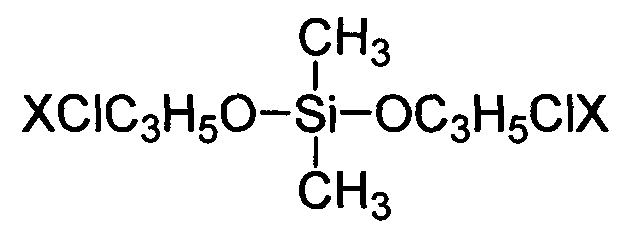

Dimethyl silicon acid dihalogen propyl ester compound serving as flame resistant plastifier and preparation method of dimethyl silicon acid dihalogen propyl ester compound

A technology of dihalopropyl dimethyl silicate and flame retardant plasticizer, applied in the field of flame retardant plasticizer, can solve problems such as application limitations, achieve simple equipment, good economic and environmental benefits, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser, and a drying tube at the top of the condenser, replace the air in the bottle with nitrogen, and add 6.45g (0.05mol) of dimethyl Dichlorosilane, 65ml of dioxane and 9.25g (0.1mol) of epichlorohydrin, heated up to 100°C, kept warm for 8h; distilled under reduced pressure to remove solvent and a small amount of low-boiling matter to obtain dichloropropane dimethyl silicate Esters, yield 86.9%.

Embodiment 2

[0028] Example 2 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 6.45g (0.05mol) of dimethyl Dichlorosilane, 40ml of acetonitrile and 10.18g (0.11mol) of epichlorohydrin were heated up to 70°C and kept for 13 hours of reaction; the solvent, excess epichlorohydrin (recycled) and a small amount of low boiling point were removed by distillation under reduced pressure to obtain Dichloropropyl dimethyl silicate, yield 84.1%.

Embodiment 3

[0029] Example 3 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 6.45g (0.05mol) of dimethyl Dichlorosilane, 20ml diethylene glycol dimethyl ether, and 11.57g (0.125mol) epichlorohydrin, heated up to 110°C, and kept warm for 5h; the solvent, excess epichlorohydrin (recycled) and A small amount of low-boiling matter was used to obtain dichloropropyl dimethyl silicate with a yield of 91.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com