Preparation method of ZIF-8/carbon fiber composite material for adsorbing aqueous organic dye

A technology of ZIF-8 and organic dyes, applied in the direction of adsorption of water/sewage treatment, water pollutants, water/sewage treatment, etc., can solve the problems of high content of organic pollutants, deep color of dye wastewater, complex components, etc., to achieve Wide range of sources, water purification, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

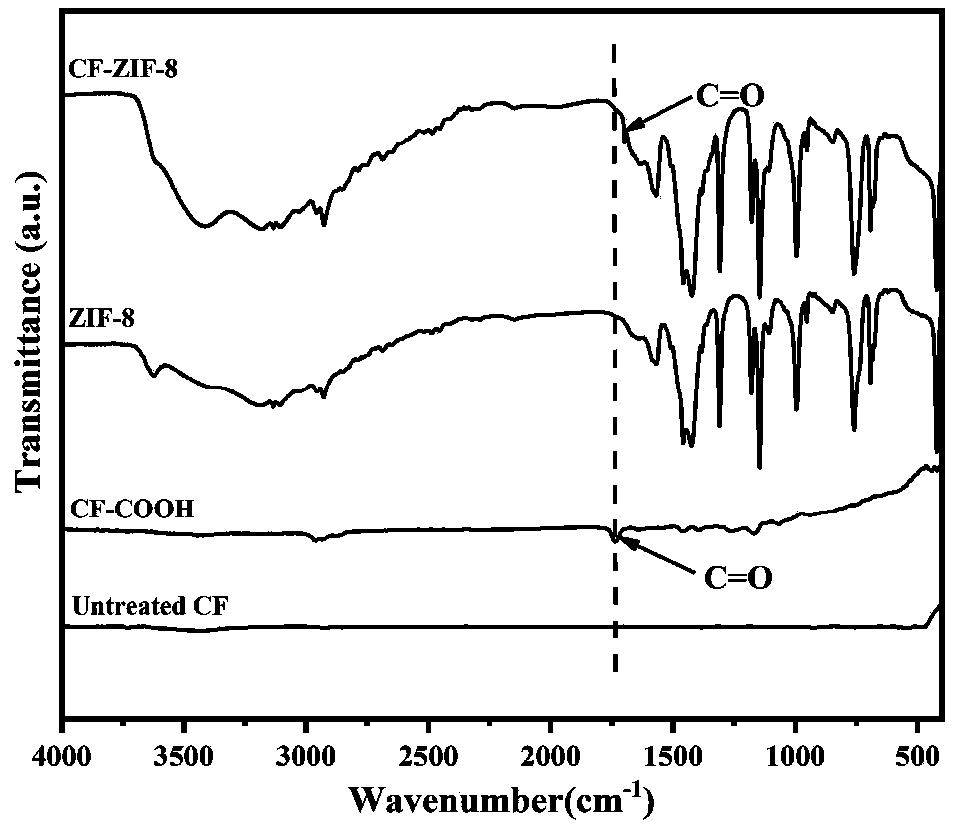

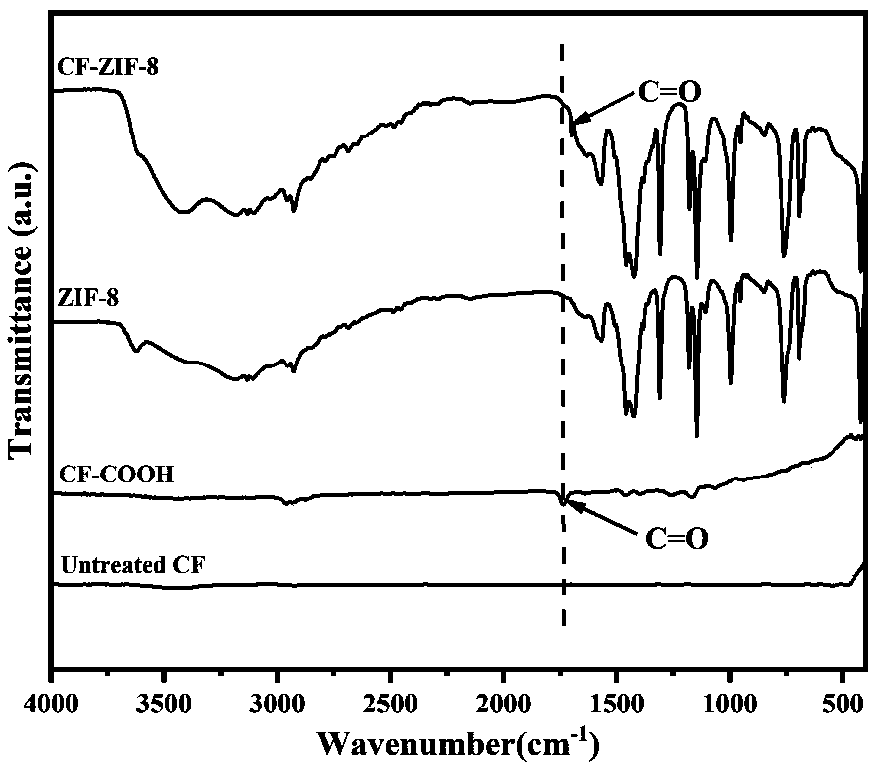

[0031] A kind of preparation method for the ZIF-8 / carbon fiber composite material of aqueous phase organic dye adsorption, comprises the following steps:

[0032] 1. Cutting the area of carbon fiber cloth for acetone desizing to 100-400cm 2 , put it into a beaker, treat it in concentrated nitric acid at 60-80°C for 4-8 hours, and then dry it to obtain a carbon fiber cloth that has been subjected to strong oxidation treatment to form carboxylate groups;

[0033] Wherein, the volume of acetone and the mass ratio of carbon fiber cloth are 30-50ml: 1-5g, the volume of concentrated nitric acid and the mass ratio of carbon fiber cloth are 10-30ml: 1-5g;

[0034] Two, the ZnO powder and 2-methylimidazole are mixed uniformly in proportion, and ground at room temperature until it becomes a white fine powder, so as to obtain the ZnO powder and 2-methylimidazole mixture;

[0035] Wherein the molar ratio of zinc oxide to 2-methylimidazole is: 5-15:9.5-28.5;

[0036] 3. Spread the carb...

Embodiment 2

[0040] A kind of preparation method for the ZIF-8 / carbon fiber composite material of aqueous phase organic dye adsorption, comprises the following steps:

[0041] 1. Put the carbon fiber monofilament desized by acetone into a beaker, treat it in concentrated nitric acid at 60-80°C for 4-8 hours, and then dry it to obtain the carbon fiber monofilament that has been subjected to strong oxidation treatment to form carboxylate groups;

[0042] Wherein, the volume of acetone and the mass ratio of carbon fiber monofilament are 30-50ml: 1-5g, the volume of concentrated nitric acid and the mass ratio of carbon fiber monofilament are 10-30ml: 1-5g;

[0043] Two, the ZnO powder and 2-methylimidazole are mixed uniformly in proportion, and ground at room temperature until it becomes a white fine powder, so as to obtain the ZnO powder and 2-methylimidazole mixture;

[0044] Wherein the molar ratio of zinc oxide to 2-methylimidazole is: 5-15:9.5-28.5;

[0045]Three, spread the ZnO powder a...

specific example 1

[0048] 1. Cut the area of the carbon fiber cloth for desizing with acetone to 10*10cm, treat it with an appropriate amount of concentrated nitric acid at 80°C for 4 hours, and then dry it in an oven to obtain a carbon fiber cloth that has been subjected to strong oxidation treatment to form carboxylate groups;

[0049] Two, the ZnO powder and 2-methylimidazole were mixed uniformly in proportion, and were ground at room temperature for 3 hours, until turning into a white fine powder, to obtain a mixture of ZnO powder and 2-methylimidazole;

[0050] 3. Spread the carbon fiber cloth obtained in step 1 that has been strongly oxidized to form carboxylate groups on a square glass plate with a side length of 10 cm, add 10 g of the ZnO powder and 2-methylimidazole mixture obtained in step 2, and continue grinding for 1.5 hours , put the second and third layers of carbon fiber cloth that have been subjected to strong oxidation treatment to generate carboxylate groups, and repeat the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com