Online moisture measuring method, measuring device and measuring system

A measuring method and technology of measuring device, which are applied in the directions of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., can solve the problems of high inspection cost, waste of energy, affecting production rhythm, etc., and achieve baking consistency Good, reduce production costs, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

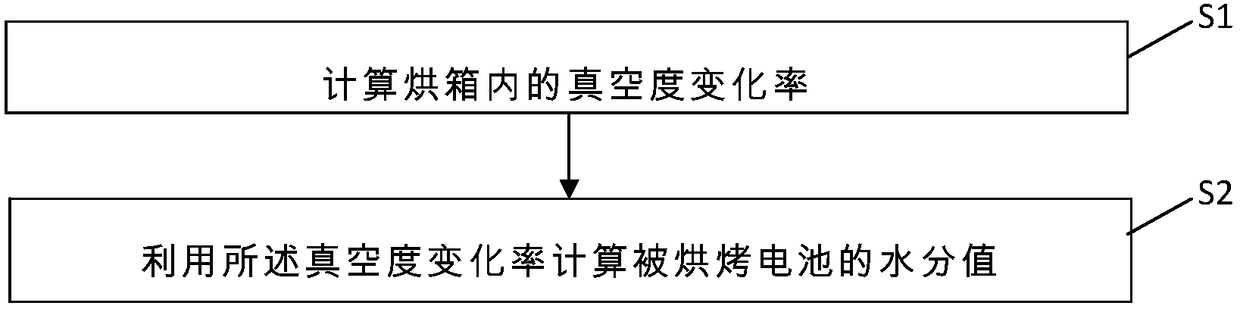

[0029] figure 1 shows an online moisture measurement method for online judgment of the dryness of the baked battery. refer to figure 1 , the online moisture measurement method includes:

[0030] Step S1, calculating the rate of change of the degree of vacuum in the oven;

[0031] Step S2, calculating the moisture value of the battery to be baked by using the vacuum degree change rate.

[0032] The idea of this online moisture measurement method is: when the battery is heated to the temperature specified by the battery manufacturer in the oven, the vacuum valve is opened to vacuum according to a certain rhythm, such as opening for one minute, closing for two minutes, etc., allowing rhythm during the process. Variety. The opening and closing time of the vacuum valve can be set according to the specific conditions of the baking system. This way of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com