Glass substrate packing paper static electricity elimination and grabbing device and method

A technology for eliminating static electricity and glass substrates, applied in static electricity, electrical components, manipulators, etc., it can solve the problems of falling on the ground, increasing the burden on staff, etc., and achieve the effect of easy clamping, smooth and smooth transmission, and increased friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

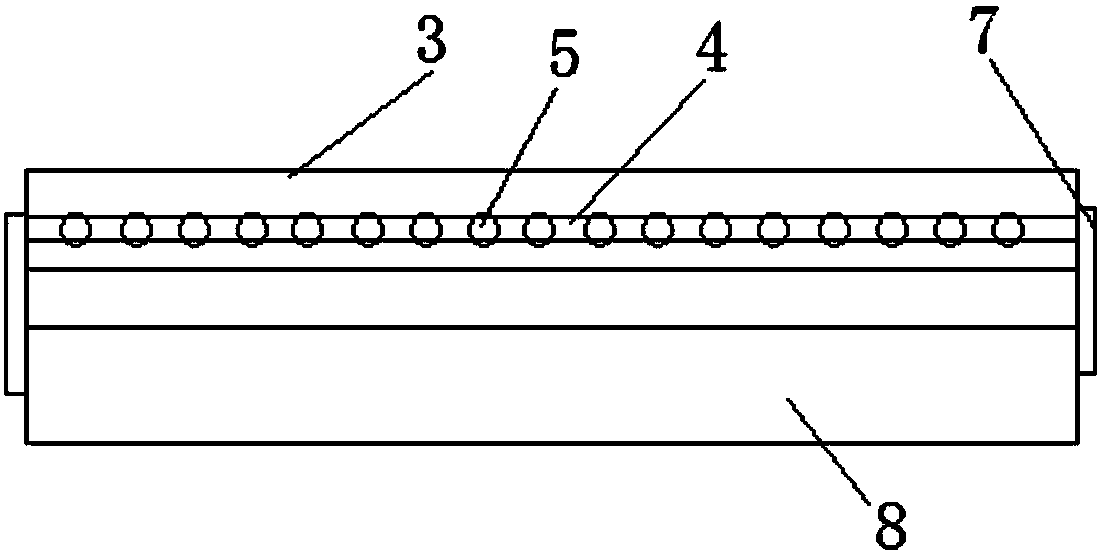

[0024] Such as figure 1 , figure 2 , image 3 As shown in the figure, a glass substrate pad paper static elimination grabbing device includes a robot arm 1 and a robot arm 2 installed on the robot arm 1. The robot arm 2 controls the rotation and movement of the space position of the robot arm 2 through the robot arm 1, and the robot arm 2 is fixedly connected. There is a manipulator beam 3, one side of the manipulator beam 3 is provided with a trachea 4, a plurality of air blowing nozzles 5 are arranged on the trachea 4, and a pair of symmetrically arranged grasping arms 7 are arranged at both ends of the manipulator beam 3. 7 can be opposite to the mechanical arm beam 3, and the two grabbing arms 7 on the same side along the length direction of the mechanical arm beam 3 at both ends of the mechanical arm beam 3 are fixed with a grabbing wheel 8, between the grabbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com