Makrolon composition

A technology of polycarbonate and composition, which is applied in the field of polycarbonate composition that can improve injection fluidity and reduce electrostatic force, and can solve problems that affect the quality of molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

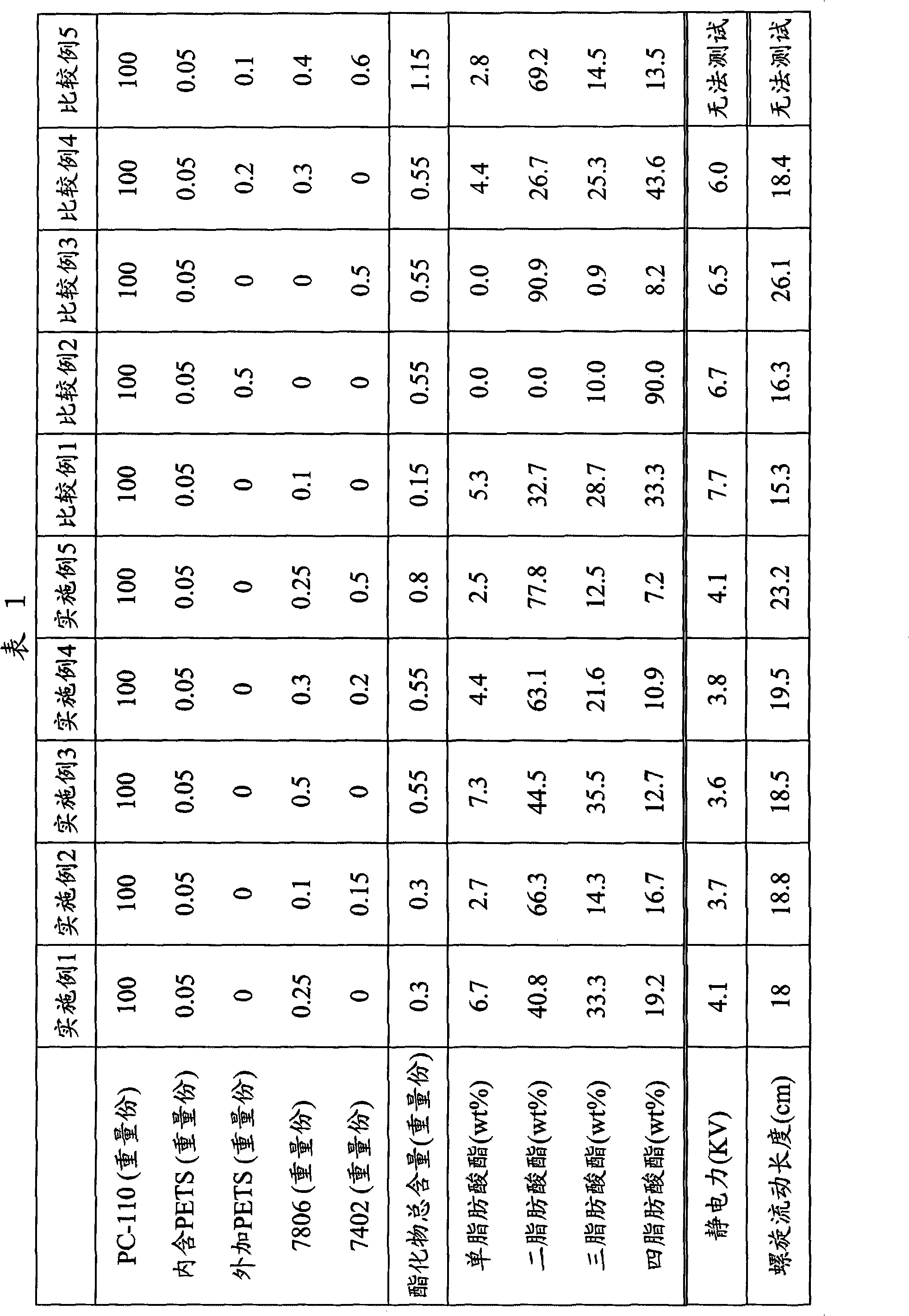

[0039] After mixing 100 parts by weight of polycarbonate (Chi Mei Industrial Co., trade name PC-110) and 0.25 parts by weight of pentaerythritol fatty acid ester mixture 7806, extrude and granulate with a biaxial extruder to obtain this product Invented polycarbonate composition, and evaluated according to the above-mentioned physical property test methods of electrostatic force and spiral flow length.

[0040] The total or partial esterification content of the fatty acid and pentaerythritol listed in Table 1 is calculated based on the total weight of the total or partial esterification of the fatty acid and pentaerythritol as 100 wt%.

Embodiment 2~5 and comparative example 1~5

[0042] The preparation process, preparation conditions and testing process of Examples 2-5 are the same as those of Example 1, except that the parts by weight of the polycarbonate composition components are changed according to the parts by weight listed in Table 1. Similarly, the test results of electrostatic force and spiral flow length are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com