Circuit tower-foundation flow-style mechanical construction method

A mechanical construction and flow-through technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of poor pile quality of the foundation as a whole, large amount of labor for self-mixing concrete, collapse of holes, etc., and achieve increased pile side friction Effects of resistance, construction site cleanliness, and hole-forming quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

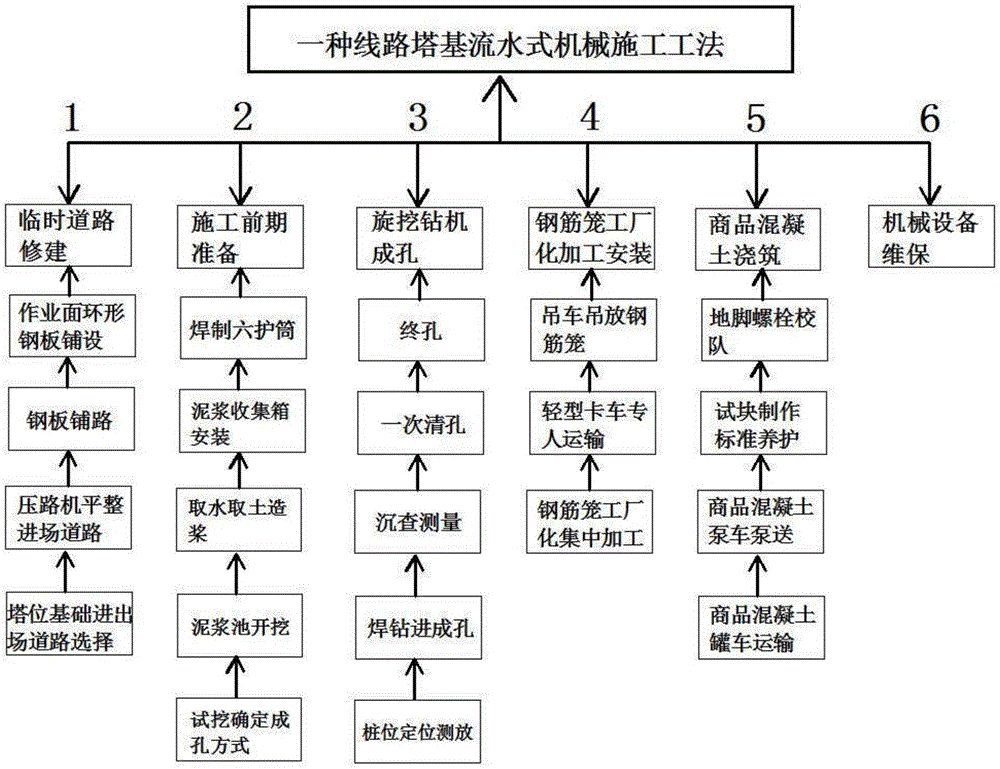

[0031] The concrete implementation steps of a kind of line tower base flow-type mechanical construction method are:

[0032] 1. Temporary road construction:

[0033] (1) According to the mechanized construction characteristics of the line foundation, select a rotary drilling rig with a maximum torque of 80-150 as the drilling machine, and use the length, width, tonnage, and turning radius of the rotary drilling rig to compare the width, turning radius, and foundation of the entry and exit roads Bearing capacity requirements as temporary road construction standards;

[0034] (2) Use excavators and bulldozers to widen, fill and level the road; use road rollers to harden the road, and then lay steel plates with a thickness of more than 50mm on the road; at the same time, use 6m*1.5m*50mm steel plates on the working surface The foot is laid in a ring, and the overlapping position of the steel plate and the steel plate is connected by spot welding with a short steel bar head and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com