Purging device for emulsion on surface of strip steel on rolling mill outlet

A technology of emulsion and rolling mill, applied in workpiece surface treatment equipment, metal rolling, metal rolling, etc., can solve problems affecting the quality of strip steel, strip steel corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

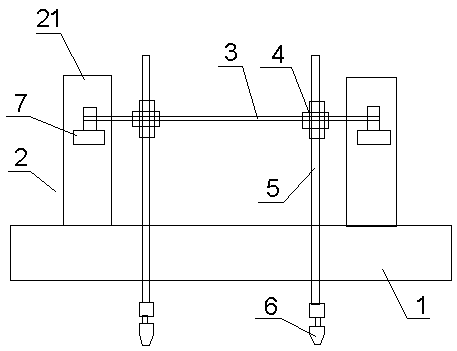

[0012] Example figure 1 As shown, the purging device of the strip surface emulsion at the exit of the rolling mill of the present invention includes a rolling mill exit cover plate 1, a bracket 2, a beam 3, a pipe clamp 4, an air pipe 5 and a nozzle 6, and the support 2 is arranged on the rolling mill exit cover The top surface of the board 1, the crossbeam 3 is horizontally arranged on the two vertical rods 21 of the support 2, the air pipe 5 is arranged on both sides of the crossbeam 3 through the pipe clamp 4, and the nozzle 6 is arranged on the The front end of the trachea 5 is connected to an air source at the tail end of the trachea 5 .

[0013] Preferably, the purging device also includes adjustable mounting bases 7, the adjustable mounting bases 7 are respectively arranged on the two vertical poles 21 of the support 2 and rise and fall along the two vertical poles 21, and the two ends of the crossbeam 3 are provided with on the adjustable mount 7.

[0014] Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com