Weld seam stabilizing device

A stable and clamping technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as welding instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

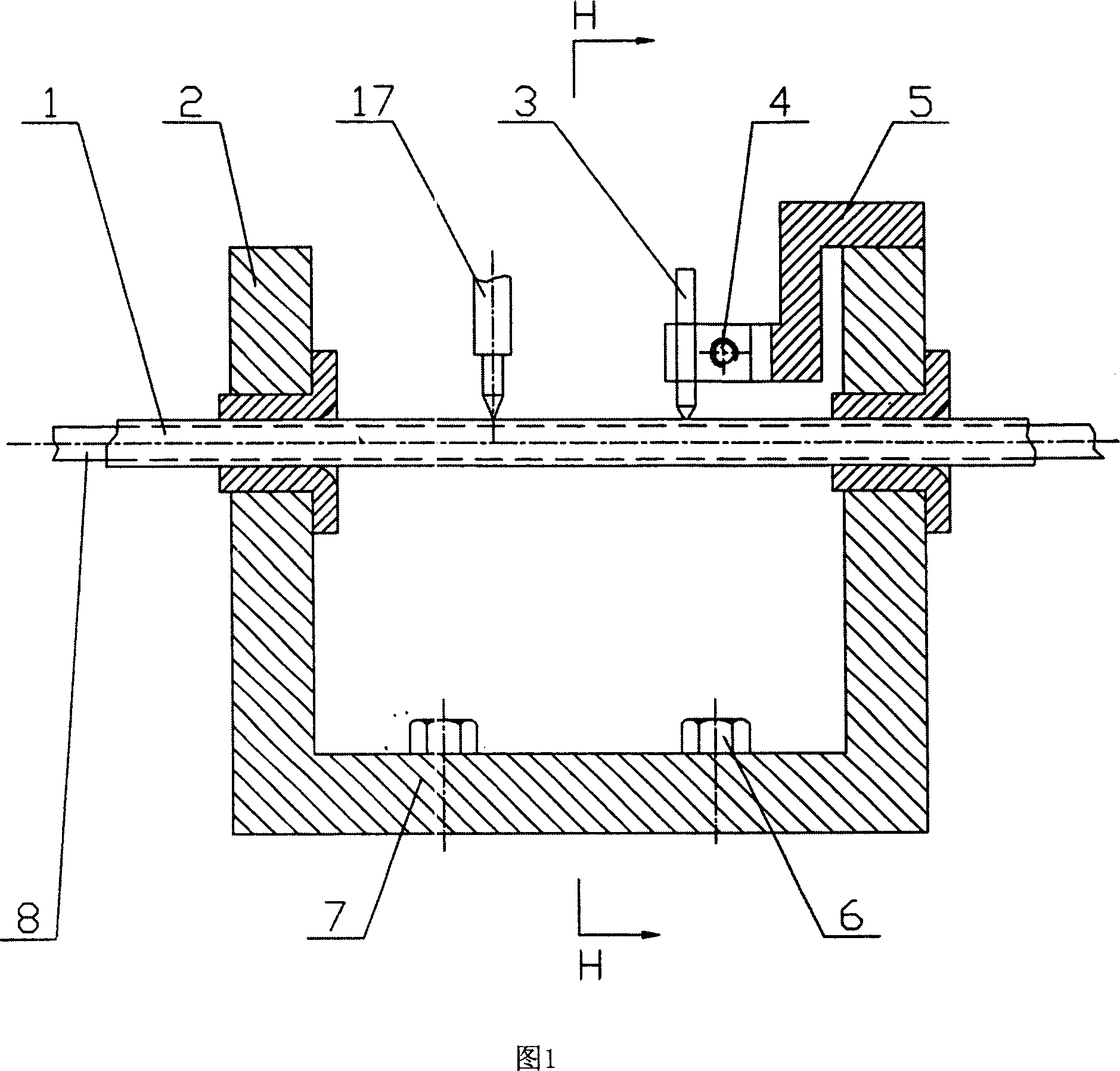

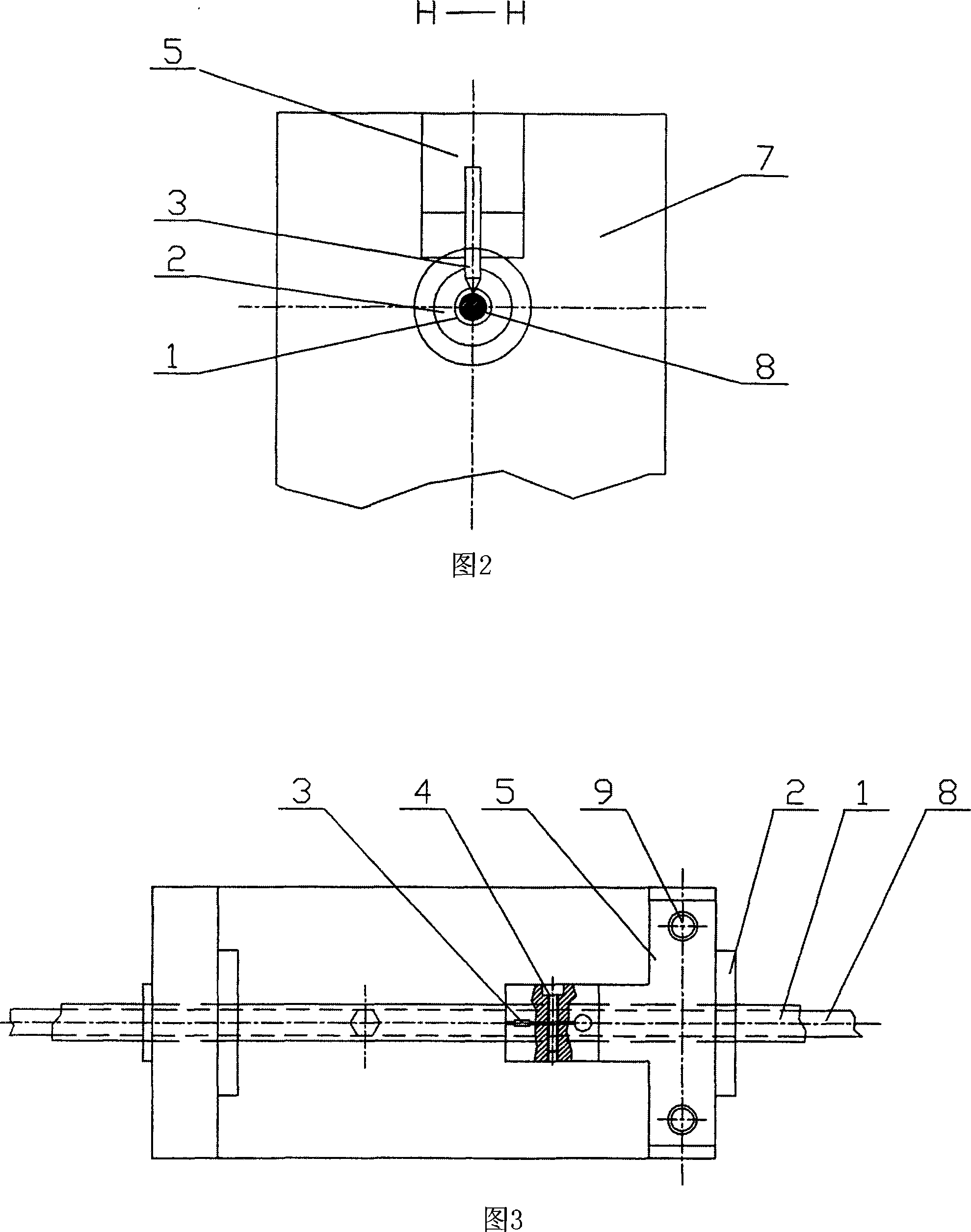

[0020] As shown in Figure 1-3, the base bracket 7 is fixed at the welding torch 17 of the cladding machine by the hexagonal screw 6; The guide plate bracket 5 is installed on the side through the inner hexagon screw 9, and the guide plate 3 is clamped by the inner hexagon screw 4 on the elastic mouth of the guide plate support 5, and the depth of the guide plate 3 in the longitudinal seam pipe can be adjusted by tightening the inner hexagon screw 4; The piece 3 is inserted into the longitudinal slit with a guide angle; the guiding part of the guide piece 3 is on the same straight line as the plastic mold 2; the longitudinal slit tube 1 with the covered metal rod 8 passes through the front multiple sets of coiled tubes The shaping roller passes through the shaping die 2 and the guide piece 3 after shaping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com