Parameter setting method of thermal process active disturbance rejection time delay controller and controller

A technology of parameter tuning and active disturbance rejection, applied in adaptive control, general control system, control/regulation system, etc., can solve the problem of time-consuming and energy-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

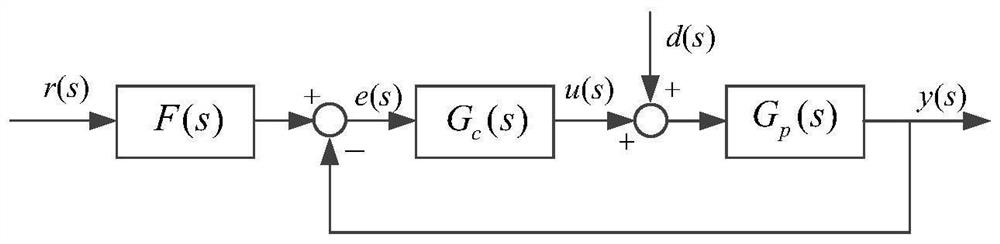

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] Embodiment 1. Simulation experiment

[0123] The simulation experiment takes the air temperature at the outlet of the pulverizer in a coal-fired power plant as the object. Through the step experiment, the first-order inertial time-delay model shown in formula (1) is identified and obtained, and then the simulation experiment is carried out based on the model. The simulation experiment adopts the active disturbance rejection time-delay controller based on the proposed parameter tuning method.

[0124]

[0125] Due to object eigenvalues Therefore, according to the parameter setting method, set the controller parameters as: λ=1, ξ=10. The simulation comparison results are as Figure 4 Shown: The simulation experiment changes the set value at t=10s and adds internal disturbance at t=550s. It can be seen from the comparison results that the proposed ADRC time-delay controller based on the parameter setting method of the present invention has a smaller set point tracki...

Embodiment 2

[0127] Example 2. On-site control experiment of air temperature at outlet of coal mill in coal-fired power plant

[0128] The actual thermal object experiment is carried out based on the adjustment of the outlet air temperature of the pulverizer in a coal-fired power plant. According to the actual operation requirements, the ADRC time-delay controller based on the parameter setting method of the present invention and the PI based on the Skogstad internal model control are compared. The fast compensation and suppression performance of the controller for the disturbance, the comparison results are as follows Figure 5 shown. The actual experimental results based on thermal objects show that the ADRC time-delay controller based on the parameter setting method of the present invention has better disturbance suppression characteristics than the PI controller based on the Skogstad internal model control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com