Pole plate structure, electrostatic driving structure using the pole plate structure and manufacturing method thereof

A plate structure, electrostatic drive technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problem of etching damping holes, etc., and achieve the effect of easy preparation and large electrostatic force/damping force ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

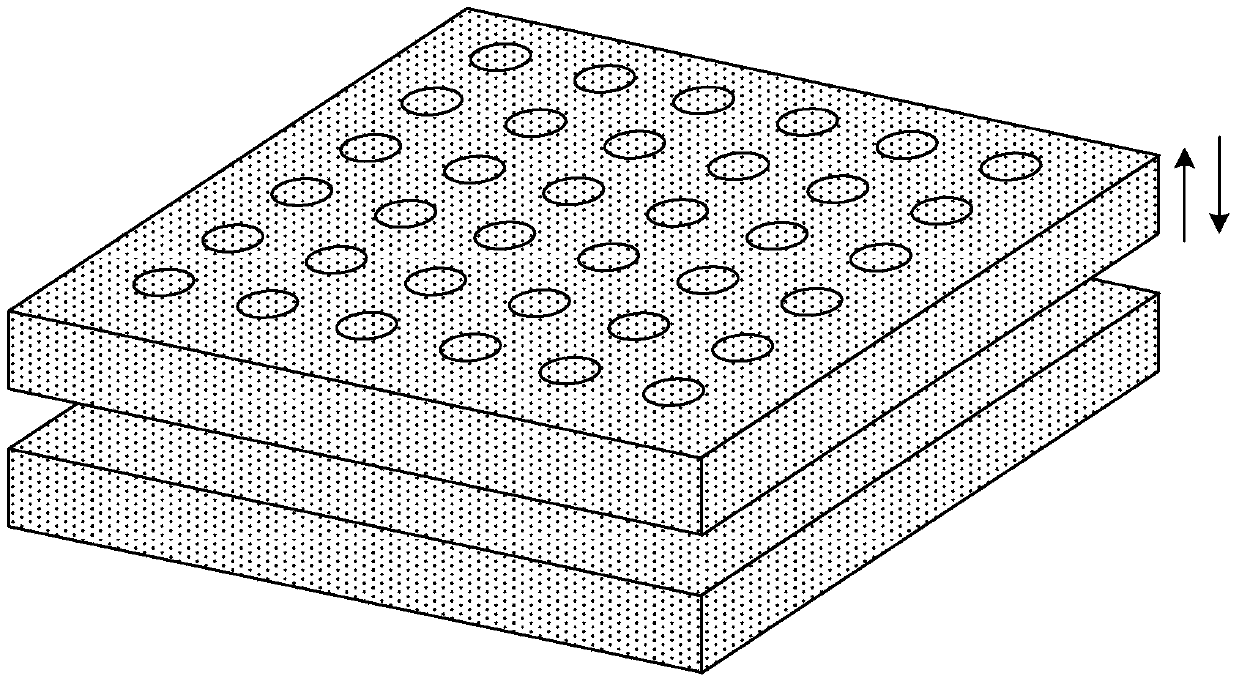

[0056] The present invention provides a pole plate structure, please refer to figure 2 and image 3 , which are respectively shown as a top view and a perspective view of the pole plate structure 1. As shown in the figure, one side of the pole plate structure 1 is provided with at least one damping hole 101 penetrating the pole plate structure 1 up and down, wherein the damping The openings of the hole 101 on the side, upper surface, and lower surface of the pole plate structure are side openings 1011, upper openings 1012, and lower openings 1013, respectively, and the area of the upper opening 1012 or the area of the lower opening 1013 is larger than the area of the lower opening 1013. The area of the side opening 1011 is described above.

[0057] like Figure 4 As shown, it is a schematic diagram showing the relative movement of two movable parts adopting the pole plate structure of the present invention in the plane. The in-plane relative movement here refers to t...

Embodiment 2

[0065] The present invention also provides a method for manufacturing a pole plate structure, comprising the following steps:

[0066] like Figure 11 As shown, step S1 is performed: providing a substrate 201 , etching a cavity structure 203 in the substrate 201 , and forming an insulating layer 202 on the surface of the cavity structure 203 .

[0067] Specifically, the substrate 201 includes but not limited to Si, Ge, SiGe and other conventional semiconductor materials. The insulating layer 202 includes but not limited to compound materials such as silicon oxide and silicon nitride. In this embodiment, the substrate 201 is an example of a Si substrate, and the insulating layer 202 is an example of silicon oxide.

[0068] The cavity structure 203 can be obtained by dry or wet etching. The function of the cavity structure 203 is to provide a floating space for the subsequent formation of the suspended pole plate structure, and its shape is not limited.

[0069] like Figur...

Embodiment 3

[0078] The present invention also provides an electrostatic driving structure adopting any one of the pole plate structures in the embodiment.

[0079] Specifically, the electrostatic driving structure includes a movable electrode and a fixed electrode, and the movable electrode and the fixed electrode may be plate electrodes or interdigital electrodes.

[0080] As an example, the movable electrode and the fixed electrode move relative to each other in the same plane, and at least one of the movable electrode and the fixed electrode adopts the pole plate structure, that is, only the movable electrode The pole plate structure of the present invention is adopted, or only the fixed electrode adopts the pole plate structure of the present invention, and both the movable electrode and the fixed electrode may adopt the pole plate structure of the present invention.

[0081] As an example, such as Figure 15 As shown, it shows an electrostatic driving structure 3 using interdigitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com