A laser drilling device for lcp flexible circuit board

A flexible circuit board and laser drilling technology, which is applied to laser welding equipment, cleaning methods using tools, manufacturing tools, etc., can solve problems such as longer intervals and lower work efficiency, so as to improve work efficiency and work proficiency Degree, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

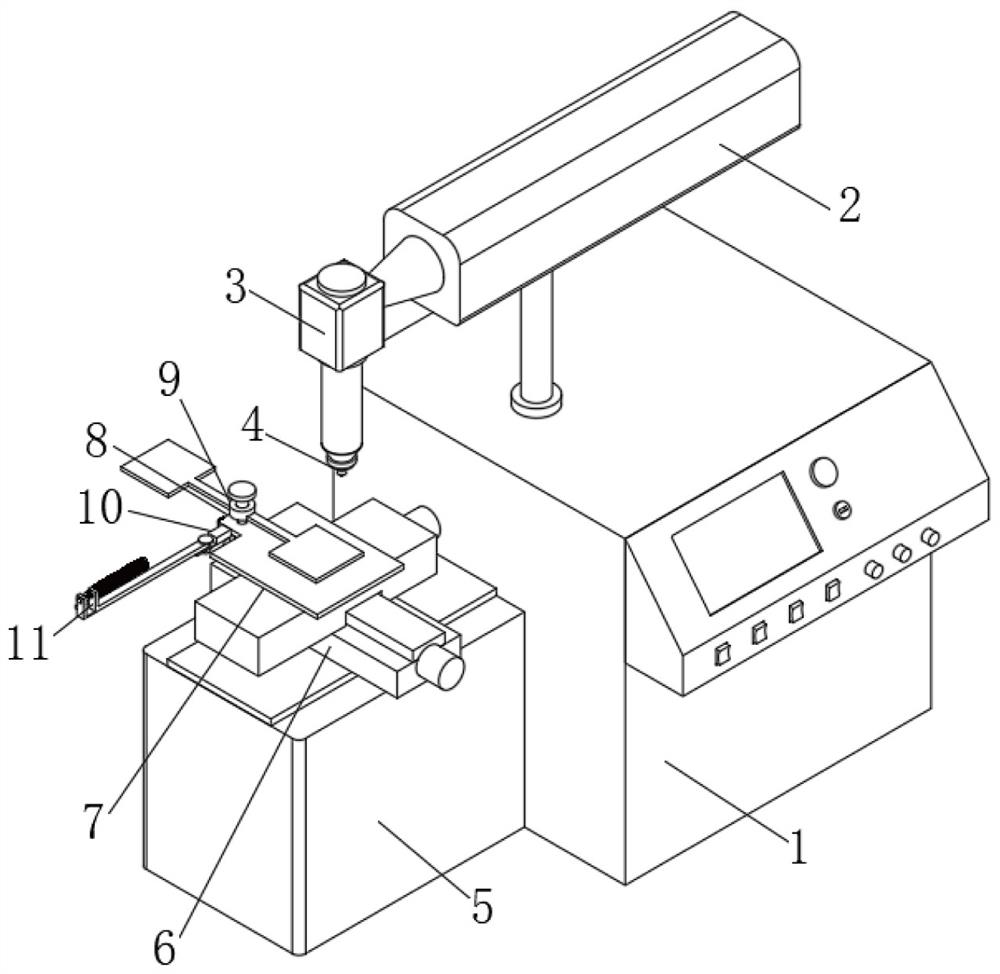

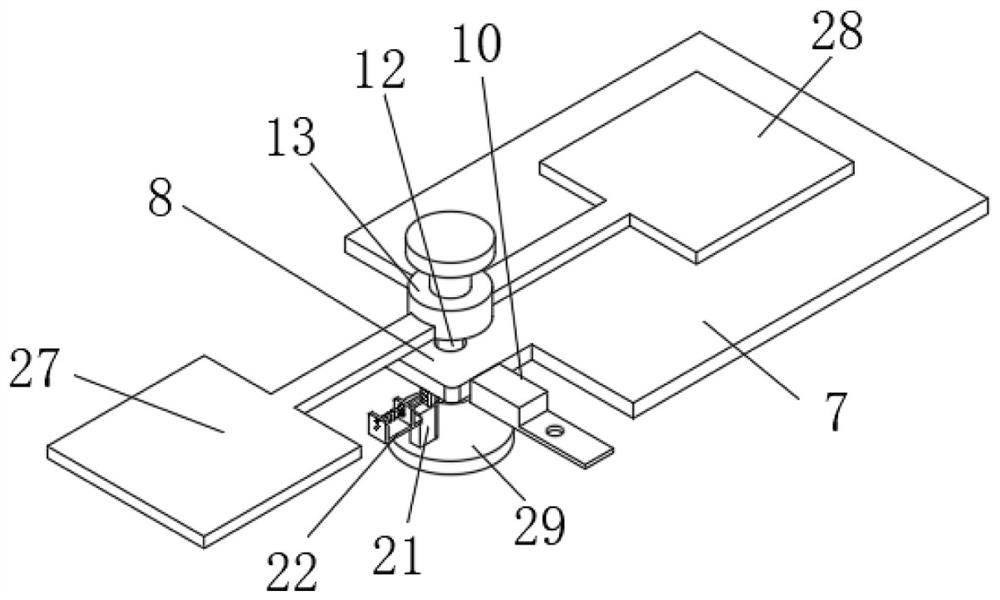

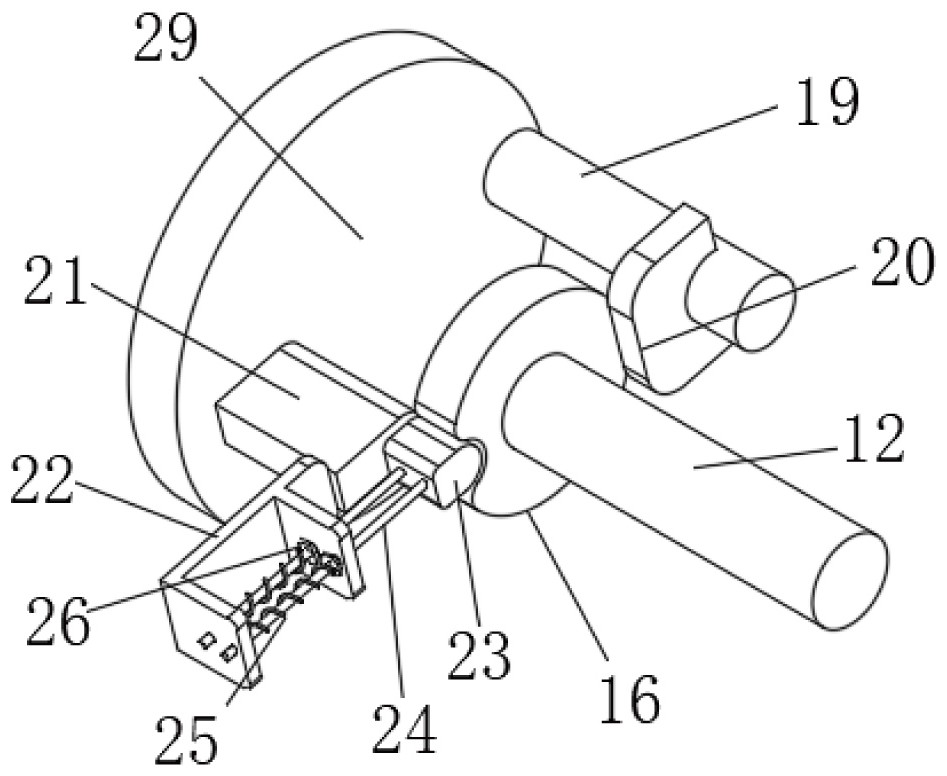

[0028] like Figure 1-Figure 5As shown, a workpiece replacement mechanism of a laser drilling device for an LCP flexible circuit board includes a bottom body 1, an upper body 2 is arranged on the upper part of the bottom body 1, a laser 3 is arranged on the side of the upper body 2, and a laser 3 is provided on the side of the upper body 2. The lower position is provided with a laser head 4, the side position of the bottom body 1 is provided with a side body 5, the side body 5 is provided with an axial adjustment frame 6, and the axial adjustment frame 6 is provided with an adjustment workbench 7, and the side of the adjustment workbench 7 There is a No. 1 mounting plate 8, and a side mounting plate 10 is provided on the side of the No. 1 mounting plate 8. It is characterized in that: No. 1 mounting plate 8 is provided with a workpiece replacement mechanism 9, and the workpiece replacement mechanism 9 includes a No. 1 movable workbench 27 , No. 2 movable workbench 28, No. 2 mo...

Embodiment 2

[0030] like Figure 1-Figure 5 As shown, the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to those in the first embodiment, and only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Figure 6-Figure 8 As shown, a cleaning mechanism of a laser drilling device for an LCP flexible circuit board, the side cleaning plate 30 is installed through the movable installation of the fixing bolt 31 and the side mounting plate 10, the fixing bolt 31 is provided with a lock nut 32, and the side cleaning plate 30 Two side rotating plates 33 are arranged on the side position of the side rotating plate 33, and No. 2 bearing 39 is arranged on the side rotating plate 33. The side rotating rod 34 is arranged in the No. 2 bearing 39. The side roller 35 and the side rotating rod 34 are fixedly installed, and the side cleaning plate The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com