Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Proof of stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

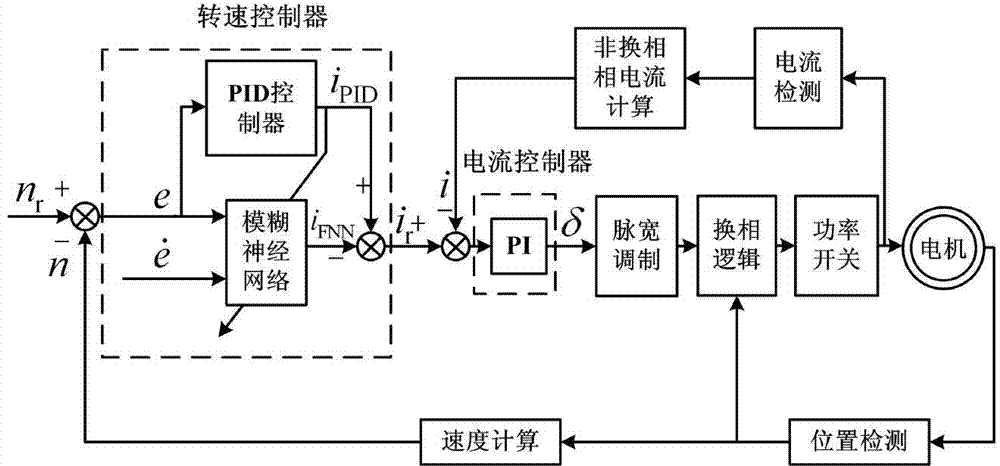

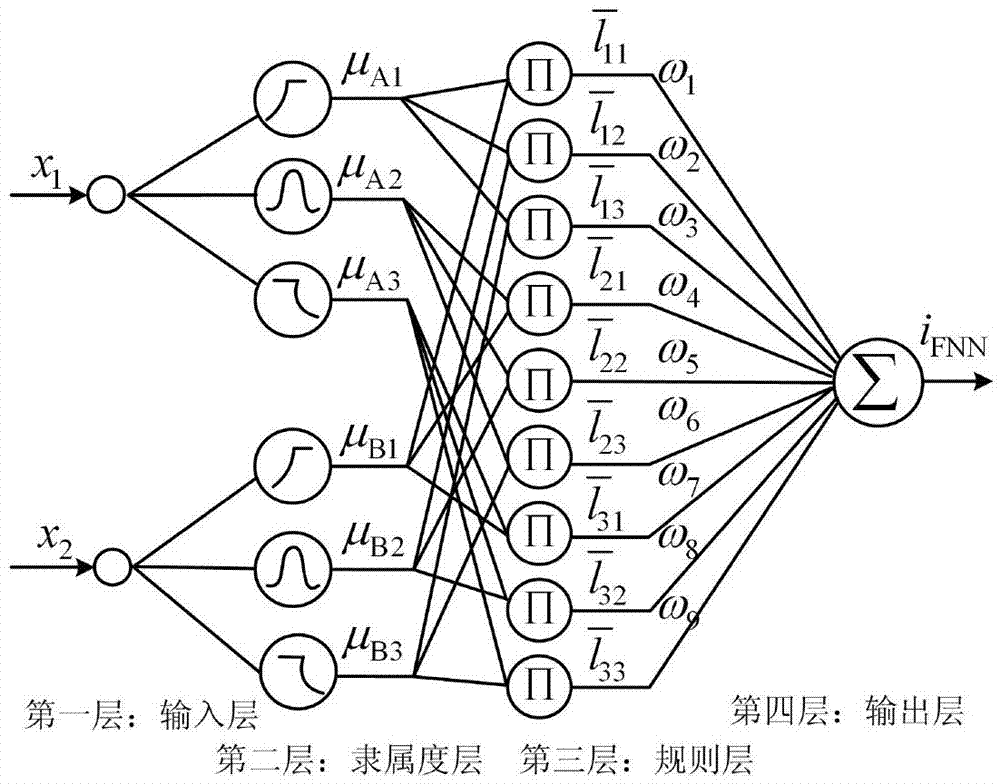

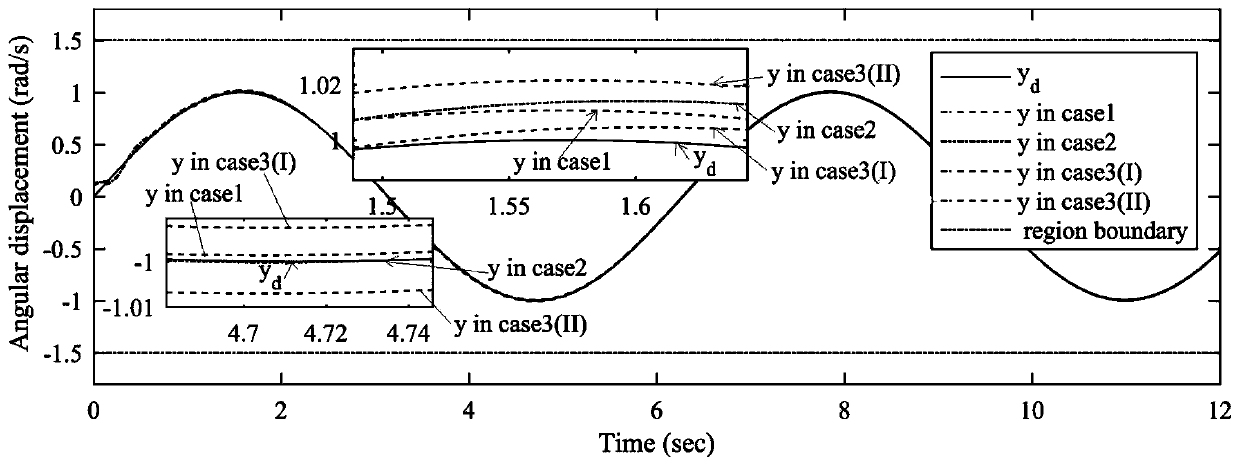

Motor rotating-speed tracking control method based on self-adaptive fuzzy neural network

The invention relates to a motor rotating-speed tracking control method based on a self-adaptive fuzzy neural network, wherein rotating-speed and current double closed-loop control is adopted, an outer ring is a rotating-speed ring, a sliding-mode control theory-based fuzzy neural-network controller (SMFNN) is designed, an inner ring is a current ring, and a PI (Proportional-Integral) controller is adopted; a fuzzy neural-network rotating-speed controller comprises two parts, wherein one part is a PID (Proportional-Integral-Derivative) controller, and the other part is the fuzzy neural network, online real-time learning is carried out through the fuzzy neural network by utilizing a parameter correcting method designed on the basis of the sliding-mode control theory, and the two parts jointly act to obtain the output ir of the rotating-speed controller, i.e. a difference obtained by subtracting the output iFNN of the fuzzy neural network from the output iPID of the PID controller is used as the output ir of the rotating-speed controller. The control precision and the anti-interference performance of a motor speed-adjusting system can be improved through the control strategy of the motor rotating-speed tracking control method.

Owner:TIANJIN UNIV

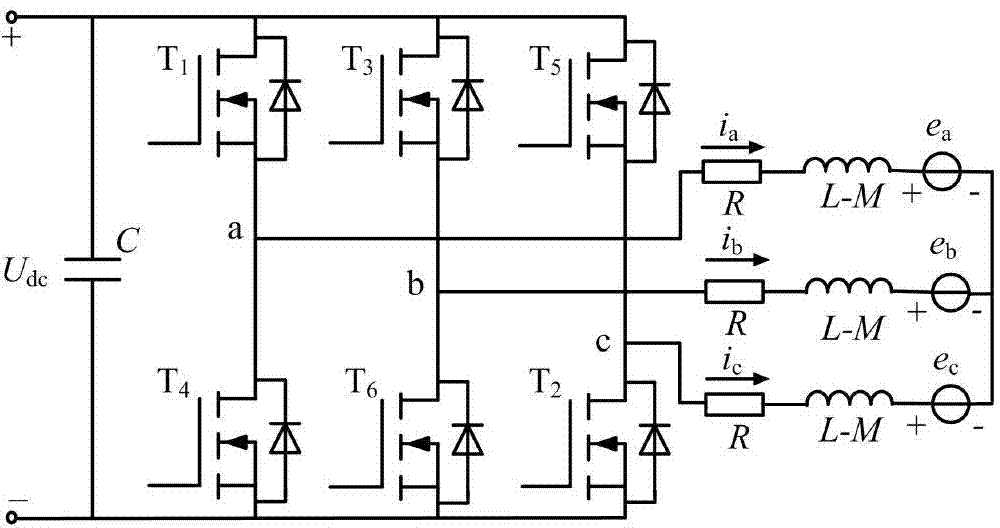

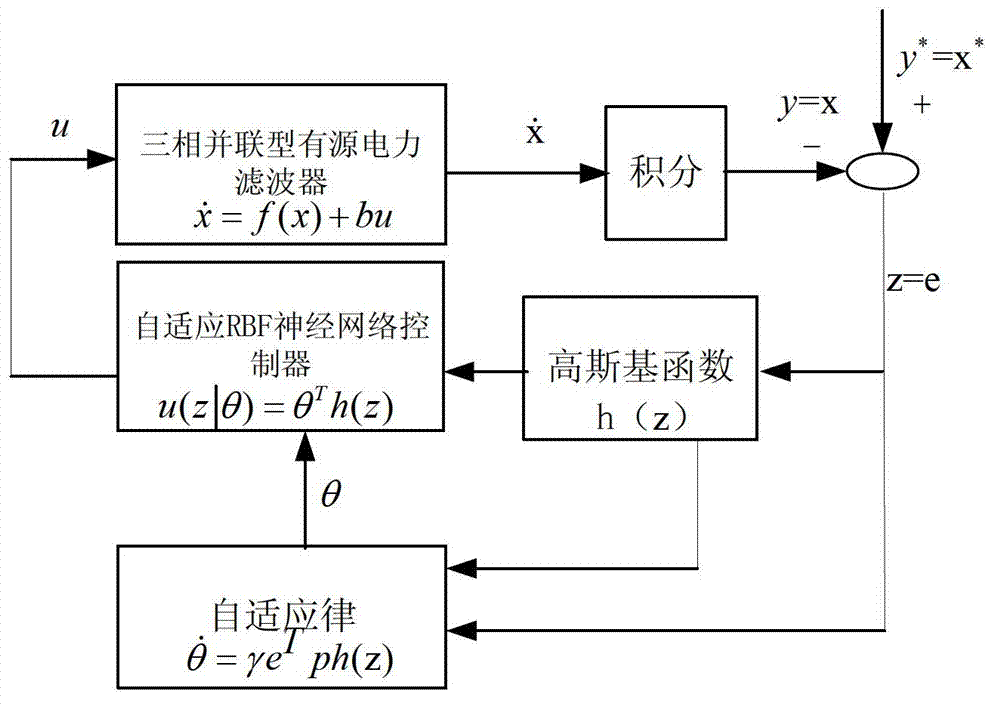

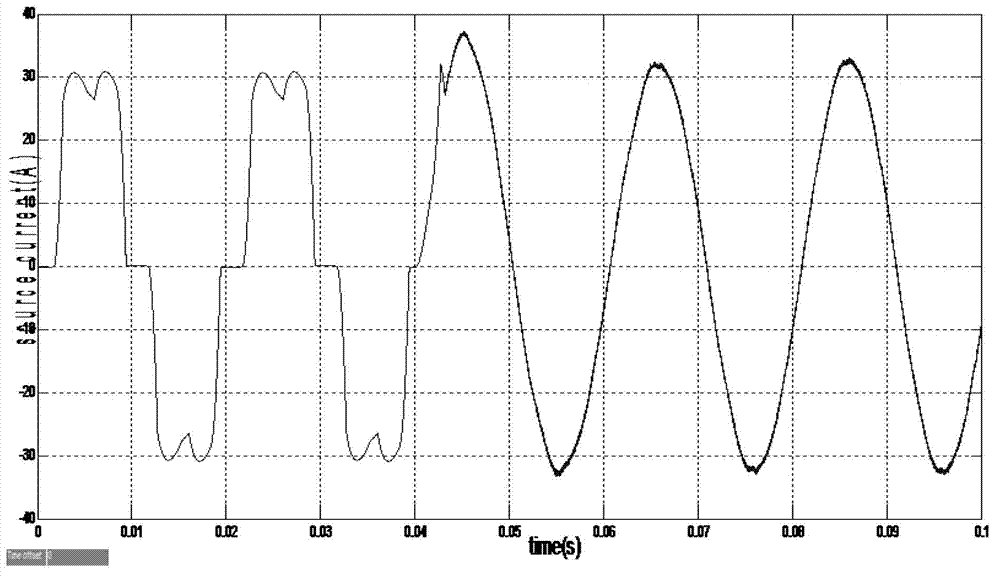

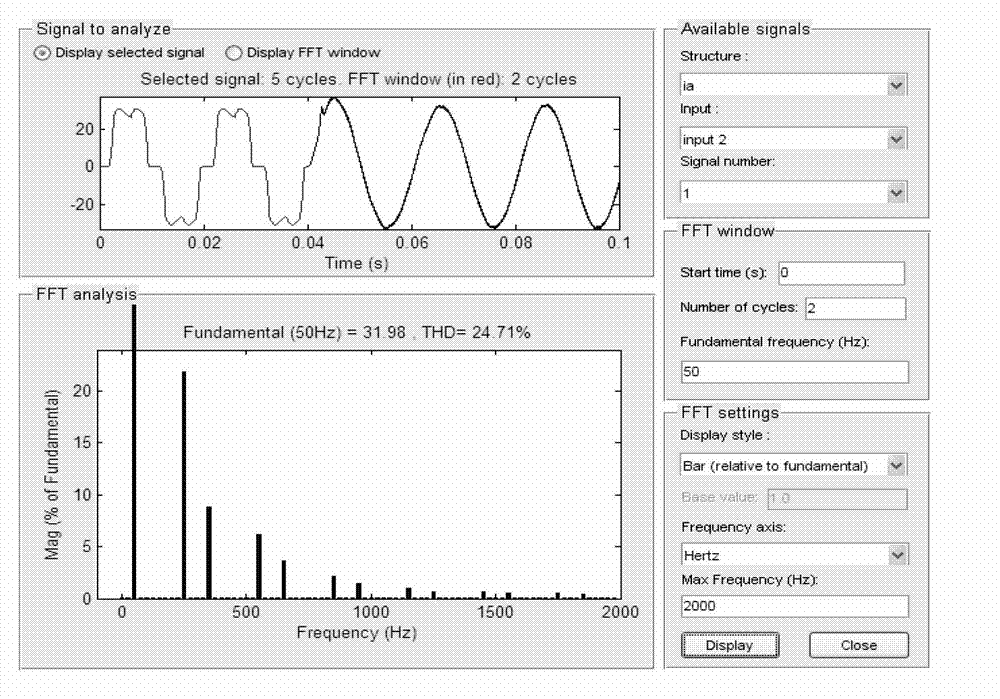

Adaptive RBF (radial basis function) neural network control technique for three-phase parallel active filters

InactiveCN102832621AImprove the quality of power supplyEliminate harmonicsActive power filteringHarmonic reduction arrangementLyapunov stabilityNetwork control

The invention relates to an adaptive RBF (radial basis function) neural network control technique for three-phase parallel active filters, belonging to an active power filter control technique. The invention provides an adaptive RBF neural network control method for three-phase parallel active power filters, which is used for controlling a compensation current output by a three-phase parallel active power filter through a controller, thereby eliminating harmonic waves and improving the power supply quality of a power grid. According to an adaptive control rule provided by the invention, the boundedness of weights is ensured, and the stability of the controller is proved by using a Lyapunov stability theory; and simulation results show that the control method effectively reduces the distortion factor of harmonic waves and is good in dynamic response, and when parameters change, the controller has good robustness and adaptability.

Owner:HOHAI UNIV CHANGZHOU

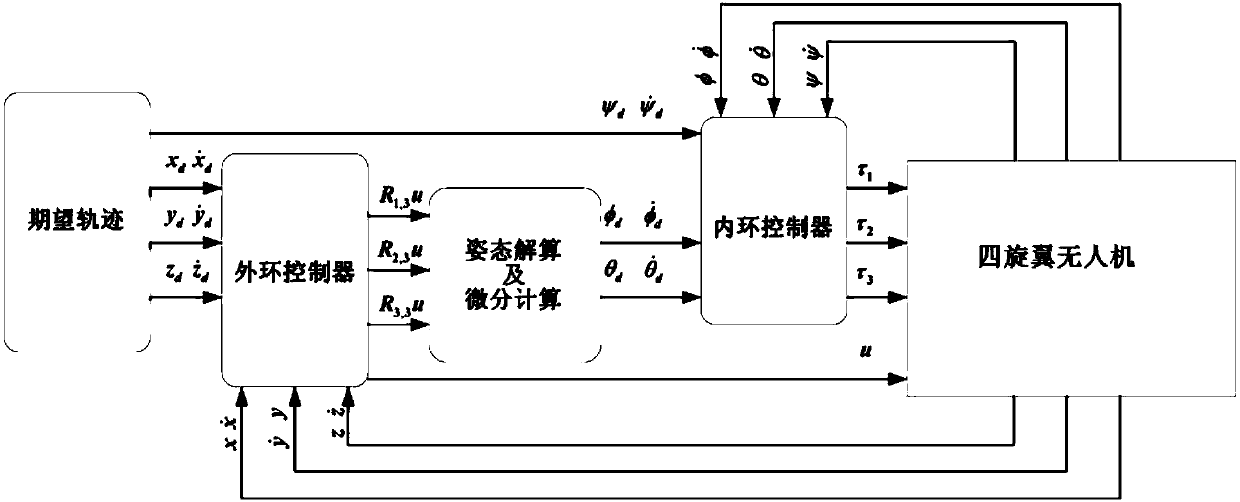

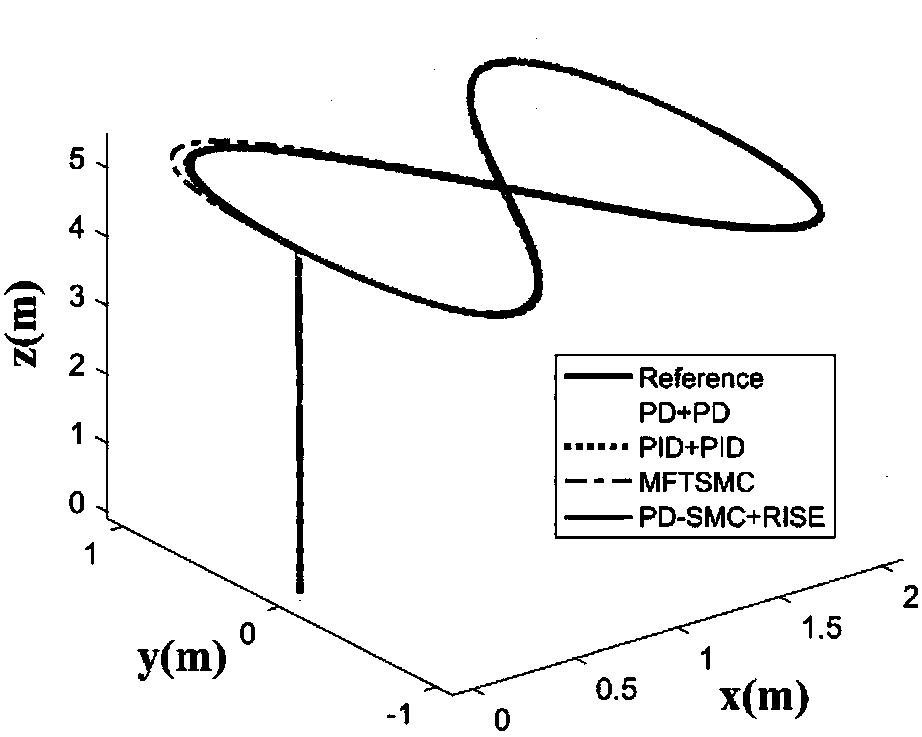

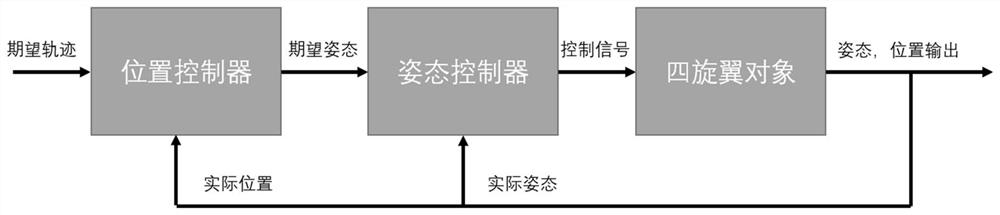

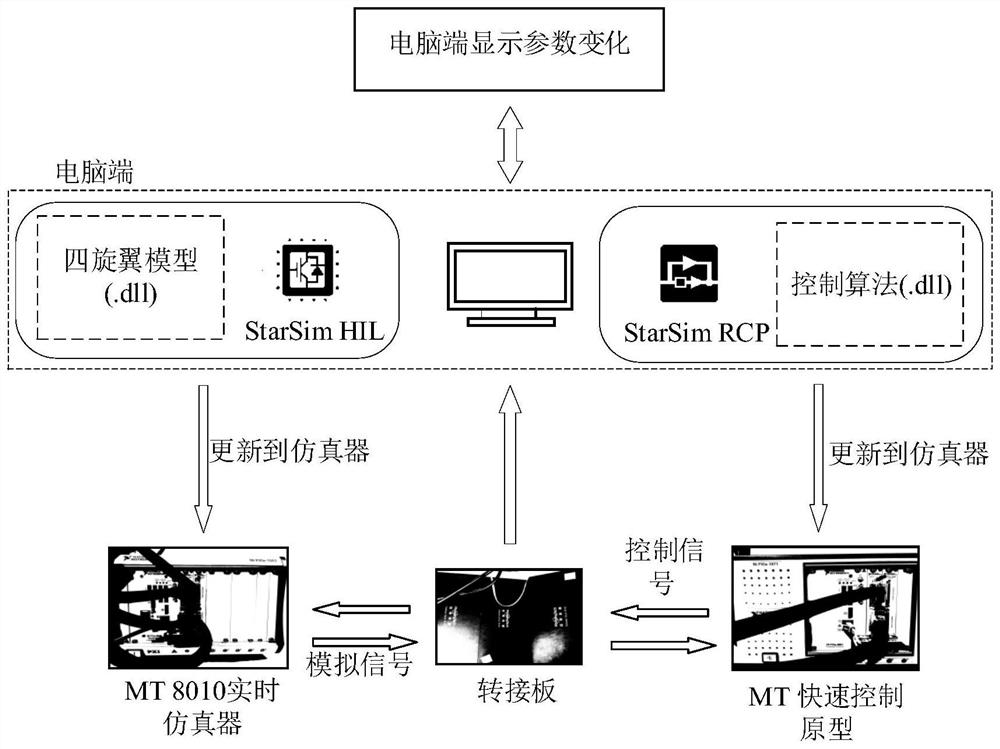

No-model quadrotor unmanned plane trajectory tracking controller and method based on PD-SMC and RISE

PendingCN108594837AReduce buffetingGood stability and effectivenessAttitude controlPosition/course control in three dimensionsAttitude controlLyapunov theorem

The invention discloses a no-model quadrotor unmanned plane trajectory tracking controller and method based on PD-SMC and RISE, and a position controller based on a PD-SMC algorithm is designed. The controller combines the characteristics that a PD controller is easy to design and an SMC controller is high in robustness, and does not need a precise outer ring model. Secondly, a posture controllerbased on an RISE algorithm is designed, and a continuous control signal of the RISE algorithm greatly reduces the vibration of a system. The beneficial effects of the invention are that the stabilities of the inner ring and outer ring subsystems are demonstrated through the Lyapunov theorem of stability. A simulation experiment result demonstrates the effectiveness of the controller proposed in the invention.

Owner:SHANDONG UNIV

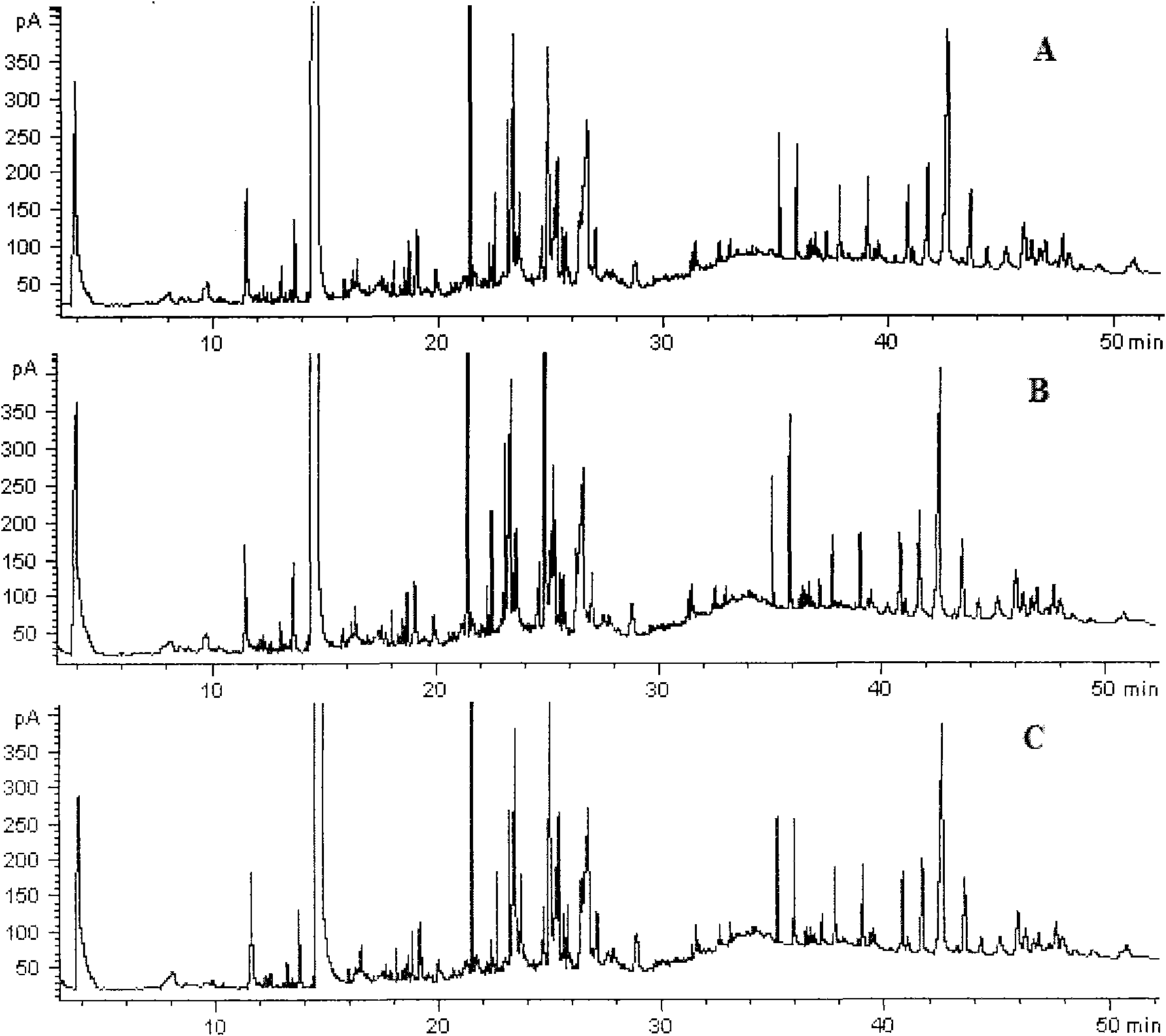

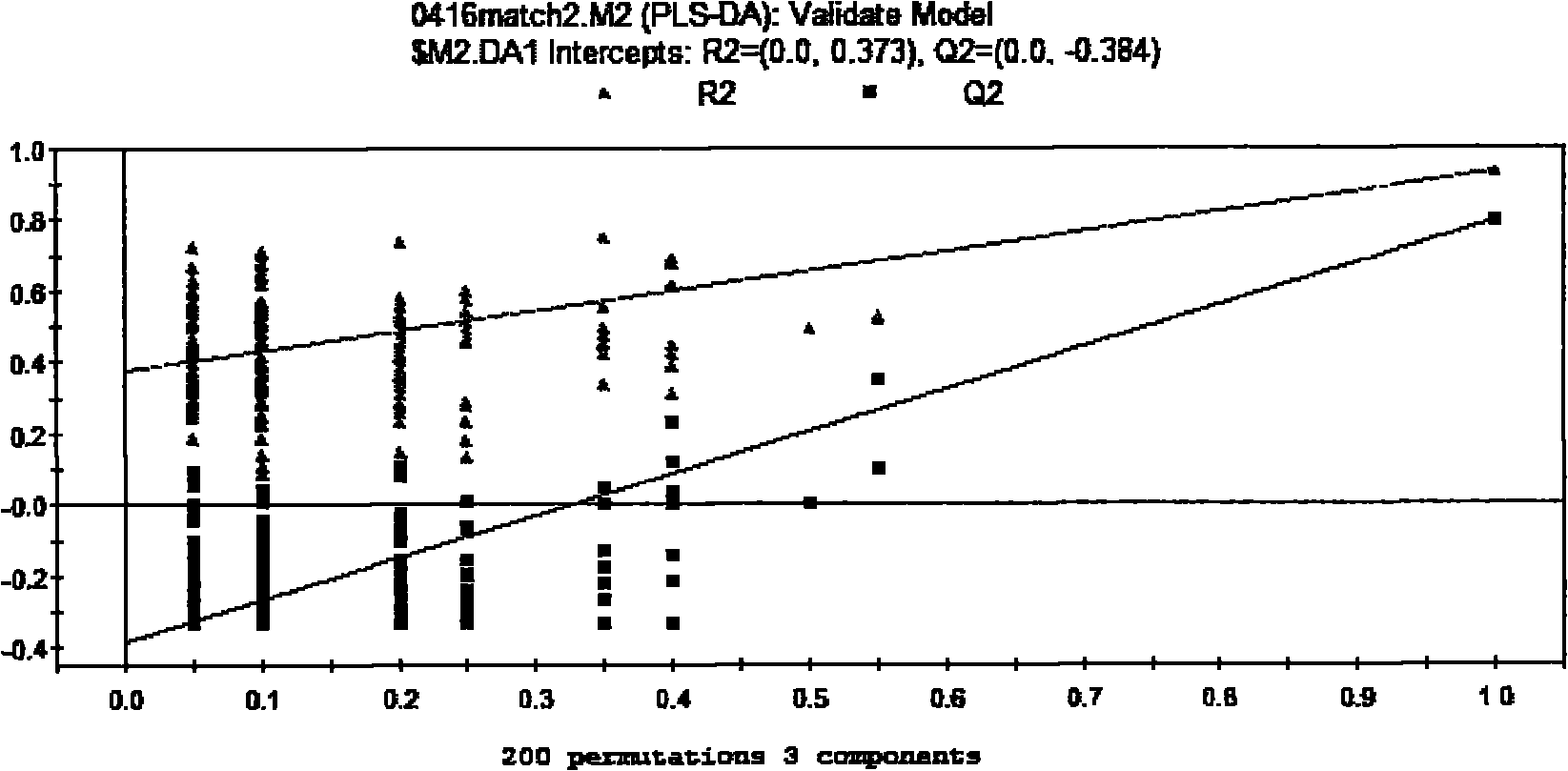

Method for discriminating cigarette brands

The invention discloses a method for discriminating cigarette brands. The method comprises the following steps of carry out analysis of cigarette cut tobacco by a gas chromatography to obtain a cigarette cut tobacco chemical fingerprint outline, and establishing a cigarette brand discriminatory analysis model by a partial least square discriminatory analysis method. The method adopts a quality control sample to monitor a whole analysis flow so that obtained modeling data is real and reliable. The method adopts a blind sample test technology to carry out a strict test on the established cigarette brand discriminatory analysis model, wherein blind samples are different batches of qualified products produced out normally and properties of the blind samples are not known by testers before tests. A result of a blind sample test shows that a correct rate of cigarette brand discriminatory analysis model prediction reaches 83.33%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

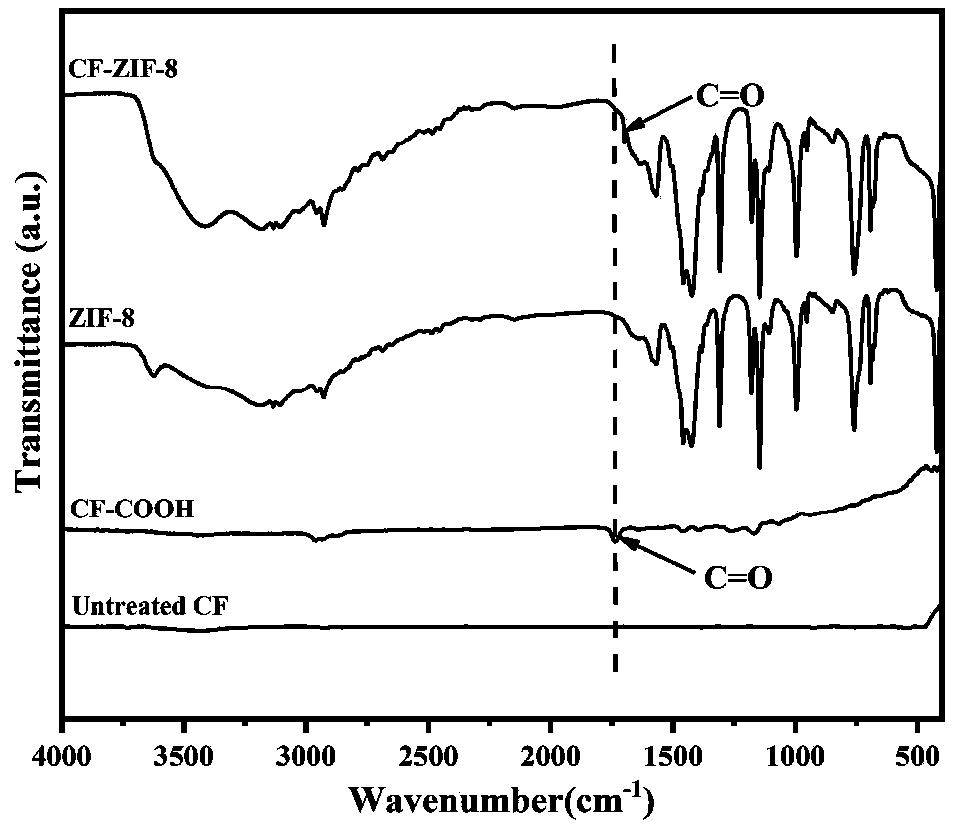

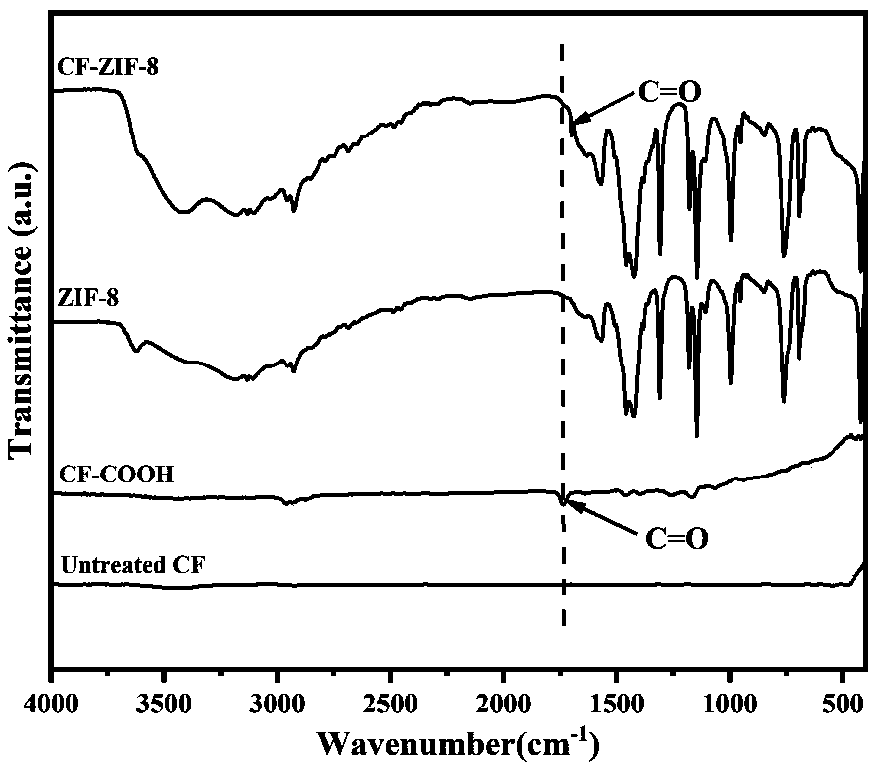

Preparation method of ZIF-8/carbon fiber composite material for adsorbing aqueous organic dye

InactiveCN109499545ALow costImprove practicalityOther chemical processesWater contaminantsFiberOrganic dye

A preparation method of a ZIF-8 / carbon fiber composite material for adsorbing an aqueous organic dye comprises the steps of carrying out strong oxidation treatment on carbon fiber cloth or a carbon fiber monofilament by using nitric acid; uniformly mixing ZnO powder and 2-methylimidazole according to a certain molar ratio; grinding an obtained mixture at a room temperature; horizontally laying thecarbon fiber cloth on a glass plate; covering one layer of mixed powder prepared in the step 2 to the carbon fiber cloth; continuing to grind the obtained mixture; when a lot of uniform powder penetrate through filaments of the carbon fiber cloth, stopping grinding; putting second layer of carbon fiber cloth and third layer of carbon fiber cloth in the same manner; repeating the steps; covering aglass plate on a mixed body of the ground cloth or monofilament and the mixed powder in the step 2; closely wrapping the mixed body by using a tinfoil; clamping the mixed body by using a fishtail clip; putting the mixed body in a drying box to be heated for reaction; after a section of time, obtaining the MOF-loaded carbon fiber cloth or the MOF-loaded carbon fiber monofilament. The preparation method of the ZIF-8 / carbon fiber composite material for adsorbing the aqueous organic dye, provided by the invention, is used for preparing MOF / carbon fiber composite materials for adsorbing the aqueous organic dyes.

Owner:CHANGCHUN UNIV OF TECH

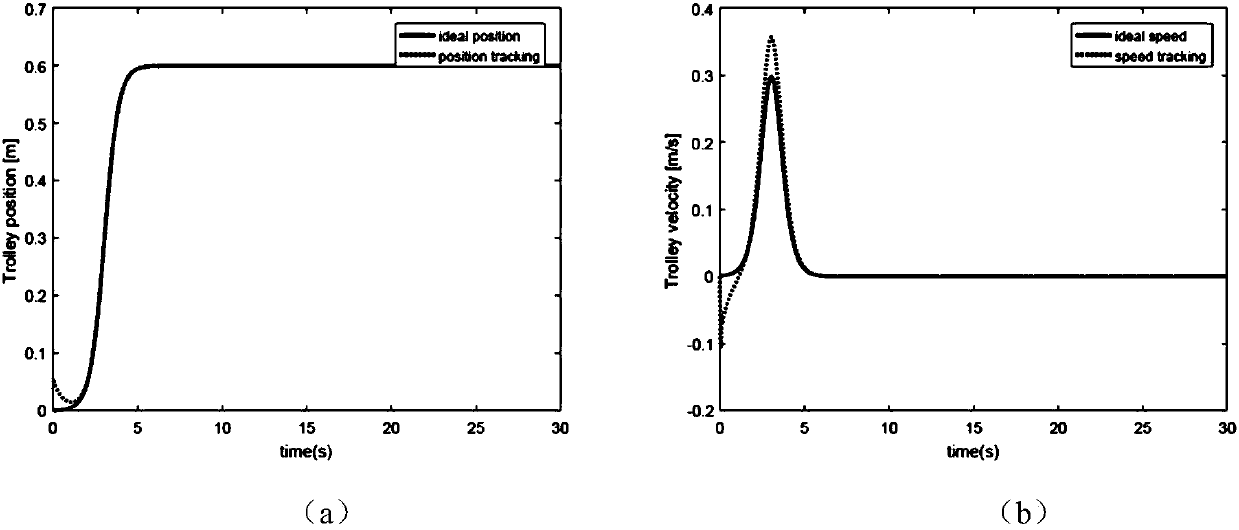

Adaptive neural network controller of bridge crane and design method thereof

PendingCN108549229AReduce the amount of data calculationQuick responseAdaptive controlLinear modelLinearization

The invention discloses an adaptive neural network controller of a bridge crane. A dynamic model of a bridge crane is established; linear processing is carried out on the dynamic model of the bridge crane; an external disturbance factor compensation item d is introduced to obtain a linear model of the bridge crane; and an adaptive neural network controller including a trolley controller and a loadcontroller is obtained based on a RBF neural network design. According to the invention, on the basis of the neural network adaptive method, the double-feedback adaptive controller is designed for trolley positioning and load oscillation prevention of the crane; and on the basis of the self-learning method, random approximation of non-linear parts like the model error and the external interference during the crane modeling process is realized, so that stability control is realized.

Owner:QUFU NORMAL UNIV

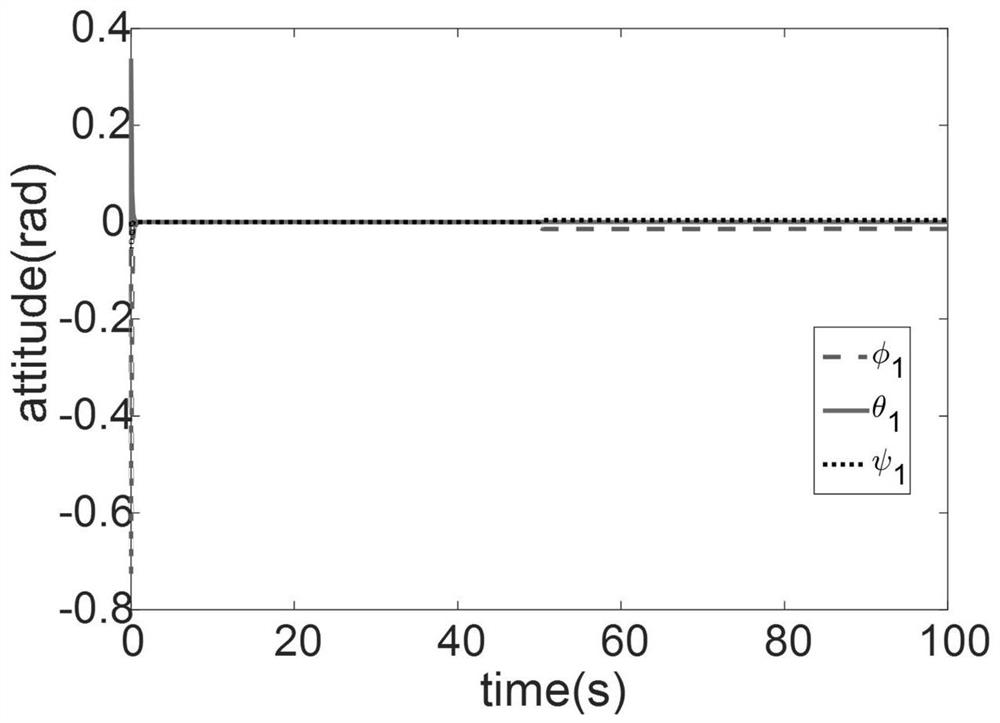

Four-rotor formation fault-tolerant control method based on adaptive neural network

ActiveCN111948944AStudy on Fault-Tolerant Control Problems of FormationProof of stabilityAdaptive controlFlight vehicleSelf adaptive

The invention discloses a quad-rotor formation fault-tolerant control method based on an adaptive neural network. Possible external interference in a formation control system comprising a plurality ofquad-rotor aircrafts is considered, a quad-rotor aircraft formation flight controller is designed through formation error information, a neural network is used to compensate the loss caused by a fault, and the Lyapunov stability theory is used to prove the stability, robustness and fault tolerance of the formation controller; on the basis of an adaptive neural network control method, an attitudefault-tolerant controller of a four-rotor inner ring is designed, the attitude fault-tolerant control effect is effectively improved, and it is proved by using the Lyapunov stability theory that the system can still track the expected attitude under the condition that an actuator fault occurs again.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

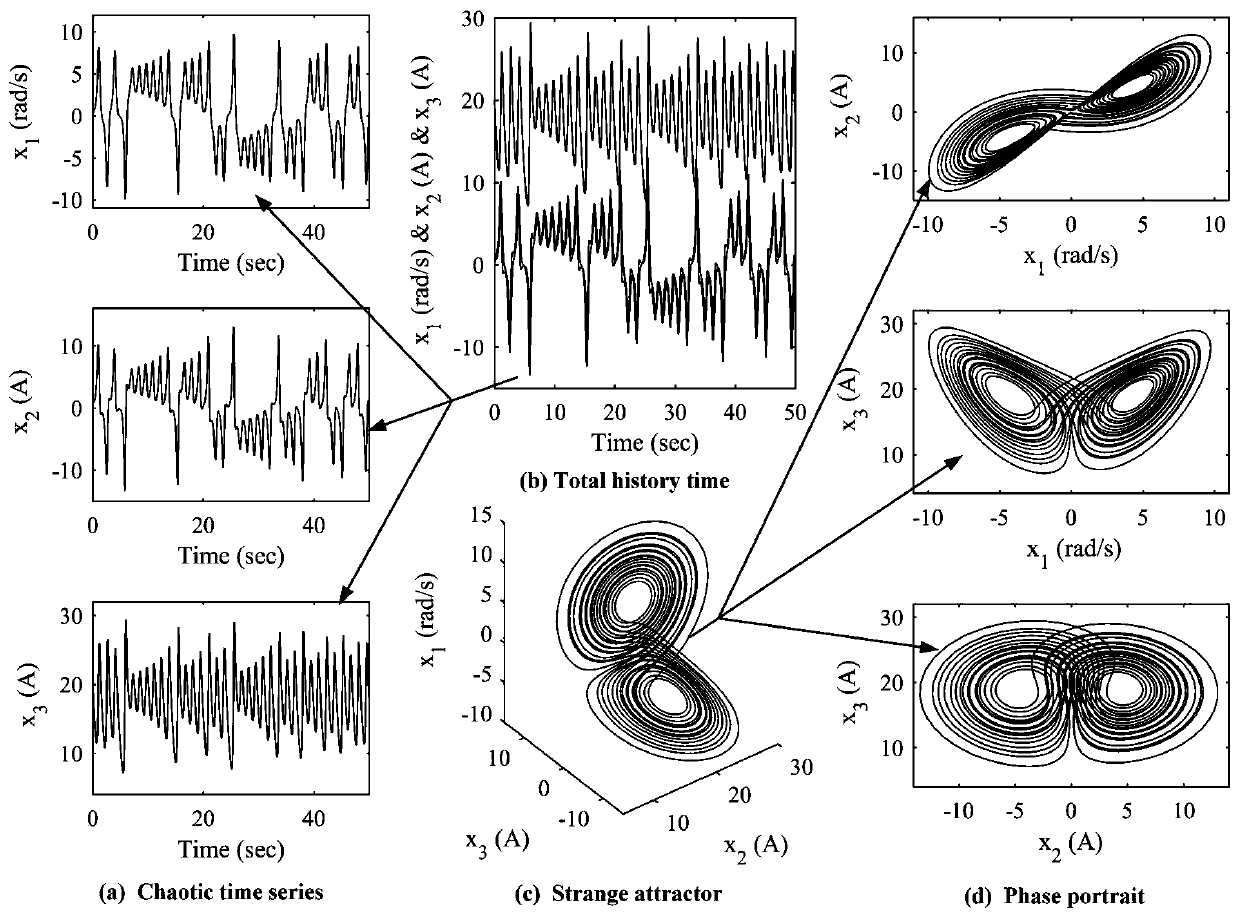

PMSM chaotic system neural network inversion control method

ActiveCN110336506AProof of stabilityControl Transient PerformanceElectronic commutation motor controlElectric motor controlDynamic modelsChaotic systems

The invention discloses a PMSM chaotic system neural network inversion control method, which comprises steps: 1) a dynamic model of the PMSM system is built; 2) a robust neural network adaptive tracking controller is built, system output tracking errors have set performance constraints, a non-strict feedback control structure and a PP-TBLF are combined, the controller for the permanent magnet synchronous motor system adopts the neural adaptive tracking control scheme of the inversion technique, during a recursive process, a Chebyshev neural network, Lyapunov functional, Nussbaum functional anda differential tracker are used respectively to process unknown nonlinearities, time delay, unknown gain symbols, and complexity explosions. The system stability can be realized, and the versatilityand the reliability of the system are enhanced.

Owner:GUIZHOU UNIV

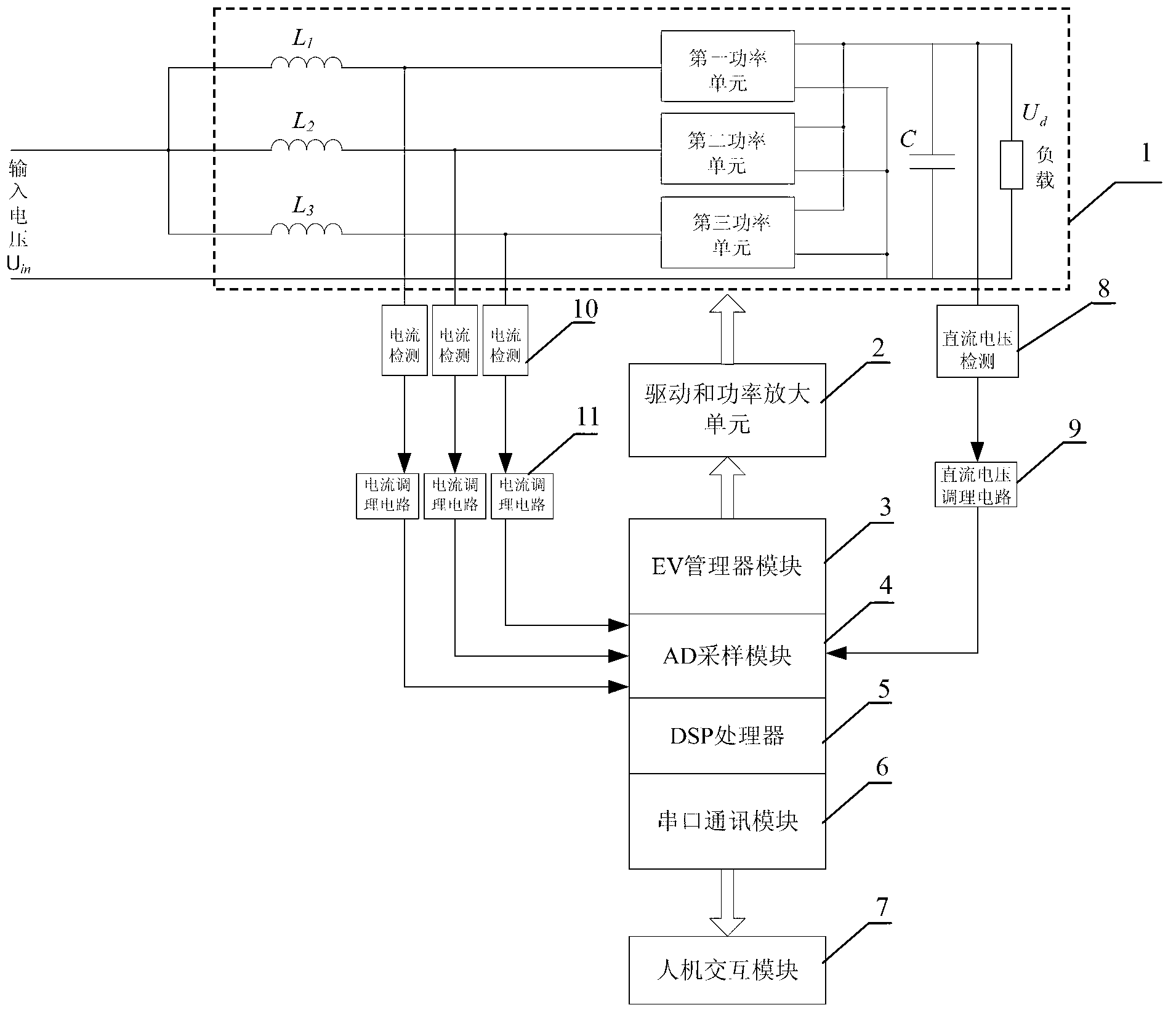

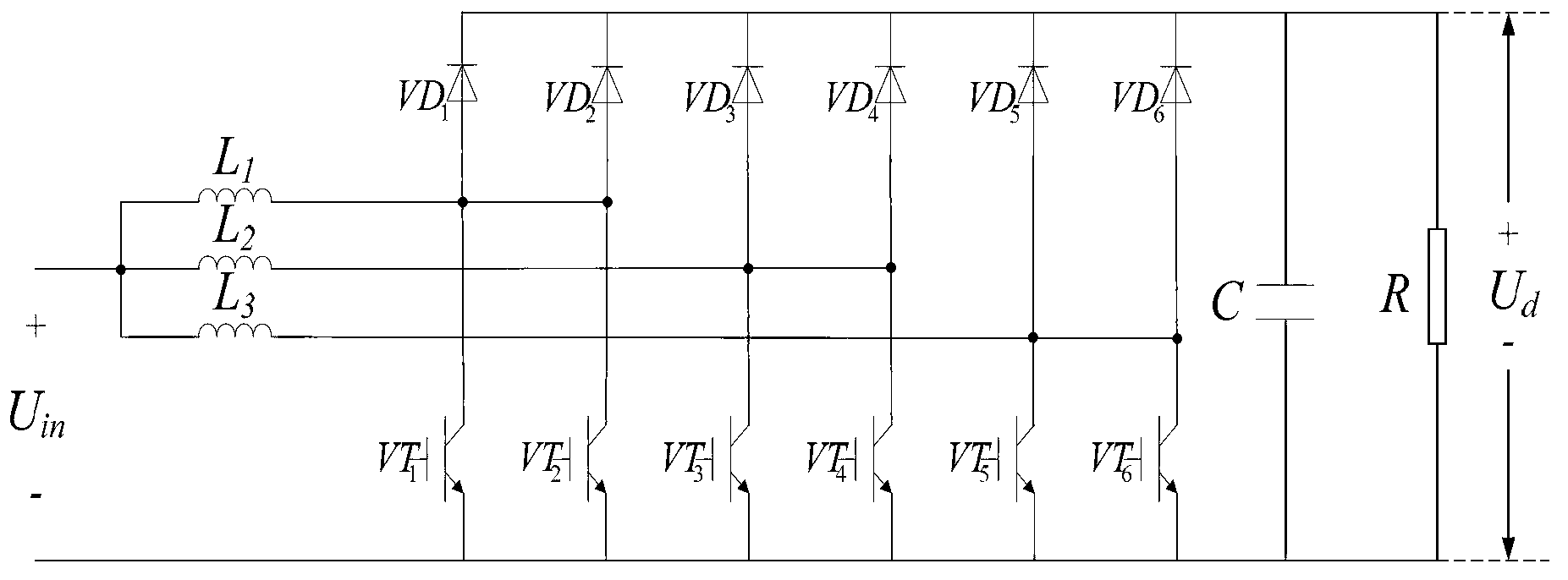

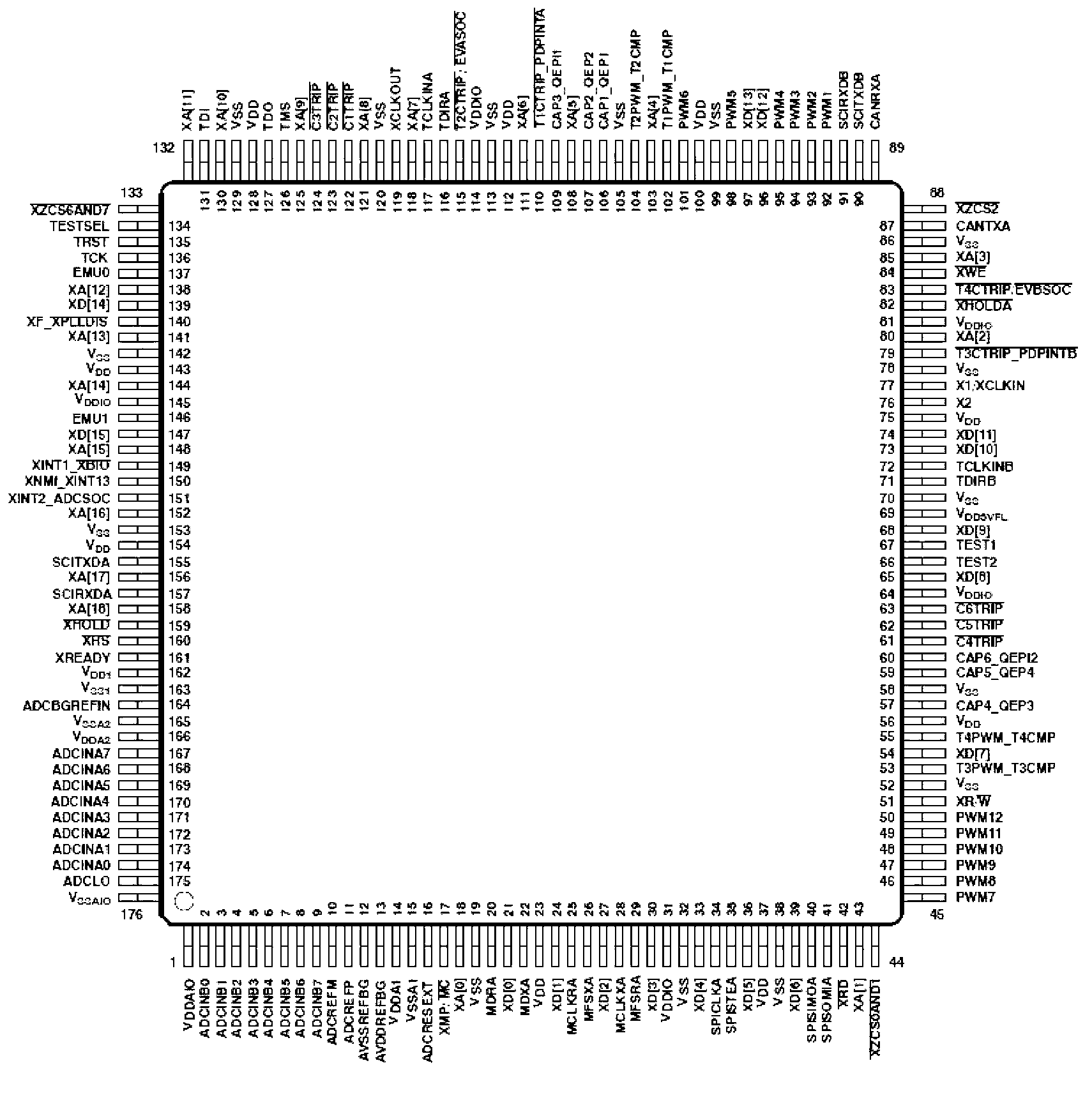

High-frequency multiphase interleaved conversion device and control method

InactiveCN103312165AReduced Power RequirementsReduce manufacturing costDc-dc conversionElectric variable regulationSwitching frequencyElectric vehicle

The invention relates to a high-frequency multiphase interleaved conversion device and a control method, and belongs to the field of power electronics and electric drive. The device comprises a drive and power amplification unit, an EV (Electric Vehicle) manager module, an AD (Analog-Digital) sampling module, a DSP (Digital Signal Processor) processor, a serial port communication module, an HCI (Human-Computer Interaction) module, a DC (Direct Current) voltage detection circuit, a DC voltage conditioning circuit, a current detection circuit, a current conditioning circuit and a main circuit. The system adopts a double closed-loop control technology and a new topological structure to realize system stability and broad stability margin; three inductors at the front end of the topological structure work alternately, and the equivalent switching frequency is 6 times of the traditional switching frequency, so that the whole converter has high frequency, and the output voltage and the ripple amplitude and harmonic component of current are reduced; and the equal-time work of the three front-end inductors per unit time reduces the power requirements on power components IGBT (Insulated Gate Bipolar Transistor) and diodes, reduces the manufacturing cost of the whole device, and improves the application value of the DC converter.

Owner:NORTHEASTERN UNIV +1

Back-stepping robust self-adaptive dynamic surface-based near-space aircraft control system

The invention discloses a back-stepping robust self-adaptive dynamic surface-based near-space aircraft control system. The system comprises the steps of: initially employing interpolation fitting to obtain an aerodynamic parameter of an aircraft cruising segment, and building a longitudinal uncertainty strict feedback block non-linear model of an aircraft; secondly, separately controlling speed and height according to state variable characteristic of the aircraft, sequentially solving a control signal by a back-stepping method, approaching unknown interference by employing a RBF neural network, and updating the parameter on line and in real time; and finally, adding a dynamic surface control method with regard to the problems of virtual control signal derivation difficulty and differentialexpansion. By the system, the problems of virtual control signal derivation difficulty and differential expansion are solved, and the system has favorable tracking property and robustness.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

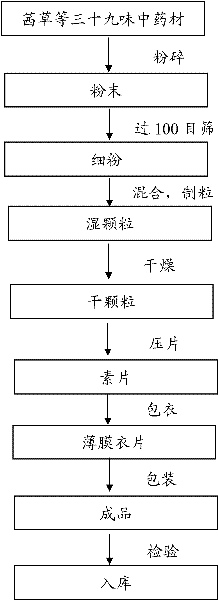

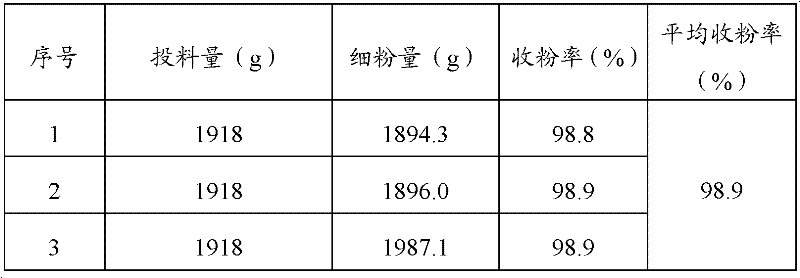

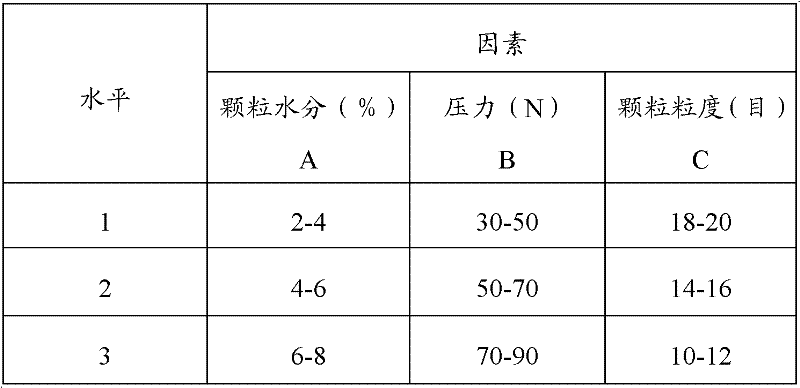

Preparation method of Chinese medicinal tablet for treating skin diseases

ActiveCN102178874AQuality improvementImprove quality stabilityAnthropod material medical ingredientsPill deliveryDiseasePositive control

The invention discloses a preparation method of a Chinese medicinal tablet for treating skin diseases. The preparation method comprises the following steps of: mixing and crushing raw materials; sieving with a 100-mesh sieve; granulating by taking 15% starch slurry as adhesive; tabletting under the conditions that the pressure is 70-90N, the granularity is controlled at 18-20 meshes and the moisture content is controlled at 4-6%; coating by using an Opadry AMB coating solution of which the concentration is 5% under the condition that the flow is 0.25-0.28kg / min; and then, preparing the Chinese medicinal tablet under the conditions that the temperature of a tablet core is 50 DEG C and the rotating speed is controlled at 7-9 revolutions / minute. The crushing yield is 98.9%, the disintegration time is controlled at 22 minutes, and the coating qualification rate reaches 98.8%. In the prepared Chinese medicinal tablet, the dissolution rate of Chinese medicinal components is improved by 45.2%, and the bioavailability is improved to 89.7%, thereby being suitable for industrialized production. By carrying out clinical verification on patients, compared with positive control drugs, the effect taking rate and the total effective rate are obviously improved (P<0.05).

Owner:史志辉 +1

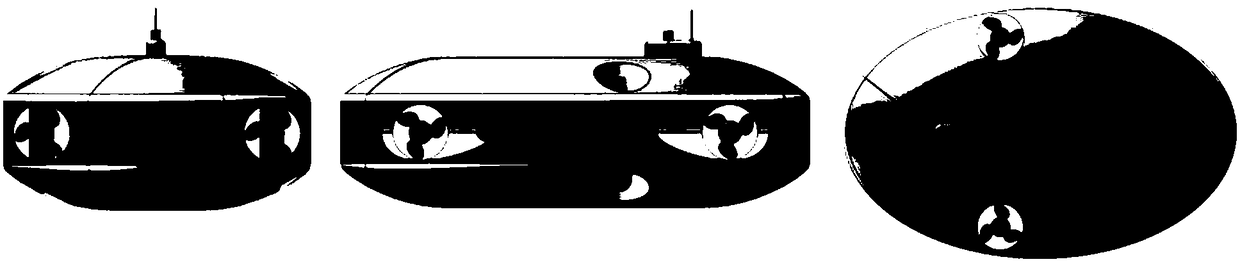

Track tracking control method for seabed flight nodes

ActiveCN109343347AAchieving Overshoot LimitationProof of stabilityAdaptive controlSix degrees of freedomPerformance function

The invention provides a track tracking control method for seabed flight nodes, and relates to a track tracking control method for seabed flight nodes. The object of the invention is to solve the problems that an existing method lacks the control capability of the track tracking error convergence dynamic process, and is difficult to realize the overshoot limit, preset of the error convergence timeand the tracking with any precision. The specific process comprises the following steps of: step 1, establishing the dynamics model of the OBFN based on the Fossen outline six-degree-of-freedom nonlinear model; step 2, transforming the established dynamics model of the OBFN to obtain a transformed dynamics model of the OBFN; step 3, defining a performance function; step 4, performing error transformation on the transformed dynamics model of the OBFN obtained in step 2 according to a three-defined performance function; step 5, selecting radial basis function neural network parameters; and step6, designing an adaptive track tracking controller based on step 4 and 5. The track tracking control method for seabed flight nodes is applied to the track tracking control field of seabed flight nodes.

Owner:HARBIN ENG UNIV

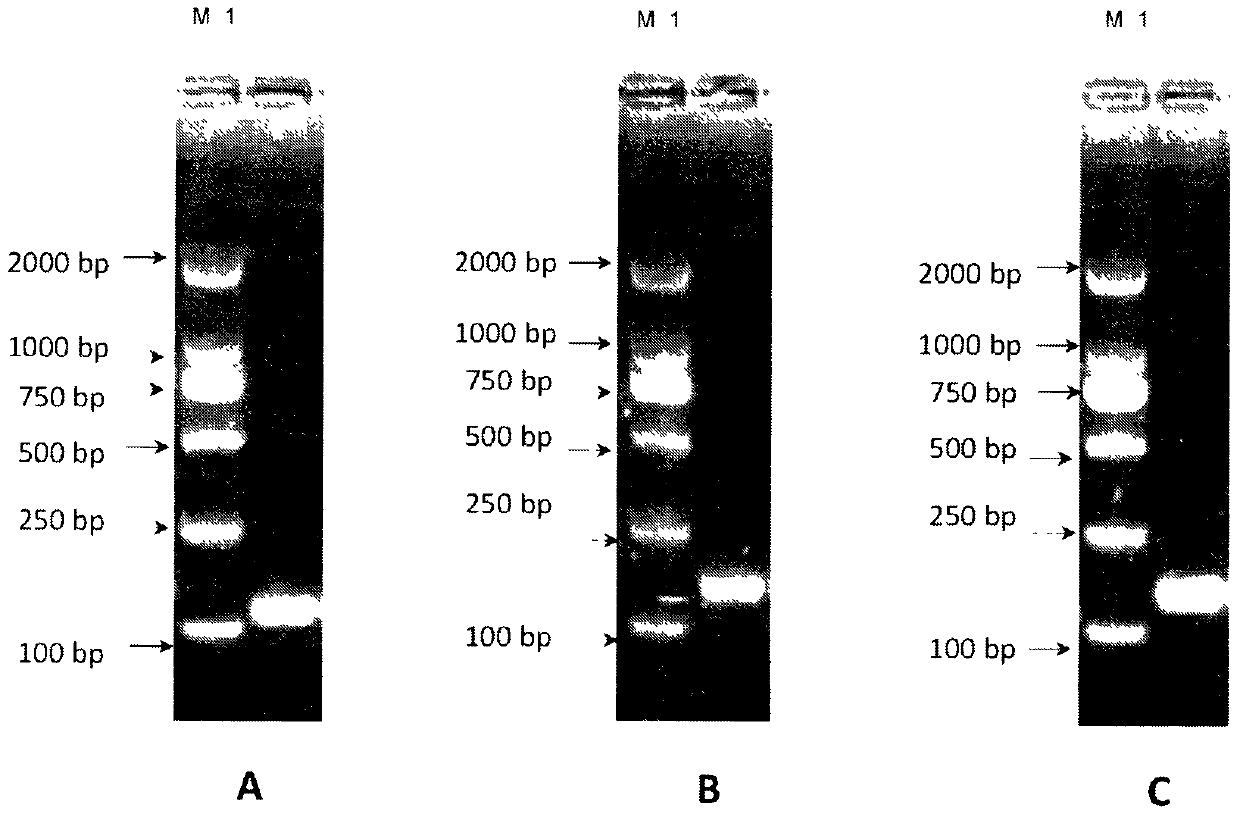

BVDV (bovine viral diarrhea virus) internal control typing fluorescent PCR (polymerase chain reaction) detection kit and preparation thereof

InactiveCN103725796AShort detection timeShorten detection timeMicrobiological testing/measurementFluorescence/phosphorescenceBovine Viral Diarrhea VirusesComplementary deoxyribonucleic acid

The invention discloses a BVDV (bovine viral diarrhea virus) internal control typing fluorescent PCR (polymerase chain reaction) detection kit and a preparation thereof. By means of the primer design, a BVDV I, a BVDV II and a PCR template for monitoring internal control are obtained through single PCR amplification, a BVDV internal control typing fluorescent PCR detection system is established through the primer design, PCR amplification and optimization of reaction conditions, the BVDV I and the BVDV II can be independently detected or synchronously detected, and quality monitoring can be performed on the detection result. The prepared kit comprises two parts of a cDNA (complementary deoxyribonucleic acid) synthesis system and an SYBR fluorescent PCR amplification system. The minimum detection limit of the kit to three types of genes is 102 copy, the kit has better specificity and repeatability, the detection quality is ensured, and the kit has a better application value.

Owner:XINJIANG AGRI UNIV +1

Four-rotor self-adaptive dynamic surface sliding mode controller based on output feedback

ActiveCN111766889ALighten the computational burdenEliminate the "differential explosion" problemSustainable transportationAttitude controlPerformance functionFlight vehicle

The invention discloses a four-rotor self-adaptive dynamic surface sliding mode controller based on output feedback. The four-rotor self-adaptive dynamic surface sliding mode controller comprises thefollowing steps: 1) constructing a four-rotor system model containing model parameter uncertainty; 2) introducing an error performance function, converting the tracking error of the four-rotor systeminto a new error constraint variable, and ensuring that the system achieves predetermined tracking performance; 3) designing a fuzzy logic system approximator for approximating complex and uncertain unknown items existing in the four-rotor aircraft, and replacing each item of the estimated weight vector with a norm of the estimated weight; 4) designing a nonlinear state observer to estimate the unmeasurable angular velocity state of the four-rotor aircraft; and 5) combining the dynamic surface with sliding mode control, and designing the four-rotor adaptive fuzzy dynamic surface sliding mode controller based on output feedback. The controller designed by the invention can ensure the flight quality of the four rotors, improve the robustness of the system, and realize that the tracking effect meets the preset conditions.

Owner:NORTHEAST DIANLI UNIVERSITY +2

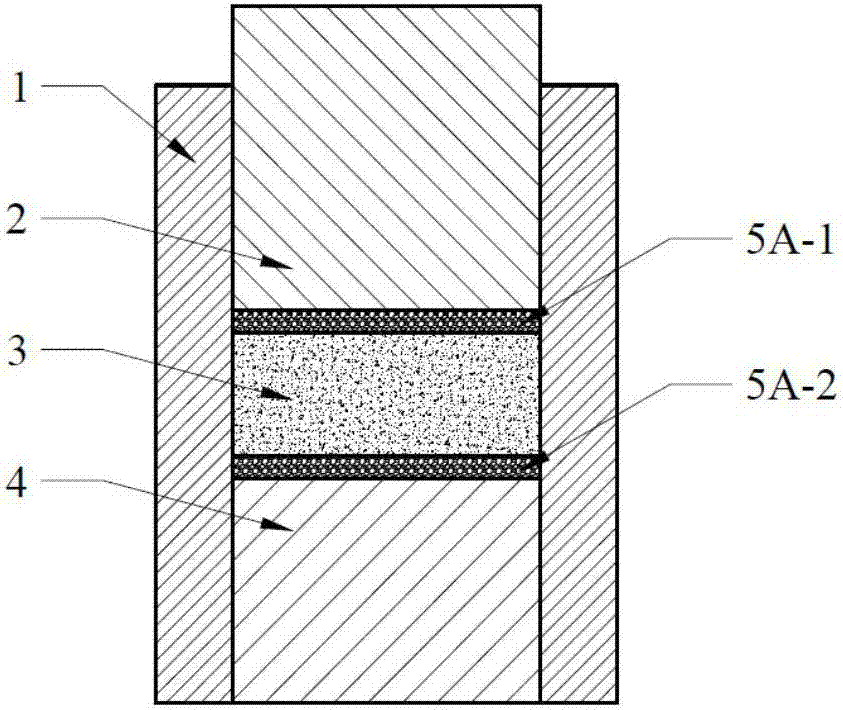

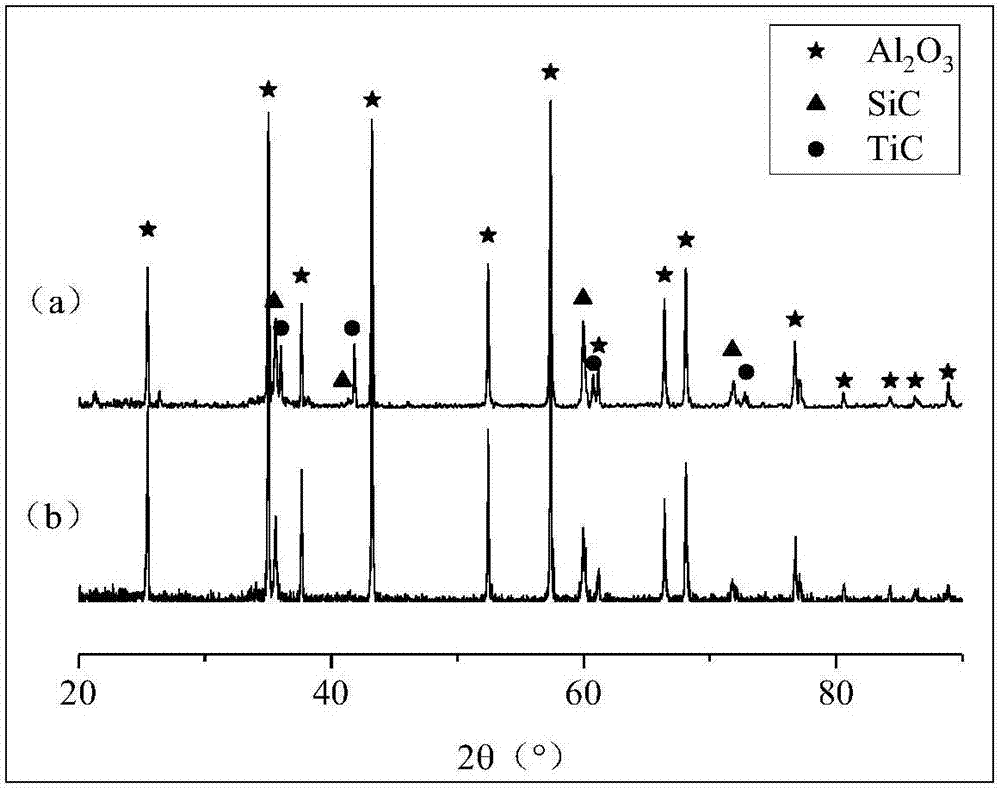

Hot pressed sintering preparation technology capable of improving density of ceramic material

The invention relates to the technical field of hot pressed sintering preparation technologies of ceramic materials, in particular to a hot pressed sintering preparation technology capable of improving density of a ceramic material. The hot pressed sintering preparation technology comprises the following steps: putting presintered ceramic powder into a graphite sleeve mould, mounting a high-strength graphite pushing block at the lower part of the graphite sleeve mould, mounting a high-strength graphite upper pressure head at the upper part of the graphite sleeve mould, respectively placing high-strength graphite powder at contact positions between the presintered ceramic powder and the upper pressure head as well as the pushing block as isolation materials, putting into a hot pressed sintering furnace, and sintering according to a sintering technology. The hot pressed sintering preparation technology provided by the invention has the advantages that operation processing is simple, the high-strength graphite powder is easy to prepare, economical and environment-friendly; sintering density and uniformity of a ceramic cutter material prepared by adopting the hot pressed sintering technology are respectively greatly improved, so that the hardness of the material is also obviously improved; and the hot pressed sintering preparation technology is also applicable to development and preparation of structural parts such as wear-resistant ceramic and high-hardness ceramic and has great application potential in the fields of cutter materials, aerospace and the like.

Owner:SHANDONG UNIV

Fault tolerance control system of uncertain system with performer fault

ActiveCN108646712AProof of stabilityProgramme controlElectric testing/monitoringPacket lossActuator fault

The invention discloses a fault tolerance control system of an uncertain system with a performer fault. A sensor, a controller and a performer in the network all uses a time driven manner, sampling time are synchronized, possible packet loss in the network transmission process is taken into consideration, switches are added between the sensor and the controller and the controller and the performerrespectively to model data packet loss, a model of a controlled object is established, and whether the performer works normally is determined according to a performer fault matrix. The fault tolerance control system has the advantages of being stable, and capable of carrying out fault tolerance control effectively.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

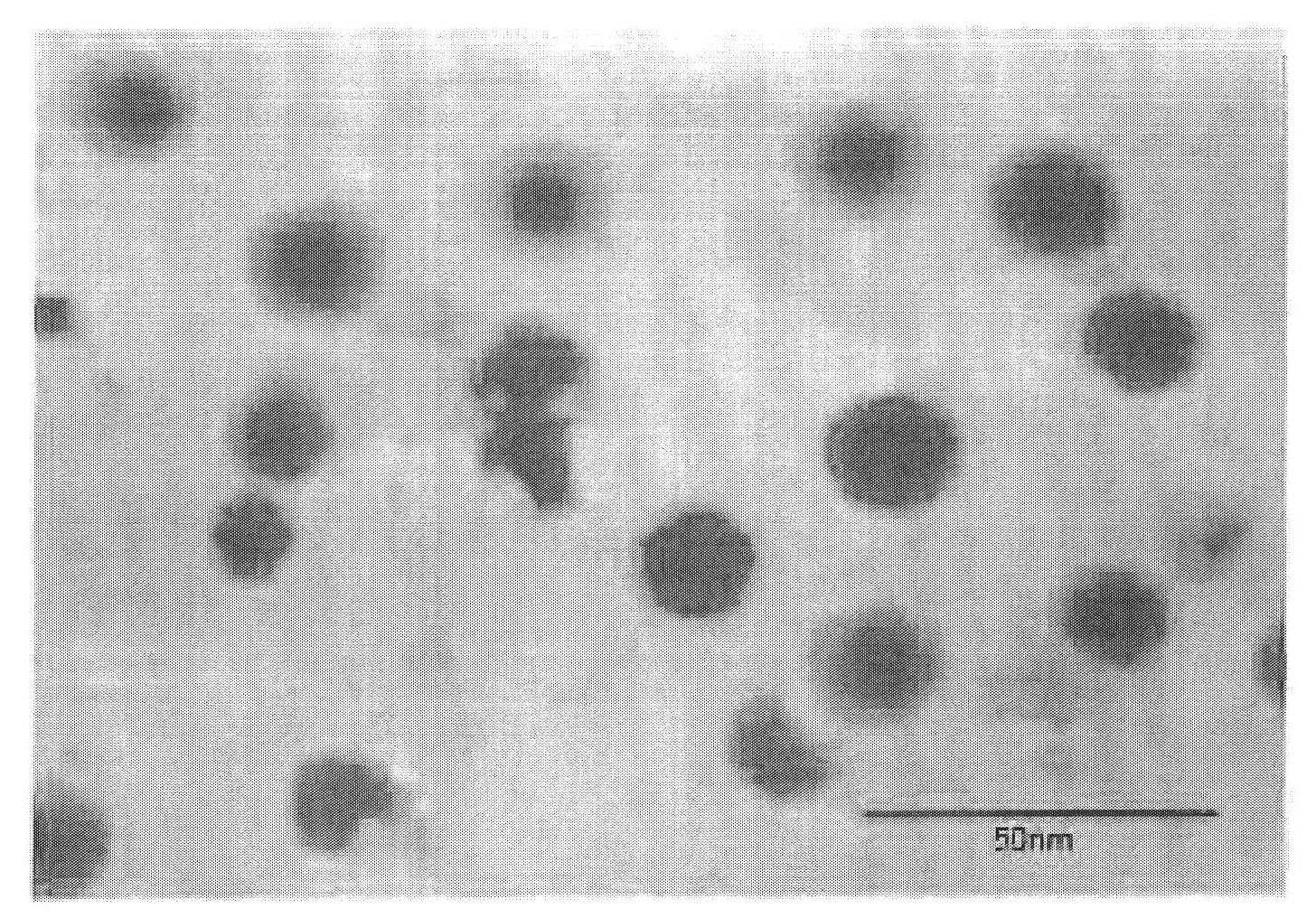

Compound sodium selenite-vitamin E oral nano-emulsion preparation for livestock and preparation method thereof

InactiveCN101982176ASimple production processEasy to operateAntibacterial agentsOrganic active ingredientsSolventRaw material

The invention relates to a compound sodium selenite-vitamin E oral nano-emulsion preparation for livestock and a preparation method thereof. The compound sodium selenite-vitamin E oral nano-emulsion preparation for livestock is prepared from the following raw materials by mass volume percent: 5 to 10% of vitamin E, 15 to 35% of emulsifier, 7.5 to 17.5% of auxiliary emulsifier, 0.1% of sodium selenite, 0.1% of antioxidant and preservative and the balance solvent. The sodium selenite-vitamin E nano-emulsion of the invention is clear and bright emulsion which consists of self-emulsified nano-particles and is a self-emulsified clear and transparent thermodynamically stable system; and the production process is simple and facilitates mass production.

Owner:QILU ANIMAL HEALTH PROD

Permanent magnet synchronous motor position sensorless control based on non-singular terminal sliding mode

ActiveCN109951121ASimple designImprove performanceElectronic commutation motor controlVector control systemsTerminal sliding modePermanent magnet synchronous motor

The invention relates to a permanent magnet synchronous motor position sensorless control based on a non-singular terminal sliding mode and belongs to the technical field of motor control. The specific steps comprise a step of firstly designing an integral non-singular fast terminal sliding surface, a step of designing a sliding mode observer and designing a control rule of a terminal sliding modeobserver with the combination of a fast power approach law, and a step of performing stability analysis on the designed observers. According to the invention, the rotor position and rotation speed estimation accuracy of a permanent magnet synchronous motor can be effectively improved, the design is simple and the engineering realization is easy, and the invention has a high application value.

Owner:ANHUI UNIV OF SCI & TECH

Robust adaptive spatial flexible system expansion control method based on neural network

ActiveCN108319135AProof of stabilitySatisfy state constraintsAdaptive controlDynamic modelsClosed loop

The invention relates to a robust adaptive spatial flexible system expansion control method based on a neural network. The method comprises the steps that a dynamic model of a space fly-net robot suitable for the design of a controller is established; the controller input U of the dynamic model is designed under the condition that the state of autonomous maneuvering units is limited; for the designed controller, the stability of a closed-loop system is proved; and for the designed controller, the autonomous maneuvering units are proved to satisfy the state constraint. The method has the advantages that the actual condition of the state constraint, which is caused by tether connection, of the autonomous maneuvering units is considered; the robust adaptive distributed consistency control method based on the neural network is used to design the controller for the space fly-net robot during deployment under a bounded disturbance condition; four autonomous maneuvering units can achieve thedesired state while satisfying the state constraint; the synergy consistency of configuration is realized; the flutter of a flexible network is reduced; and a good flexible network type is maintained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

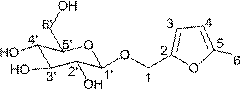

Preparation method and application of 5-methyl furfuryl alcohol-beta-D-glucoside

InactiveCN108440618AImprove sensory qualityImprove aroma volume and aroma qualityTobacco preparationSugar derivativesFurfuryl alcoholSodium methoxide

The invention provides a preparation method of 5-methyl furfuryl alcohol-beta-D-glucoside. The preparation method is characterized in that firstly, trichloroacetimidate sugar and 5-methyl furfuryl aresubjected to glycosylation reaction; then, a methanol solution of sodium methoxide is used for deacetylation to obtain the 5-methyl furfuryl alcohol-beta-D-glucoside. The method has the advantages that the reaction conditions are mild; the aftertreatment is simple; through simple and short steps, the preparation of the 5-methyl furfuryl alcohol-beta-D-glucoside is convenient. When the 5-methyl furfuryl alcohol-beta-D-glucoside is applied into cigarettes for perfuming, the fragrance quality and the fragrance quantity of the cigarettes can be improved; the farraginous gas is lightened; the irritation is reduced; the aftertaste is pure. The 5-methyl furfuryl alcohol-beta-D-glucoside has good cigarette perfuming stability.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

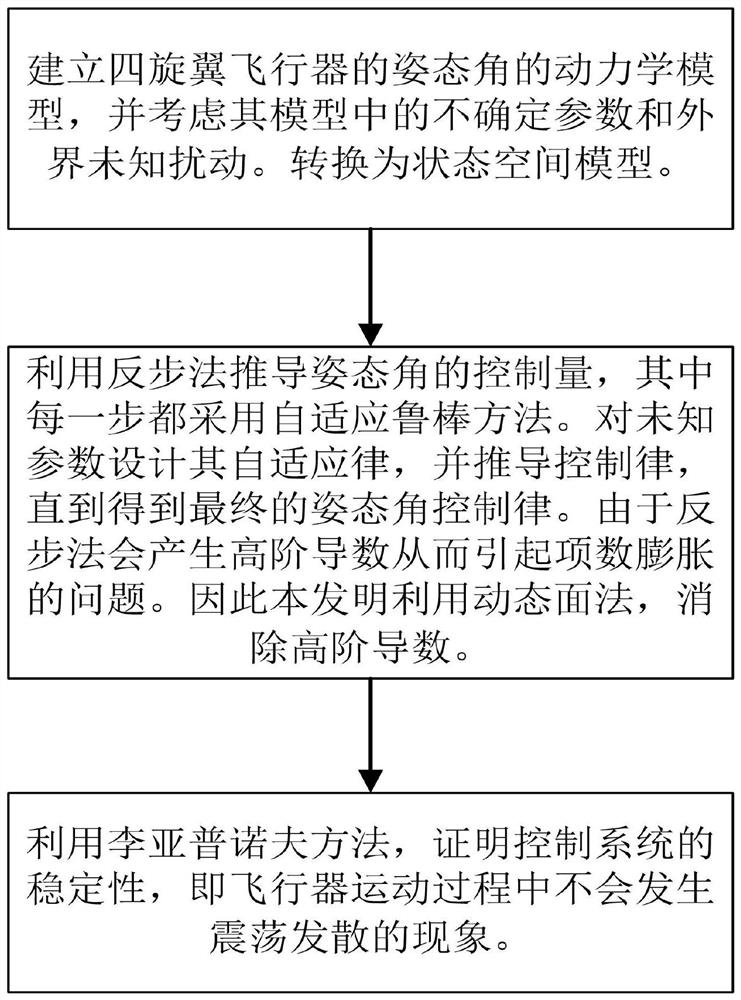

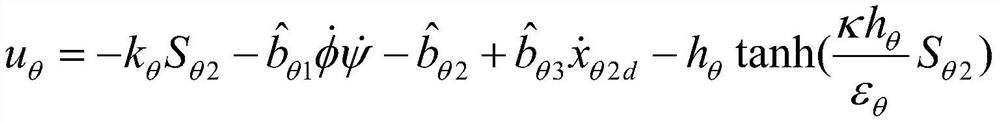

Attitude control method of rotorcraft

PendingCN112578805AEasy to adjustReduced accuracy requirementsAttitude controlSustainable transportationProportional integral differentialBackstepping

The invention relates to an attitude control method of a rotorcraft, which is used for controlling a pitch angle, a roll angle and a yaw angle of the rotorcraft, establishing a kinetic model of the attitude angle of the rotorcraft, estimating unknown parameters in the kinetic model in real time by using an adaptive method, compensating the uncertainty of the kinetic model, improving the robustnessof the control system by using a robustness method, and enhancing the anti-interference capability. Each attitude angle system is a second-order system, a backstepping method is adopted for derivation, derivation is sequentially carried out from the first order, a self-adaptive robust method is adopted for solving a result of each order, and finally the control law of the attitude angle is obtained. According to the method, the attitude angle is controlled by adopting a self-adaptive robust method, control parameters do not need to be accurately set like PID control (proportional-integral-derivative control), only the control parameters need to be large enough within a certain range, and parameter adjustment is simpler and more convenient; the requirement for the accuracy of the model isnot high, unknown parameters can be accurately estimated, and the tracking accuracy of expected signals is improved.

Owner:湖北航天飞行器研究所

Anti-interference adaptive dynamic planning method for CACC system

ActiveCN112034859AStability is quickly achievedProof of stabilityPosition/course control in two dimensionsVehiclesDynamic planningInterference resistance

The invention provides an anti-interference adaptive dynamic planning method for a CACC system, and relates to the technical field of heterogeneous motorcade control. According to the ADP motorcade cooperative control method based on data driving, the motorcade stability problem under the condition that actuator delay, external interference and front vehicle interference exist at the same time issolved through model building and the ADP motorcade cooperative control method based on data driving, and the motorcade can rapidly reach the stable state through the ADP motorcade cooperative controlmethod. In terms of vehicle stability analysis, the stability of a vehicle is proved by analyzing the size of the cost function updated by a controller. Through analysis, the cost function is boundedand is smaller than the minimum value, and it is proved that the state of the vehicle and the control input reach the stable state.

Owner:东北大学秦皇岛分校

Puffer fish fine processing method

The invention relates to a method of fine processing of puffer fish. Firstly, puffer fish is cleaned and treated to remove blood, and then the detoxication treatment is performed by cutting off the fish fins, the mouth, the skin, the eyes, the gill and the viscera. Secondly, the edible part treatment is performed and comprises head, body and bone treatments. Further, the blood, the mucosa, the mucilage, the subcutaneous tissue, the fin, the skin, the mouth, the eyes, the gill and the viscera produced in the process are collected and placed in a dish for inedible parts. Finally, the treated muscle, head, rib and spinal bone are soaked in clear water for 3-6 hours at 0-2 DEG C (the soaking water is replaced for 3 times) and then placed in a dish for edible parts. The method reduces tetrodotoxin and inedible parts to the greatest extent, ensures the safety and sanitation of the processed puffer fish products, and ensures the safety and stability in edibility of puffer fish after long-term preservation.

Owner:OCEAN UNIV OF CHINA

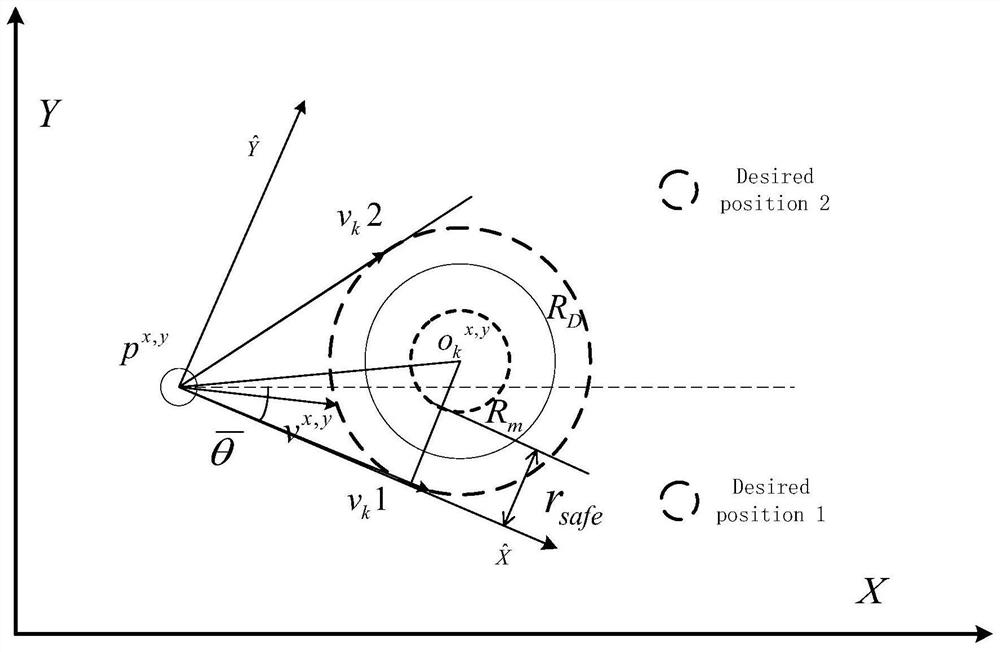

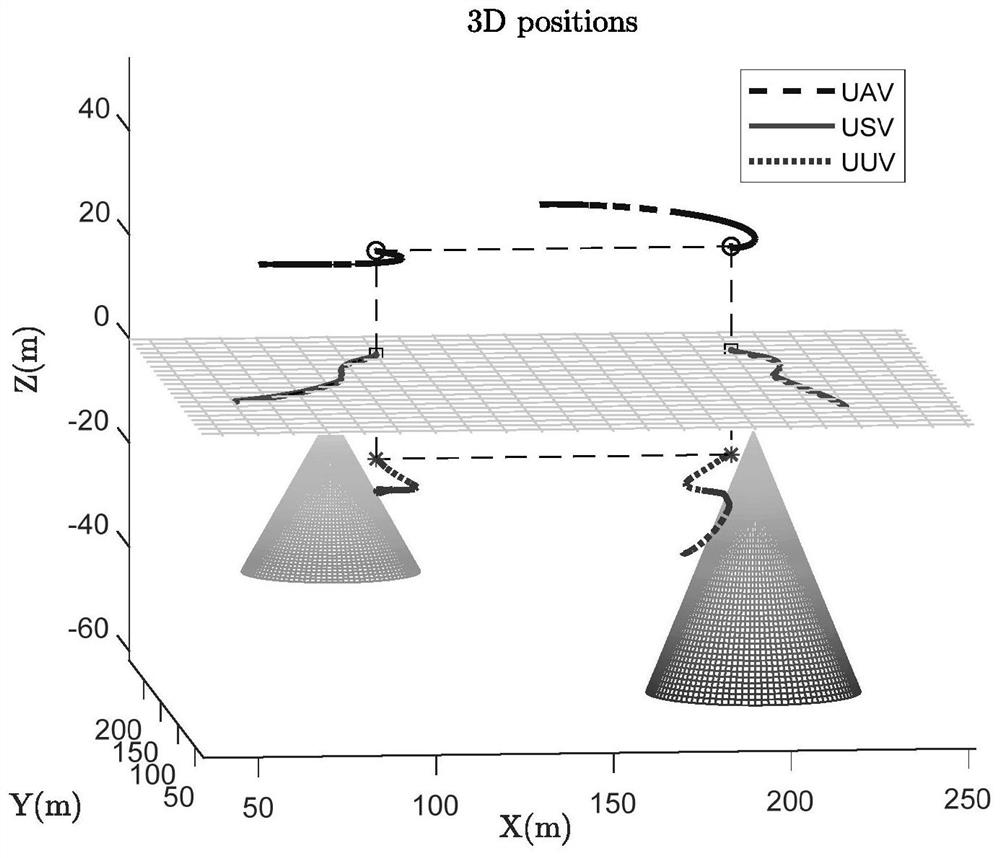

Water area heterogeneous multi-unmanned-vehicle consistent formation method

PendingCN113721638AProof of stabilityExcellent indicatorsAltitude or depth controlObstacle avoidanceAerospace engineering

The invention provides a water area heterogeneous multi-unmanned-vehicle consistent formation method. The method aims at solving the problem of model heterogeneity of unmanned aerial vehicles in different environments, such as the problem of environment difference of unmanned aerial vehicles, unmanned ships and underwater vehicles in a water area environment. Consistency control laws of three heterogeneous models are respectively designed by considering environmental parameters and differences of different motion space dimensions, the design process of the consistency algorithm is re-deduced, the stability is proved through block Kronecker product and matrix transformation, and some sufficient conditions for parameter selection are given. According to the invention, the optimization problem and the obstacle avoidance problem in the forming process are considered, different areas such as a circle and a peak threat model are introduced for the obstacle avoidance model problem in an actual water area, and different potential function expressions are constructed. Then the heterogeneous multi-agent system is converted into a closed-loop error system, formation control, an obstacle avoidance optimization function and an index function are defined, and a consistent non-quadratic obstacle avoidance optimal control strategy is deduced by adopting an inverse optimal control algorithm.

Owner:HARBIN ENG UNIV

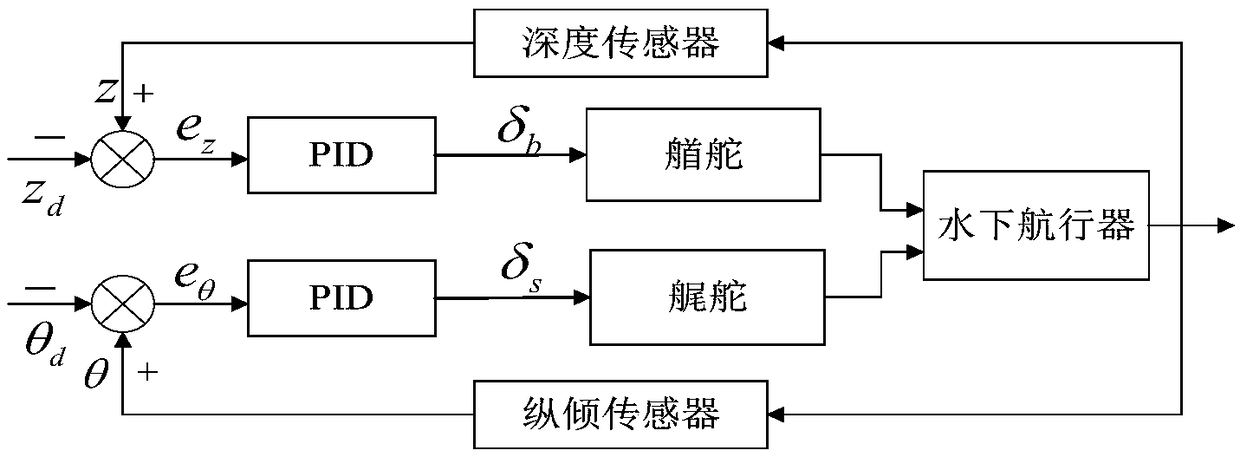

Stem-stern joint steering depth control strategy of underwater vehicle and PID controller thereof

ActiveCN109144080ASolving Strong Nonlinear Coupling ProblemsDepth effectAltitude or depth controlAutomatic controlSteering control

The invention, which belongs to the field of automatic control, discloses a stem-stern joint steering depth control strategy of an underwater vehicle and a PID controller thereof. In order to solve aproblem of strong non-linear coupling between a depth channel and a longitudinally inclined channel during underwater vehicle controlling by using a stem rudder and a stern rudder, the invention putsforward a stem-stern joint steering control strategy based on the nonlinear coupling characteristic with full consideration of the strong nonlinear coupling characteristic between the stem rudder andthe stern rudder. A stem-stern joint control law of a depth channel and a stem-stern joint control law of a longitudinally inclined channel are extracted; a coupled equation set is established; and then the coupled equation set is solved to obtain respective control laws of the stem rudder and the stern rudder, thereby realizing depth controlling of an underwater vehicle having the stem rudder andthe stern rudder. Therefore, a problem of strong non-linear coupling between a depth channel and a longitudinally inclined channel during the depth controlling of the stem rudder and the stern rudderis solved theoretically; the designed controller is close to the engineering reality; and the good control effect is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

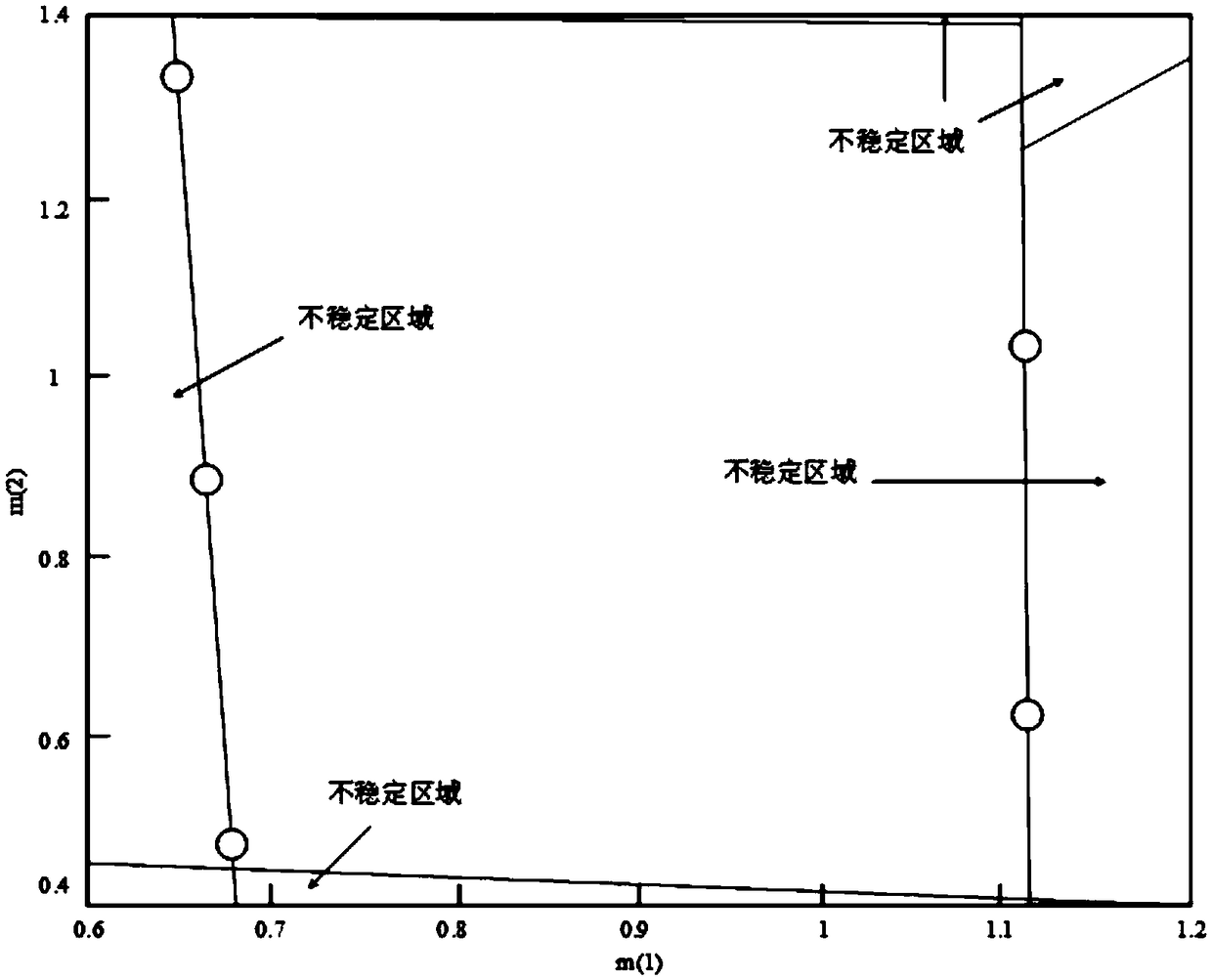

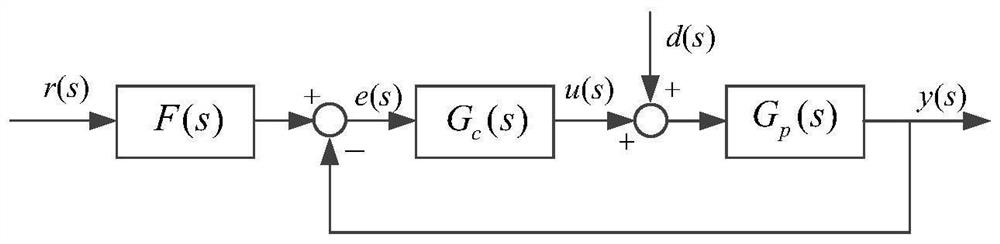

Parameter setting method of thermal process active disturbance rejection time delay controller and controller

The invention discloses a parameter setting method of a thermal process active disturbance rejection time delay controller and a controller, and the parameter setting method comprises the following steps: setting a control object with a first-order inertia pure lag characteristic by adopting an active disturbance rejection time delay controller parameter setting mode based on relative time delay margin; wherein the parameters of the auto-disturbance rejection time delay controller parameter setting mode based on the relative time delay margin comprise a gain parameter b0, an extended state observer parameter omega o and a proportional gain parameter kp; the specific quantitative characterization of the auto-disturbance rejection time delay controller parameter setting mode based on the relative time delay margin being as follows: a dimensionless number lambda and a dimensionless number xi are introduced to characterize kp and omega o, quantitative comparison is carried out based on therelative time delay margin, and then giving a reference setting value of the dimensionless number. According to the parameter setting method of a thermal process active disturbance rejection time delay controller, the stability of a closed-loop system after parameter setting can be guaranteed, the auto-disturbance rejection time delay controller parameter setting method is suitable for most thermotechnical processes with the first-order inertia pure lag characteristic, and good control quality can be obtained.

Owner:SOUTHEAST UNIV

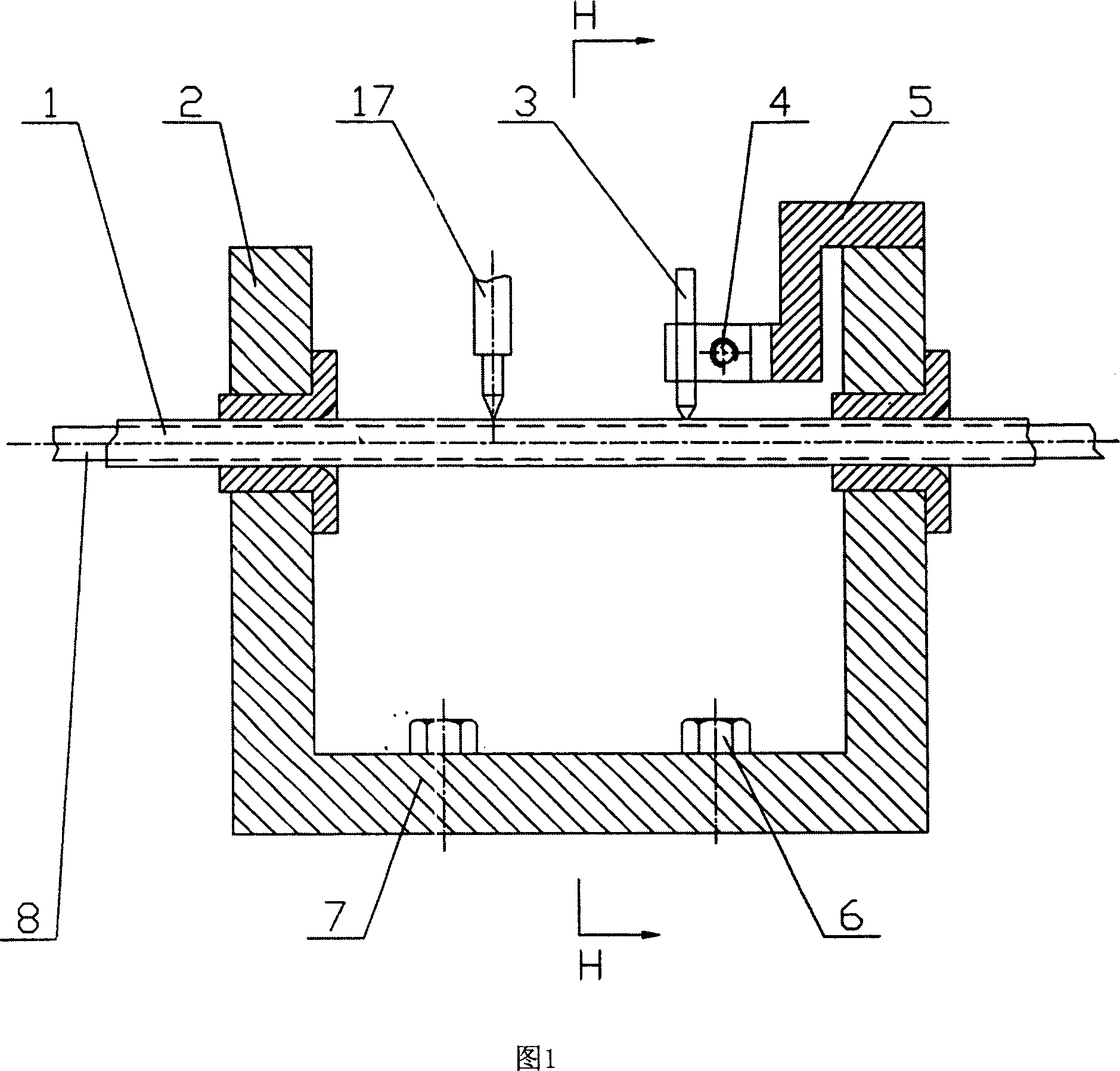

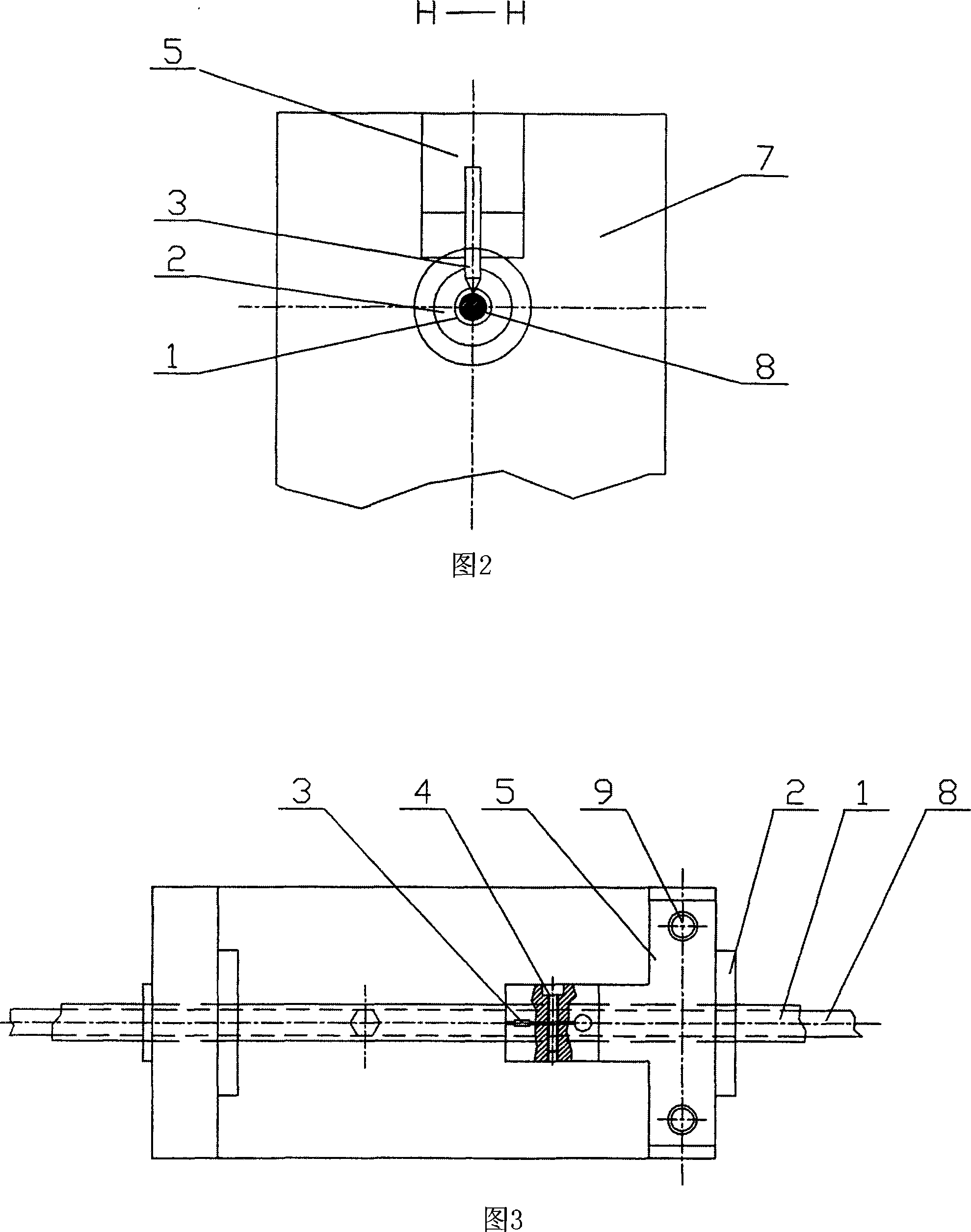

Weld seam stabilizing device

InactiveCN101143415AWeld firmlyProof of stabilityWelding/cutting auxillary devicesAuxillary welding devicesOrganic structureWeld seam

The invention relates to a stable welding line device with covered welding. Both ends of a pedestal bracket are provided with plastic moulds. One side of the pedestal bracket is provided with a prerotation vane bracket, the elastic opening of which is provided with a prerotation vane. The organic structure of the invention is able to totally control the variable factors of a longitudinal seam, which makes the welding stable and reliable, so when the invention is in dry running and welding running, the invention is able to prove the welding stability of the device.

Owner:FUSHI INT DALIAN BIMETALLIC CABLE

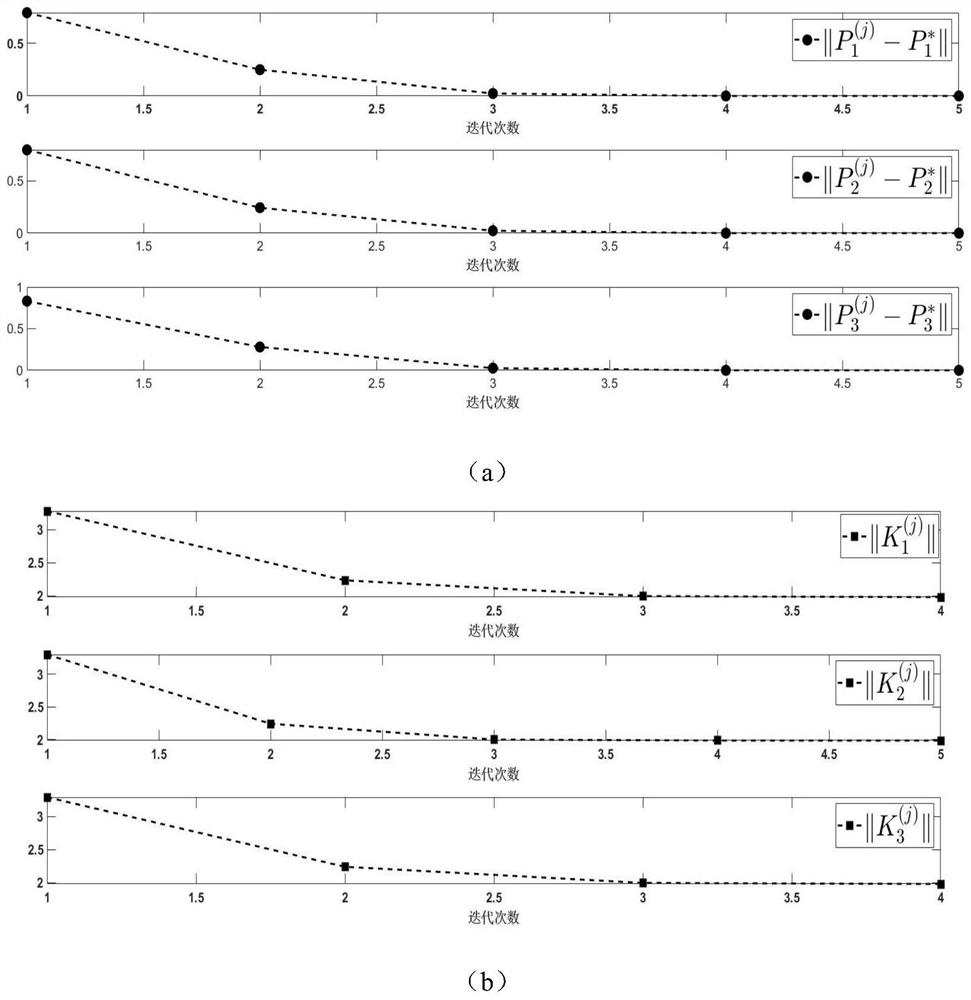

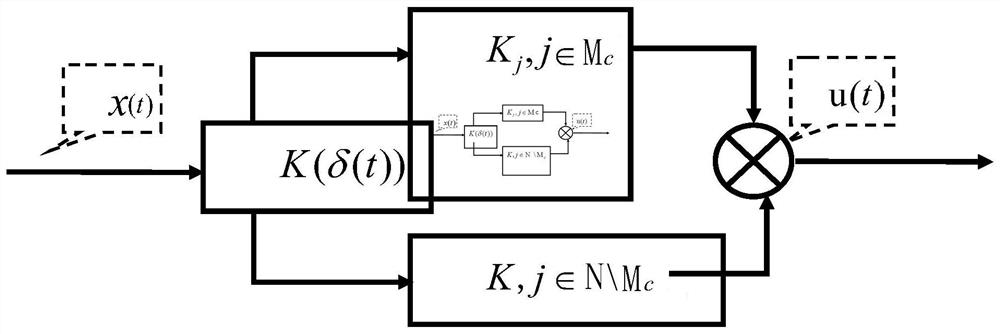

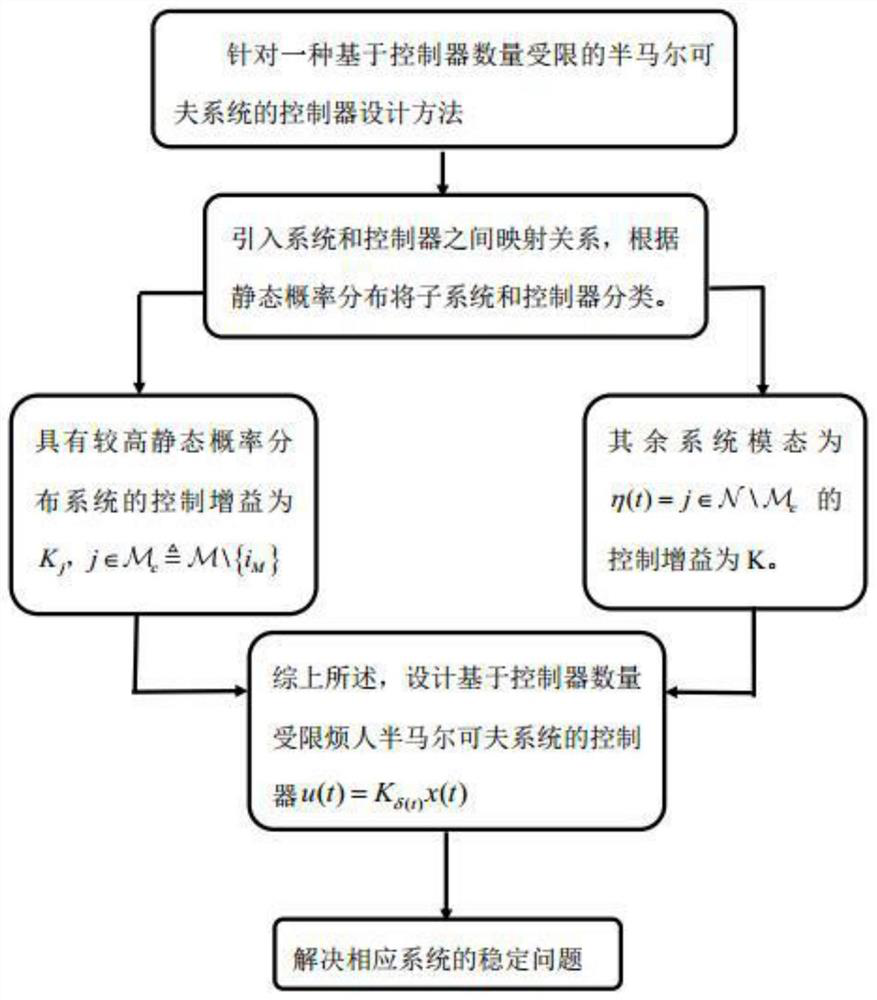

Design method of controller based on semi-Markov system with limited controller number

ActiveCN112099352ALimited number of solutionsRealize Design PrinciplesAdaptive controlController designSystems design

The invention discloses a design method of a controller based on a quantity-limited semi-Markov system. The controller design method comprises the following steps: S1, establishing a random hopping system; S2, according to the system established in the step S1, designing controllers with the number limited to be M, wherein M is larger than or equal to 1 and smaller than or equal to N; S3, constructing a corresponding Lyapunov function by utilizing the established system, and calculating to obtain a final control gain and an LMI solving result; and S4, proving that the designed number-limited controller is the minimum variance approximate value of the modal dependent controller. The method for designing the number-limited controller is based on the principle of the mapping relation betweenthe N subsystems and the M controllers and the stationary probability sequence, the sufficient LMI condition for designing the controllers is obtained through the Lyapunov function method. Therefore,the method is suitable for the situation that under the condition that the number of the controllers is limited, the controllers are designed to control the stability of the system according to a minimum variance approximate value of a modal dependent controller.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

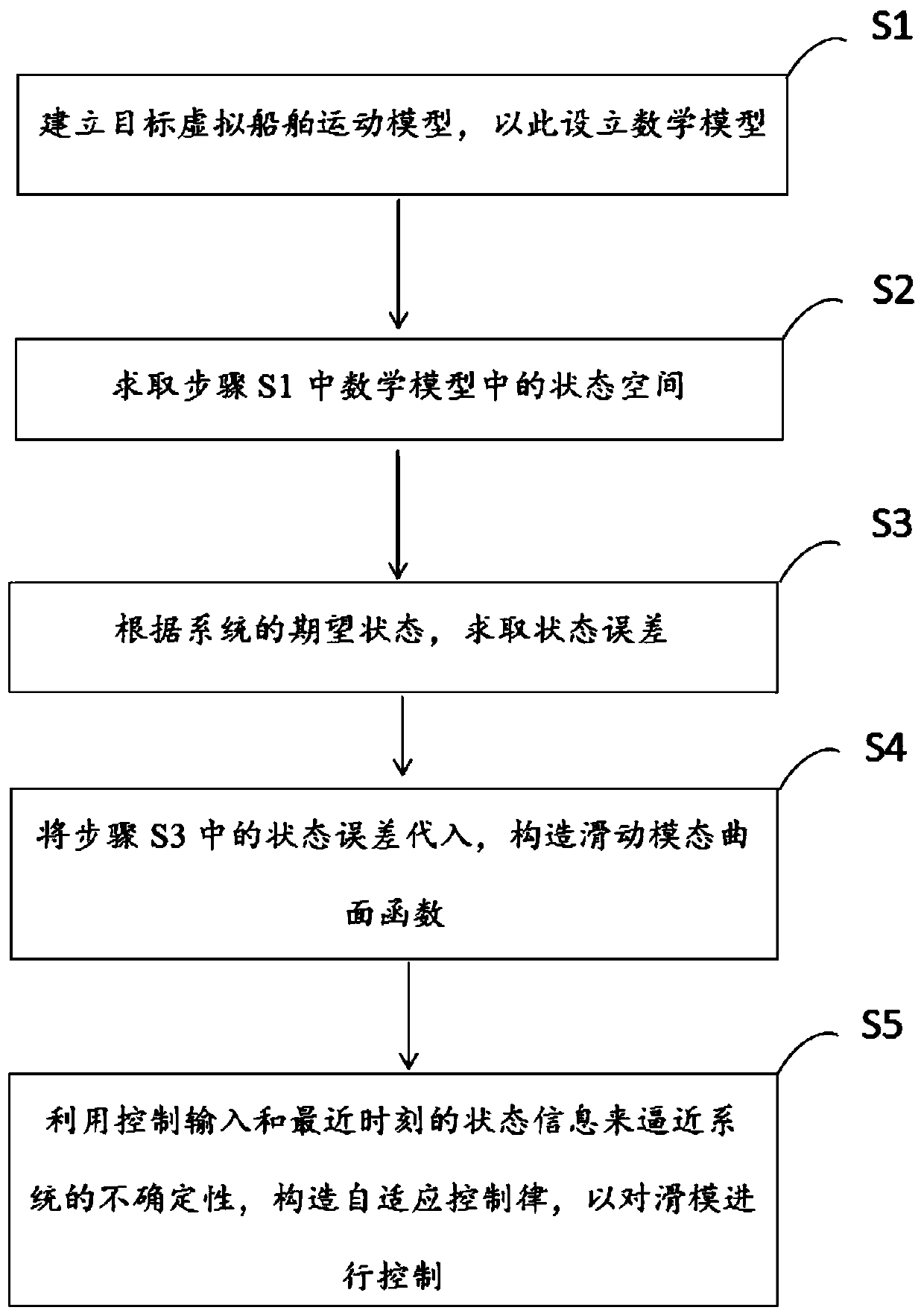

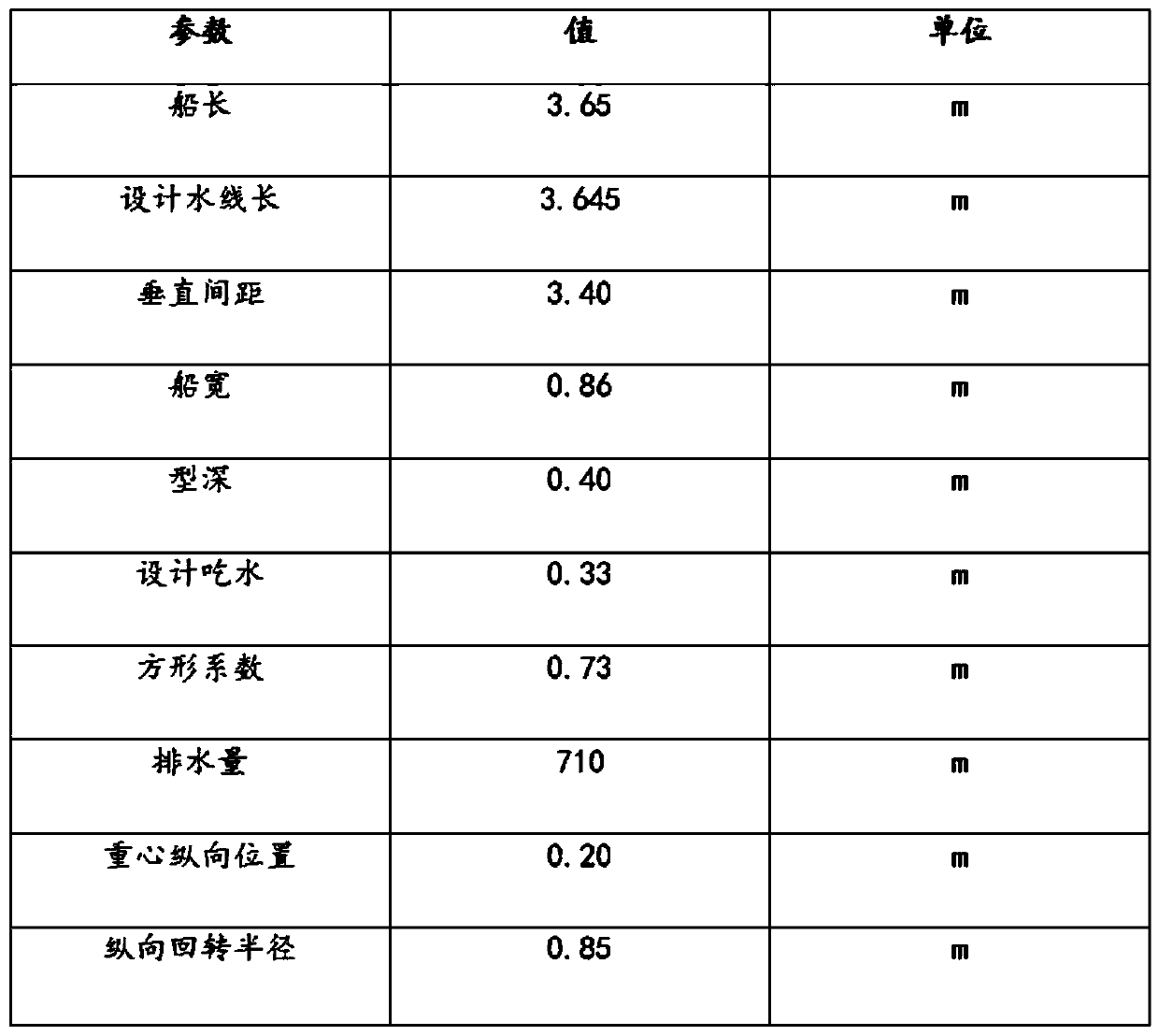

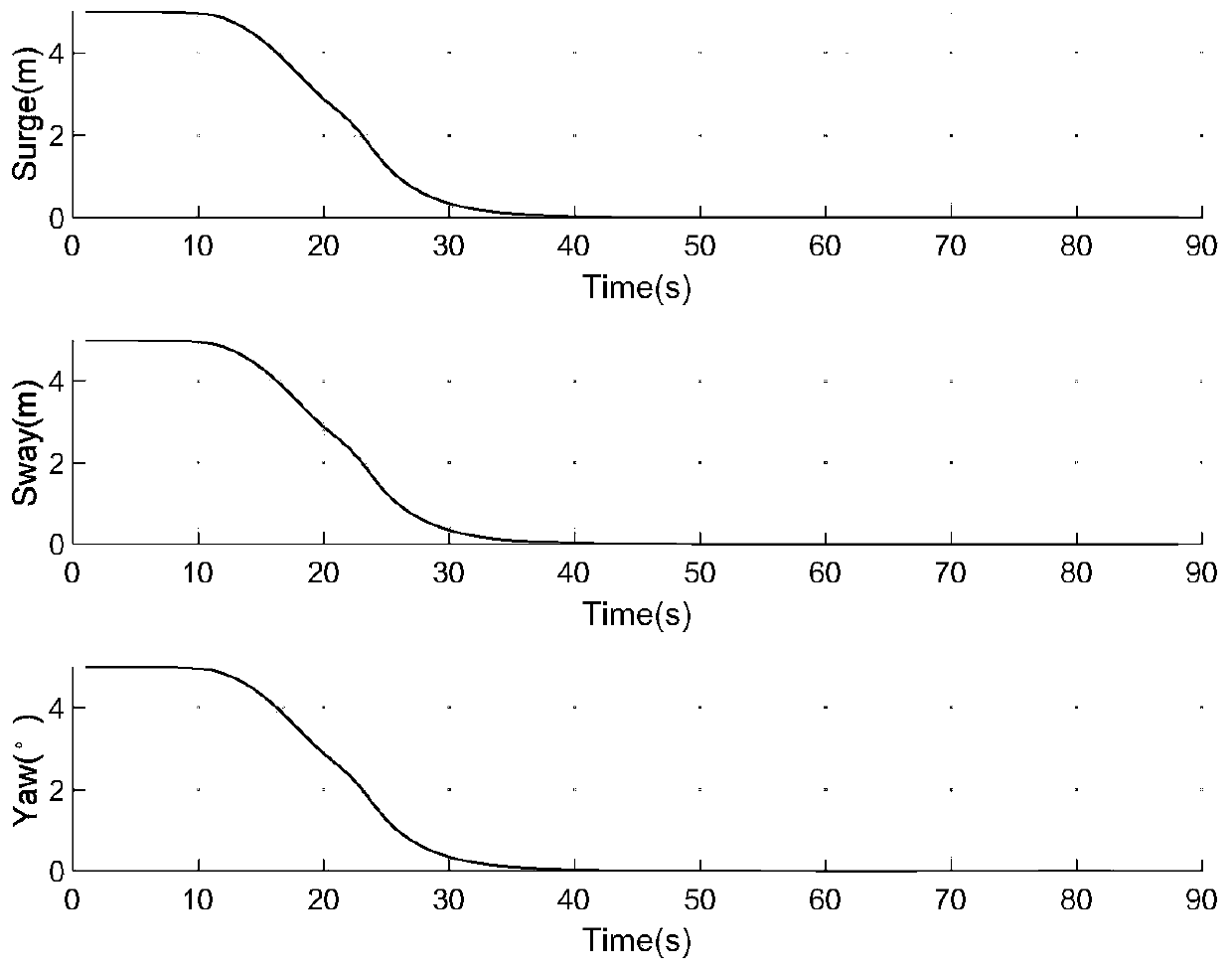

Ship motion self-adaptive sliding mode control method based on time lag fractional order

ActiveCN111580387AImprove control efficiencyImproved accuracy and stabilityAttitude controlAdaptive controlSliding mode controlTime lag

The invention discloses a time lag fractional order-based ship motion adaptive sliding mode control method. The method comprises the following steps of S1, establishing a target virtual ship motion model, and setting a mathematical model according to the target virtual ship motion model; S2, solving a state space in the mathematical model in the step S1; S3, solving a state error according to an expected state of a system; S4, substituting a state error in the step S3, and constructing a sliding mode surface function; and S5, approaching uncertainty of the system by using the control input andthe state information at the latest moment, and constructing an adaptive control law to control the sliding mode. The method is advantaged in that by means of the self-adaptive sliding mode control algorithm, the ship can be automatically adjusted when being disturbed, and a stable state of the ship can be rapidly restored.

Owner:JIMEI UNIV +1

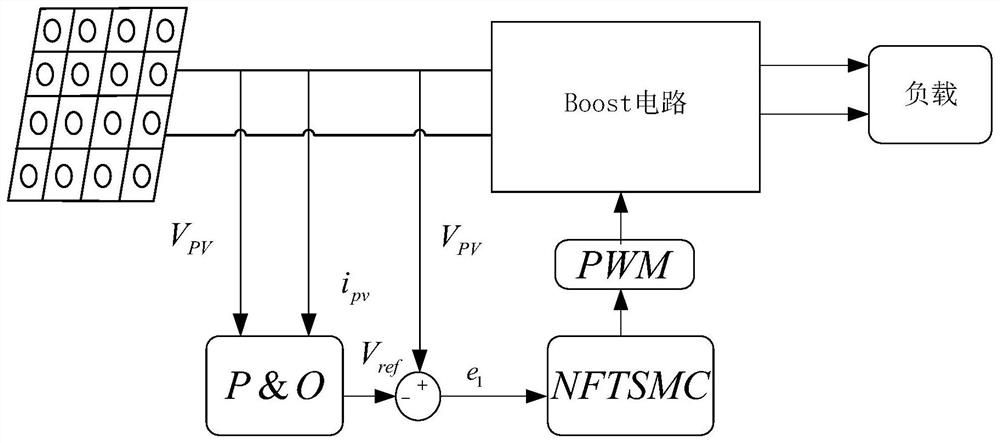

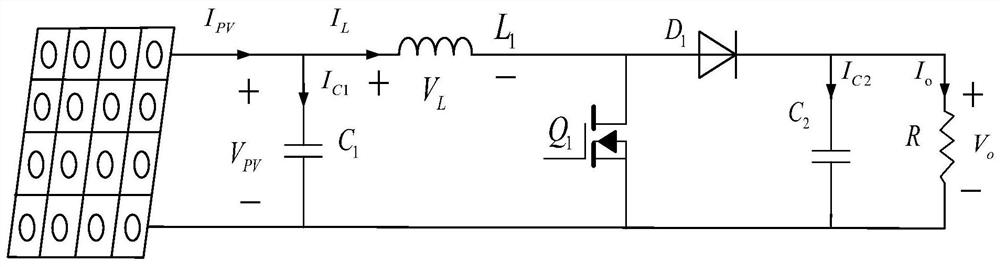

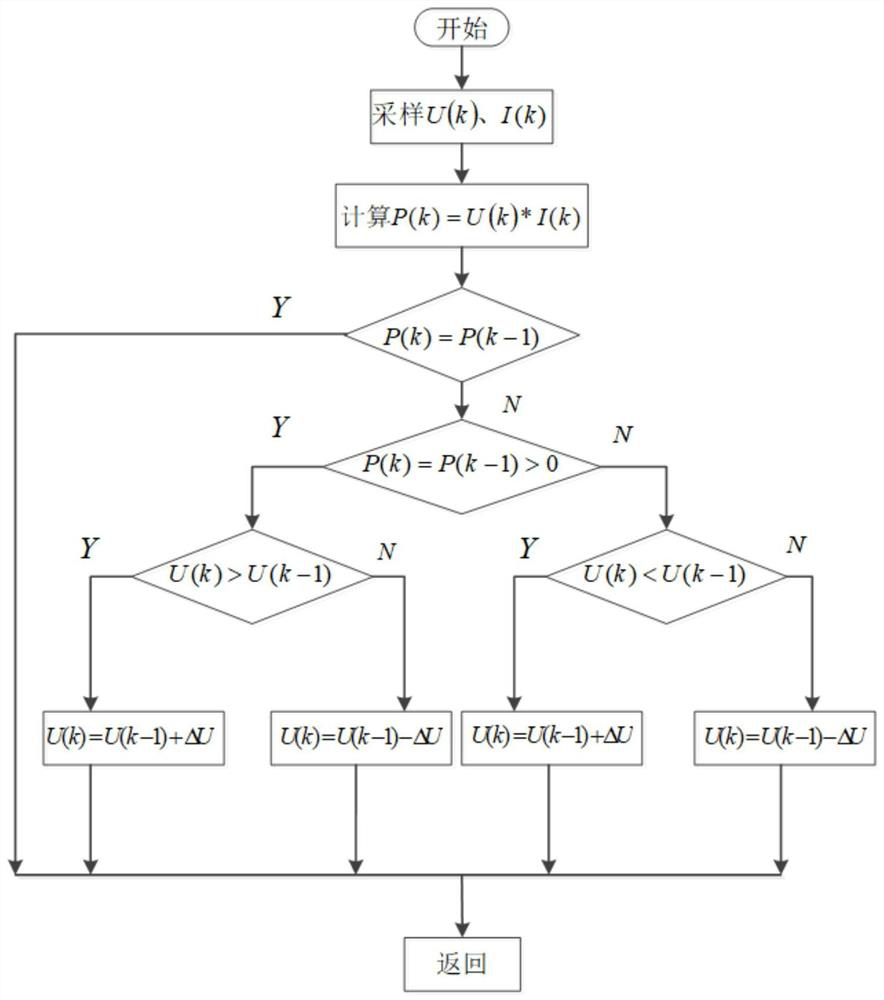

Photovoltaic system maximum power point tracking method based on nonsingular fast terminal sliding mode control

ActiveCN113359938AEasy to controlQuick responsePhotovoltaic energy generationElectric variable regulationMathematical modelEquivalent control

The invention discloses a photovoltaic system maximum power point tracking method based on nonsingular fast terminal sliding mode control, and belongs to the technical field of photovoltaic power generation. The method comprises the following steps: firstly, establishing a mathematical model of a Boost converter in a photovoltaic system, and obtaining a state variable of the photovoltaic system; searching a voltage corresponding to the maximum power point through a perturbation observation algorithm, and taking the voltage as a reference voltage; calculating a tracking error e1 between the photovoltaic output voltage and the reference voltage, and deriving the tracking error e1 to obtain an auxiliary tracking error e2; designing a novel non-singular fast terminal sliding mode surface, and combining an equivalent control law and an index reaching law to obtain a switch control quantity; and finally, carrying out stability analyzing on the controller. According to the method, improvement is made on the basis of a traditional sliding mode surface, the singular problem of a terminal sliding mode is avoided, global rapid convergence of the system can be achieved, and therefore the system has good dynamic performance and stability and high robustness.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com