Prefabricated stair flow type production line

A production line, flow-through technology, applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve problems such as low efficiency, achieve good synchronization, less manual operation, convenient and quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Preferred embodiments of the present invention are provided below to help further understanding of the present invention. Those skilled in the art should understand that the descriptions of the embodiments of the present invention are only exemplary, and are not intended to limit the solution of the present invention.

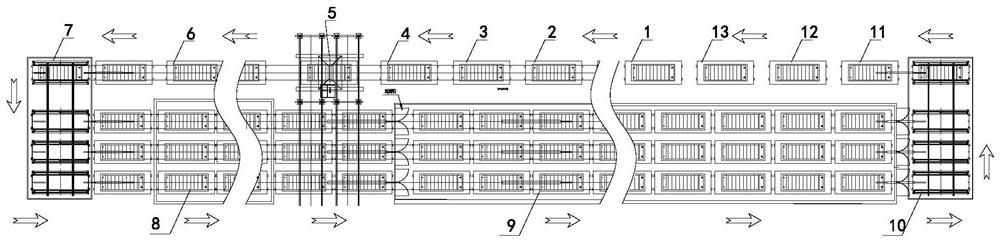

[0054] See attached figure 1 Schematic illustration, the prefabricated staircase flow-type production line in an embodiment of the present invention includes a molding station, a pouring station 5, a first ferry station 7, a resting station 8, a maintenance station 9, and a second ferry station 10 and demolding station 11 are connected end-to-end through the production track 2827 to form an annular flow-type production line, and the prefabricated staircase molds are sequentially circulated on the above-mentioned stations according to the production rhythm to complete the production of prefabricated stairs; Station 5 and demolding station 11 form the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com