Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Production will not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

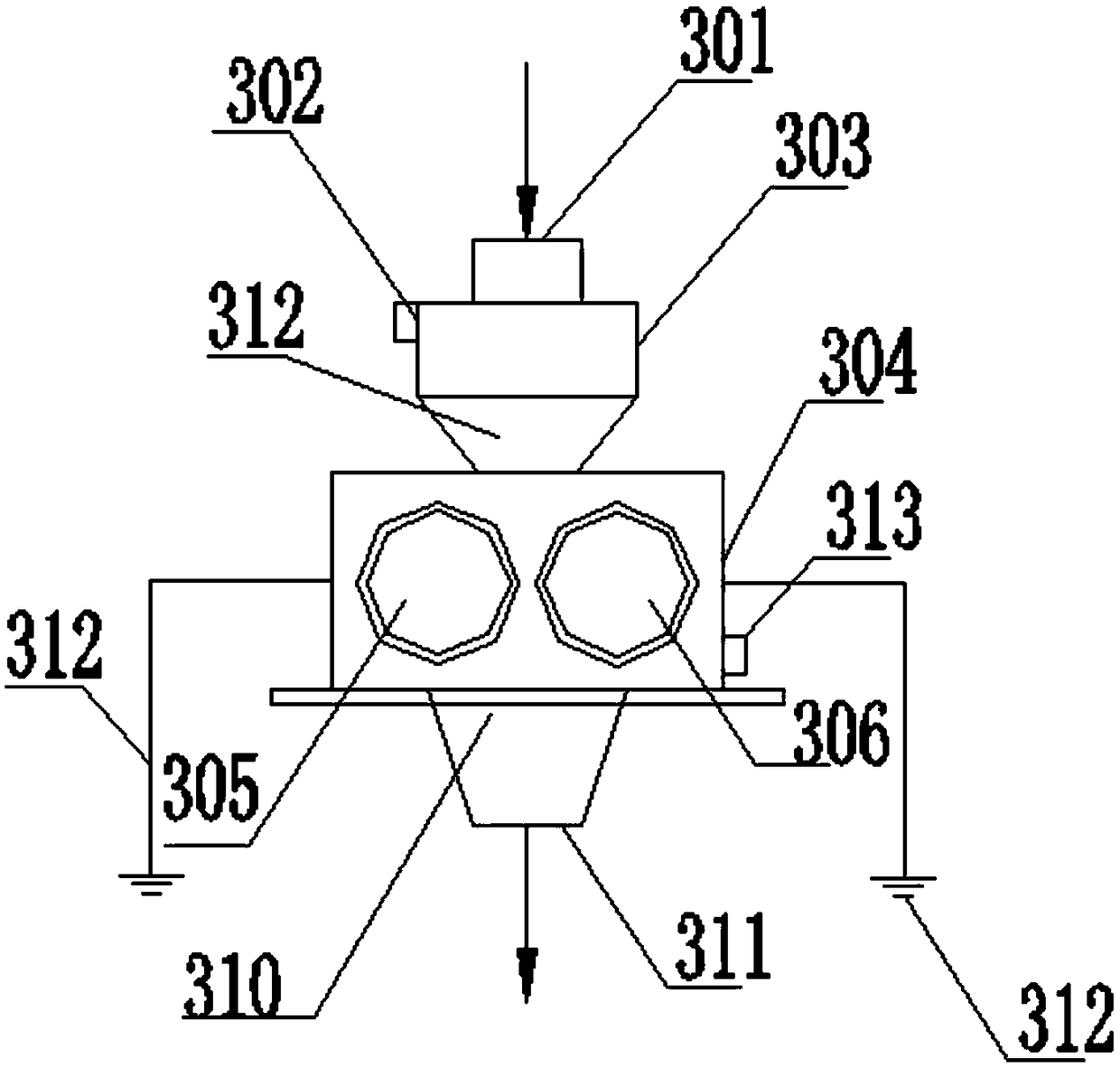

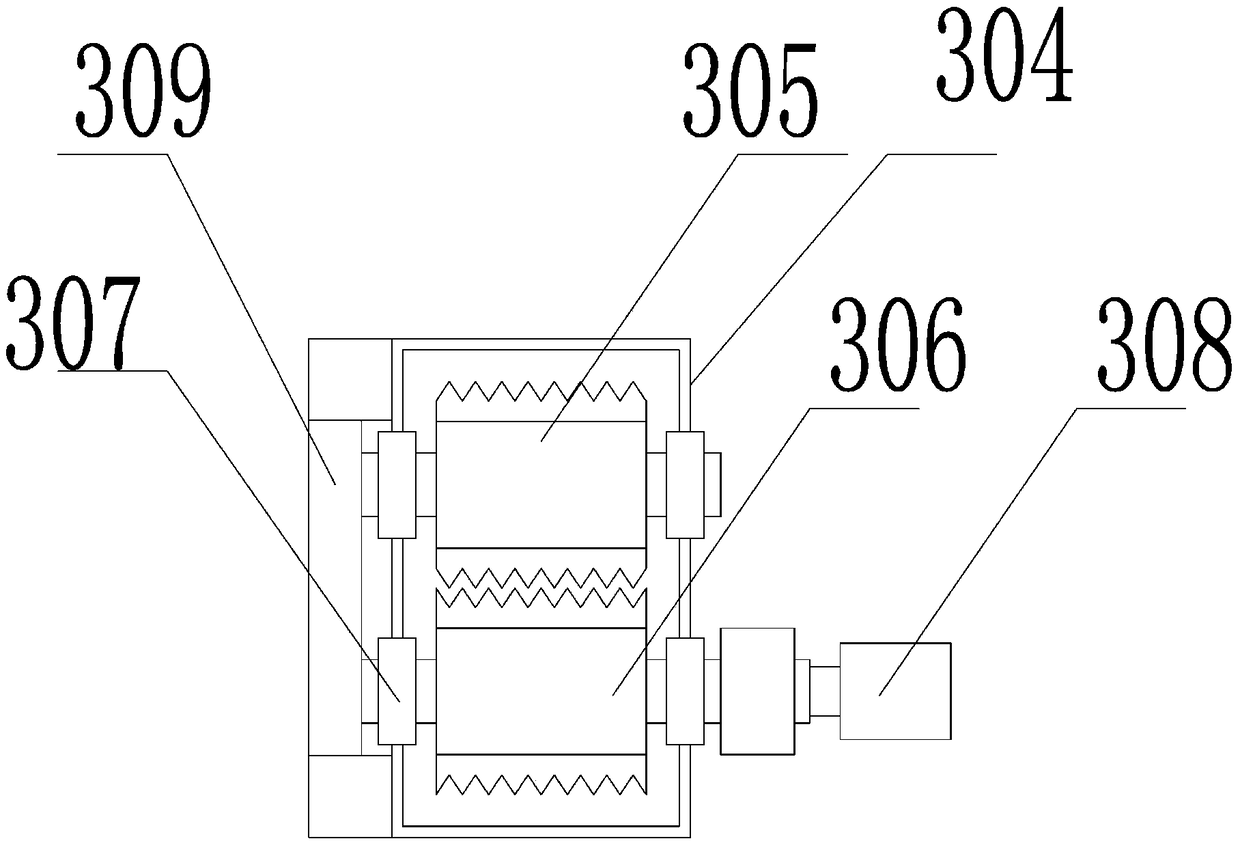

System and method for synergistic disposal of waste lithium ion batteries in cement kiln

PendingCN108772407AHarmlessRealize resource disposalSolid waste disposalTransportation and packagingDecompositionSlag

The present invention provides a system and a method for synergistic disposal of waste lithium ion batteries in a cement kiln. The system is based on the characteristics of substances contained in thewaste lithium ion batteries and aims at the problems existing in the prior art. The system includes a waste lithium ion battery storage device, an anhydrous and anaerobic biaxial crusher, a verticalpyrolysis furnace, a neutralization tower, a valuable element extraction system and a cement kiln system; the disposal method is as follows: classified pretreatment of the waste lithium ion batteries,anhydrous and anaerobic breakdown, evaporation decomposition sintering in the vertical pyrolysis furnace into solid mixed slag, and extracting of valuable elements from the solid mixed slag; neutralization of fluorine-containing and phosphorus-containing compound gases, high-temperature incineration of combustible waste gases in the cement kiln, and disposal of all waste residues, and clean production and environmental protection can be achieved. The system has simple device structure, can realize the maximum utilization of resources and energy in the whole system, and can realize the low cost recovery of the valuable elements by a simple method.

Owner:长沙中硅环保科技有限公司 +1

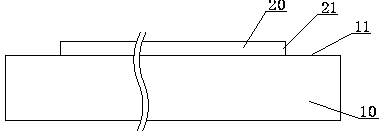

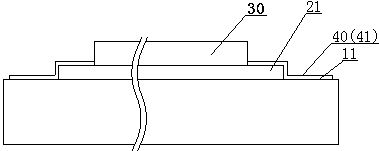

A method for manufacturing a flexible capacitive touch screen

InactiveCN109271068AReduce thicknessProduction will not affectInput/output processes for data processingCapacitancePolyamic acid

A method for manufacturing a flexible capacitive touch screen includes Step 1, coating a polyamic acid solution on a first surface of a glass substrate and polymerizing to form a PI film, wherein an edge of the PI film is located on the first surface of the glass substrate, and a bare region of the glass substrate exists outside the PI film; Step 2, forming a barrier layer on the edge of the PI film, wherein the barrier layer spans the edge of the PI film and covers a part of the film body at the edge of the PI film from the bare area; Step 3, fabricating a touch control circuit layer of a capacitive touch screen on the PI film; and Step 4, stripping the PI film with the touch circuit layer from the glass substrate to obtain a flexible capacitive touch screen based on the PI film. The method for manufacturing a flexible capacitive touch screen prevents the PI film constituting the touch screen from falling off the glass substrate in advance, thereby improving the success rate of the entire flexible capacitive touch screen manufacturing process.

Owner:SHANTOU GOWORLD DISPLAY TECH CO LTD +2

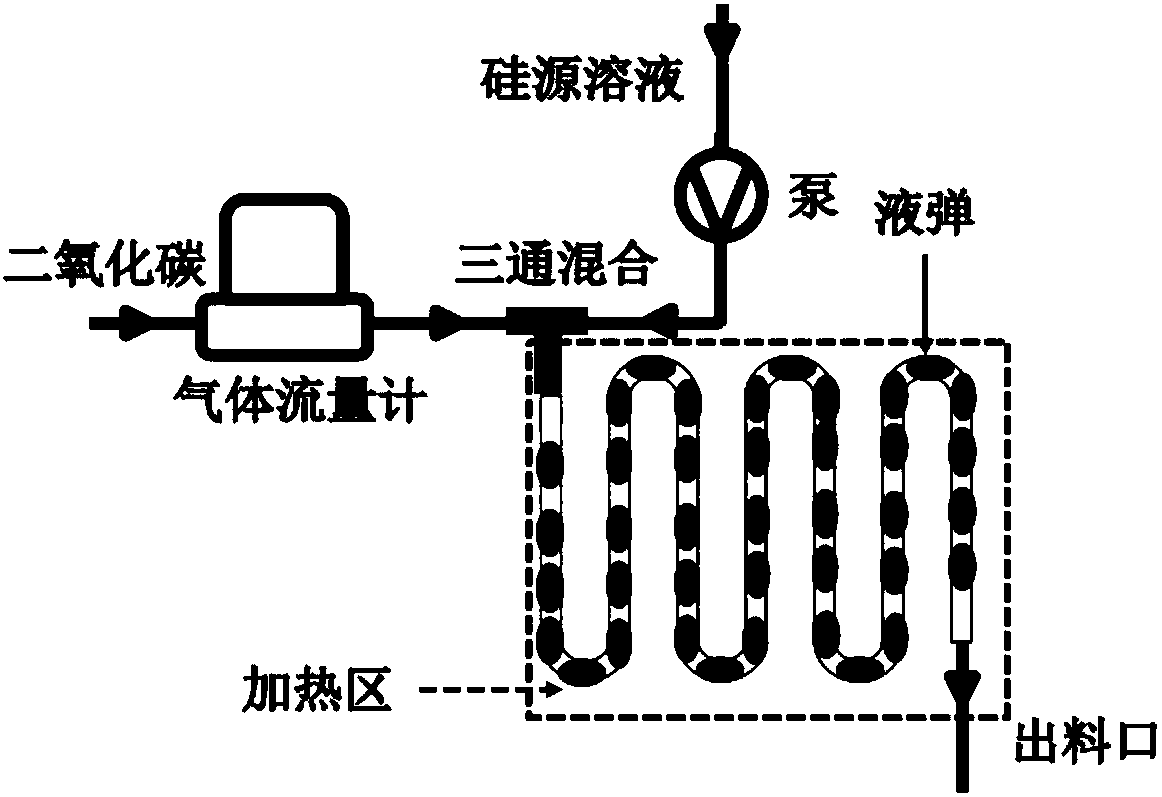

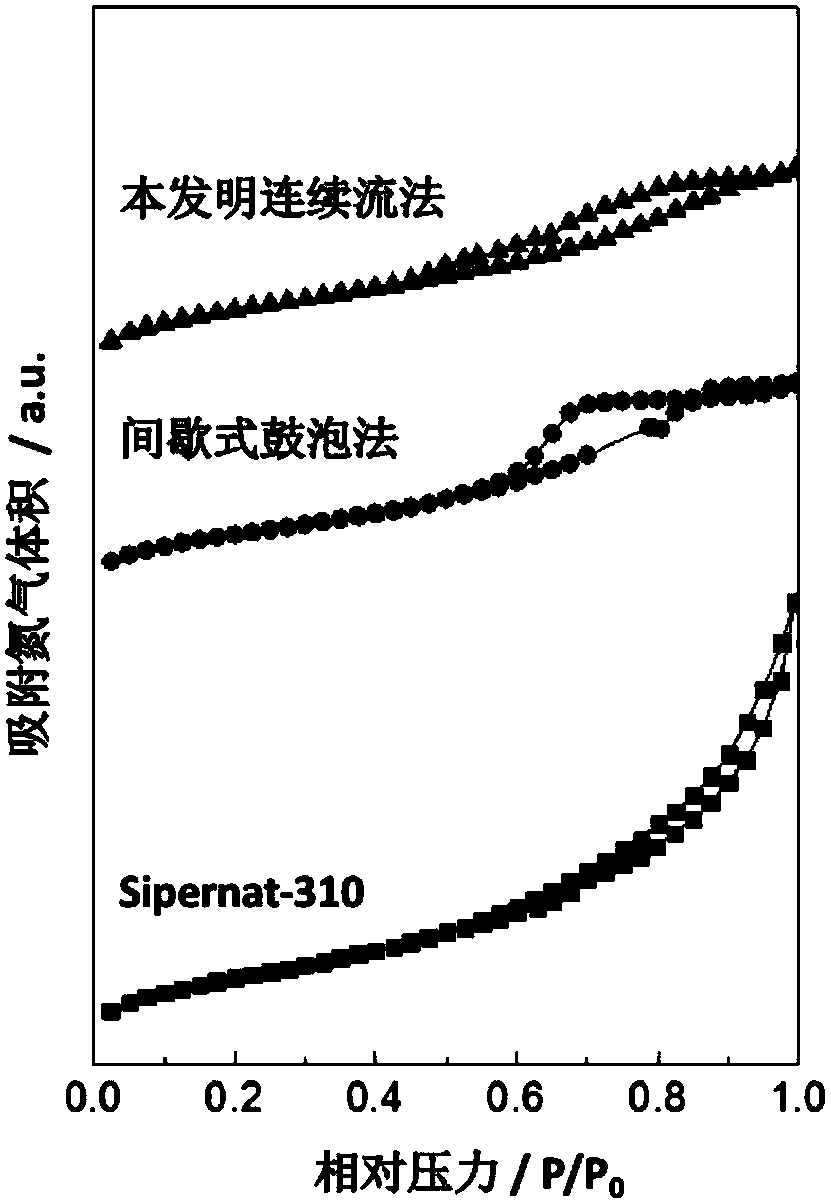

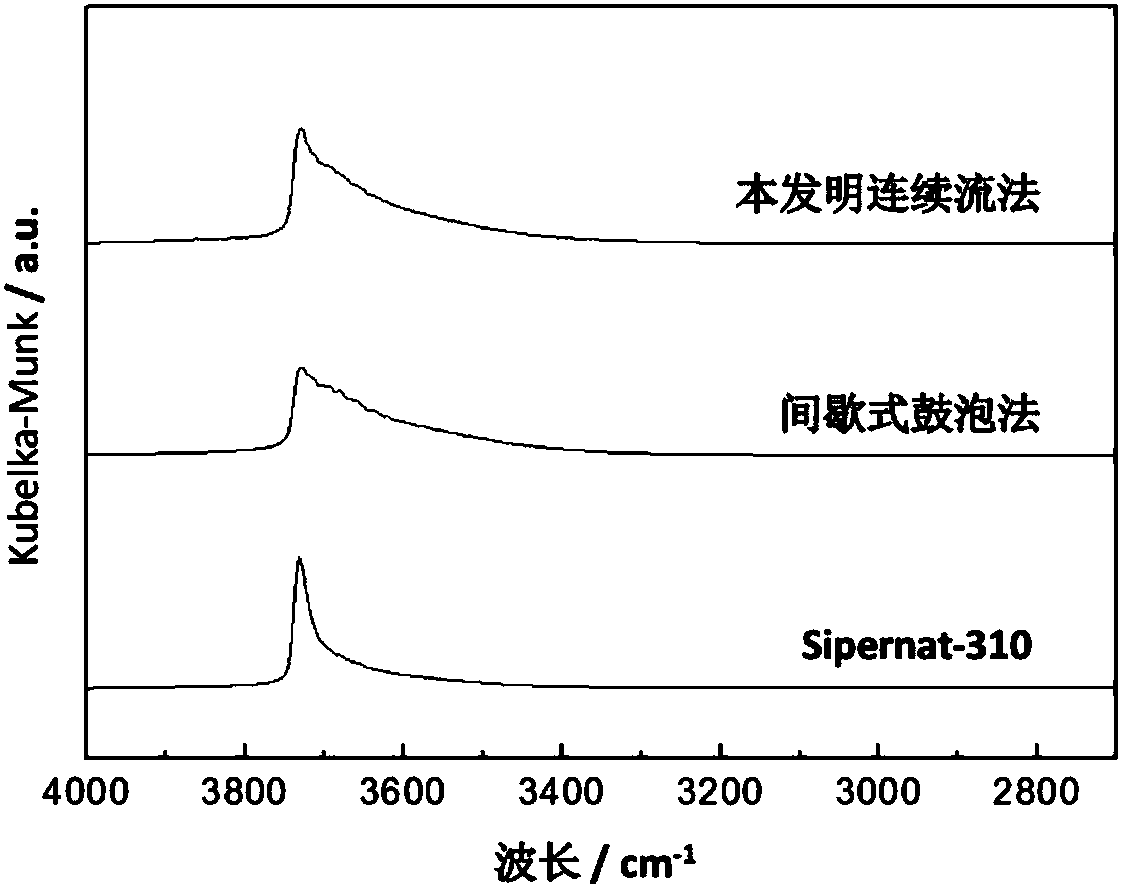

Method for preparing silicon dioxide with high specific surface area by using tubular continuous flow method

The invention discloses a method for preparing silicon dioxide with high specific surface area by using a tubular continuous flow method, and develops a novel precipitation method based on a small tube diameter tubular continuous flow method. The method is used for producing the silicon dioxide with high specific surface area, wherein a raw material for producing white carbon black is sodium silicate, silica sol or a mixed solution of sodium silicate and silica sol, and carbon dioxide gas serving as an acidifying agent goes through a gas-liquid alternating section flow formed by the tubular continuous flow method, so that the problem of mass and heat transfer on micro level is solved fundamentally. Therefore, according to the method disclosed by the invention, silicon dioxide with high specific surface area, small particles and stable product quality can be produced continuously.

Owner:合肥星巢环保科技有限公司

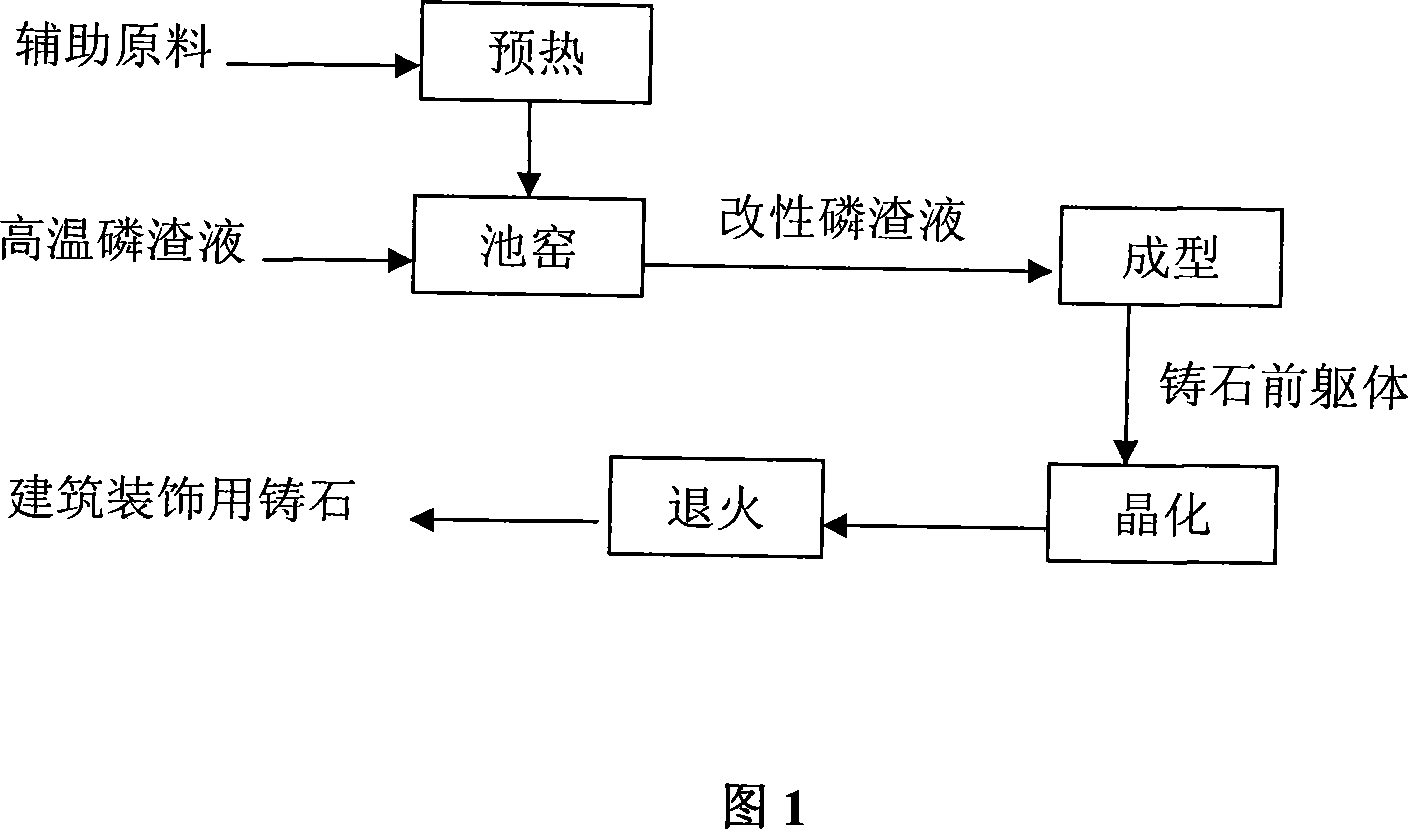

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a technique for the preparation of phosphorus dregs cast stone used for construction decoration and using high temperature phosphorus dregs fluid. The invention is characterized in that: firstly, the configuration and the preheating of auxiliary raw material: quartz sand and kaoline are taken as auxiliary raw materials and heated to 1,300-1,450 DEG C; secondly, hot ingredient: the high-temperature phosphorous dregs fluid, which is discharged from a phosphorus electric stove, passes a fluid groove and flows into a pond kiln, and the auxiliary raw material is put into a pond kiln simultaneously, wherein, the quality ratio of the phosphorus dregs to the auxiliary raw material is 65-75:25-35; thirdly, melting: the melting mix of the phosphorous dregs and the auxiliary raw material reaches 1,450-1,580 DEG C; fourthly, shaping; last, crystallization and annealing: the crystallization is processed under 1,000-1,150 DEG C for 60-120 minutes, and then is annealed to room temperature, thus a product is made. The invention can effectively use the thermal energy of the high-temperature phosphorous dregs fluid to realize the conversion of the phosphorous dregs fluid into the resources and reduce the energy consumption and the cost of cast stone production, thereby causing the phosphorous dregs cast stone adaptive to the purpose of large-scale construction decoration.

Owner:浙江中地大科技有限公司

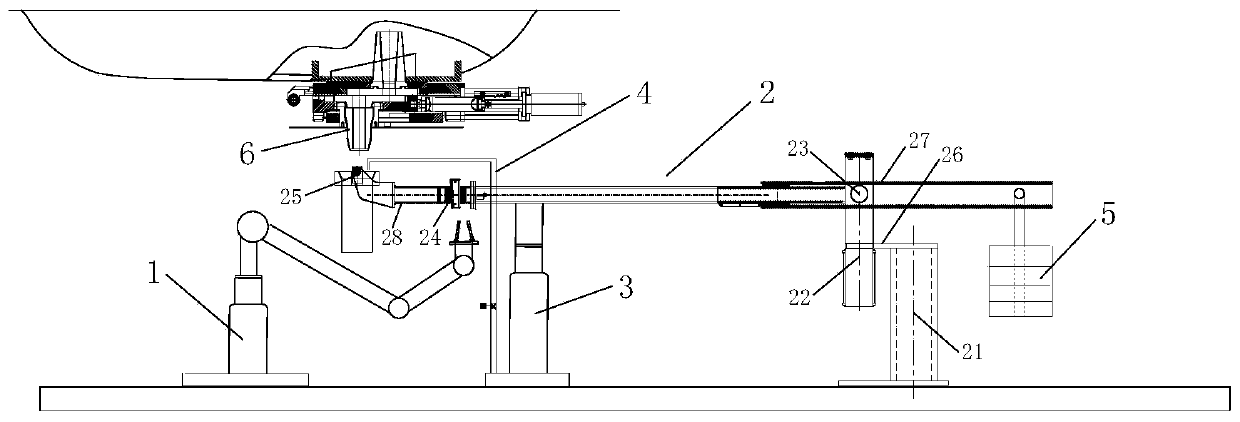

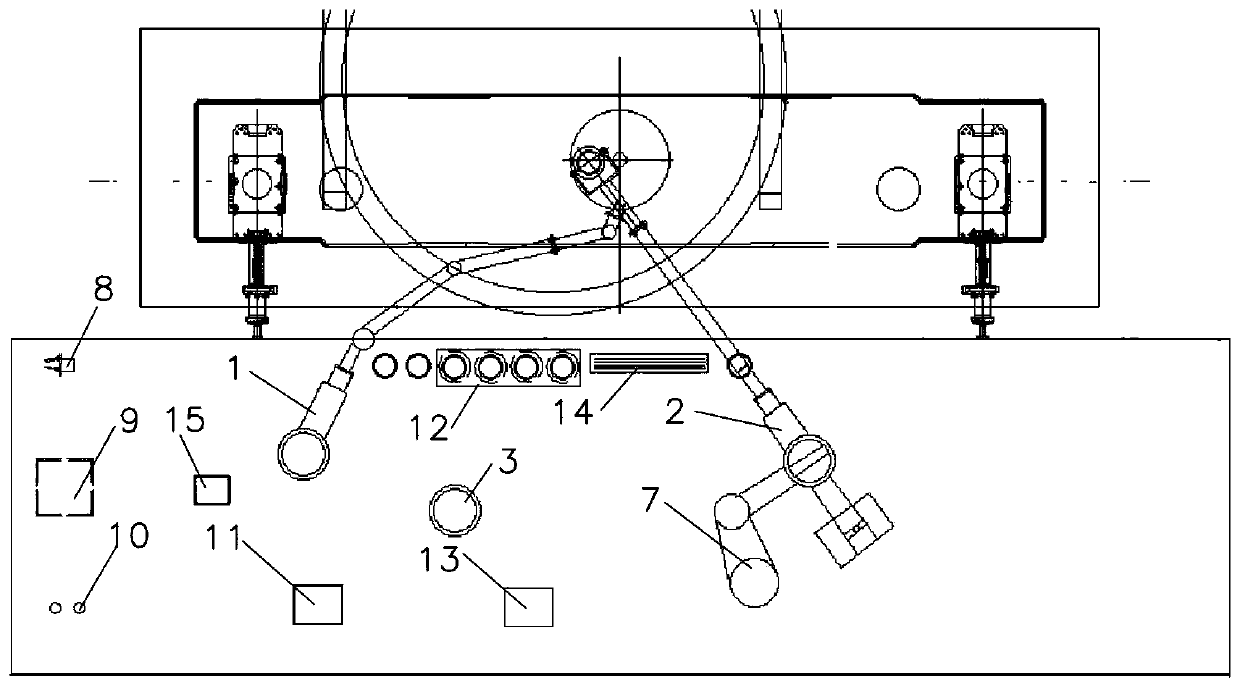

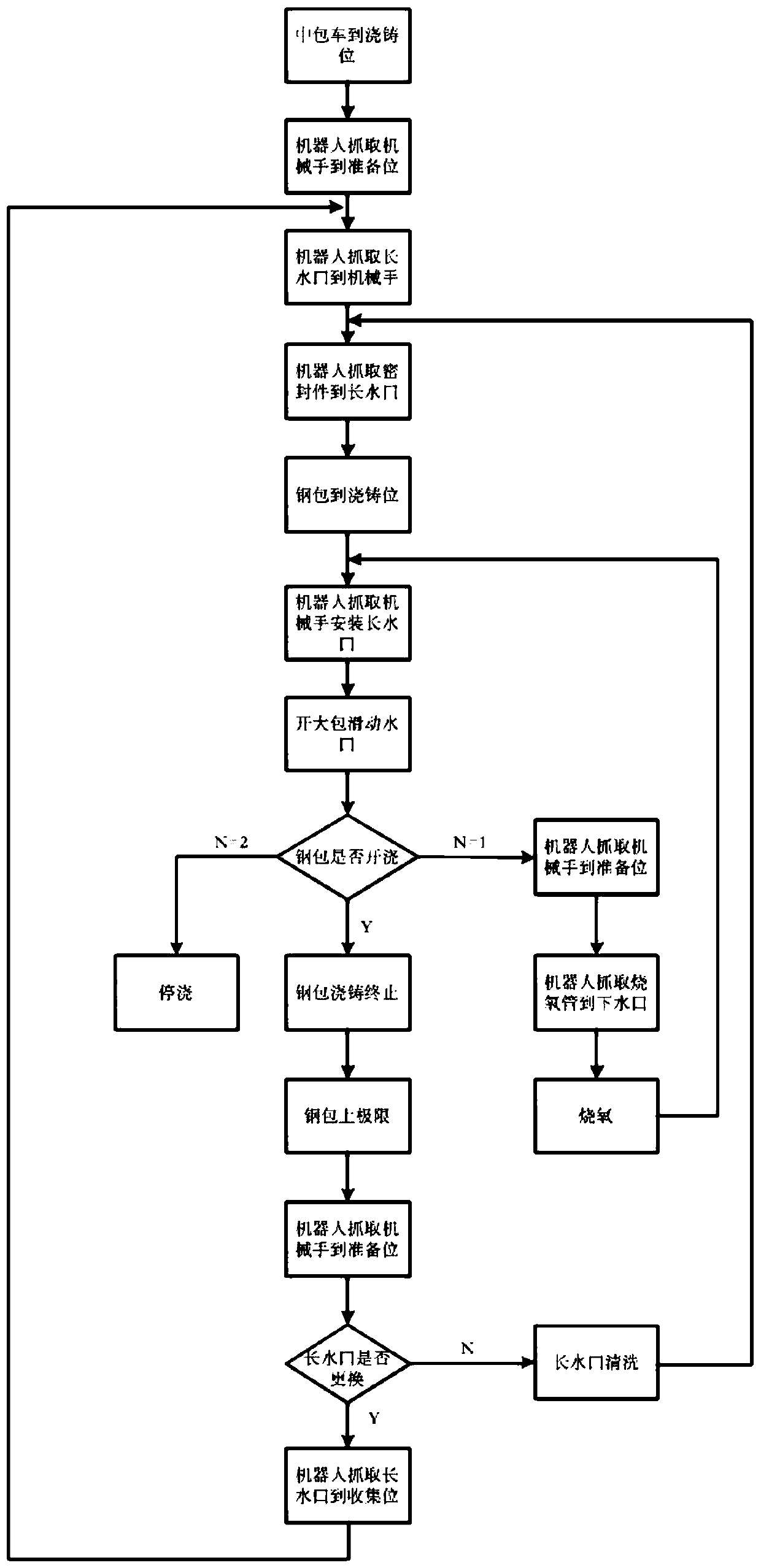

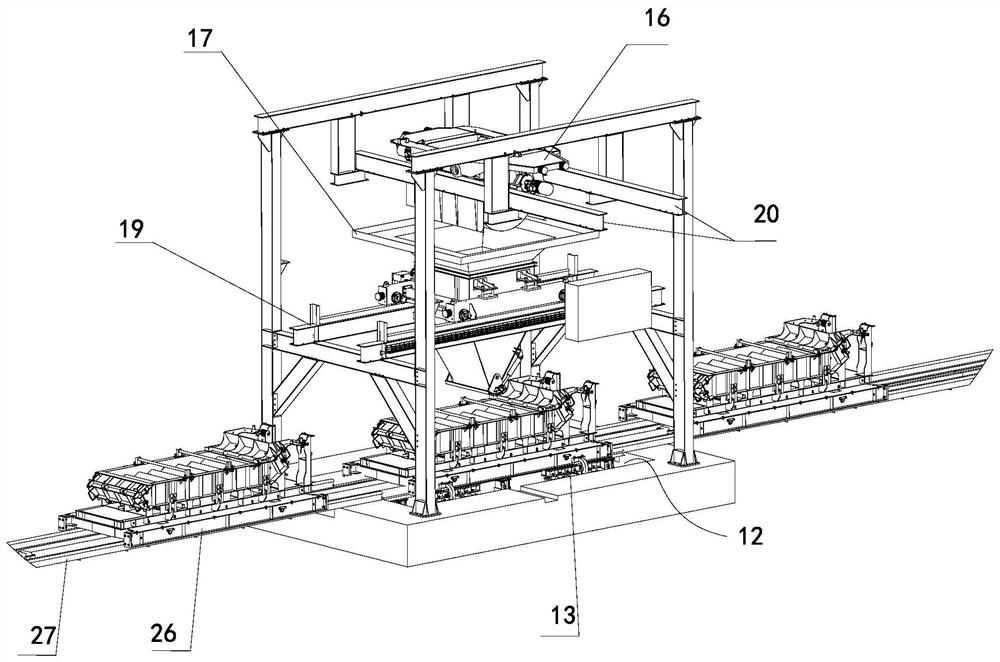

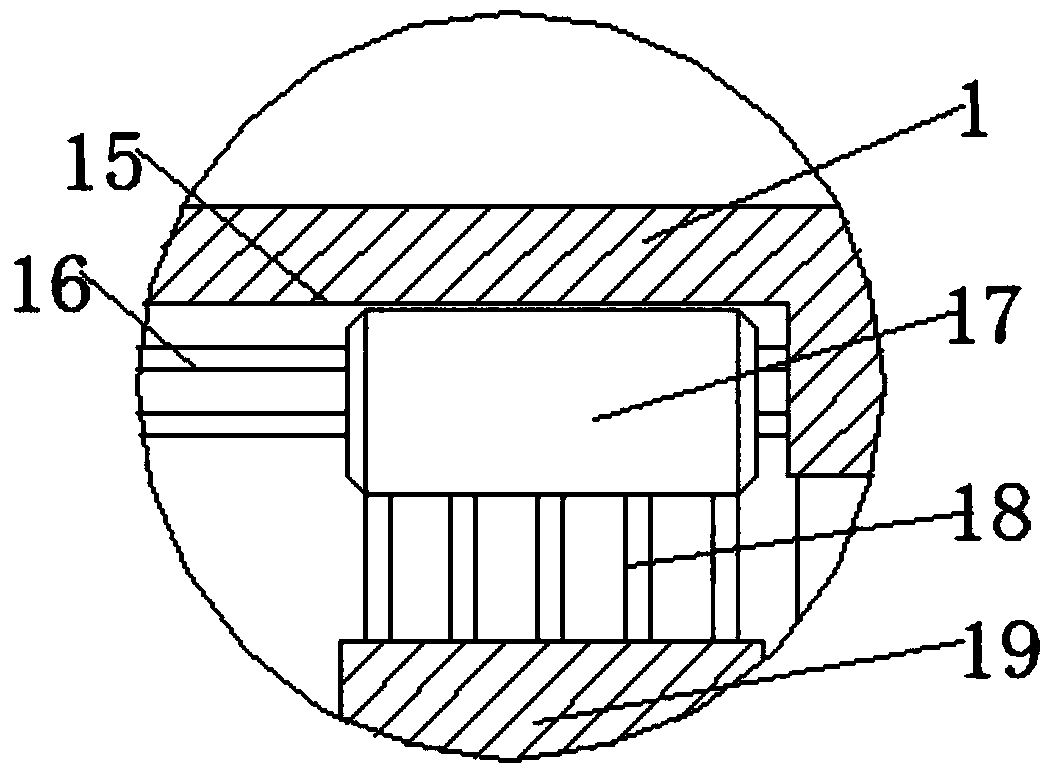

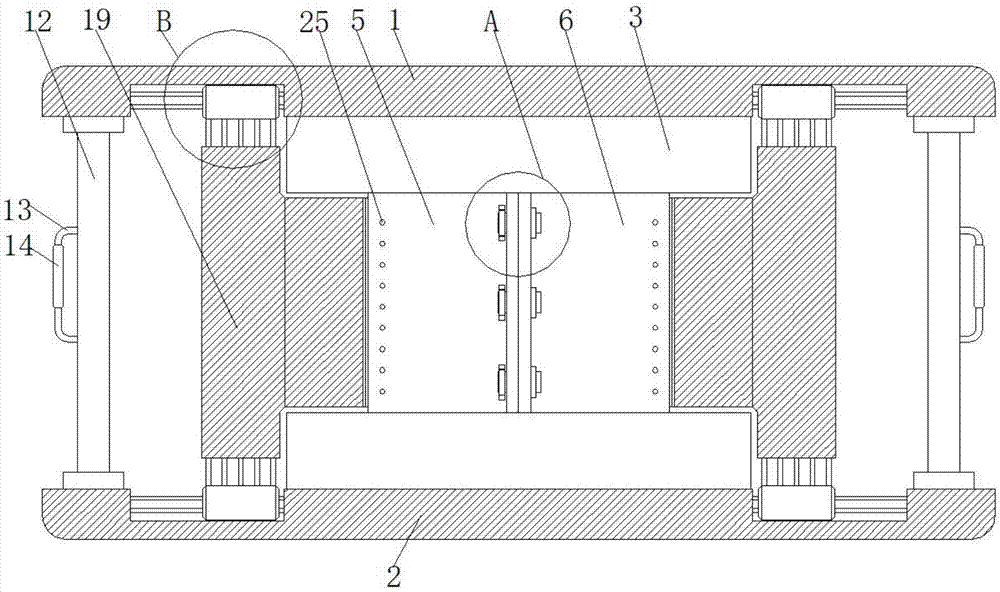

Unmanned system and operation method of steel ladle casting area

ActiveCN111168051AEnsure health and safetyReduce investmentMelt-holding vesselsCasting parameters measurement/indication devicesRobot handEngineering

The invention relates to an unmanned system and operation method of a steel ladle casting area. The method comprises the steps that a mechanical arm is prepared, wherein a robot grabs the mechanical arm from a mechanical arm standby station, the mechanical arm is placed into a fixed bayonet of a locating pile, and the mechanical arm is released; a long nozzle is prepared, wherein the robot takes out the long nozzle from a long nozzle storage device, the long nozzle approaches a mechanical arm long nozzle backing ring according to the set position, the position of the long nozzle is finely adjusted through a robot vision recognition system and a mechanical arm recognition mark, and then the long nozzle is placed into the long nozzle backing ring; a sealing part is mounted, wherein the sealing part is grabbed by the robot from a sealing part storage device and is placed into the long nozzle; and the long nozzle is mounted, wherein after a steel ladle rotates in place, the mechanical armis grabbed by the robot to drive the long nozzle and a lower nozzle to be aligned, the long nozzle is mounted in, the robot retreats, and the mechanical arm supports the long nozzle and presses the lower nozzle all the time. The unmanned system and operation method have the advantages that the mechanical arm and the robot cooperate to replace manual operation, and operations of long nozzle replacement, tundish molten steel temperature measuring and sampling, tundish covering agent adding and steel ladle oxygen pipe burning are completed.

Owner:ANGANG STEEL CO LTD

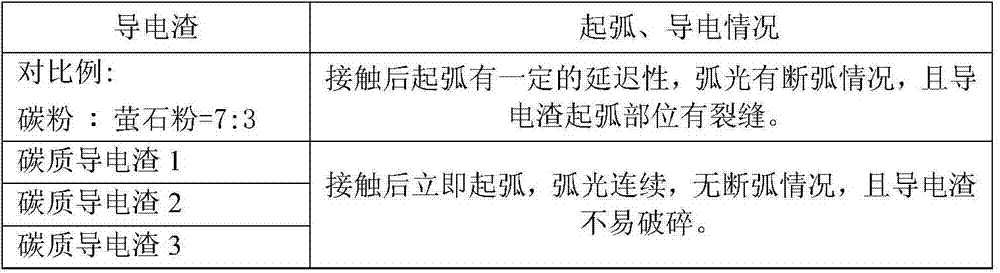

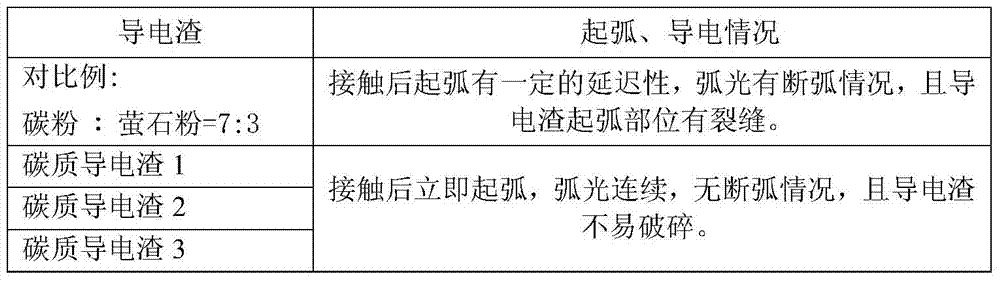

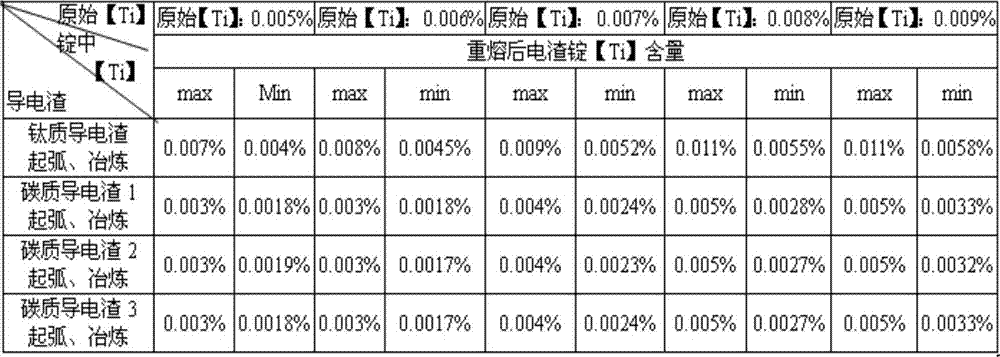

Carbon conductive slag for electroslag steel smelting

The invention provides carbon conductive slag suitable for electroslag steel smelting and a preparation method thereof. The conductive slag is prepared by carbon powder, fluorite and Na2SiO3 water solution, is excellent in electrical conductivity and arc starting performance, can play an important role in the low-titanium-content steel smelting, reduces the waste rate, and improves the production efficiency.

Owner:DAYE SPECIAL STEEL CO LTD

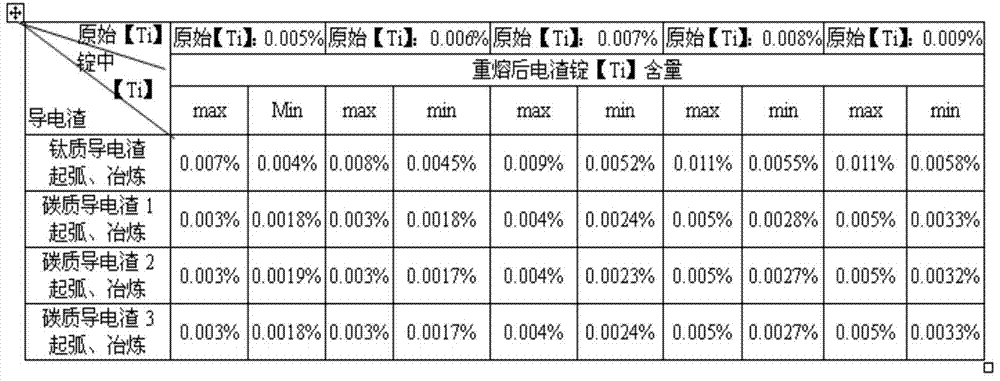

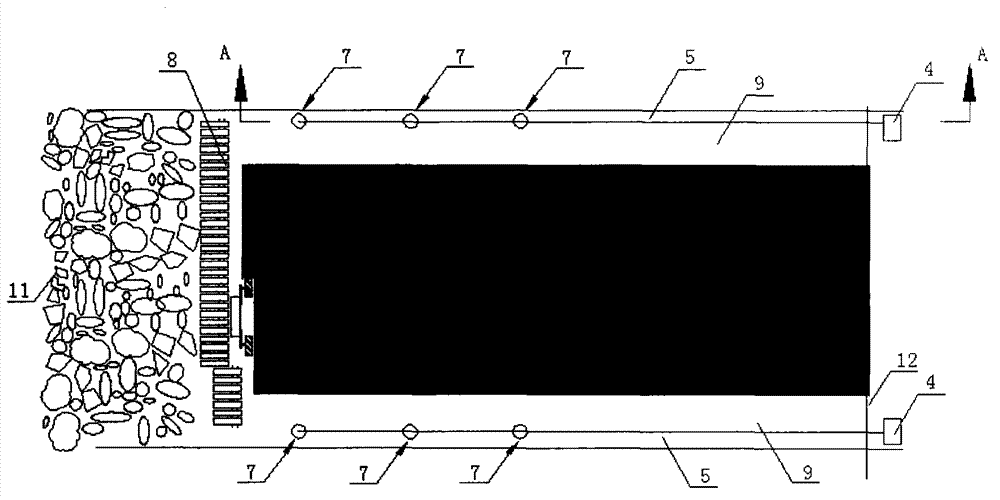

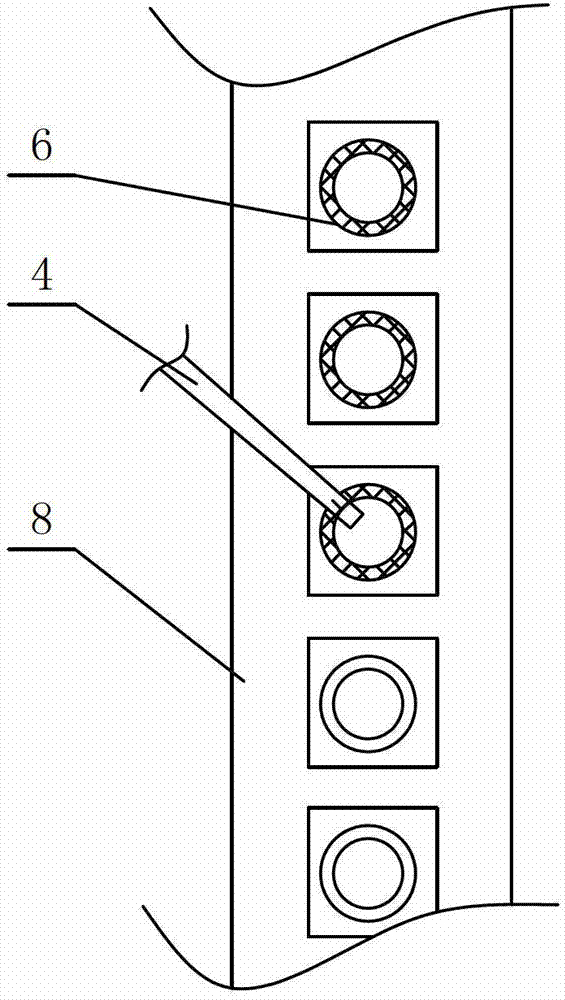

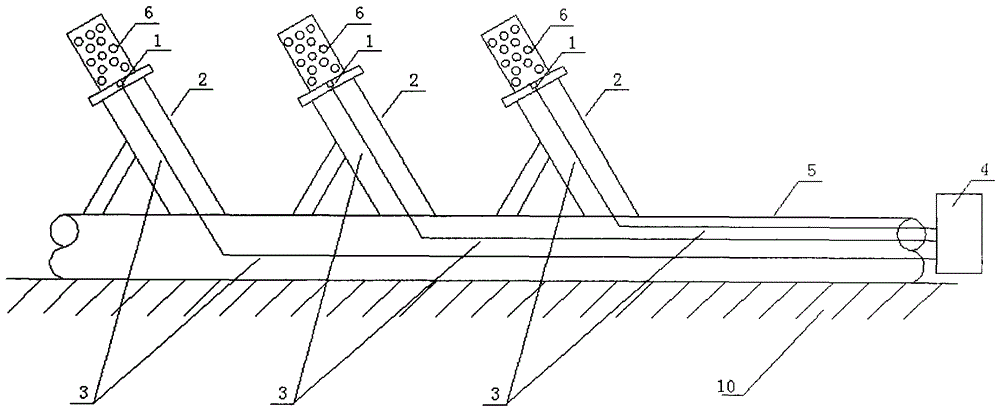

Coal mine goaf temperature monitoring method and monitoring device

InactiveCN103196580AAvoid damageAvoid the effects of stagnant waterThermometers using electric/magnetic elementsUsing electrical meansBaseboardTemperature monitoring

The invention discloses a coal mine goaf temperature monitoring method and a monitoring device. The method includes the following steps: (1) arranging at least one temperature measuring point in a working face gate road, (2) arranging a fixing support device at the temperature measuring point and arranging a temperature sensing element on the fixing support device, (3) connecting the fixing support device and a protecting element and maintaining a certain height between the temperature sensing element and a baseboard, (4) connecting the temperature sensing element and a signal transmission element, wherein the signal transmission element stretches outside a preset stop line through the fixing support device and the protecting element, (5) gradually embedding the temperature measuring point and the temperature sensing element into a goaf, along with the working face being pushed ahead, and (6) using a signal collection and analysis device for receiving signals transmitted by the signal transmission element, analyzing and obtaining temperature change situations in the goaf, and achieving a monitoring purpose. The coal mine goaf temperature monitoring device comprises the temperature sensing element, the fixing support device, the signal transmission element, the signal collection and analysis device and the protecting element. The coal mine goaf temperature monitoring method and the monitoring device are low in cost, convenient to operate and good in monitoring effect.

Owner:CCTEG CHINA COAL RES INST

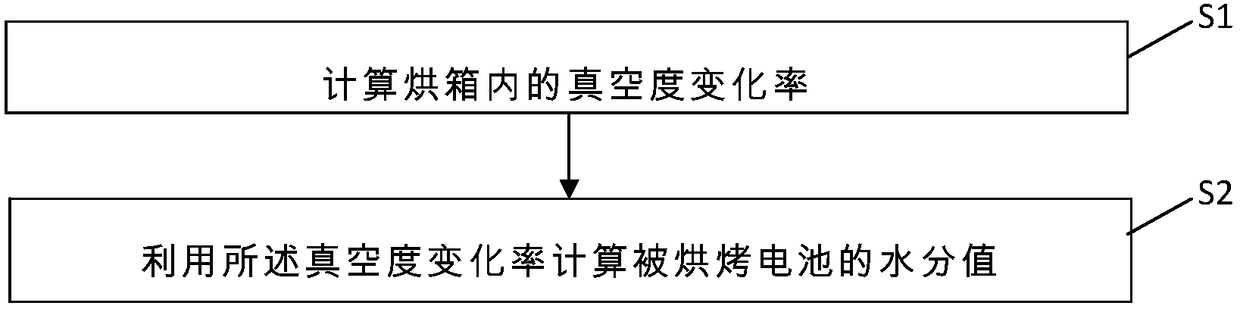

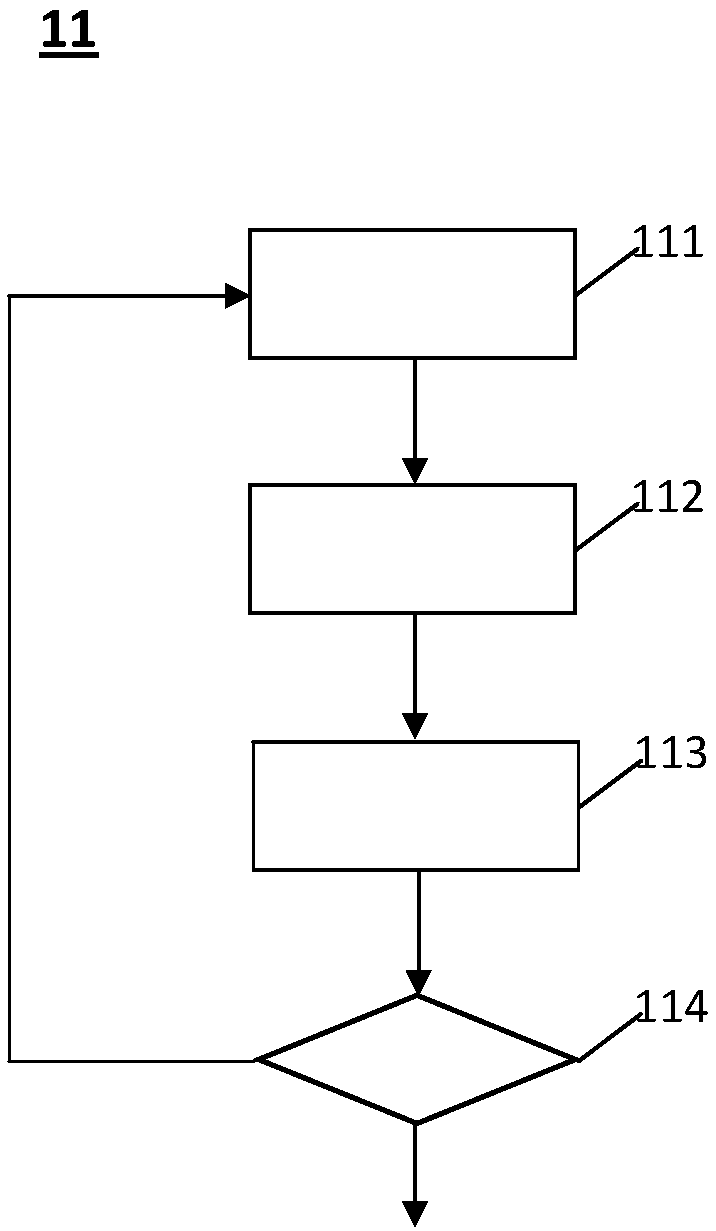

Online moisture measuring method, measuring device and measuring system

PendingCN108278890AGood baking consistencyIncrease productivityDrying solid materials without heatPhysicsTemperature measurement

The invention discloses an online moisture measuring method, measuring device and measuring system. The online moisture measuring method, measuring device and measuring system are used for judging thedrying degree of a baked battery on line. The measuring method comprises the following steps of calculating the change rate of the vacuum degree in a baking oven; and calculating the moisture value of the baked battery by utilizing the change rate of the vacuum degree. The measuring device comprises a first module and a second module, wherein the first module is used for calculating the change rate of vacuum degree in the baking oven, and the second module is used for calculating the moisture value of the baked battery by utilizing the change rate of the vacuum degree. The measuring system comprises a vacuum degree measuring device, a temperature measuring device and an online moisture measuring device, wherein the vacuum degree measuring device is arranged in the baking oven, the temperature measuring device is arranged in the baking oven, and the online moisture measuring device is connected to the vacuum degree measuring device and the temperature measuring device. According to theonline moisture measuring method, measuring device and measuring system, the moisture value of the battery is calculated by utilizing the real-time environmental parameters in the baking oven, the baking consistency of the battery is good, the battery cannot be damaged, the production efficiency can be greatly improved, and the production cost can be greatly lowered.

Owner:深圳力士智造科技有限公司

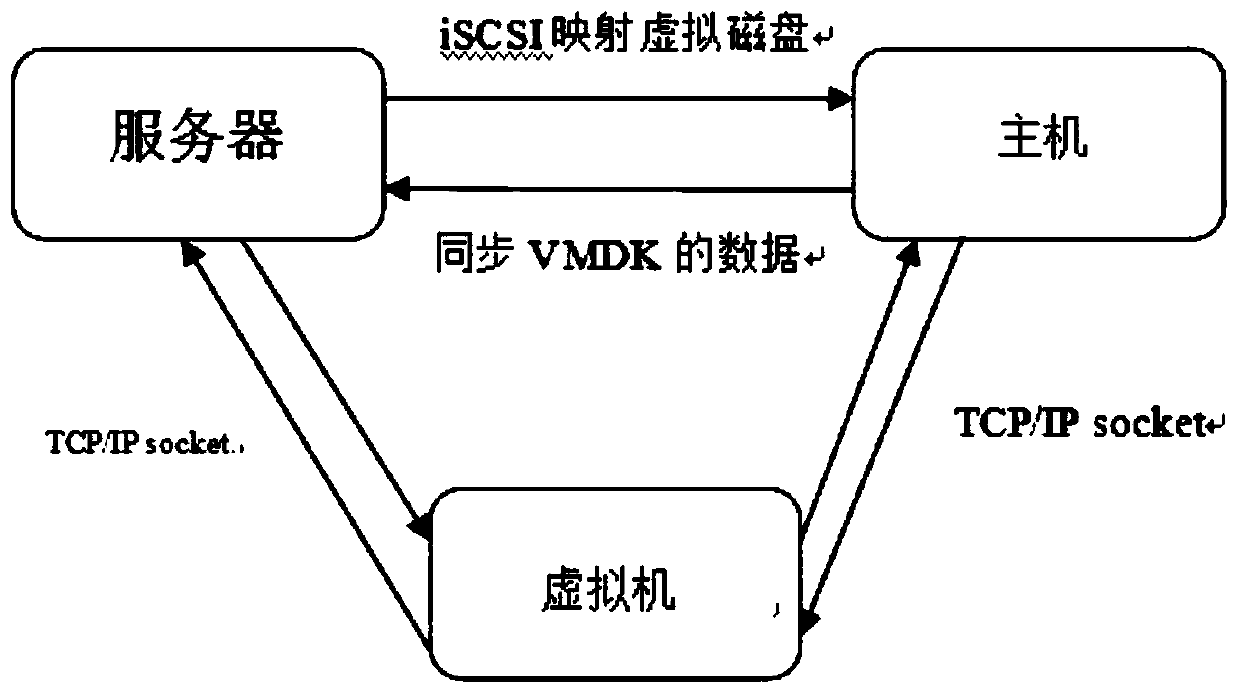

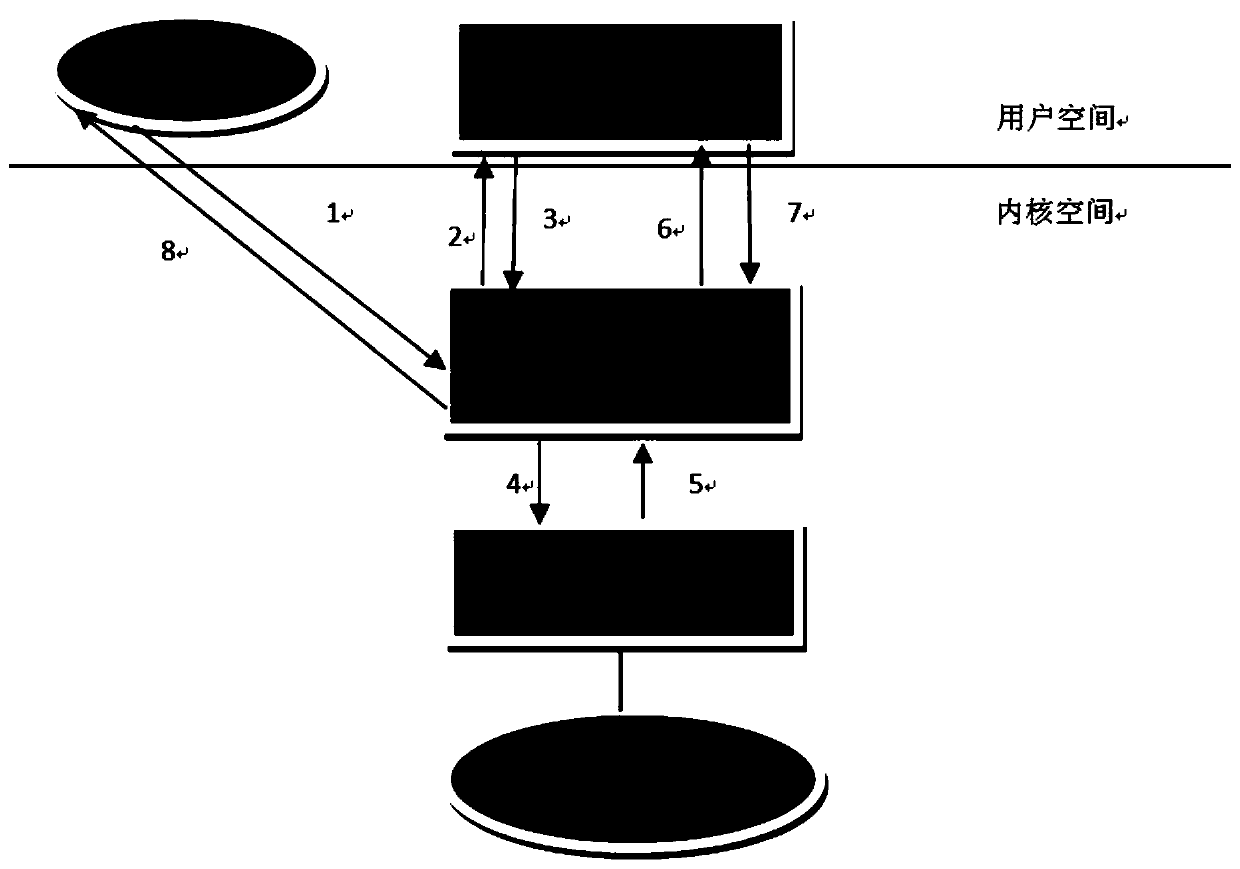

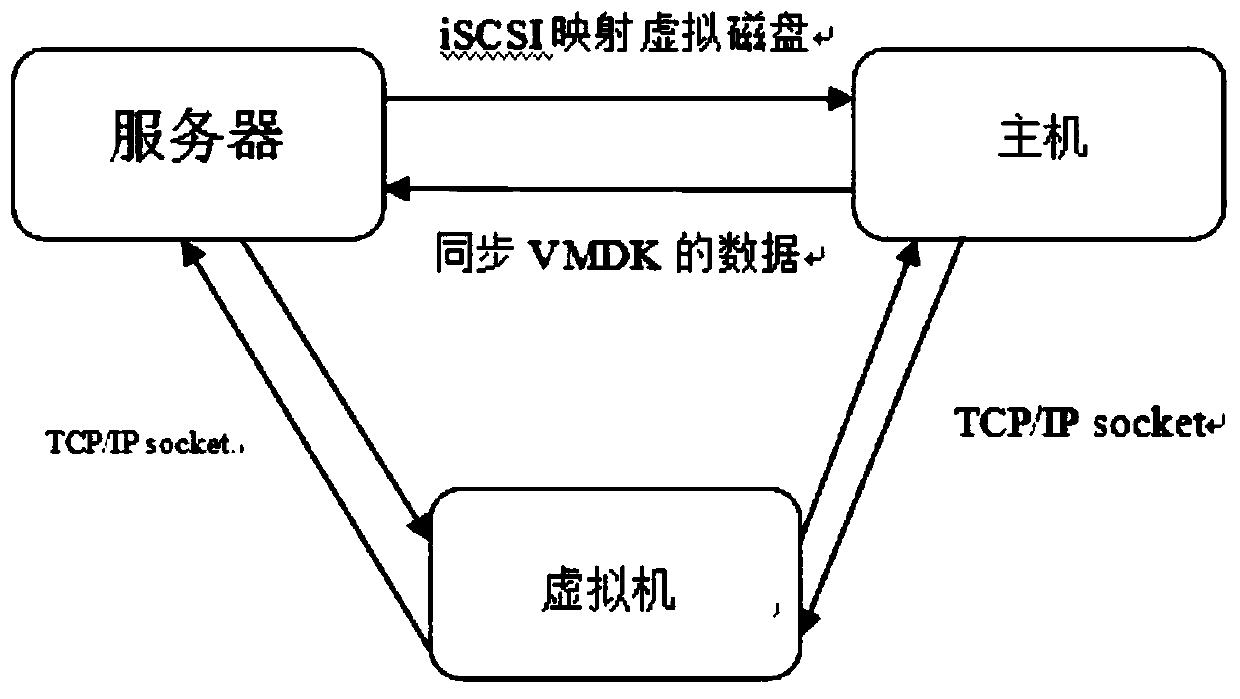

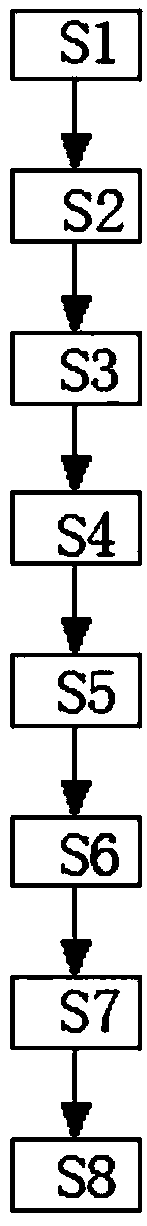

Continuous data protection method of application programming interface for IO filtering

ActiveCN111124620AProduction will not affectSoftware simulation/interpretation/emulationDisks (device)Operational system

The invention discloses a continuous data protection method of an application programming interface for IO filtering. The continuous data protection method comprises the following steps: creating a virtual machine on a host; installing a VIB plug-in program on the host; mounting a virtual disk device on the server on the host; carrying out full-amount and incremental backup on a virtual machine disk on the host; capturing an I / O request sent to a virtual machine disk by a guest operating system of a virtual machine on a host in real time, and writing the captured I / O request into a virtual disk mounted on the host by a server; and for the I / O request which cannot be processed in time, recording the I / O request in the bitmap file, and then synchronizing the I / O request of the virtual machine disk recorded in the bitmap file to the virtual disk mounted on the host by the server. According to the method, only the VIB plug-in program needs to be installed on the host and a virtual machineneeds to be newly built, the plug-in works in the user space of the host, and system kernel crash of the host cannot be caused by faults of the plug-in.

Owner:NANJING UNARY INFORMATION TECH

Preparation ingredients and preparation method of preserved duck eggs

The invention discloses preparation ingredients of preserved duck eggs. The ingredients include duck eggs, plant ash, salt, tea residues, sodium carbonate decahydrate, loess, rice husks, quicklime, ethylenediamine tetraacetic acid and flavoring powder. The mass ratio of the ingredients is as follows: 50.0-100.0 parts of the duck eggs, 500.0-1000.0 parts of the plant ash, 150.0-300.0 parts of the salt, 40.0-80.0 parts of the tea residues, 7000.0-9000.0 parts of the rice husks, 250.0-500.0 parts of the sodium carbonate decahydrate, 550.0-1100.0 parts of the quicklime, 10.0-30.0 parts of the ethylenediamine tetraacetic acid and 100.0-200.0 parts of the flavoring powder. Compared to the prior art, the beneficial effects of the invention are as follows: lead powder is a necessary ingredient when producing traditional preserved duck eggs, but the use of the lead powder greatly increases the lead content of the traditional preserved duck eggs. However, through adopting the ethylenediamine tetraacetic acid to replace the lead powder, not only is preserved duck egg production not be influenced, but also the lead content of the preserved duck eggs can be effectively reduced; and meanwhile, through adding the flavoring powder, the produced preserved duck eggs have a five-spice flavor so as to be convenient for preserved duck egg selling.

Owner:安徽省卓创信息科技服务有限公司

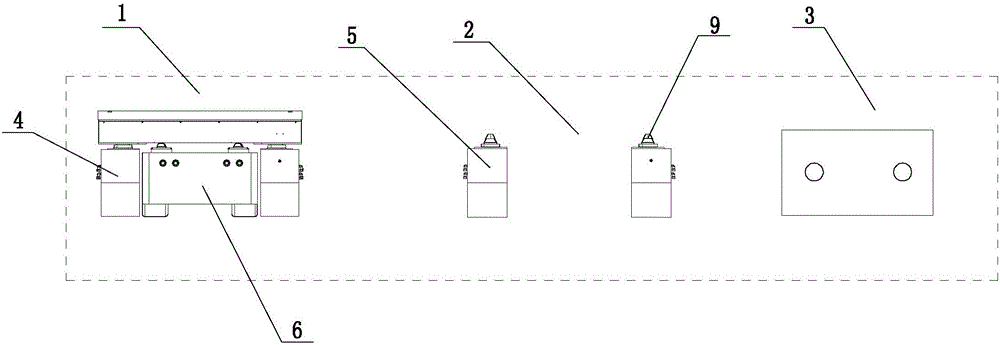

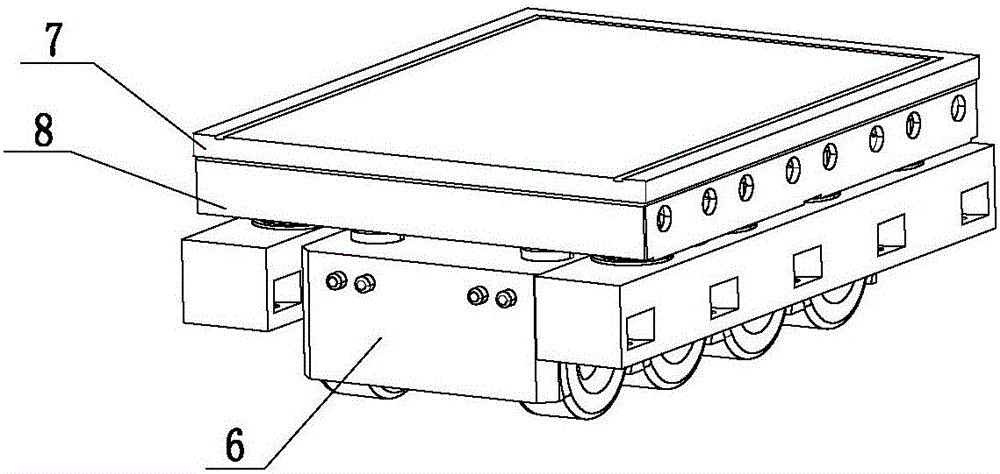

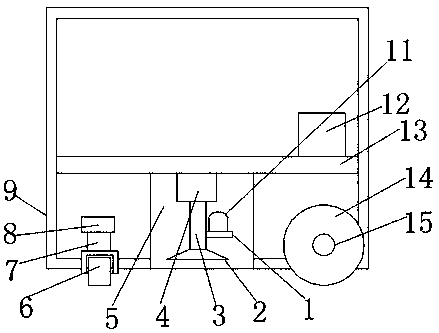

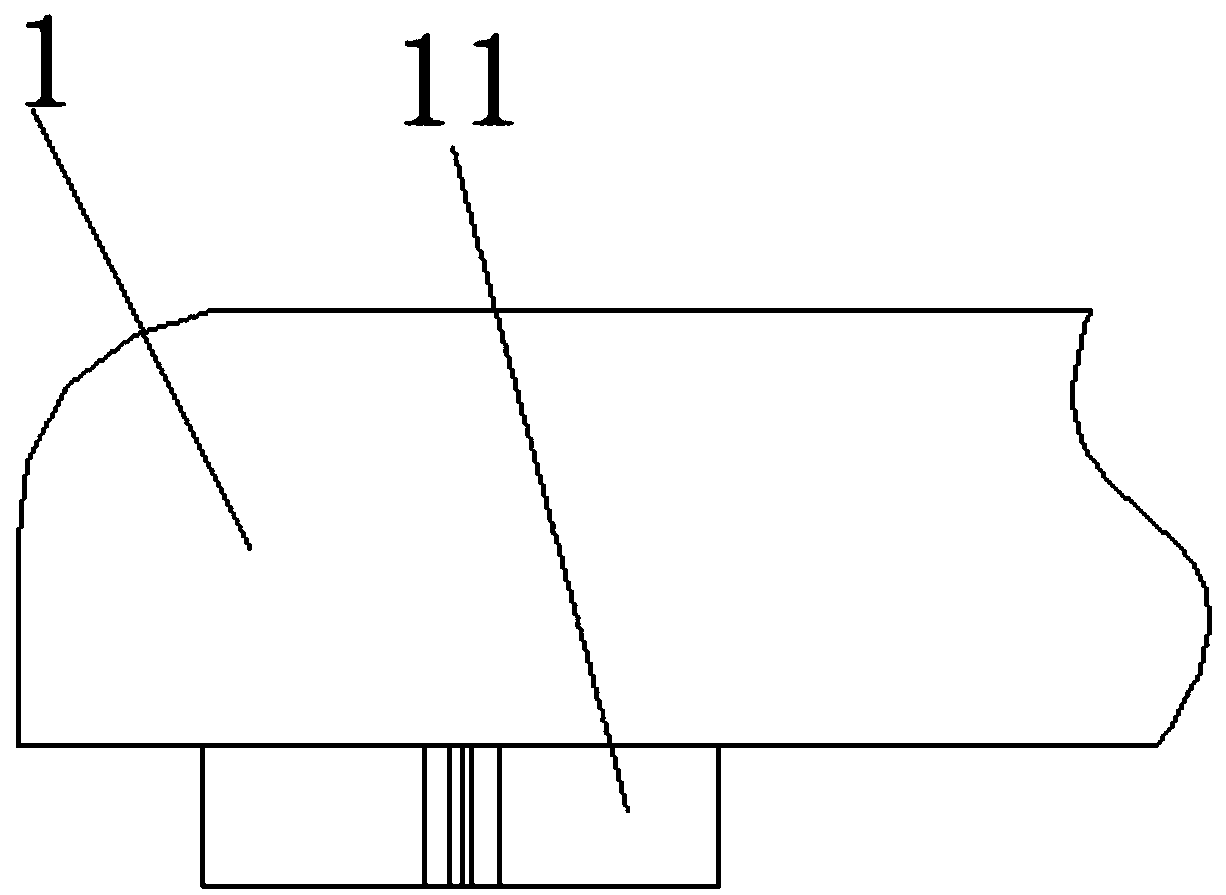

Transfer system for aircraft part machining

InactiveCN106425643ASimplify tedious workHigh repeat positioning accuracyMetal working apparatusTransfer systemElectrical and Electronics engineering

The invention discloses a transfer system for aircraft part machining and belongs to the technical field of aircraft part machining. The transfer system for aircraft part machining comprises a transfer trolley, a tray, a tray holder, a host machining storage area and an aircraft part storage area. The tray is provided with a machining station for workpiece machining, and aircraft parts are preassembled on the machining station of the tray. The tray holder is arranged on the top of the transfer trolley. The top of the transfer trolley is provided with a plurality of ejector rods for jacking the tray holder. A storage area for storage of the tray is arranged on the top face of the tray holder. The aircraft part storage area comprises two rows of jacking racks for storage of the tray holder, a transfer trolley containing channel is formed between the jacking racks, and the height of the jacking racks is equivalent to that of the transfer trolley. The host machining storage area is arranged at the bottom of a host used for machining the aircraft parts, and comprises two rows of second jacking racks for storage of the tray and the tray holder, a transfer trolley containing channel is formed between the two second jacking racks, and the height of the second jacking racks is equivalent to that of the transfer trolley.

Owner:ZHEJIANG RIFA AVIATION DIGITAL EQUIP

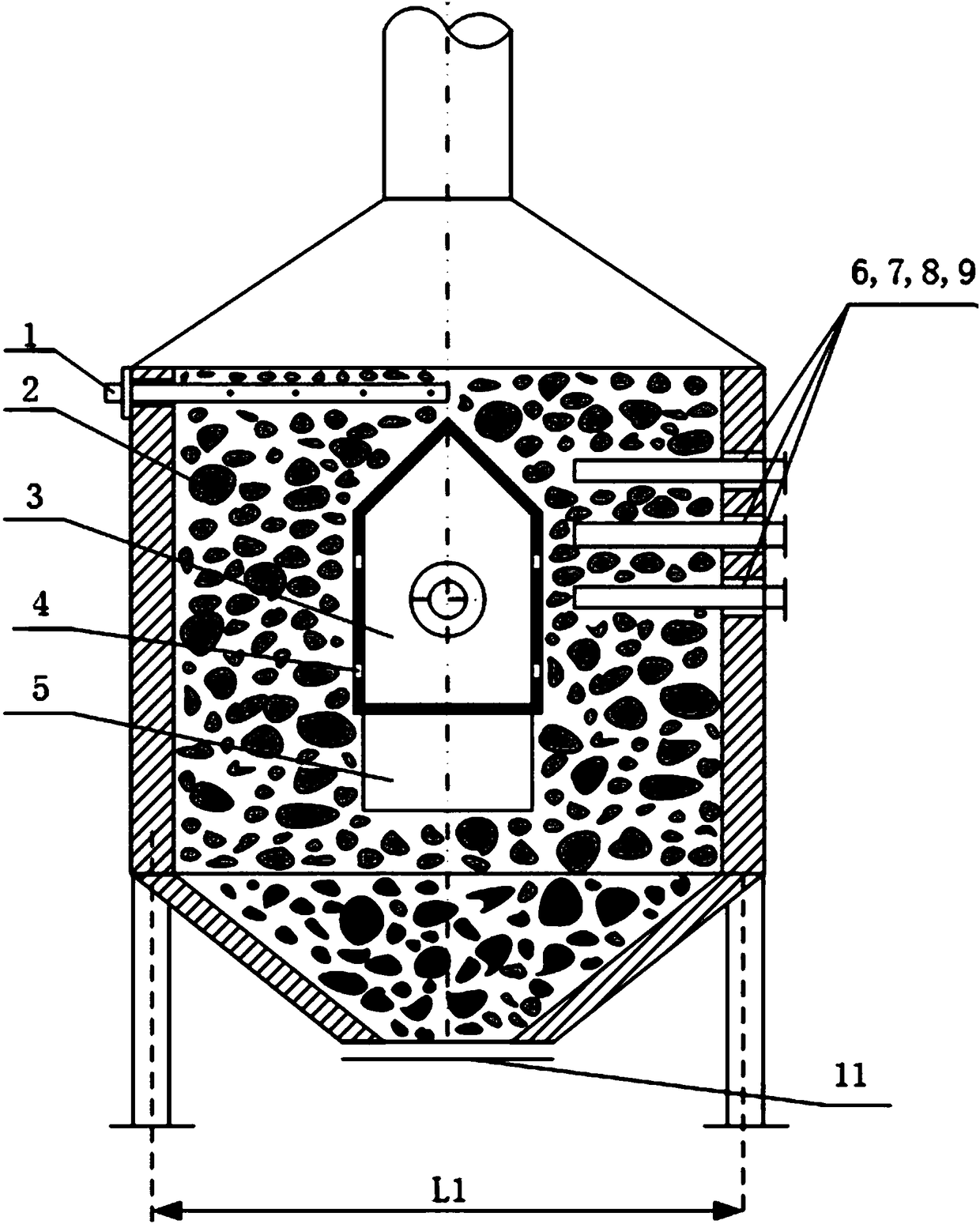

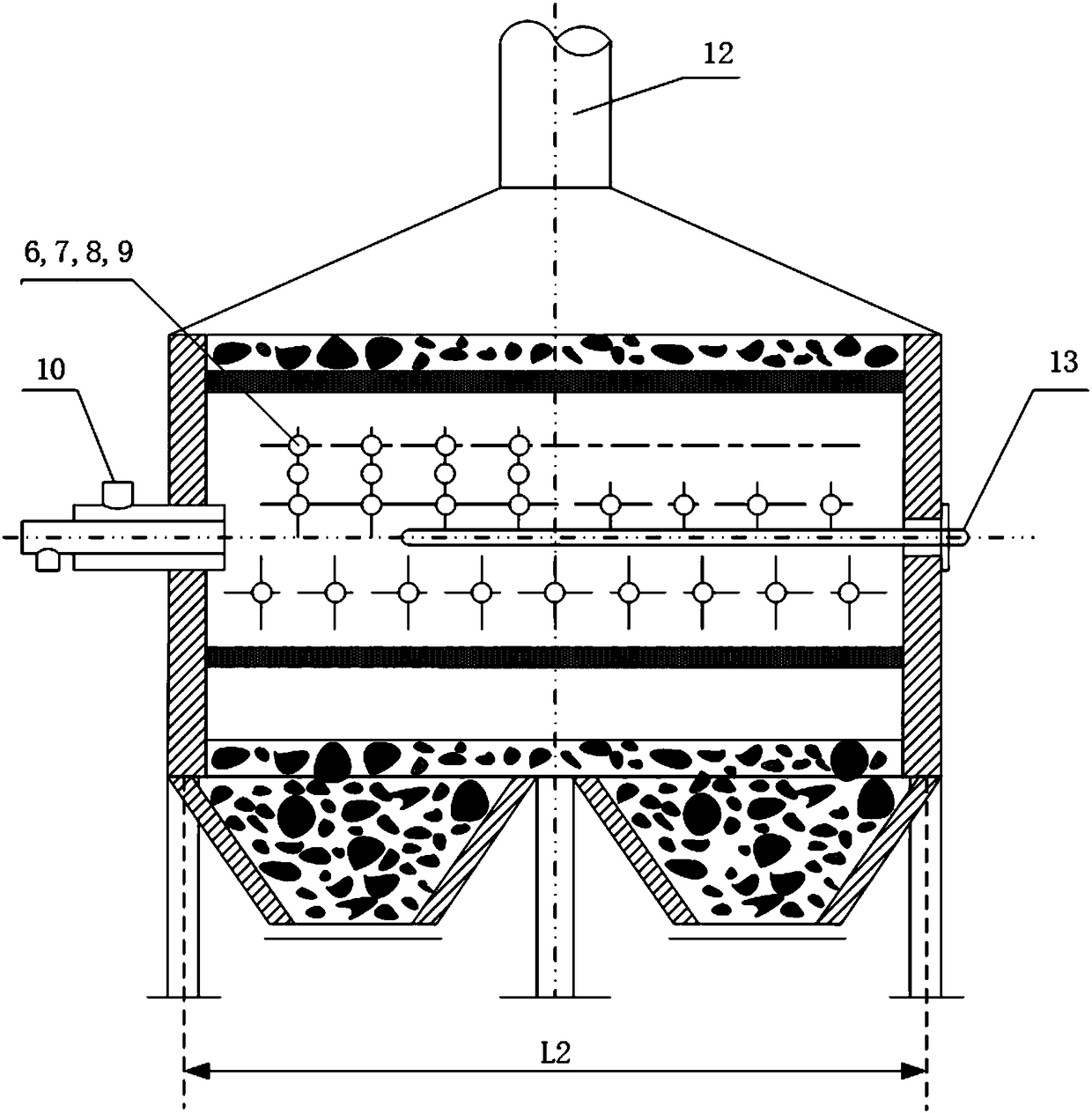

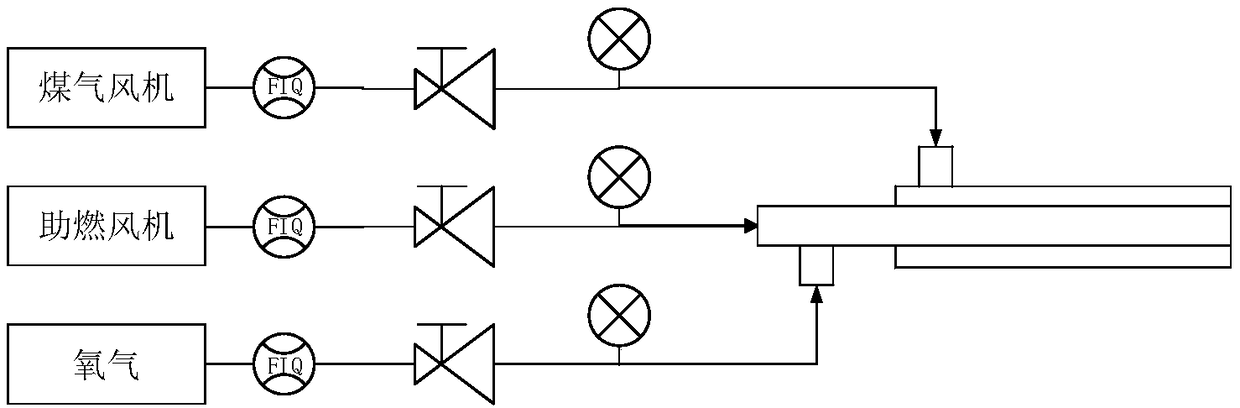

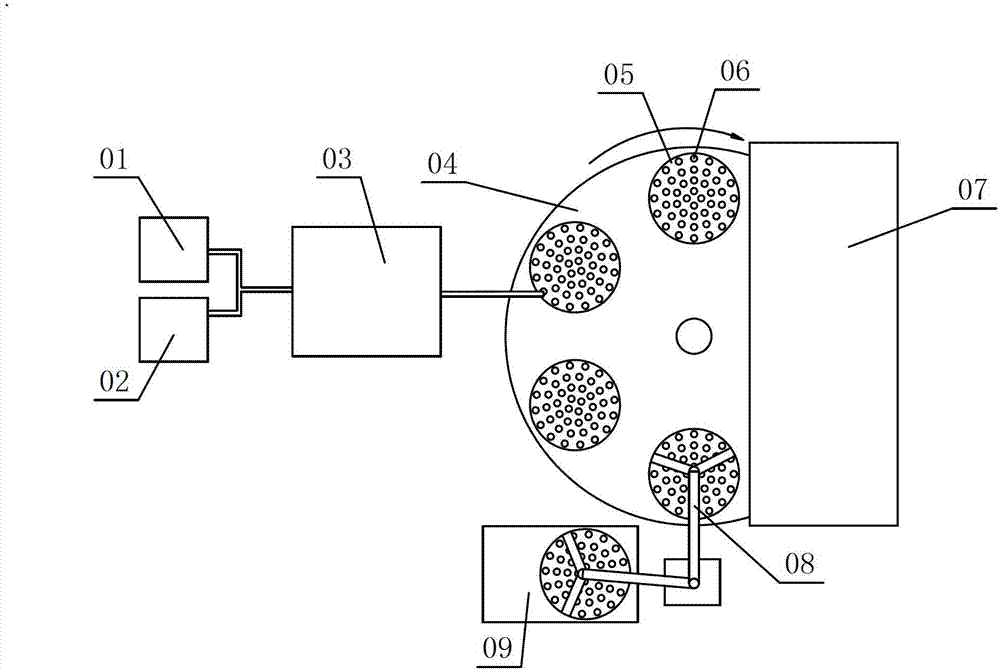

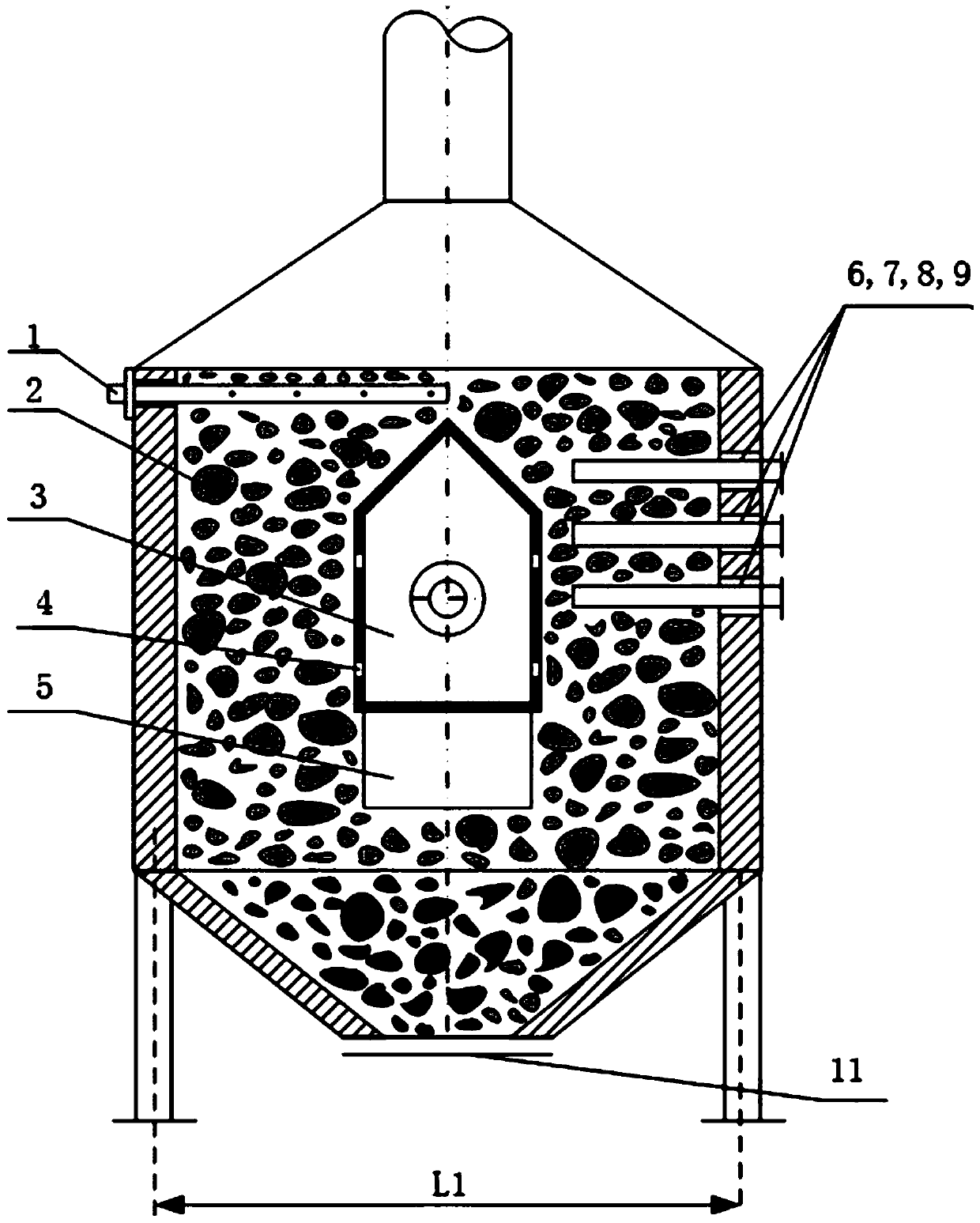

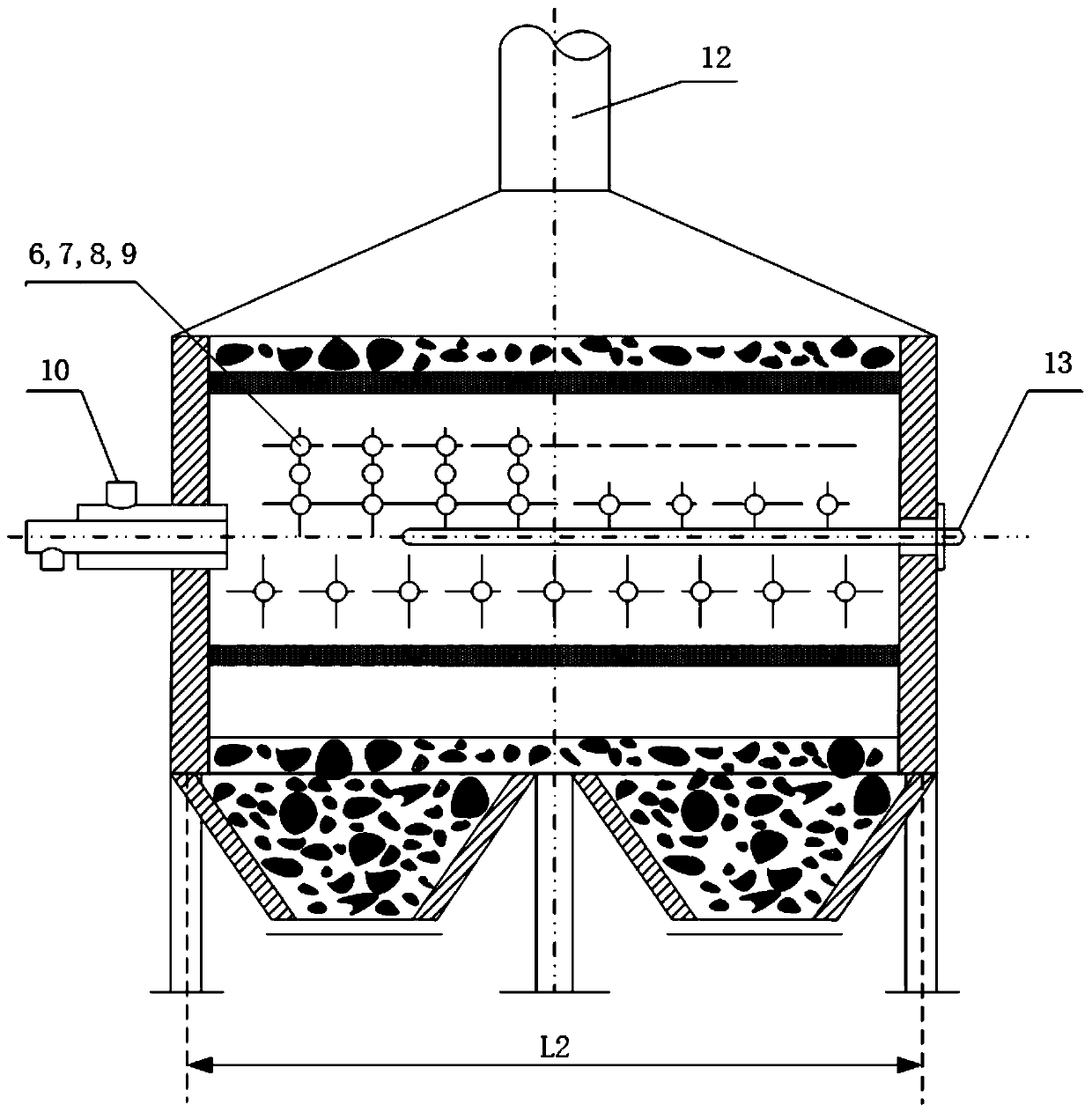

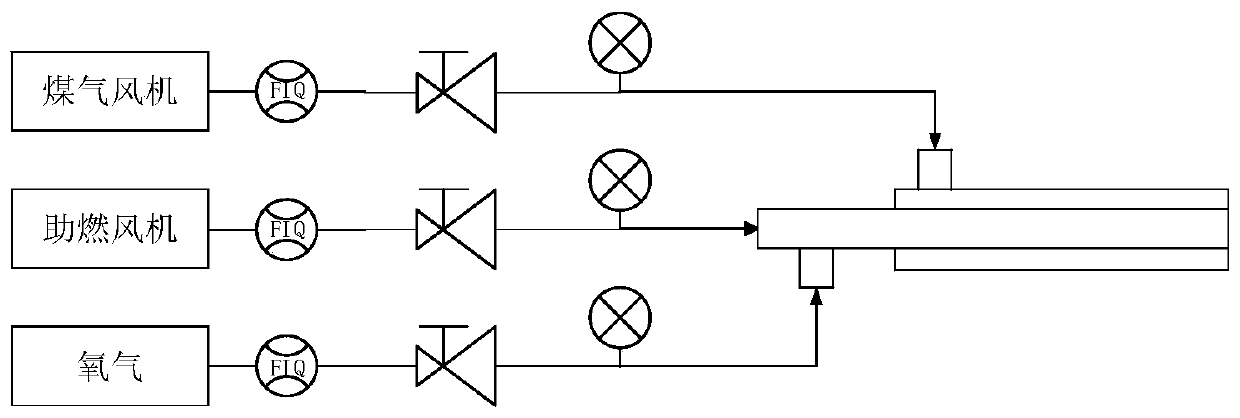

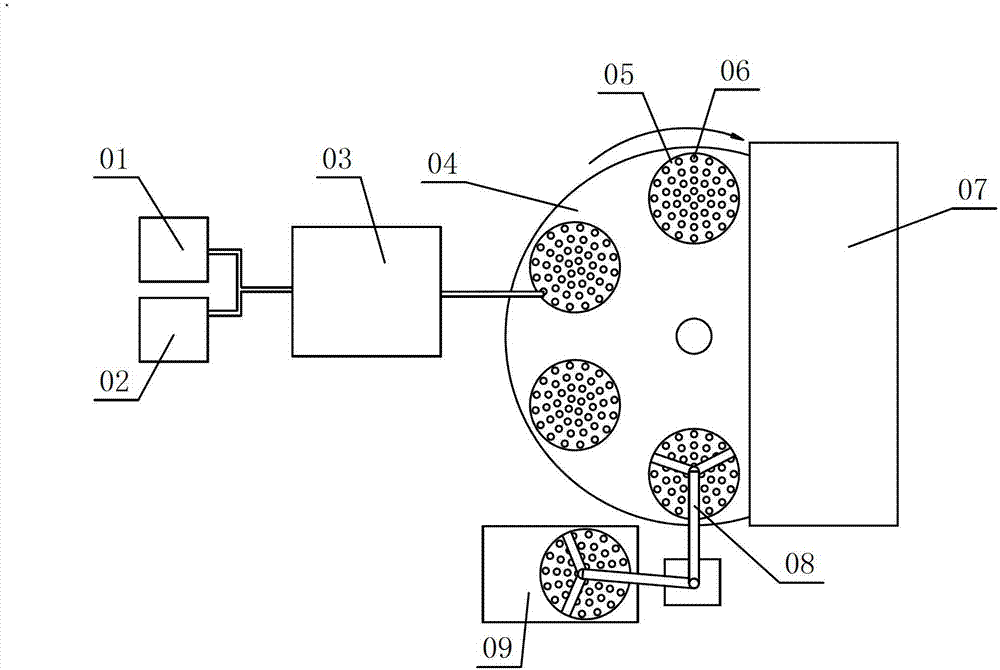

Internal heat low temperature dry distillation thermal state simulation detection device and method

ActiveCN108181121AImprove applicabilityAvoid exploringStructural/machines measurementThermal stateProcess engineering

The invention discloses an internal heat low temperature dry distillation thermal state simulation detection device and method. The outlets of a combustion blower, a gas blower and an oxygen supply device are respectively communicated with the oxidant gas inlet, the gas inlet and the oxygen inlet of a heating unit through pipelines, and each pipeline is provided with a regulating monitoring control device; the furnace body is internally provided with a flame path, the wall surface of the flame path is provided with multiple flame holes, and the heat output port of the heating unit is piped into the flame path; the furnace body is internally filled with semi-coke which is arranged outside the flame path; and the furnace body is provided with multiple detection devices, and the detection ends of the detection devices are piped into the flame path or the detection ends of the detection devices are piped into the semi-coke in the furnace body. The physical-chemical process in the internalheat low temperature dry distillation furnace can be reflected in a simulation way through the offline test so that the theoretical guidance can be provided for solving the problems appearing in industrial production, the time required for solving the problems can be reduced without influencing production and the economic loss can also be reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Repairing method for refractory material layer of rotary kiln

The invention relates to the technical field of rotary kiln, in particular to a repairing method for a refractory material layer of a rotary kiln. The repairing method comprises the steps that temperature in a rotary kiln body is reduced under the condition that the rotary kiln is not shut down; and the refractory material layer to be repaired is directly repaired through a slurry gunning machine,wherein the gunning slurry can be quickly condensed under a high-temperature condition, so that the refractory material layer to be repaired can be repaired in time, and prevented the refractory material layer to be repaired from further falling off to affect the production of the rotary kiln. According to the repairing method for the refractory material layer of the rotary kiln, the repair effect is good, the production of the rotary kiln cannot be influenced, and the service life of the rotary kiln is prolonged.

Owner:PANZHIHUA GANGCHENG GROUP

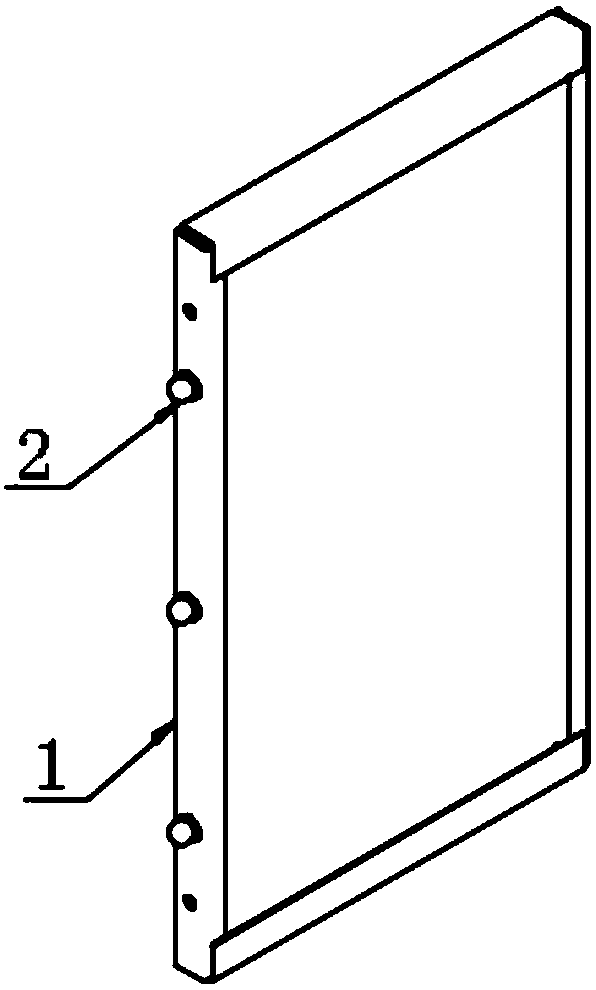

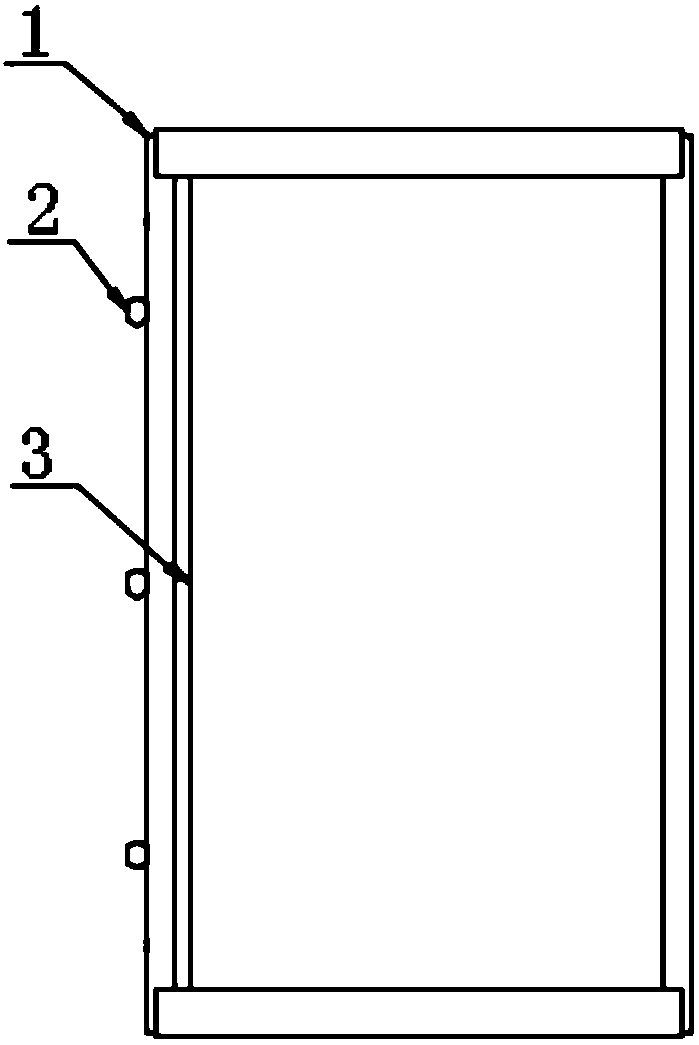

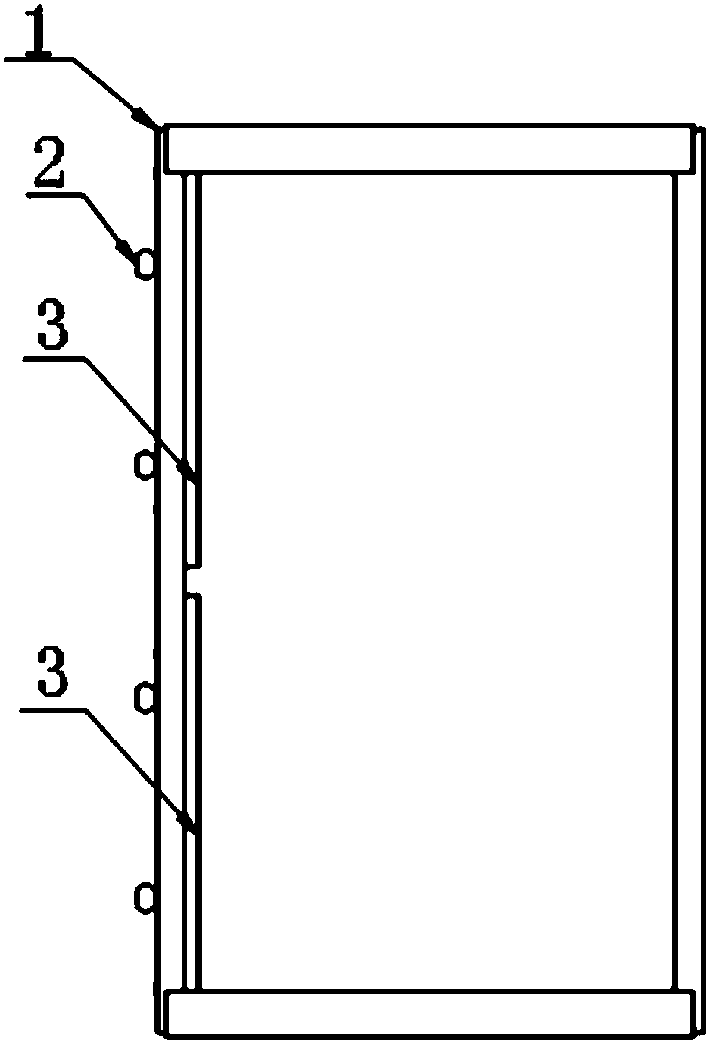

Hook type car wall, elevator car with car wall and assembly method of car wall

InactiveCN110077937ALow costImprove connection strengthBuilding liftsAutomotive engineeringCompressibility

The invention discloses a hook type car wall, an elevator car with the car wall and an assembly method of the car wall. The hook type car wall comprises car wall panels, a reinforcing rib and hangingnails, wherein the car wall panels include a main panel and two side panels, holes are formed in the side panels, firstly, the hanging nails are installed on the reinforcing rib, then the hanging nails respectively pass through the corresponding holes in the side panels, finally, the reinforcing rib is fixedly connected with the side panels, and an elastic piece is installed between the reinforcing rib and the car wall panels. According to the hook type car wall, a hook and the reinforcing rib can be produced in advance, the same reinforcing rib can be used for the car walls with different widths and different heights, and the production of the car wall cannot be influenced; the thickness of the reinforcing rib is increased, or the reinforcing rib is bent, so that the connecting strength of the hanging nails can be increased, and the thickness of the car wall panels does not need to be changed, so that the cost is reduced; and the elastic piece has compressibility, so that the hangingnails of the same size are suitable for connecting the car walls with different thicknesses, gaps cannot be generated between the car walls, the connecting strength is increased, and the effect of vibration and noise reduction is achieved.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

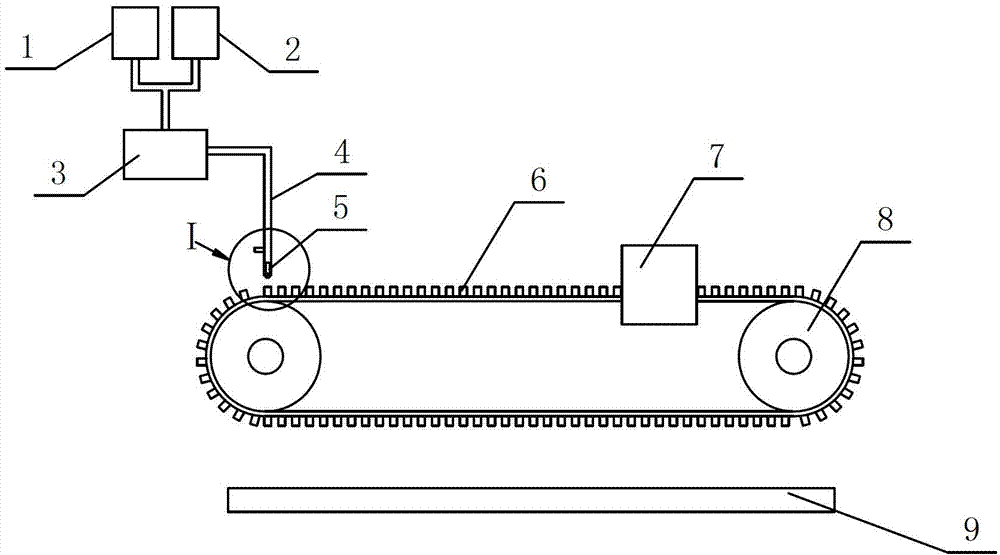

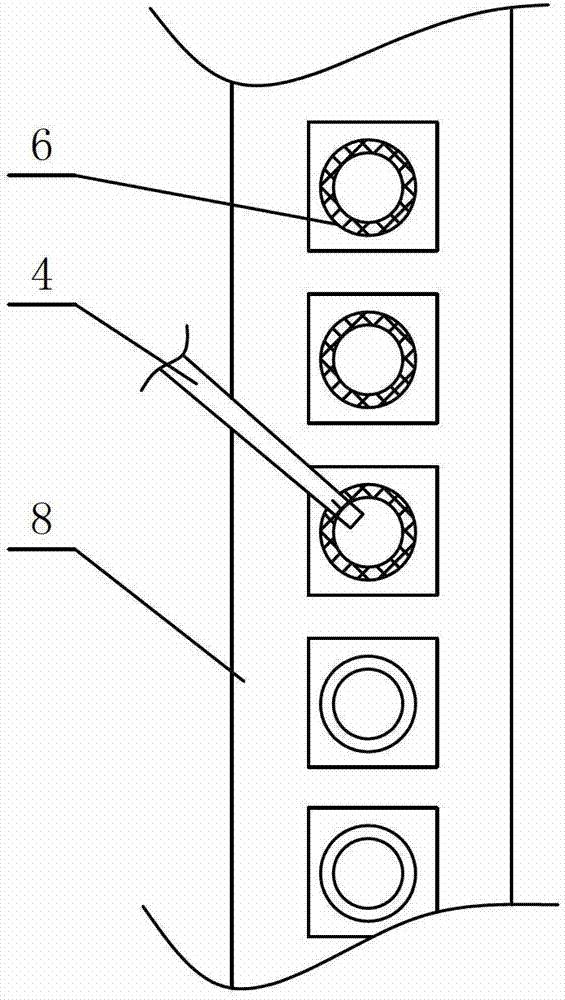

Production process of foaming headset sleeve

InactiveCN102857855AReduce production processImprove molding qualityElectrical transducersMixed materialsMaterials science

The invention discloses a production process of a foaming headset sleeve, and the production process comprises the following steps of a, preparation of materials: placing a well mixed material A and a well mixed material B respectively into a mixing kettle to be stirred; b, mixing: simultaneously placing the material A and the material B into the mixing kettle to be adequately stirred and mixed to form a mixed material; c, injection: continuously injecting the mixed material into a plurality of molds which are matched with each headset sleeve in shape through a mixing reaction kettle, arranging the molds in a single row in the transverse direction, and realizing automatic circular work through a transmission device; d, baking: automatically feeding the molds with the mixed material into a baking box to be baked through the transmission device; and e, demolding: pouring out the headset sleeves from the molds through the transmission device so as to enable the headset sleeves to be separated from the molds after baking is completed. Compared with the prior art, the production process of the foaming headset sleeve has the advantages of simplicity in production equipment, few in manufacturing procedures, simplicity in mold structure, long in service life, capability of being formed in one step, good forming quality, low production cost and low energy consumption.

Owner:刘天镐

Dry kiln refractory material layer repairing method

InactiveCN108253796AGood repair effectExtended service lifeLinings repairInternal temperatureFlameout

The invention relates to the technical field of dry kilns, in particular to a dry kiln refractory material layer repairing method. The method comprises the steps that under the condition of no flameout of a dry kiln, the internal temperature of a kiln body of the drying kiln is reduced to 80-170 DEG C; a slurry gunning machine is used for directly repairing a refractory material layer to be repaired, the repaired area is less than 0.15 square meter, and sprayed slurry can be quickly solidified under the high-temperature conditions and can repair the refractory material layer to be repaired intime to prevent the refractory material layer from further falling off and affecting production of the dry kiln. Through the repairing method, the repairing effect is good, production of the dry kilncannot be affected, and the service life of the dry kiln is prolonged.

Owner:四川有色金砂选矿药剂有限公司

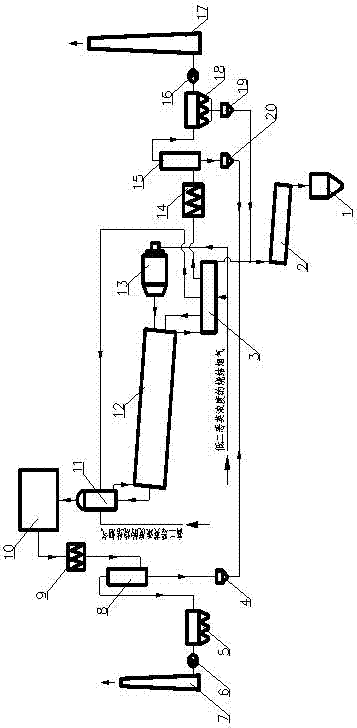

Comprehensive processing process for sintering smoke gas

ActiveCN102393147BProduction will not affectRealize desulfurization treatmentIncreasing energy efficiencyHandling discharged materialThermodynamicsCombustion

The invention discloses a comprehensive processing process for sintering smoke gas, wherein traditional cement-producing equipment is directly adopted by the process, and the process comprises the following steps of: 1) recovering the residual heat, wherein one part of the sintering smoke gas with low dioxin concentration is used as combustion-supporting air to enter an air-heating furnace of a rotary kiln, the other part of the sintering smoke gas is used as cooling gas to enter a grate cooler, the high-temperature smoke gas coming from the grate cooler is used as combustion-supporting gas to respectively enter the rotary kiln and enter a decomposing furnace from the middle part of the decomposing furnace, and the high-temperature smoke gas after being combusted through the rotary kiln enters the decomposing furnace from the bottom of the decomposing furnace; 2) removing dioxin, wherein the sintering smoke gas with high dioxin concentration enters the decomposing furnace from the middle part of the decomposing furnace, and the temperature in the decomposing furnace is larger than or equal to 800 DEG C; and 3) desulfurizing, wherein the high-temperature smoke gas after the dioxin is removed through the decomposing furnace enters a preheater for temperature reduction, the smoke gas after the temperature reduction through the preheater enters a kiln-tail desulfurizing device fordesulfurization after passing through a kiln-tail residual-heat boiler, the desulfurized smoke gas is discharged after dust removal, and a desulfurizer is placed in the kiln-tail desulfurizing device.

Owner:CISDI ENG CO LTD

Preparation device of fluoroplastic resin thin film

InactiveCN107804006AImprove stabilityAvoid offsetFlat articlesHydraulic cylinderArchitectural engineering

The invention discloses a fluoroplastic resin film preparation device, which comprises a preparation machine body, a horizontally arranged isolation plate is welded inside the preparation machine body, and a drive motor is fixed on the outer wall of the top end of the isolation plate by screws. The middle of the bottom outer wall of the machine body is recessed upwards to form a groove, the top inner wall of the groove is fixed with a hydraulic cylinder by screws, the piston rod of the hydraulic cylinder is welded with a vertically arranged connecting rod, one of the connecting rods The bottom end of the side outer wall is welded with a horizontally arranged support plate, and the top outer wall of the support plate is fixed with a vacuum machine by screws. The invention makes the new type more stable in the production process, prevents the position of the equipment from shifting due to long use time, does not affect production, and avoids the problem of inconvenient movement due to the large volume of the preparation machine body.

Owner:江苏名欧高分子科技有限公司

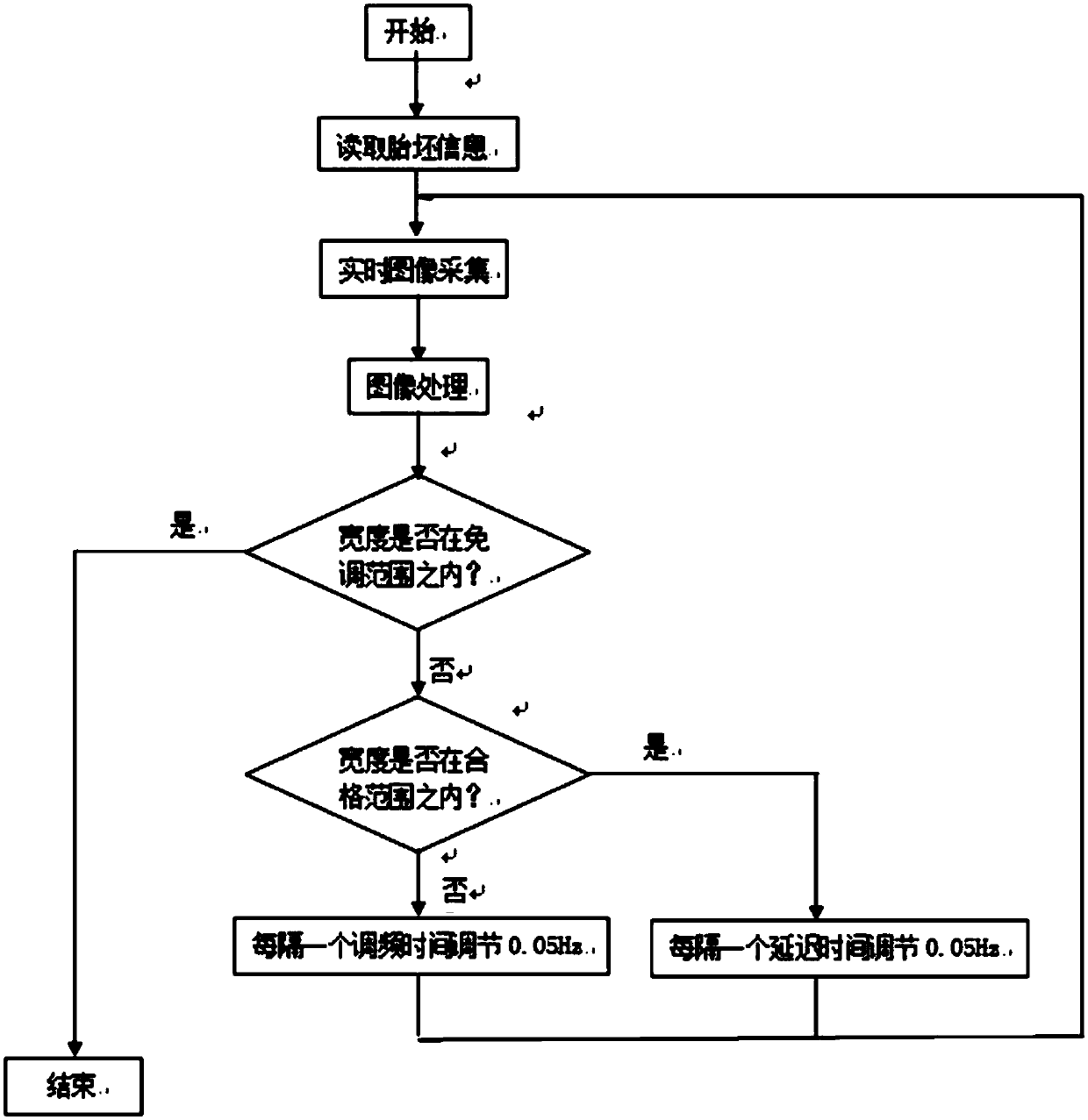

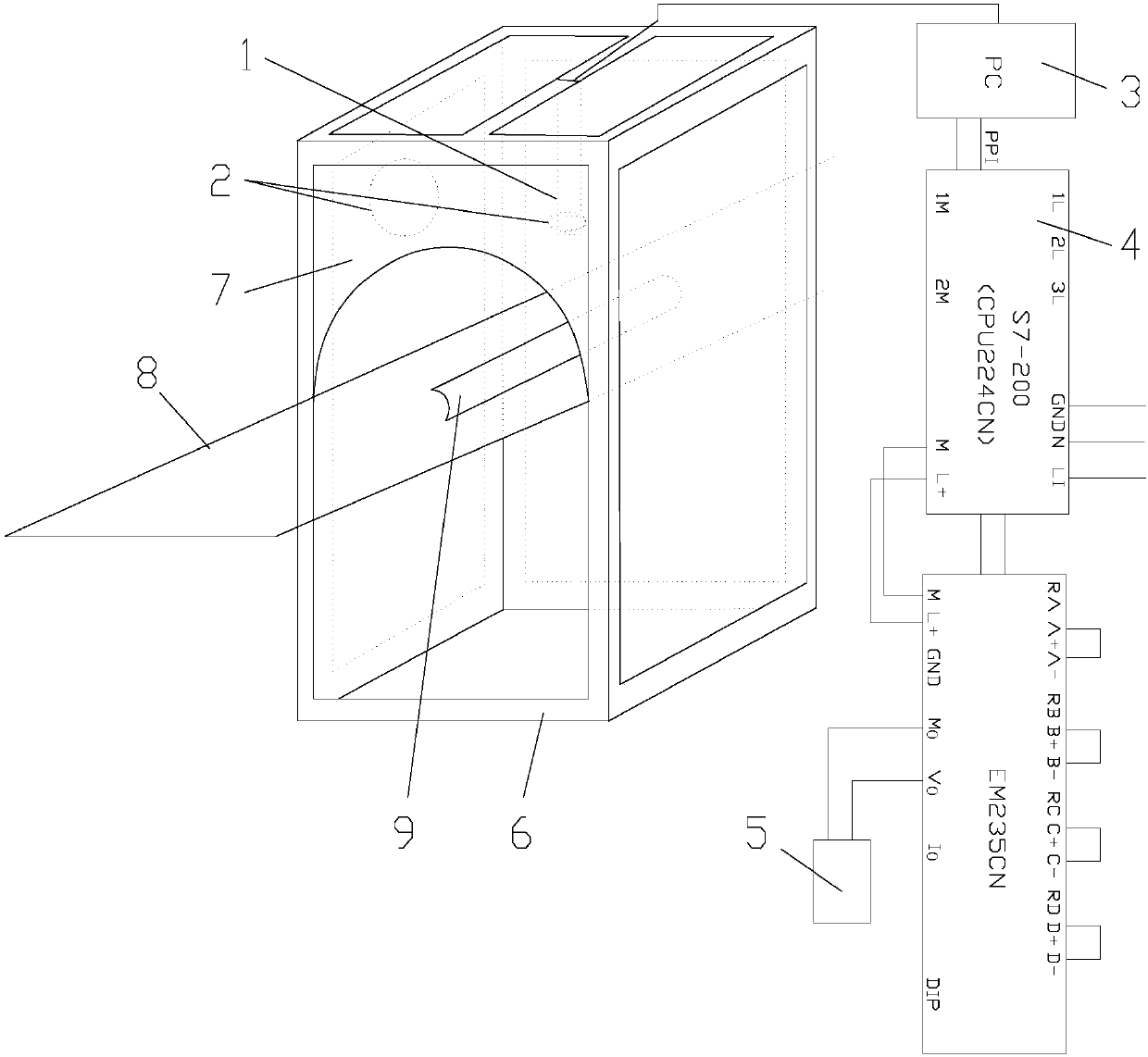

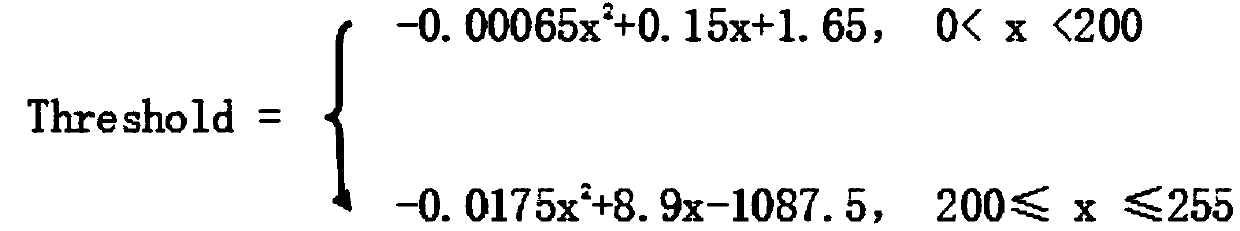

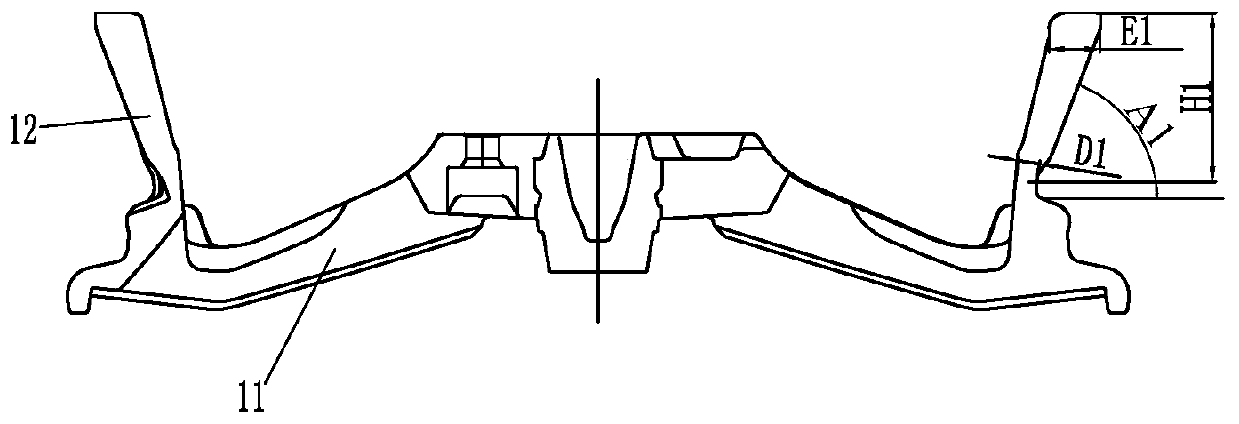

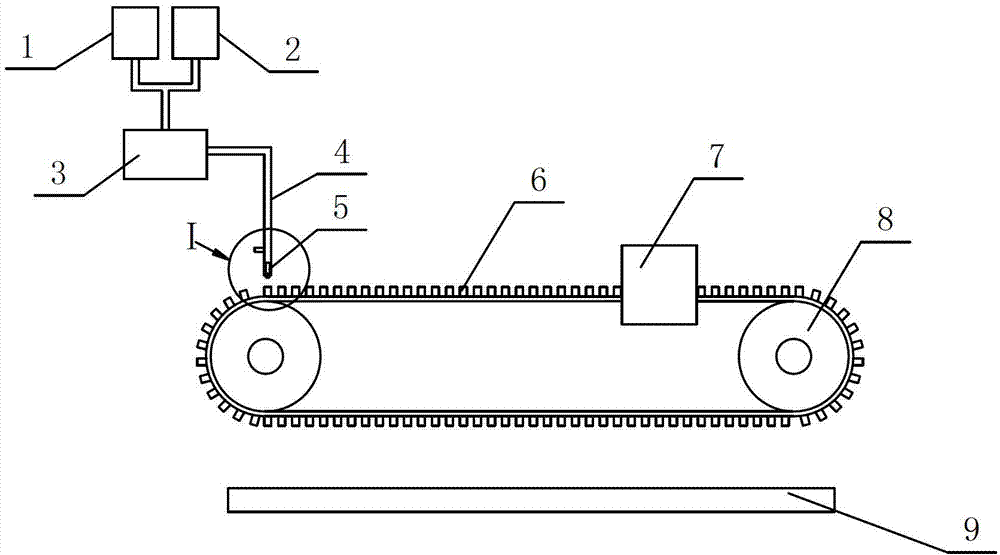

A tire blank width detection and transmission speed control method and detection control system

The invention discloses a tire billet width detection and conveying speed control method and a detection and control system. The method comprises the following steps: (1) arranging a tire billet width detection device; (2) presetting an adjustment-free range and a qualification range of a tire billet width, acquiring an image of a tire billet on a conveying belt through an industrial camera, calculating a real-time width of the tire billet through an industrial computer by using an image processing algorithm, obtaining a specific control method, and adjusting the rotating speed of a tire billet conveying belt driving motor through an analog voltage output control frequency converter of a PLC. The system comprises the industrial camera, a light source, the industrial control computer, the PLC, the frequency converter and a detection box. By the adoption of a non-contact image processing technology, the width of the tire billet can be detected on line and in real time, and the detection precision is high; furthermore, the rotating speed of the tire billet conveying belt driving motor can be automatically controlled and adjusted on line, so that the problem of the production quality, which is caused by fluctuation of the conveying speed, is solved. The tire billet width detection and conveying speed control method and the detection and control system are short in motor rotating speed adjustment, low in defective rate, high in production efficiency and low in cost.

Owner:CHONGQING UNIV

An internal heating type low temperature carbonization thermal state simulation detection device and method

ActiveCN108181121BImprove applicabilityShorten the timeStructural/machines measurementThermal stateThermodynamics

The invention discloses an internal heat low temperature dry distillation thermal state simulation detection device and method. The outlets of a combustion blower, a gas blower and an oxygen supply device are respectively communicated with the oxidant gas inlet, the gas inlet and the oxygen inlet of a heating unit through pipelines, and each pipeline is provided with a regulating monitoring control device; the furnace body is internally provided with a flame path, the wall surface of the flame path is provided with multiple flame holes, and the heat output port of the heating unit is piped into the flame path; the furnace body is internally filled with semi-coke which is arranged outside the flame path; and the furnace body is provided with multiple detection devices, and the detection ends of the detection devices are piped into the flame path or the detection ends of the detection devices are piped into the semi-coke in the furnace body. The physical-chemical process in the internalheat low temperature dry distillation furnace can be reflected in a simulation way through the offline test so that the theoretical guidance can be provided for solving the problems appearing in industrial production, the time required for solving the problems can be reduced without influencing production and the economic loss can also be reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

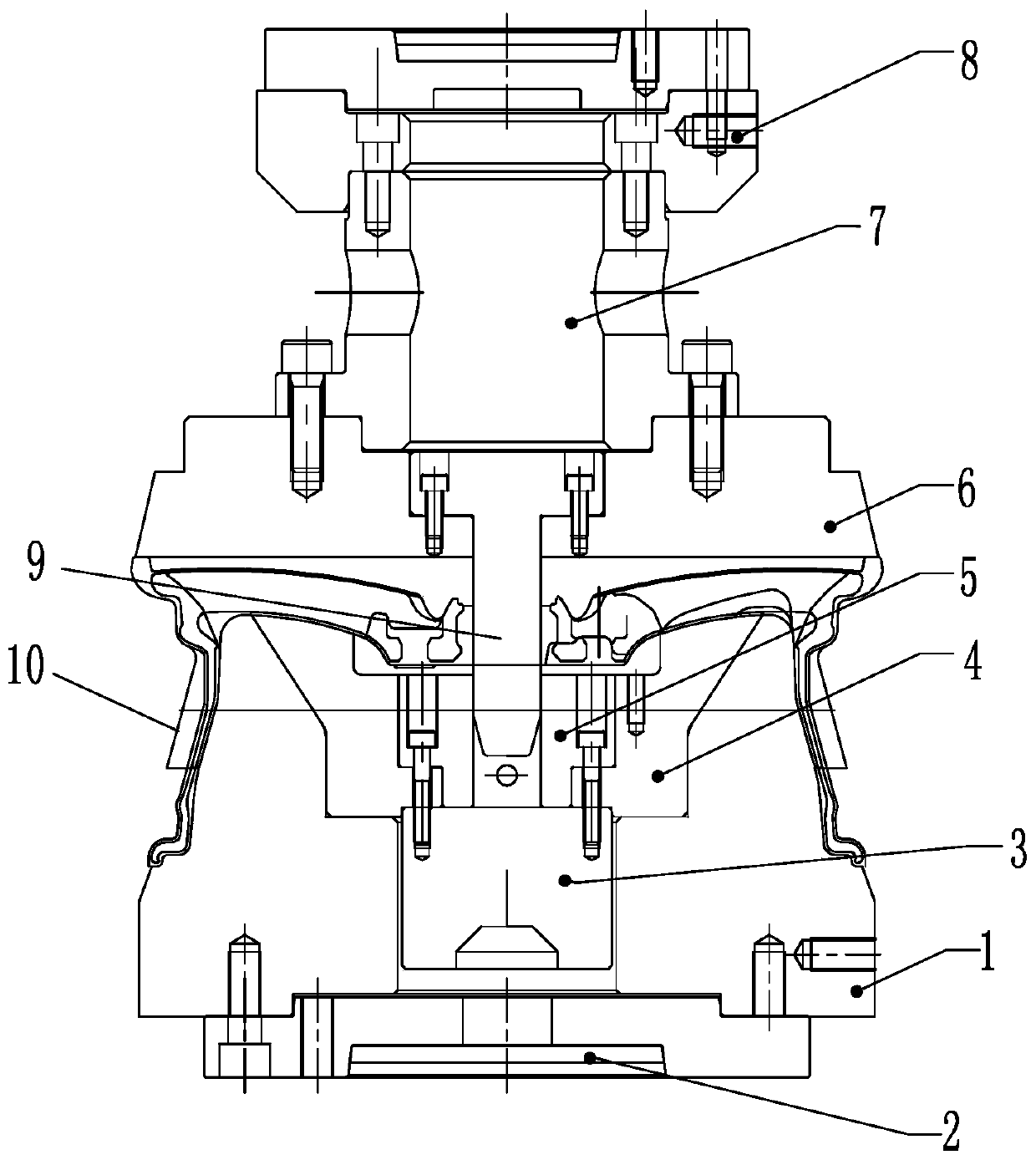

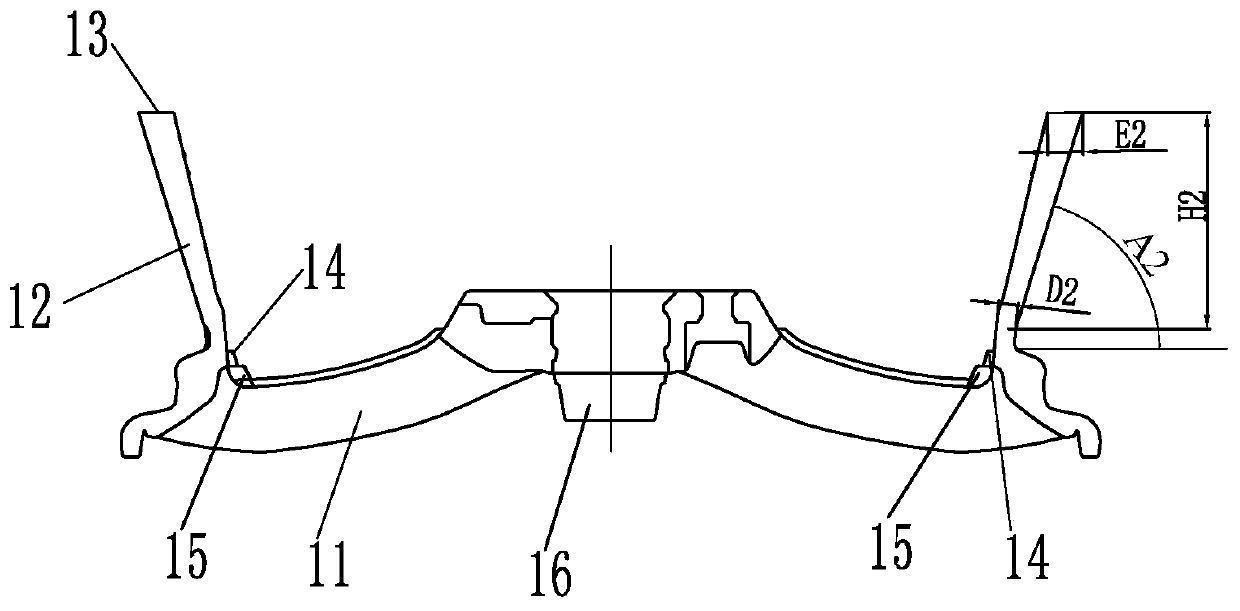

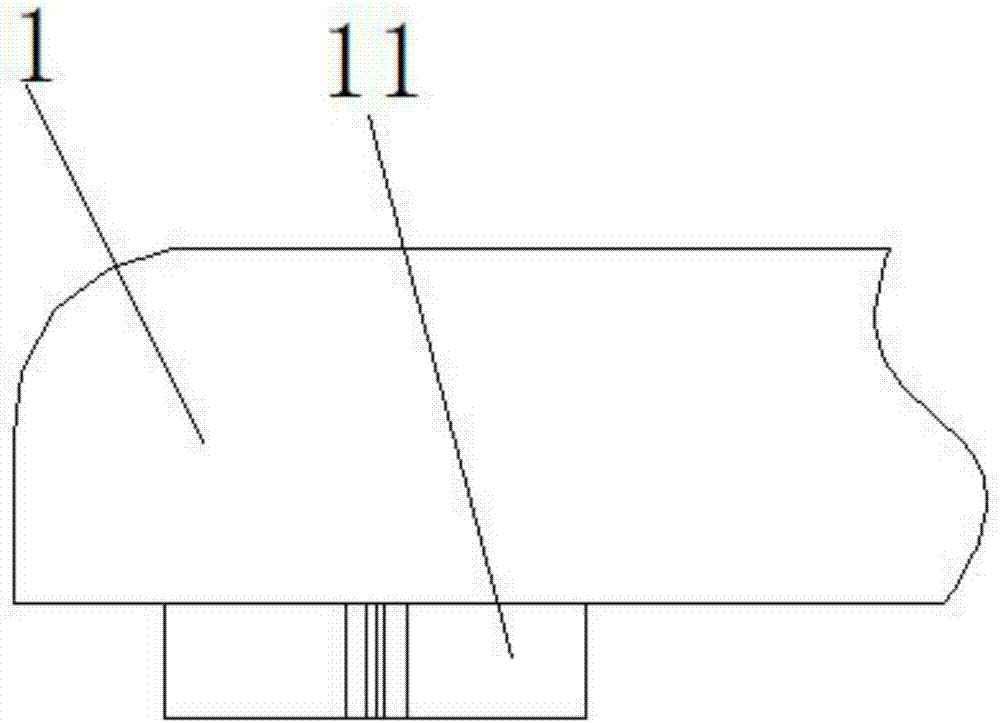

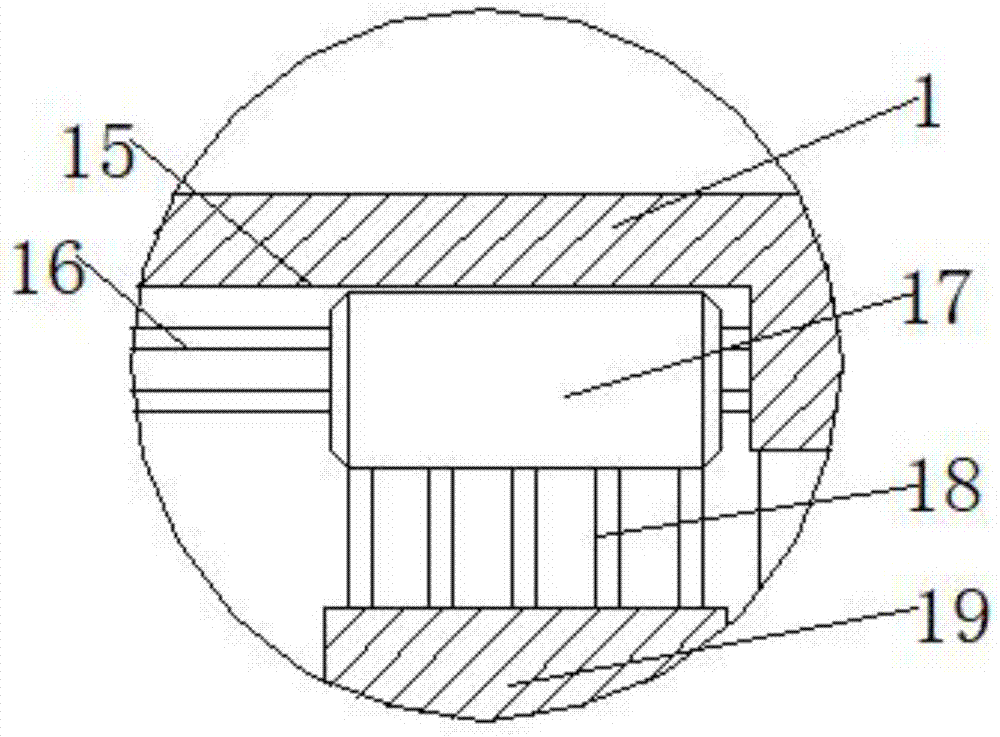

Spinning process for automobile aluminum alloy hub

ActiveCN110871229AReduce investmentReduce intermediate processing linksRimsHeating furnaceMachining process

The invention discloses a spinning process of an automobile aluminum alloy hub. The spinning process comprises the following steps that (1), a spinning die is heated to enable the temperature to reach270-290 DEG C, a release agent is sprayed on the surface of the spinning die, an aluminum alloy hub blank is taken out from a casting die, and the aluminum alloy hub blank is directly put into a heating furnace to continue heating until the temperature reaches 355-375 DEG C; (2), a manipulator grabs the aluminum alloy hub blank coming out of the heating furnace and places the aluminum alloy hub blank on the spinning die, and an upper tail jacking tool above the spinning die is controlled to jointly clamp an aluminum alloy hub blank with the spinning die; (3), the aluminum alloy hub blank is subjected to spinning machining by a spinning tool; and (4), the upper tail jacking tool is controlled to ascend to the original point, and an ejector ejects a spinning blank completing the spinning machining process upwards, so that the spinning blank is separated from the spinning die. According to the spinning process, the production period is short, product processing precision and quality canbe effectively guaranteed, and energy consumption is saved.

Owner:柳州一阳科技股份有限公司

Production process of foaming headset sleeve

InactiveCN102857855BReduce production processImprove molding qualityElectrical transducersMixed materialsMaterials science

The invention discloses a production process of a foaming headset sleeve, and the production process comprises the following steps of a, preparation of materials: placing a well mixed material A and a well mixed material B respectively into a mixing kettle to be stirred; b, mixing: simultaneously placing the material A and the material B into the mixing kettle to be adequately stirred and mixed to form a mixed material; c, injection: continuously injecting the mixed material into a plurality of molds which are matched with each headset sleeve in shape through a mixing reaction kettle, arranging the molds in a single row in the transverse direction, and realizing automatic circular work through a transmission device; d, baking: automatically feeding the molds with the mixed material into a baking box to be baked through the transmission device; and e, demolding: pouring out the headset sleeves from the molds through the transmission device so as to enable the headset sleeves to be separated from the molds after baking is completed. Compared with the prior art, the production process of the foaming headset sleeve has the advantages of simplicity in production equipment, few in manufacturing procedures, simplicity in mold structure, long in service life, capability of being formed in one step, good forming quality, low production cost and low energy consumption.

Owner:刘天镐

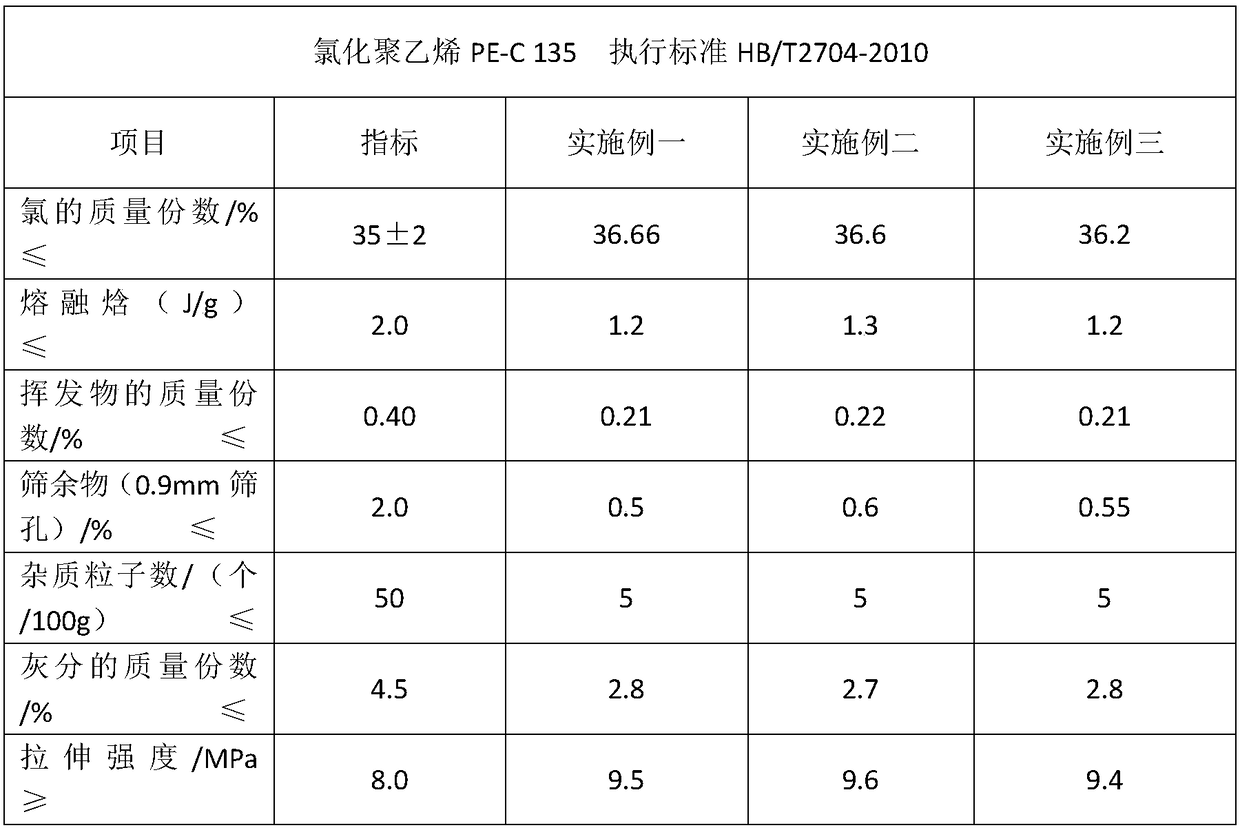

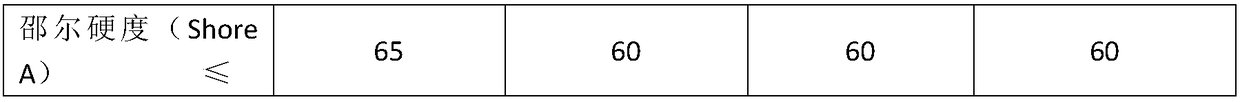

Water-saving and environment-friendly chlorinated polyethylene production method

InactiveCN108752504AProduction will not affectSolving Corrosion ProblemsReaction temperatureShort terms

The invention discloses and provides a water-saving and environment-friendly chlorinated polyethylene production method and belongs to the field of chlorinated polyethylene preparation. The method comprises the specific steps as follows: water is added to a chlorination reactor firstly; water in the reactor is heated, polyethylene, magnesium oxide and a reaction aid are added after stirring is started, and heating is started; liquid chlorine is introduced into the reactor, the chlorine ratio is 50%-60% when the reaction temperature is increased to 130 DEG C from 60 DEG C, the rest liquid chlorine is introduced at the constant temperature of about 130 DEG C, and the reaction is ended when the set chlorine introduction amount is reached; centrifugal separation and drying are performed on thematerial in the reactor, and chlorinated polyethylene and industrial magnesium chloride are prepared. The problem of corrosion to a centrifuge screen due to short-term contact with high-concentrationhydrochloric acid is solved, equipment loss is reduced, and the service life of equipment is prolonged; washing of acid with a lot of water is avoided, the water resource is saved, the phenomenon that acid is not thoroughly washed with water is avoided, and the acid is washed thoroughly; meanwhile industrial magnesium chloride can be produced.

Owner:潍坊硕邑化学有限公司

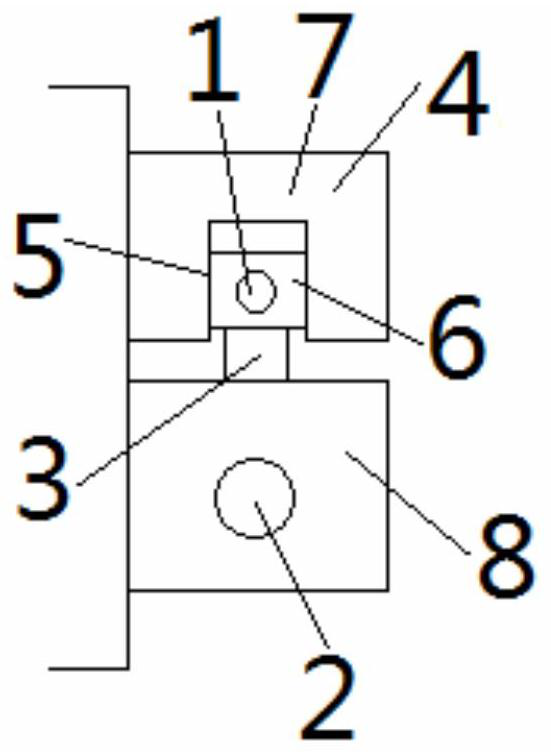

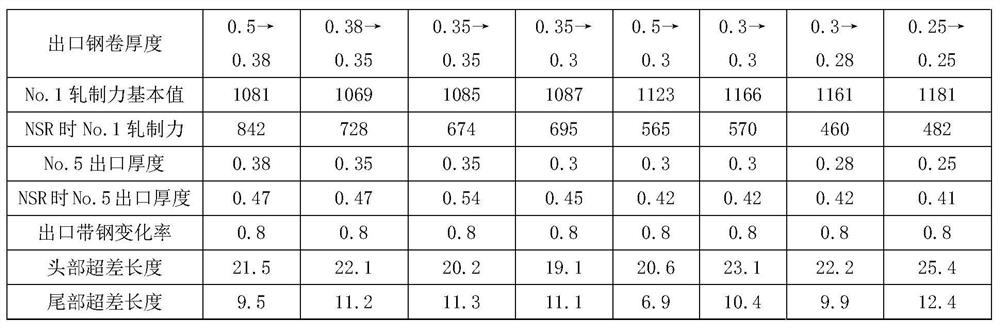

A rolling method for preventing collapse in thin strip rolling

ActiveCN110814026BPrevent collapseSimple stepsRoll force/gap control deviceMetal rolling stand detailsEngineeringStrip steel

The present invention provides a kind of rolling method that is applied in metallurgical technical field to prevent the collapse in thin strip steel rolling, the rolling step of described rolling method that prevents thin strip steel rolling is: 1) through The standard roll gap size value of the roll gap is set in the control part; 2) When the end of the strip to be rolled is transported to the roll gap position of the rolling machine, the control part controls the actual roll gap size value to increase; 3) The strip to be rolled When the end of the strip passes through the roll gap, the thickness of the end of the thin strip rolled by the roll gap is greater than the standard roll gap size value; 4) After the time for the end of the strip to be rolled to pass through the roll gap reaches the set compensation time , the control part controls the numerical value of the actual roll gap size to decrease, and the rolling method for preventing collapse in thin strip steel rolling of the present invention increases the thickness of the end of the thin strip steel, replaces the sleeve, and does not need to set the sleeve The steps are cumbersome, and there will be no collapse of the steel coil without a sleeve, which will not affect the production of the next process, and the process of setting the sleeve is cancelled.

Owner:MAANSHAN IRON & STEEL CO LTD

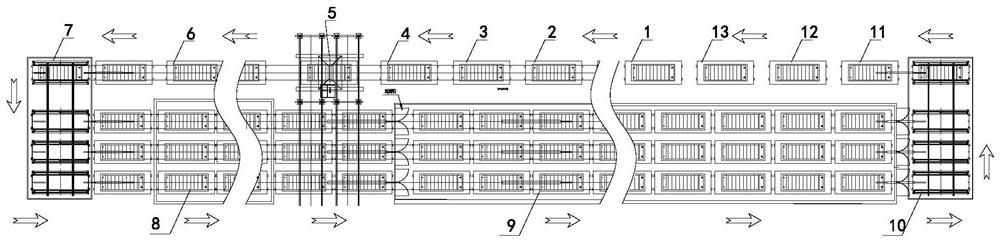

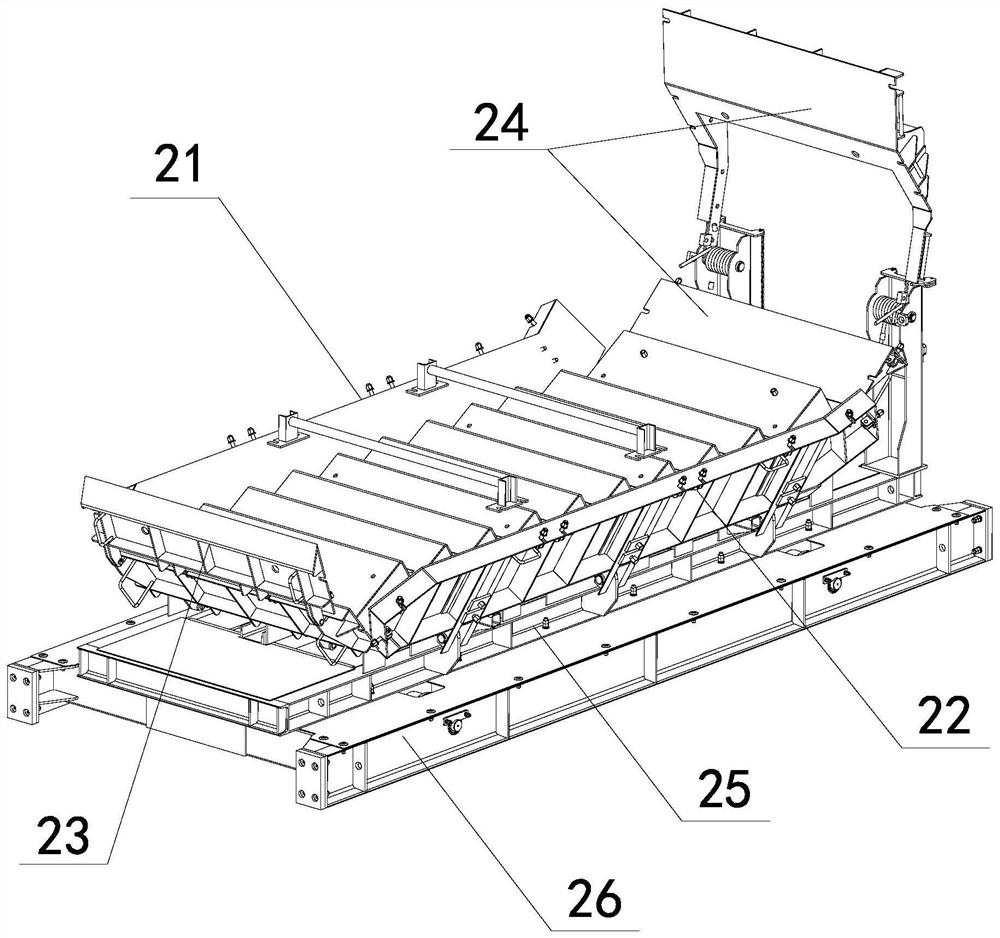

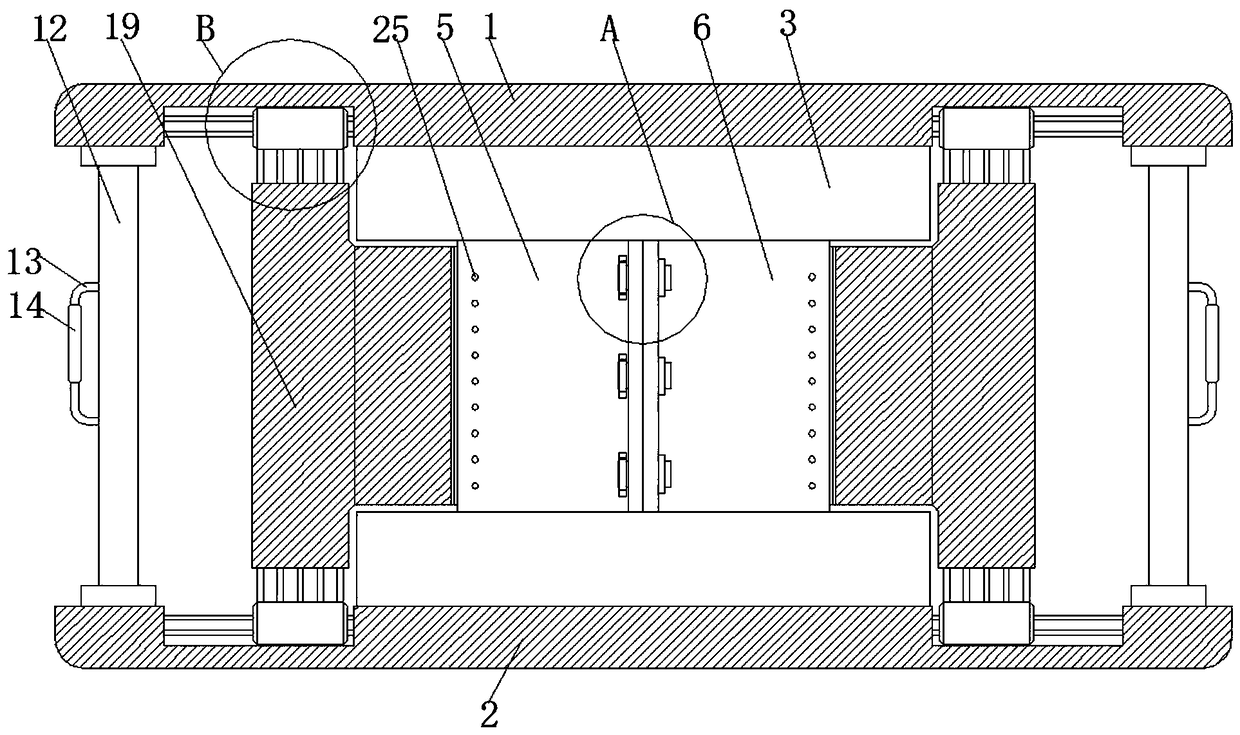

Prefabricated stair flow type production line

ActiveCN113787604AImprove job proficiencyLower requirementCeramic shaping plantsAuxillary shaping apparatusEngineeringAssembly line

The invention provides a prefabricated stair flow type production line which comprises an annular flow type production line formed by sequentially connecting a mold assembling station, a pouring and tamping station, a first ferry station, a static curing station, a curing station, a second ferry station and a mold disassembling station end to end through a production track, a prefabricated stair mold comprises a mold body and a bearing trolley which are detachably connected, the mold body is driven by the bearing trolley to move to all stations in sequence, the procedures of cleaning, oil spraying, mold assembling, embedded part and reinforcement cage mold entering are executed, the procedures of concrete pouring and vibrating are executed, first-time cross-line circulation is executed, the procedure of static curing is executed, the procedure of concrete curing is executed, second-time cross-line circulation is executed, and the mold body enters the next round of production again after the mold disassembling and hoisting procedures are executed. According to the prefabricated stair flow type production line, the prefabricated stair molds are subjected to automatic circulation assembly line type production at all the stations, needed manual operation is little, and the per capita production efficiency is far higher than that of a fixed bench mold production mode in the prior art.

Owner:筑友智造智能科技有限公司

A mold for the production of shaft coupling covers with the function of extruding waste materials

The invention discloses a mold with a waste squeezing-out function and for production of a coupling cover. The mold with the waste squeezing-out function and for production of the coupling cover comprises a top plate and a bottom plate. Fixed iron blocks are fixedly connected to the opposite sides of the top plate and the base plate correspondingly. Square grooves are formed in the corresponding sides of the fixed iron blocks correspondingly, a left mold plate and a right mold plate are fixedly connected between the inner walls of the two square grooves, and the left mold plate is located on the left side of the right mold plate. According to the mold with the waste squeezing-out function and for production of the coupling cover, oblique pipes, oblique grooves, sliding grooves, sliding blocks, sliding rods, rubber strips and the treatment mold plates are arranged, the sliding blocks can move, the sliding blocks on the two sides are made to move on the sliding rods, the oblique pipes are made to slide out of the oblique grooves, and the treatment mold plates can slightly move up and down under the elastic effect of the rubber strips and are convenient to adjust, so that waste is squeezed out conveniently from the oblique grooves, using is convenient, the next time of machining is not affected, defective products are unlikely to be generated accordingly, and the working efficiency is improved.

Owner:湖北伟冶科技有限公司

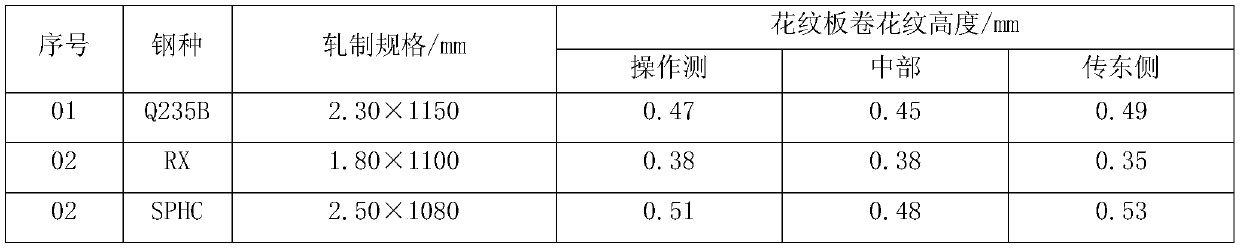

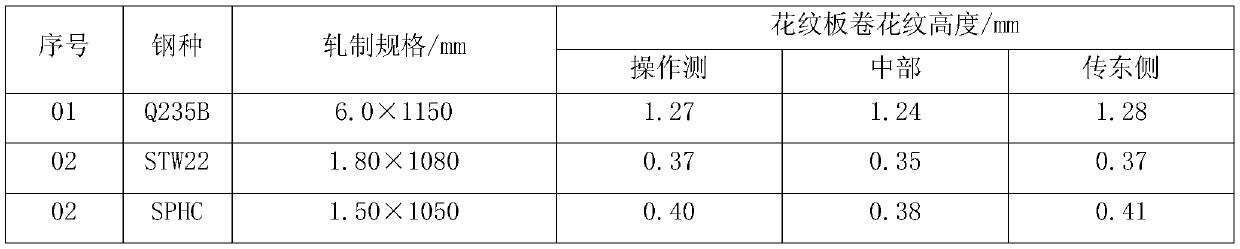

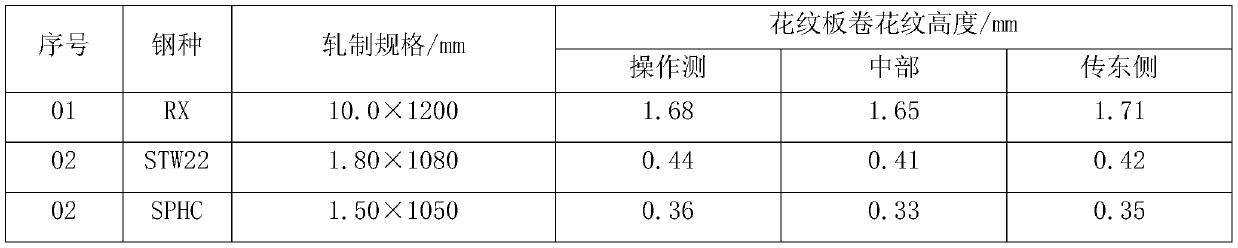

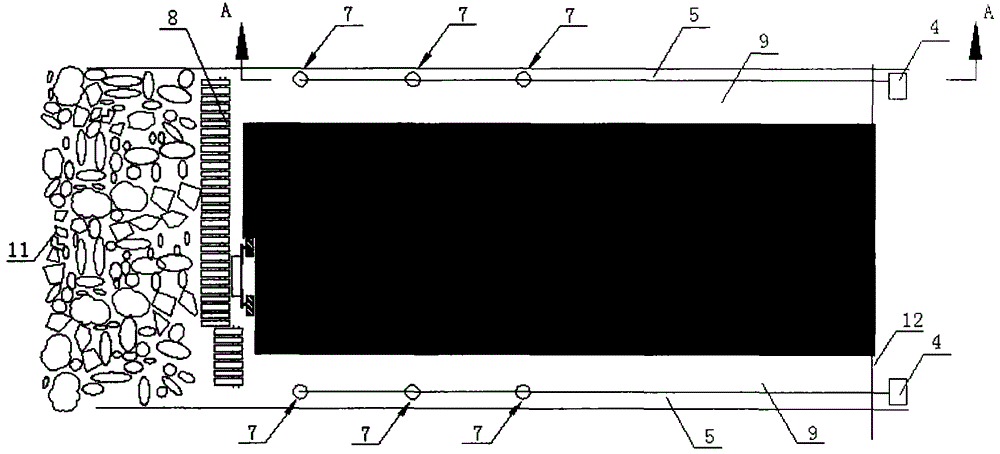

Manufacturing method of hot-rolled checkered plate

ActiveCN111530928AGuaranteed rolling qualityProduction will not affectMetal rolling arrangementsStrip steelContinuous rolling

The invention discloses a manufacturing method of a hot-rolled checkered plate. Rolling of the checkered plate is arranged at the early stage of service of a finish rolling supporting roller of a hotcontinuous rolling unit. According to the manufacturing method of the hot-rolled checkered plate, by improving a rolling process of the hot-rolled checkered plate, the rolling process of the checkeredplate is arranged at the earlier stage of the service of the finish rolling supporting roller of the hot continuous rolling unit, the checkered plate is rolled by using a strip steel rolling production line on the premise of not increasing the production cost, the rolling quality of the checkered plate is guaranteed, the subsequent strip steel production is not influenced as well, the method notonly solves the conflict between the checkered plate shape and the pattern height in a traditional rolling process, but also solves the problem that the wave-shaped defect of the flat strip steel rolled in the middle and early stages of the finish rolling supporting roller of the finishing rolling unit is difficult to control, realizes batch rolling of the thin-specification and ultra-thin-specification high-quality checkered plate, and has good market popularization value and application prospect.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

A temperature monitoring method and monitoring device for a coal mine goaf

InactiveCN103196580BAvoid damageAvoid the effects of stagnant waterThermometers using electric/magnetic elementsUsing electrical meansEngineeringTemperature monitoring

The invention discloses a coal mine goaf temperature monitoring method and a monitoring device. The method includes the following steps: (1) arranging at least one temperature measuring point in a working face gate road, (2) arranging a fixing support device at the temperature measuring point and arranging a temperature sensing element on the fixing support device, (3) connecting the fixing support device and a protecting element and maintaining a certain height between the temperature sensing element and a baseboard, (4) connecting the temperature sensing element and a signal transmission element, wherein the signal transmission element stretches outside a preset stop line through the fixing support device and the protecting element, (5) gradually embedding the temperature measuring point and the temperature sensing element into a goaf, along with the working face being pushed ahead, and (6) using a signal collection and analysis device for receiving signals transmitted by the signal transmission element, analyzing and obtaining temperature change situations in the goaf, and achieving a monitoring purpose. The coal mine goaf temperature monitoring device comprises the temperature sensing element, the fixing support device, the signal transmission element, the signal collection and analysis device and the protecting element. The coal mine goaf temperature monitoring method and the monitoring device are low in cost, convenient to operate and good in monitoring effect.

Owner:CCTEG CHINA COAL RES INST

A carbonaceous conductive slag for electroslag steel smelting

The invention provides a carbonaceous conductive slag suitable for electroslag steel smelting and a preparation method thereof. The conductive slag is prepared from carbon powder, fluorite powder and Na2SiO3 aqueous solution, has good electrical conductivity and arc starting performance, can play an important role in smelting steel with low titanium content, reduces scrap rate, and improves production efficiency.

Owner:DAYE SPECIAL STEEL CO LTD

Mold with waste squeezing-out function and for production of coupling cover

The invention discloses a mold with a waste squeezing-out function and for production of a coupling cover. The mold with the waste squeezing-out function and for production of the coupling cover comprises a top plate and a bottom plate. Fixed iron blocks are fixedly connected to the opposite sides of the top plate and the base plate correspondingly. Square grooves are formed in the corresponding sides of the fixed iron blocks correspondingly, a left mold plate and a right mold plate are fixedly connected between the inner walls of the two square grooves, and the left mold plate is located on the left side of the right mold plate. According to the mold with the waste squeezing-out function and for production of the coupling cover, oblique pipes, oblique grooves, sliding grooves, sliding blocks, sliding rods, rubber strips and the treatment mold plates are arranged, the sliding blocks can move, the sliding blocks on the two sides are made to move on the sliding rods, the oblique pipes are made to slide out of the oblique grooves, and the treatment mold plates can slightly move up and down under the elastic effect of the rubber strips and are convenient to adjust, so that waste is squeezed out conveniently from the oblique grooves, using is convenient, the next time of machining is not affected, defective products are unlikely to be generated accordingly, and the working efficiency is improved.

Owner:湖北伟冶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com