A kind of preparation method of TB ultrafiltration membrane, the treatment method of oily waste water

A technology of ultrafiltration membrane and scraping membrane, which is applied in osmosis/dialysis water/sewage treatment, ultrafiltration, separation methods, etc., can solve the problems of membrane fouling, reduced sewage treatment effect, membrane pore blockage, etc., to improve the retention rate, Good application prospect, the effect of reducing electrostatic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of TB ultrafiltration membrane, comprising the following steps:

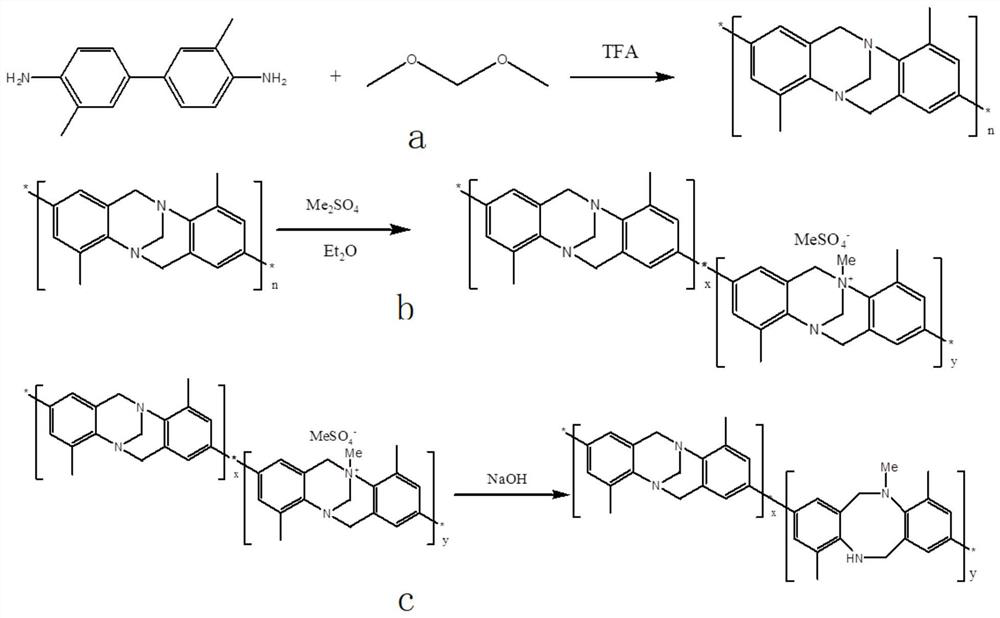

[0040] 1) Synthesize TB polymer according to Polym.Chem.5(2014)5267-5272.

[0041] 2) Methylate the polymer TB prepared in step 1) and dimethyl sulfate according to the molar ratio of 1:0.5: weigh 12g (48.36mmol) of the polymer TB prepared in step 1), cut it into pieces with scissors and put Put into a 1000mL three-necked flask, add 440mL of diethyl ether and stir under ice bath conditions, add 2.3mL (24.29mmol) dimethyl sulfate into the three-necked flask with a pipette gun when the temperature drops to 4°C, remove the ice bath , when the temperature rises to room temperature, transfer it to an oil bath whose temperature has been stabilized at 30°C in a fume hood, and gradually increase the temperature. The reaction temperature should be kept at 35°C±1°C, and the reflux condenser tube is refluxed, and a balloon is placed on the condenser tube , to prevent ether from being evaporated...

Embodiment 2

[0047] TB and TB m Synthesis and M TBm+EGM The preparation is with embodiment 1;

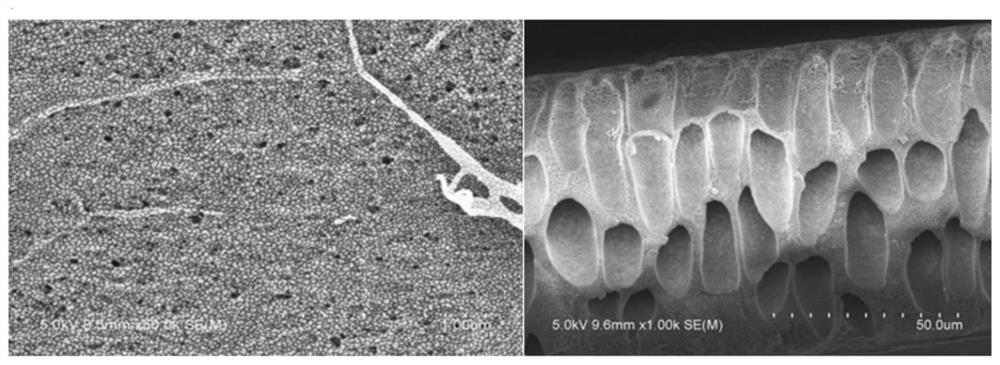

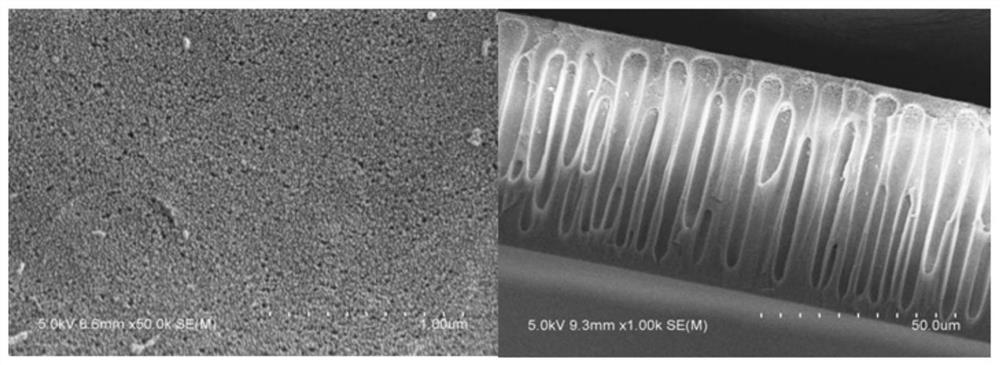

[0048] The treatment method of oily waste water provided by the present invention utilizes the above-mentioned M prepared by the present invention TBm+EGM deal with. The membrane was pre-pressed at 1.5 bar for 30 minutes, and then operated at 1.0 bar for 30 minutes to obtain the initial pure water flux. Then filter with emulsified oil (1.0g / L) for 1h, rinse thoroughly with deionized water, and then measure the water flux of the washed membrane for 30min. The process of filtering the emulsified oil and backwashing the water is repeated three times. The quality of the permeate was weighed every 2 minutes with an electronic balance. With an effective membrane area of 35cm 2 The pure water flux of the membrane measured by the dead-end filtration membrane device is 140.45L / (m 2 h bar), M TBm+EGM The interception rate and anti-pollution of emulsified oil are 99.94% and 81.23% respectively. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com