Coiling shape control method for medium-high carbon steel with omega (C) larger than or equal to 0.45%

A control method, medium and high carbon technology, applied in tension/pressure control, manufacturing tools, metal rolling, etc., can solve the problems of reducing the percentage of medium and high carbon steel coil rework, coil overflow edge and staggered layers at the end of coiling, etc. Achieve the effect of reducing safety risk and quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: see figure 1 , a kind of ω (C) ≥ 0.45% middle and high carbon steel coil shape control method, described control method comprises the following steps:

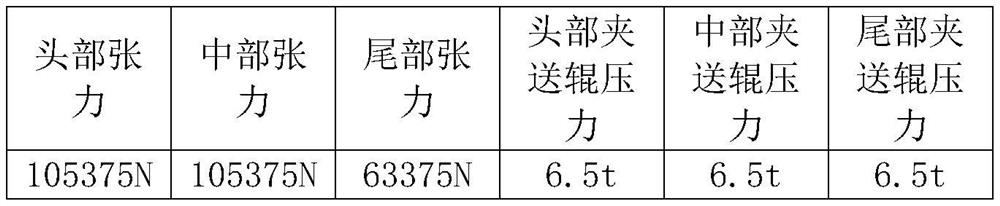

[0021] 1) After the coiling model receives the strip steel type, CT temperature, thickness, and width transmitted by the finishing rolling model, it calculates the coiling unit tension required for this piece of strip steel, and the corresponding Corresponding pinch roller pressure value;

[0022] 2) After the pinch roller at the head of the strip bites the steel, the pinch roller enters the pressure ring control according to the previously set pressure, and the pinch roller has no torque output at this time;

[0023] 3) The head of the strip steel is wound onto the reel. After the reel load is established (and the finish rolling and tension reduction are completed), the reel is converted into the total tension according to the previously issued unit tension, and according to the total tension according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com