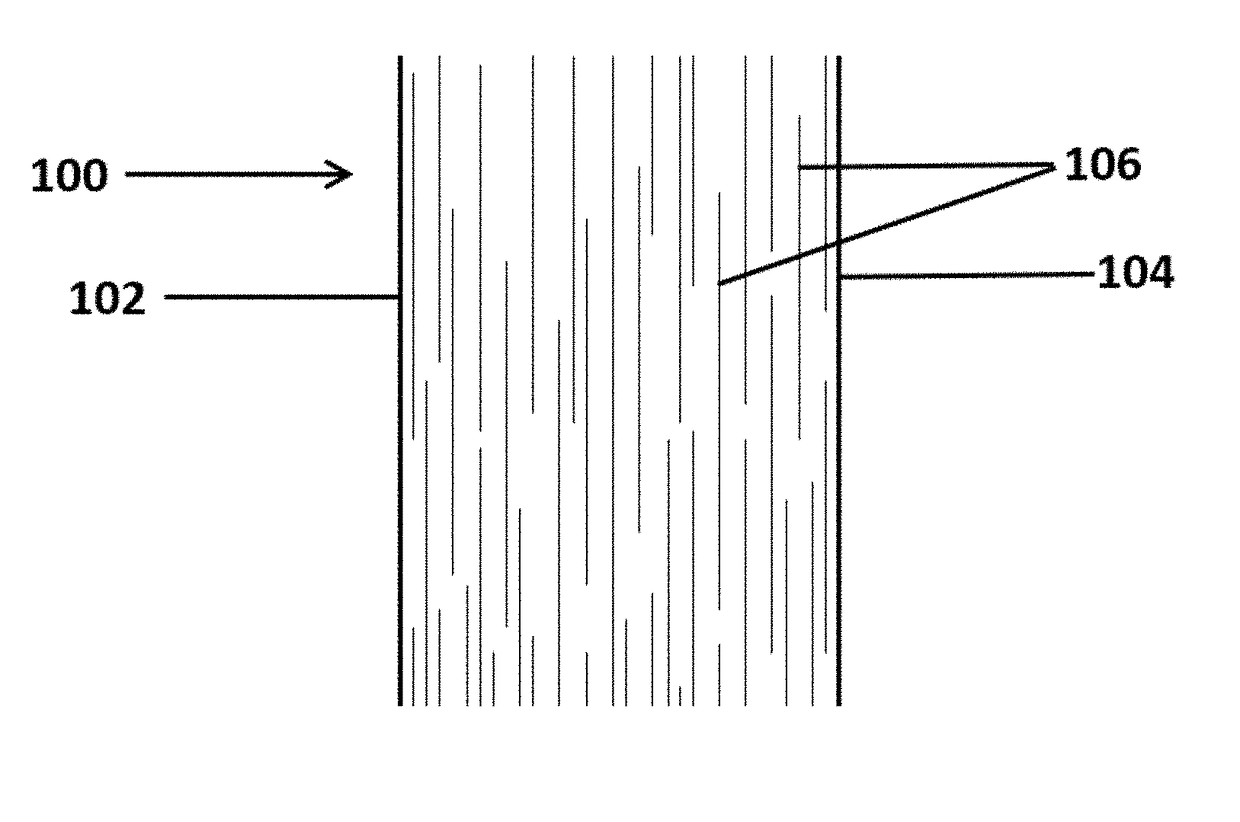

Barrier additives

ActiveUS20180002496A1Improve performanceIncrease spacingPhotovoltaic energy generationPolymer sciencePolymer composition

The present invention relates to processes for making compatibilized high aspect ratio barrier additives and polymer compositions that comprise compatibilized high aspect ratio barrier additives. The invention also relates to compositions produced by these processes, and articles formed from polymer compositions of this invention. The barrier additives provide passive barriers to gas molecules such as oxygen and carbon dioxide minimizing transit of such molecules through sidewalls of polymer articles containing the barrier additives.

Owner:COLORMATRIX HLDG

Powder removal method of 3DP printed thin-walled porous metal blank

ActiveCN108971493ATo powder to achieveReduce intensityCleaning using liquidsAnhydrous ethanolMetallic materials

The invention relates to the technical field of porous metal material and 3D printing, in particular to a powder removal method of a 3DP printed thin-walled porous metal blank. The method comprises the following steps of firstly, selecting metal powder required for molding, spraying a bonding agent to the metal powder and manufacturing a printing blank through the 3DP method; secondly, putting theprinting blank to be subjected to powder removal in a drying box to be heated for 1-2 h and then putting the printing blank into an ultrasonic cleaning machine containing an anhydrous ethanol solution to conduct ultrasonic powder removal; and thirdly, putting the printing blank subjected to powder removal into the drying box again to conduct heating treatment and then obtain the thin-walled porous metal blank with the structural integrity. Through the powder removal method, the powder of the porous printing blank with the low strength can be removed. The powder removal method has the characteristics that powder removal operation is easy, the cost is low, and the method is energy-saving and environment-friendly. The method can be adopted to conduct powder removal on 3DP printed thin-walledporous metal blanks in batch, can achieve the powder removal mechanization and provides a guarantee for mass production of 3DP parts.

Owner:NANTONG INST OF TECH +1

Glass substrate packing paper static electricity elimination and grabbing device and method

InactiveCN108214455ASmooth and smooth transmissionIncrease frictionProgramme-controlled manipulatorGripping headsManipulatorEngineering

The invention discloses a glass substrate packing paper static electricity elimination and grabbing device and method. The device comprises a mechanical arm and a mechanical hand mounted on the mechanical arm. The mechanical hand is controlled by the mechanical arm to rotate and move in the space. The mechanical hand is fixedly connected with a mechanical arm beam. One side of the mechanical arm beam is provided with an air pipe. A plurality of blowing nozzles are arranged on the air pipe. The two ends of the mechanical arm beam are each provided with two grabbing arms arranged symmetrically.The grabbing arms can move relative to the mechanical arm beam. A grabbing wheel is fixed between the two grabbing arms on the same side of the two ends of the mechanical arm beam in the length direction of the mechanical arm beam. The grabbing wheel is fixedly connected with the corresponding grabbing arms. An air inlet of the air pipe is connected to an electrostatic wind source. According to the glass substrate packing paper static electricity elimination and grabbing device, the air pipe is fixed to the mechanical arm beam arranged on the mechanical arm; the multiple blowing nozzles are arranged on the air pipe; when a robot takes glass, the blowing nozzles blow electrostatic wind to the space between the glass and packing paper, electrostatic force between the glass and the packing paper is reduced instantly, the electrostatic force below the packing paper still exists, and accordingly, a glass substrate is conveyed smoothly and stably.

Owner:彩虹(合肥)液晶玻璃有限公司

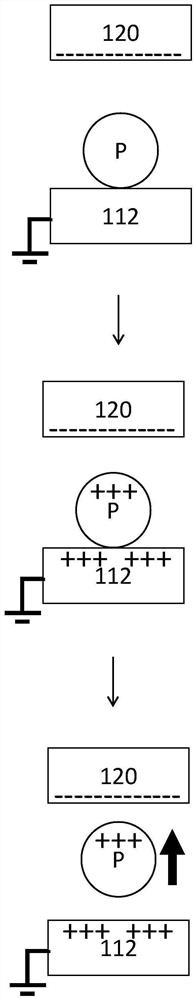

Radiation detector and method

ActiveUS20160041271A1Reduce electrostatic forceElectric discharge tubesMaterial analysis by optical meansCharge carrierVoltage source

Disclosed is a radiation detector, comprising a chamber or cavity that produces charge carriers when radiation is incident thereon. The chamber is defined in part by a deformable plate along one side of the chamber or cavity; and a rigid plate spaced and electrically insulated from the deformable plate. A charging voltage source is present for applying a voltage to the deformable plate; such that wherein the deformable plate is attracted toward the rigid plate by electrostatic forces when charged by the charging voltage source, and moves away from the rigid plate when charge carriers produced in the chamber or cavity by incident radiation reduce the electrostatic forces between the deformable and rigid plates.

Owner:MIRION TECH INC

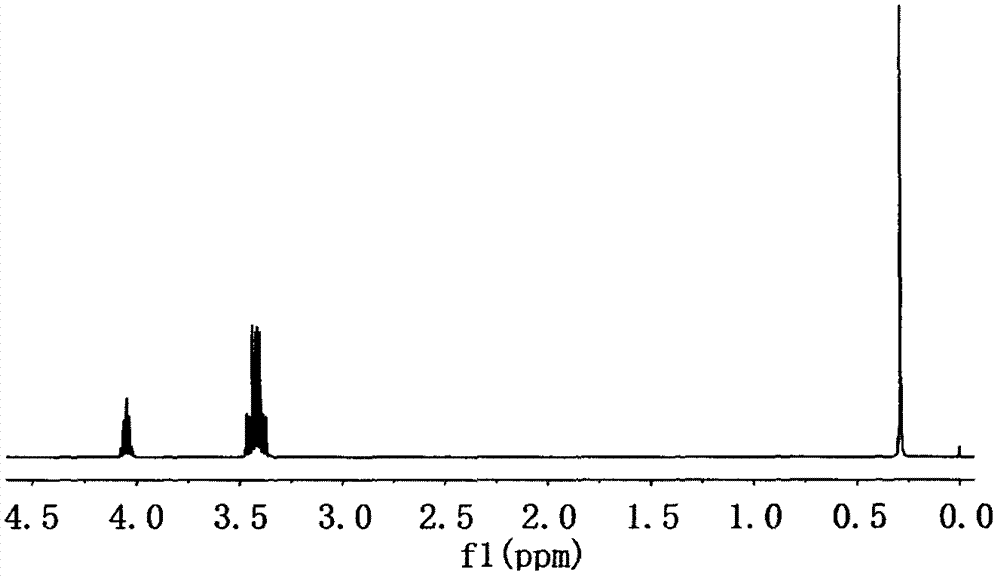

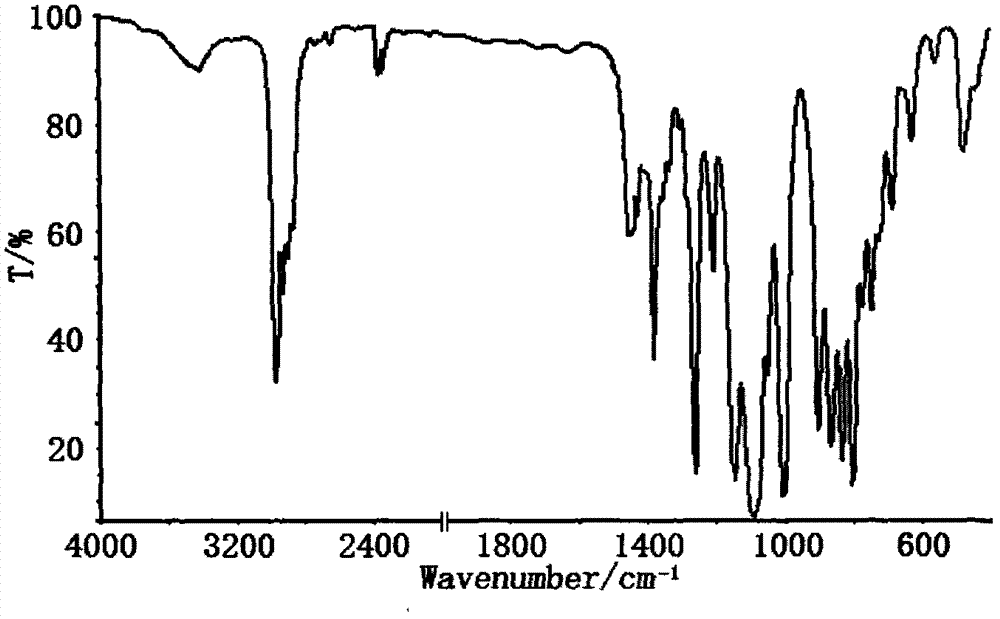

Conductive binder for positive electrode of lithium ion battery, positive electrode of lithium ion battery and preparation method

InactiveCN104282909BImprove adhesionImprove ionic conductivitySecondary cellsNon-aqueous electrolyte accumulator electrodesBattery chargeAdhesive

The invention provides a conductive adhesive for a lithium ion battery positive pole. The adhesive comprises a fluorine-containing sulfimide lithium ion polymer. An ionic polymer main chain of the conductive adhesive comprises a superacid structure containing -SO2N-Li+SO2-, and the lithium ion can be effectively dissociated, so that the lithium ion conductivity is improved, and the battery capacity and battery charging and discharging cycle ratio under large-current charging and discharging are improved. Meanwhile, the electrochemical performance of the lithium ion battery taking the adhesive as a positive pole adhesive is stable, and the lithium ion battery is difficultly degraded along with the charging and discharging cycle, so that the service life of the battery is effectively prolonged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Display device incorporating multiple dielectric

InactiveCN104871066AReduce accumulationReduce electrostatic forceSemiconductor/solid-state device manufacturingDigital computer detailsDielectricDisplay device

This disclosure provides systems, methods and apparatus for providing multiple dielectric coatings for a shutter assembly. The multiple dielectric coatings include an outer dielectric coating and one or more inner dielectric coatings. The outer dielectric coating has an electrical trap density that is lower than electrical trap densities of the one or more inner dielectric coatings. The lower electrical trap density reduces the amount of charge buildup over various surfaces of the shutter assembly. This reduction in charge buildup also reduces electrostatic forces that may cause incorrect operation of the shutter assembly.

Owner:SNAPTRACK

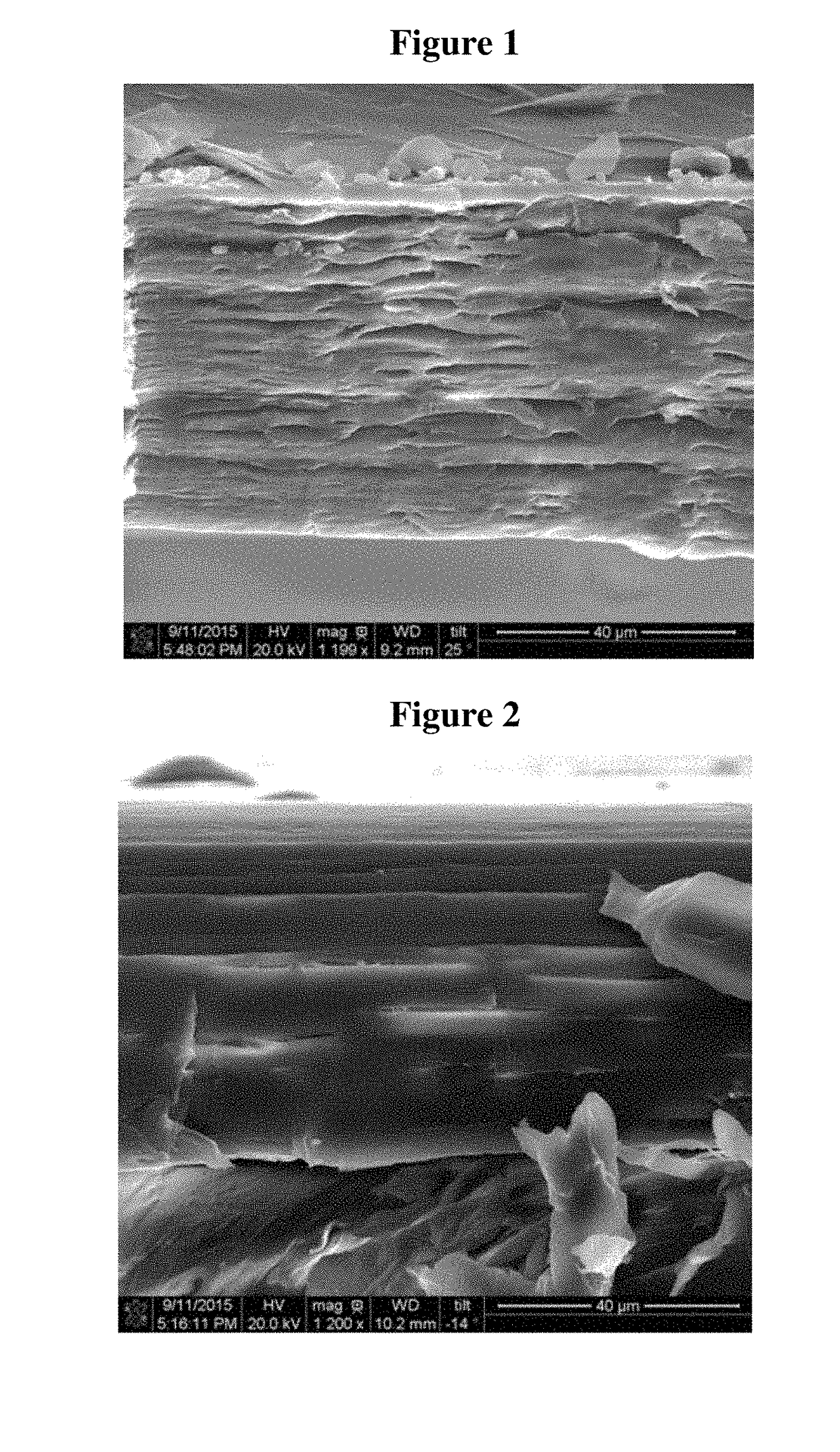

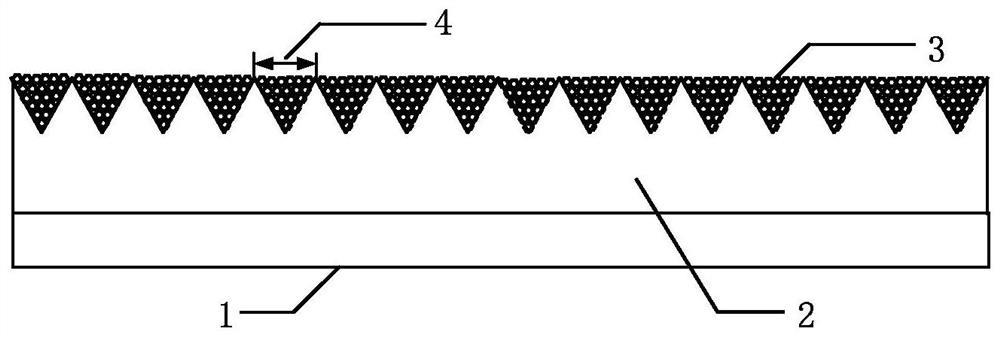

Lunar dust protection conductive film with micro-nano structure and preparation method thereof

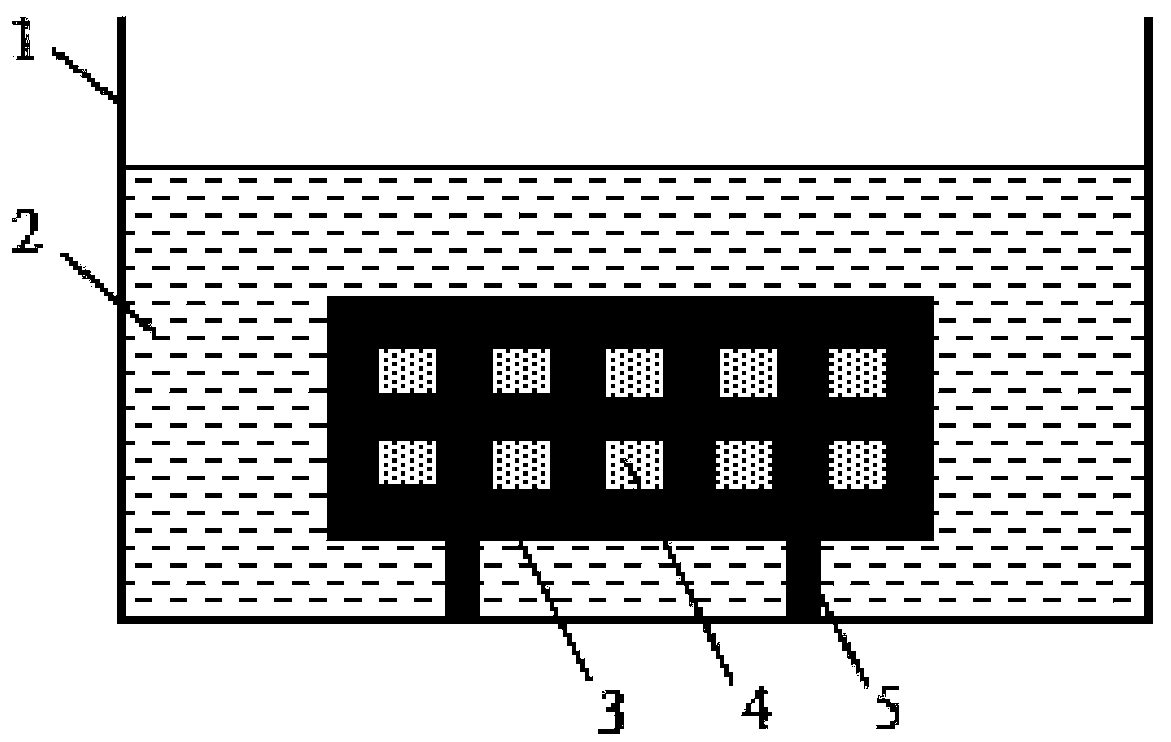

ActiveCN112885504ALower surface energyReduce van der Waals forcesConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersRough surfaceNano structuring

The invention relates to the technical field of lunar dust protection, in particular to a lunar dust protection conductive film with a micro-nano structure and a preparation method thereof. The lunar dust protection conductive thin film comprises a metal substrate layer, a first-level micrometer structure layer and a second-level nanometer conductive filling layer, wherein the first-level micrometer structure layer with a rough surface is formed on the metal substrate layer through a reverse mold technology; and a conductive layer is coated on the first-level micrometer structure layer to form the second-level nanometer conductive filling layer. According to the invention, the surface energy between the protected surfaces is reduced through the first-level micrometer structure layer, so that the Van der Waals force between the lunar dust and the protected surfaces is reduced; according to the lunar dust protection conductive film, the conductive characteristic of the protection film is improved by constructing the second-level nanometer conductive filling layer, so that the electrostatic force between lunar dust and a protected surface is reduced, and a good lunar dust protection effect is achieved by reducing Van der Waals force and the electrostatic force between the lunar dust and the protected surface at the same time.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

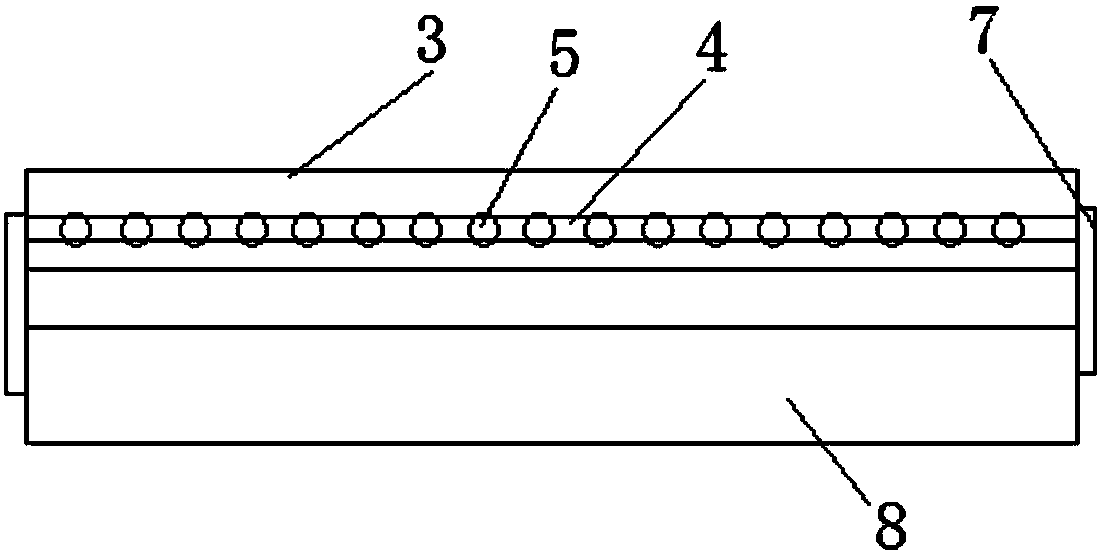

Pole plate structure, electrostatic driving structure using the pole plate structure and manufacturing method thereof

ActiveCN106800270BHigh electrostatic force/damping force ratioReduce damping forceDecorative surface effectsChemical vapor deposition coatingRelative motionEngineering

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

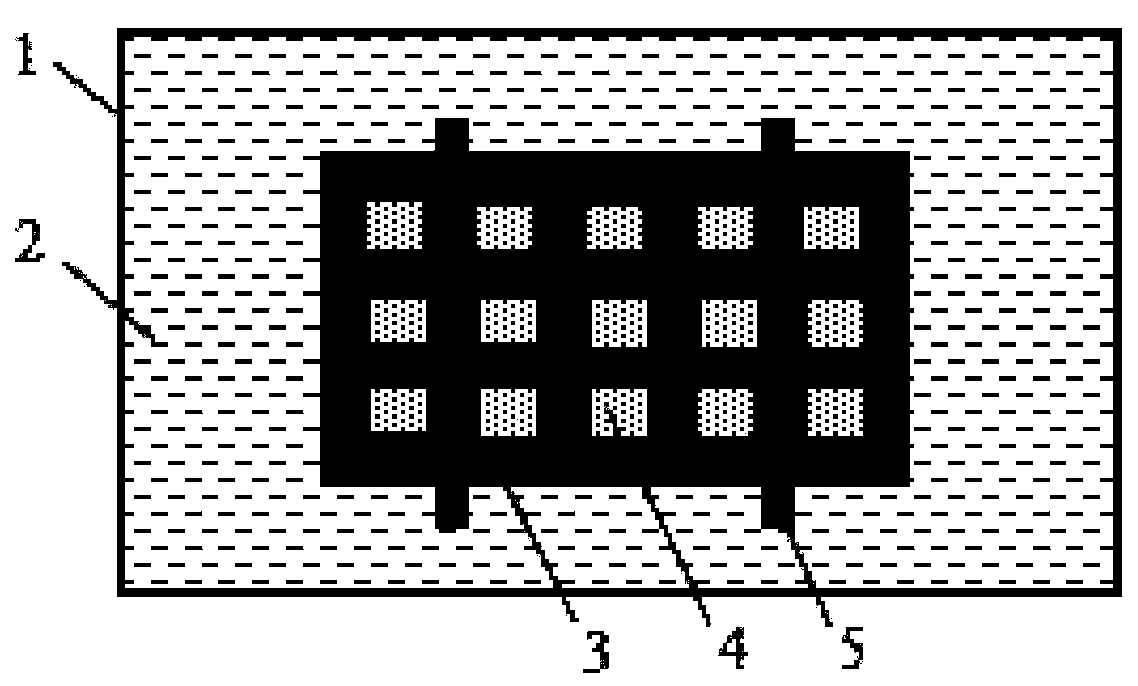

Mask box with electrostatic damage resistance and processing method thereof

PendingCN114310828AReduce electrostatic forceTransmission systemsPhotomechanical apparatusEngineeringStructural engineering

The invention discloses a mask box with an anti-static damage function and a processing method thereof. The mask box comprises a base and a plurality of supporting elements, the base is provided with a bearing face, a groove is formed in the bearing face, and the groove is provided with a bottom face. The supporting element surrounds the bearing surface of the base and is configured to support a mask. The groove has a depth extending between the bearing surface and the bottom surface, and the depth is between 300 [mu] m and 3400 [mu] m, thereby weakening the electrostatic force borne by the particles on the bearing surface. By controlling the processing depth of the groove in the base of the mask box or the distance between the bottom surface of the groove and the downward surface of the mask, the influence of residual voltage of the mask on particles on the surface of the base can be effectively weakened, so that the particles are prevented from being attracted to the downward surface of the mask, and a pattern area is prevented from being polluted.

Owner:GUDENG PRECISION IND CO LTD

Variable capacitance device

ActiveUS20120206857A1Accurate operationReduce electrostatic forceCapacitor with electrode distance variationCapacitor with voltage varied dielectricCapacitanceLight beam

A variable capacitance device that operates properly at a point along a signal line through which a high-voltage RF signal passes while reducing a necessary DC voltage includes a substrate, a beam, and lower drive electrodes. The beam is connected to the substrate through a support portion. Lower drive electrodes and the beam generate a capacitance when a DC voltage is applied, and an electrostatic force due to this capacitance deforms the beam. The lower drive electrodes face the beam and are coupled to each other through the beam. An RF signal propagates between the lower drive electrodes.

Owner:MURATA MFG CO LTD

Aging-resistant polycarbonate composition

The invention relates to the technical field of polycarbonate, and especially relates to an aging-resistant polycarbonate composition. The aging-resistant polycarbonate composition comprises the following components in parts by mass: 3-12 parts of malonate, 3.5-6.8 parts of nano titanium dioxide, 15-25 parts of pentaerythritol, 10-20 parts of mica, 5-12 parts of polysiloxanes-polycarbonate, 2.6-4.2 parts of glass fiber, 30-45 parts of polycarbonate, 12-18 parts of an ultraviolet resistance agent, and 1.5-3.9 parts of stearamide. The polycarbonate composition is helpful for improving the injection liquidity, and reducing the electrostatic force of the following produced products, and at the same time, improving the efficacy of the integral production process and the quality of the produced products. The polycarbonate composition resists aging.

Owner:魏忠

Method of manufacturing a golf ball

Owner:DUNLOP SPORTS CO LTD

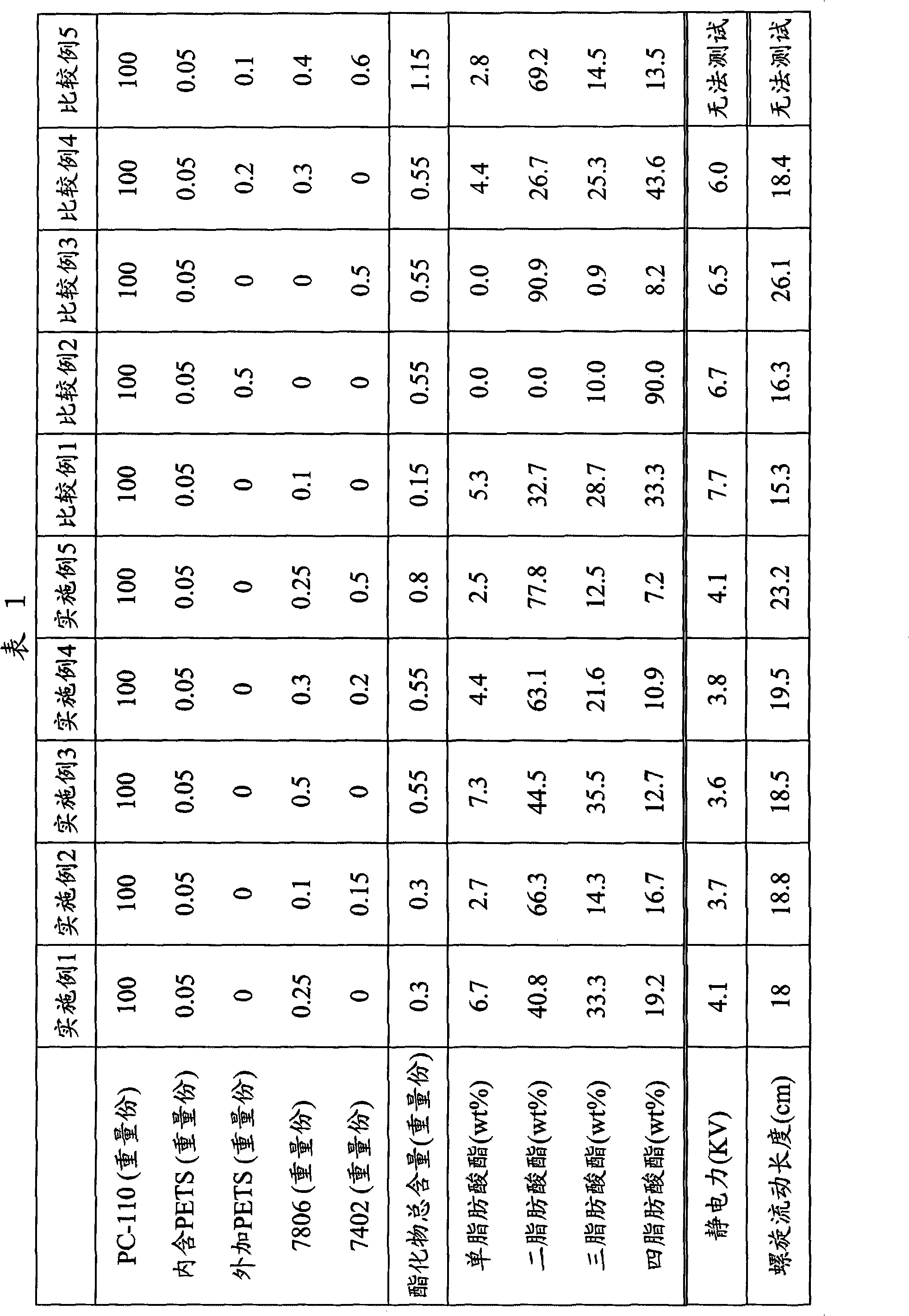

Makrolon composition

The invention discloses a makrolon composition comprising all or parts of makrolon, aliphatic acid, and pentaerythritol esterified esters. The total weight of the makrolon is 100 parts by weight, the weight of parts or all of makrolon is 0.2-1.0 part by weight. The all or parts of the makrolon contains 1-10wt% pentaerythritol single aliphatic ester, 35-80w% Isoamyl mangano glycol fatty acid ester, 10-40wt% Isoamyl alcohol fatty acid 3-aliphatic ester, and 5-20wt% Isoamyl alcohol fatty acid 4-aliphatic ester. The makrolon composition is helpful for improving the injection liquidity, and reducing the electrostatic force of the following produced products, and at the same time, improving the efficacy of the integral production process and the quality of the produced products.

Owner:CHI MEI CORP

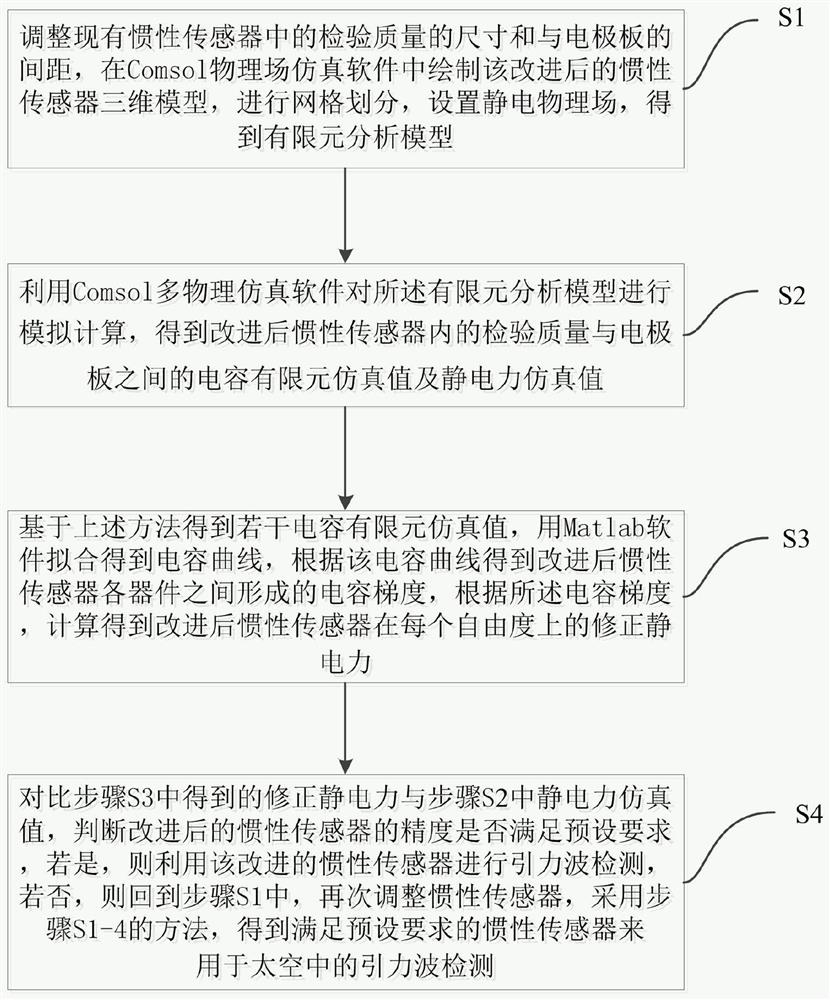

Inertial sensor correction verification method based on finite element analysis model

PendingCN114297898AReduce electrostatic forceReduced static force requirementsDesign optimisation/simulationCapacitanceElement analysis

The invention provides an inertial sensor correction verification method based on a finite element analysis model, and the method comprises the steps: adjusting the size of an inspection mass in an existing inertial sensor and the distance between the inspection mass and an electrode plate, and obtaining an improved inertial sensor; utilizing a finite element analysis model to obtain a capacitance finite element simulation value and an electrostatic force simulation value between the inspection mass and the electrode plate in the improved inertial sensor, and a capacitance gradient formed among devices of the improved inertial sensor; obtaining a corrected electrostatic force according to the capacitance gradient; therefore, the inertial sensor meeting the preset requirements is obtained and is used for gravitational wave detection in the space. The method has the beneficial effects that the electrostatic force borne by the inspection mass in the improved inertial sensor is reduced, and the electrostatic force requirement applied to inertial sensor position control through the injection electrode is reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

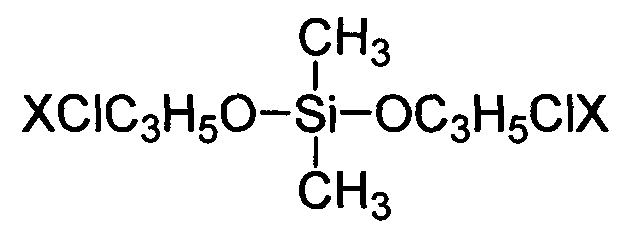

Preparation method of flame retardant plasticizer dimethyl silicate di(1,3-dihaloisopropyl) ester compound

ActiveCN104672269BHas char formationPrevent secondary combustionGroup 4/14 element organic compoundsEpoxyPropanol

The invention relates to a preparation method of a flame-retardant plasticizer bis(1,3-dihaloisopropyl) dimethyl silicate compound. The structure of the compound is shown in the following formula: where X=Cl or Br. The preparation method is as follows: under the protection of nitrogen, in the temperature range of 30 DEG C to 70 DEG C, the molar ratio of dimethyldichlorosilane or dimethyldibromosilane and 1,3-dihaloisosilane is 1:2 to 3. Propanol is reacted in an organic solvent for 5-9 hours, and after purification, bis(1,3-dihaloisopropyl) dimethyl silicate is obtained. The bis(1,3-dihaloisopropyl) dimethyl silicate of the invention has high flame retardant performance and good compatibility with polymer materials, and is suitable for use as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin, etc. The flame retardant plasticizer has the advantages of simple production process, low cost and easy industrialized production.

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

Organosilicone additive for inhibiting coating pigment reunion and settlement

The invention discloses an organosilicon additive for inhabiting coating pigment reunion and settlement and relates to the technical field of organosilicone materials. The organosilicone additive is prepared from, by weight, 10-15 parts of emulsified silicone oil, 6-11 parts of polyvinyl butyral, 4-8 parts of modified chlorinated paraffin, 3-6 parts of C5 petroleum resin, 2-4 parts of active magnesium oxide, 2-4 parts of tricetyl phosphate, 1-2 parts of microcrystalline wax, 1-2 parts of sulfated castor oil, 1-2 parts of vulcanized lard oil, 1-2 parts of 2-methyl cyclopentanone, 1-2 parts of dimethyl phosphate, 0.5-1 part of zinc dihydrogen phosphate, 0.5-1 part of edetic acid, 0.5-1 part of cyclopropylmagnesium bromide and 0.5-1 part of sodium tripolyphosphate. The organosilicone additive is short in preparation period and low in cost, uniform dispersion of pigments is facilitated by synergistic effect of raw materials through strictly controlled temperature rising and dropping speed and feeding sequence, and reunion and settlement of the pigments are prevented.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

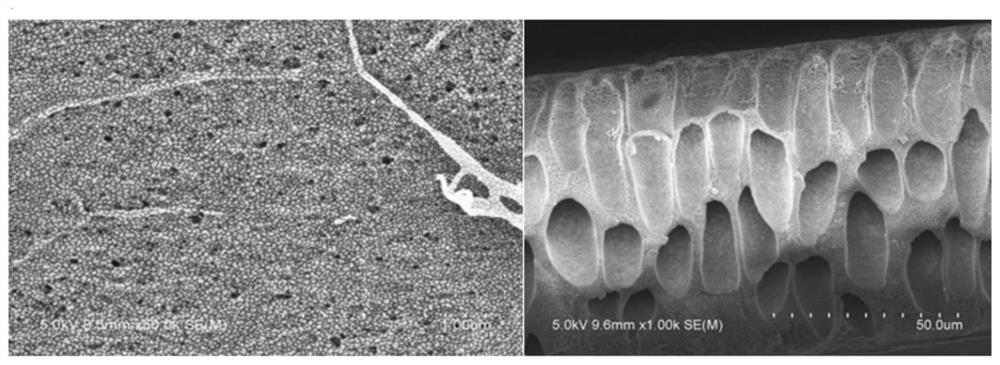

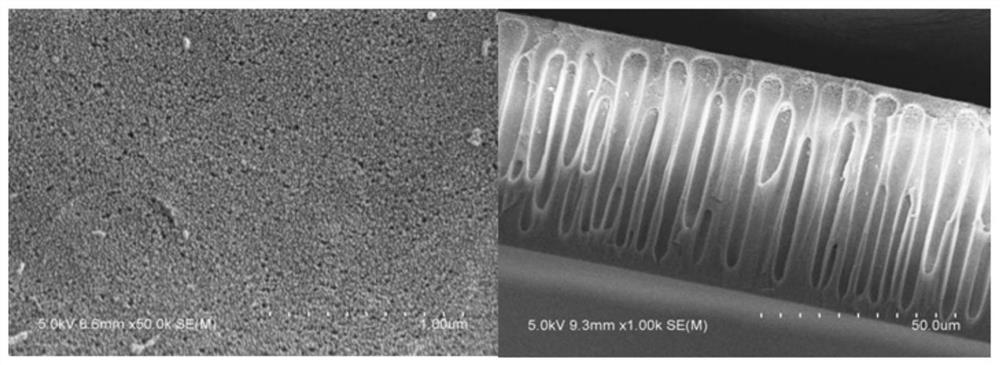

A kind of preparation method of TB ultrafiltration membrane, the treatment method of oily waste water

ActiveCN109876680BImprove hydrophilicityReduce electrostatic forceFatty/oily/floating substances removal devicesUltrafiltrationBound waterProtein molecules

The invention provides a preparation method of TB ultrafiltration membrane and a treatment method of oily wastewater. Compared with the prior art, the present invention reacts TB with dimethyl sulfate to obtain methylated TB, and then uses hydrogen to oxidize After sodium hydrolysis and ring opening, it is mixed with N-methylpyrrolidone and ethylene glycol monomethyl ether according to a certain ratio to form a casting solution to prepare a TB ultrafiltration membrane. The addition of EGM to the coating solution affects the phase separation thermodynamics and mass transfer kinetics of the casting solution membrane system, further improving the hydrophilicity of the membrane. The hydrophilic surface of the prepared base ultrafiltration membrane can combine water molecules to form an ordered water layer, thereby effectively reducing the electrostatic force between the membrane surface and protein molecules; at the same time, the polymer conformation will not change when the protein contacts the membrane surface, so Significantly reduced protein adsorption. It also has a very high interception rate for emulsified oil wastewater, which can reach 98.55%-99.64%, and has a good application prospect.

Owner:ANHUI POLYTECHNIC UNIV

Dimethyl silicon acid dihalogen propyl ester compound serving as flame resistant plastifier and preparation method of dimethyl silicon acid dihalogen propyl ester compound

ActiveCN104710464AHas char formationPrevent secondary combustionGroup 4/14 element organic compoundsEpoxyOrganic solvent

The invention relates to a dimethyl silicon acid dihalogen propyl ester compound serving as a flame resistant plastifier anda preparation method of the dimethyl silicon acid dihalogen propyl ester compound. The structure of the compound is shown in the formula, wherein ClXC3H5O is CH2ClCHXCH2O or (CH2Cl)(CH2X)CHO,X=Cl or Br. The preparation method comprises the following steps: dissolving dimethyl dihalogen silicon alkane in an organic solvent, adding epoxy chloropropane of which the mol is 2-3 times of that of the dimethyl dihalogen silicon alkane, performing temperature rise to enable the temperature to be 70-110 DEG C, performing a heat preservation reaction for 5-13 hours, and performing purification so as to obtain the dimethyl silicon acid dihalogen propyl ester. The dimethyl silicon acid dihalogen propyl ester disclosed by the invention is high in flame resistant efficacy, is good in plasticity, and is suitable for being used as a flame resistant plastifier of a polyvinyl chloride, polyurethane, an epoxy resin, an unsaturated resin and the like. The production technology is simple, the cost is low, and the industrialized production is easy to realize.

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

Micromechanical sensor and method for producing a micromechanical sensor

ActiveCN107422146AImproves sensitivity and resilienceReduce electrostatic forceAcceleration measurementSpeed/acceleration/shock instrument detailsOptoelectronicsOxide

A micromechanical sensor (100) is provided. The surface-micromechanically manufactured micromechanical sensor (100) includes at least one mass element formed in a third functional layer (60) and configured in a non-perforated manner at least in certain portions. A gap (S) below the mass element is formed by removal of a second functional layer (30) and at least one oxide layer (20). The removal of the at least one oxide layer (20) takes place by introducing a gaseous etching medium into a defined number of etching channels arranged substantially parallel to one another. The etching channels are configured to be connected to a vertical access channel in the third functional layer (60).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com