Manufacturing method of hot-rolled checkered plate

A manufacturing method and checkered plate technology, applied in the direction of metal rolling, etc., can solve the problems of deteriorating plate shape quality, inability to stably produce thin or extremely thin checkered plates in batches, and insufficient height of checkered plates, etc., to solve the problem of checkered plate The conflict between plate shape and pattern height, good marketing value and application prospect, and the effect of solving wave shape defects that are difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

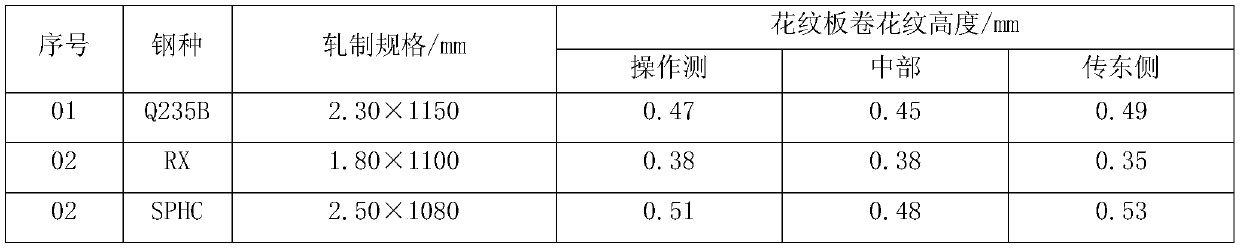

[0024] In this example, 1,200 tons of checkered plates are rolled, and 67 rolls are produced at one time. The rolling specifications: thickness is 1.8-5.75mm, width is 1080-1280mm, and the specific production steps are as follows:

[0025] (1) The rolling of patterned coils is arranged after the 683km service period after the replacement of the finish rolling backup rolls;

[0026] (2) In the patterned plate rolling process, the total rolling kilometers is 71km, and the embossing frame work rolls are replaced once during the rolling cycle;

[0027] (3) The rolling specification of checkered plate transitions from wide to narrow: 5.75×1280mm→4.5×1250mm→2.750×1180mm→replace patterned roll→3.5×1250mm (12 rolls)→2.30×1150(6 rolls)→1.8×1100mm( 20 rolls) → 2.5×1080mm (8 rolls);

[0028] (4) The embossing rolls for rolling thin-gauge rolls are used for the second time on the machine;

[0029] (5) After the patterned coil rolling is completed, two kinds of steel coils are rolled at ...

Embodiment 2

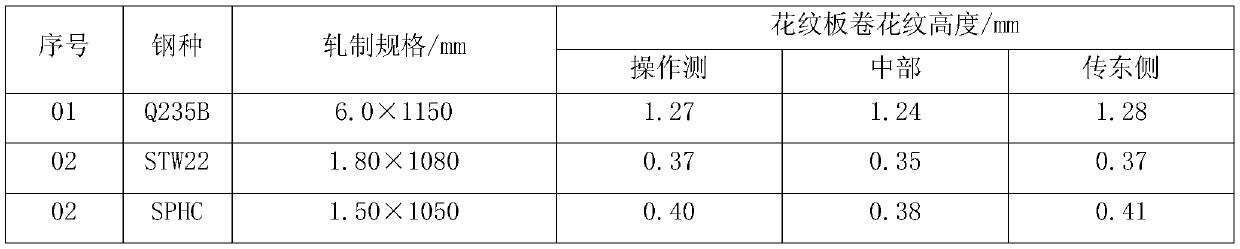

[0035] In this embodiment, 1,750 tons of checkered plates are rolled, and 92 rolls are produced at one time. The rolling specifications: thickness is 1.5-6.0mm, width is 1050-1250mm, and the specific production steps are as follows:

[0036] (1) The rolling of patterned coils is arranged after the 800km service period after the replacement of the finish rolling backup rolls;

[0037] (2) In the rolling process of the checkered plate, the total rolling mileage is 92km, and the working rolls of the embossing stand are replaced twice during the rolling cycle;

[0038] (3) Checkered plate rolling specifications transition from wide to narrow: 3.0×1250mm (5 rolls)→2.5×1190mm (3 rolls)→2.0×1100mm (5 rolls)→1.8×1080mm (12 rolls)→1.5×1050mm ( 7 rolls)→replace pattern roller→5.0×1250mm→6.0×1150mm→7.6×1100mm→6.5×1080mm→replace pattern roller→5.0×1250mm→5.75×1230mm→5.0×1200mm→4.0×1180mm;

[0039] (4) The embossing rolls for rolling thin-gauge rolls are used for the second time on the ma...

Embodiment 3

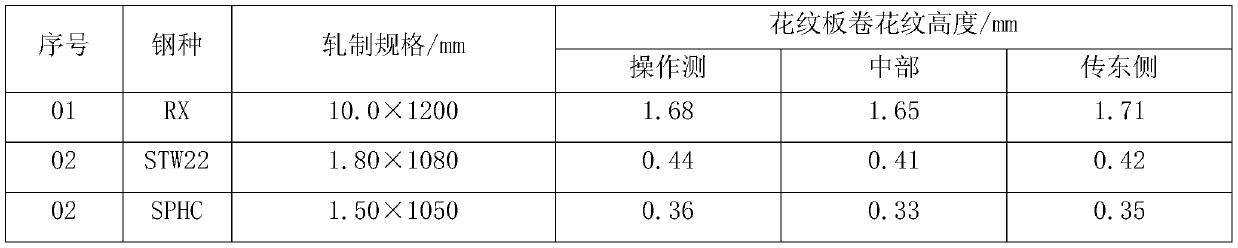

[0046] In this embodiment, rolling of 1520 tons of checkered plates is carried out, and 84 rolls are produced at one time. The rolling specifications: the thickness is 1.5-10.0 mm, and the width is 1050-1280 mm. The specific production steps are as follows:

[0047] (1) The rolling of patterned coils is arranged after the 731km service period after the replacement of the finish rolling backup rolls;

[0048] (2) In the rolling process of the checkered plate, the total rolling mileage is 92km, and the working rolls of the embossing stand are replaced twice during the rolling cycle;

[0049](3) Checkered plate rolling specifications transition from wide to narrow: 4.5×1250mm (7 rolls)→3.0×1250mm (5 rolls)→2.5×1200mm (3 rolls)→1.8×1150mm (15 rolls)→2.0×1080mm ( 4 rolls)→1.5×1050mm (5 rolls)→replace pattern roller→4.5×1250mm→5.0×1150mm→4.5×1100mm→3.5×1080mm→replace pattern roller→6.0×1250mm→7.5×1230mm→8.0×1200mm→10.0× 1200mm, in the thin-gauge checkered plate rolling process, in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com