Preparation method of high-performance lithium salt

A high-performance, lithium salt technology, which is applied in the field of high-performance lithium salts and perfluorinated alkyl-substituted high-performance lithium salts, high-performance lithium salts, can solve problems such as poor thermal stability of carbonate electrolytes, and achieve improved Electrochemical performance, reaction process control, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of ethylene sulfonylimide lithium salt, structural formula is

[0038] React 1mol of dibromoethane with 2.1mol of sodium sulfite at 100°C to get Then add phosphorus trichloride to the obtained product and react at 150°C. The amount of phosphorus trichloride is added according to the chemical molar amount in the chemical reaction formula, preferably in excess of 0.1-0.3%, to obtain ethylenesulfonyl chloride

[0039] Reaction of vinylsulfonyl chloride obtained above with potassium fluoride at 50°C to obtain vinylsulfonyl fluoride Wherein the mol ratio of vinylsulfonyl chloride and potassium fluoride is 1:1;

[0040] Introduce ammonia gas into the ethylene sulfonyl fluoride obtained above for bubbling, then add diethyl ether, and react at 10°C to obtain ethylene sulfonamide Wherein the molar ratio of ethylenesulfonyl fluoride to ammonia is 1:2.1;

[0041] The ethylene sulfonamide obtained above was added to lithium hydroxide and reac...

Embodiment 2

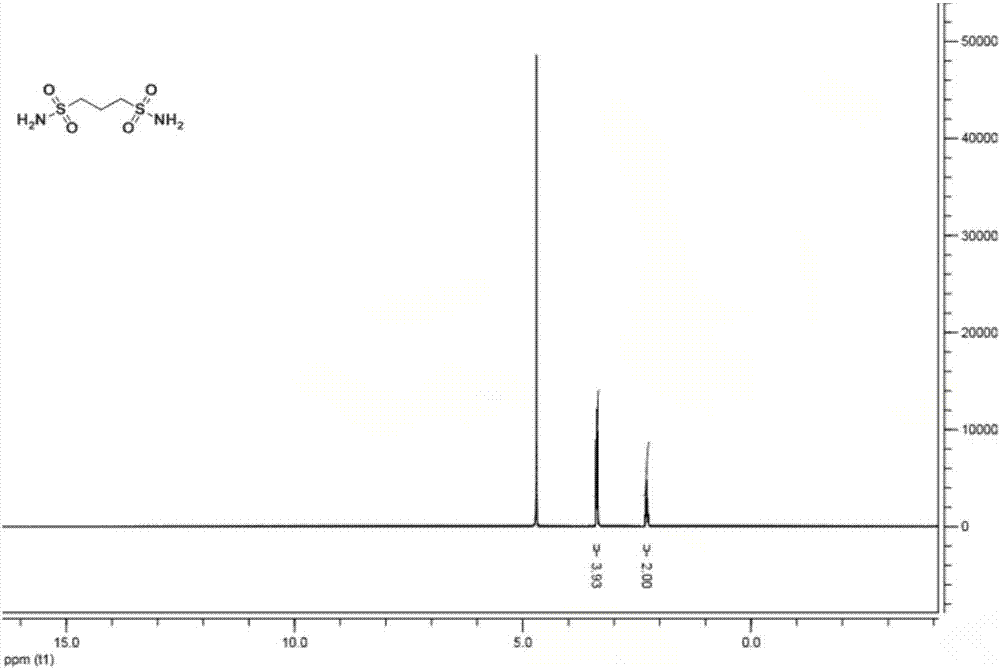

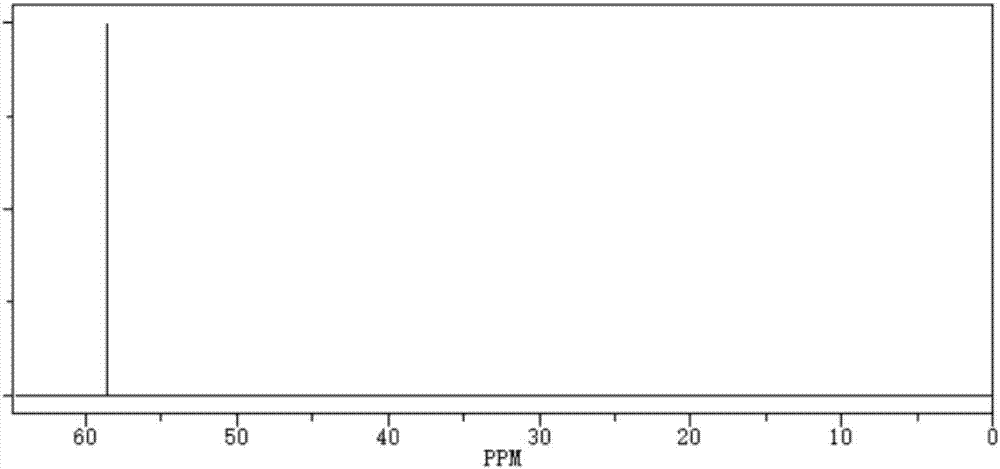

[0045] Example 2: Lithium salt of 1,3-propane disulfonylimide CAS No. 1034120-61-0

[0046] React 1mol of dibromopropane with 2.3mol of sodium sulfite at 120°C to obtain Then add phosphorus trichloride to the obtained product and react at 160°C. The amount of phosphorus trichloride is added according to the chemical molar amount in the chemical reaction formula, preferably in excess of 0.1-0.3%, to obtain 1,3-propanedi Sulfonyl chloride

[0047] React the 1,3-propanedisulfonyl chloride obtained above with potassium fluoride at 60°C to obtain 1,3-propanedisulfonyl fluoride Wherein the molar ratio of 1,3-propanedisulfonyl chloride to potassium fluoride is 1:1.5;

[0048] Bubble ammonia gas into the 1,3-propanedisulfonyl fluoride obtained above, then add ether, and react at 5°C to obtain 1,3-propanedisulfonamide Wherein the molar ratio of 1,3-propanedisulfonyl fluoride to ammonia is 1:2.3;

[0049] Add the above-mentioned product 1,3-propanedisulfonamide to lithium hydro...

Embodiment 3

[0053] Example 3: Lithium salt of perfluoro-substituted 1,3-propane disulfonylimide

[0054] React 1mol of dibromopropane with 2.2mol of sodium sulfite at 115°C to obtain Then add phosphorus trichloride to the obtained product and react at 155°C. The amount of phosphorus trichloride is added according to the chemical molar amount in the chemical reaction formula, preferably in excess of 0.1-0.3%, to obtain 1,3-propanedi Sulfonyl chloride

[0055] React the 1,3-propanedisulfonyl chloride obtained above with potassium fluoride at 55°C to obtain 1,3-propanedisulfonyl fluoride Wherein the molar ratio of 1,3-propanedisulfonyl chloride to potassium fluoride is 1:1.3;

[0056] Bubble ammonia gas into the 1,3-propanedisulfonyl fluoride obtained above, then add diethyl ether, and react at 8°C to obtain 1,3-propanedisulfonamide Wherein the molar ratio of 1,3-propanedisulfonyl fluoride to ammonia is 1:2.2;

[0057] Add the above product 1,3-propanedisulfonamide to lithium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com