Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Play the role of "bridge"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granulation polishing film, preparing method thereof and application thereof

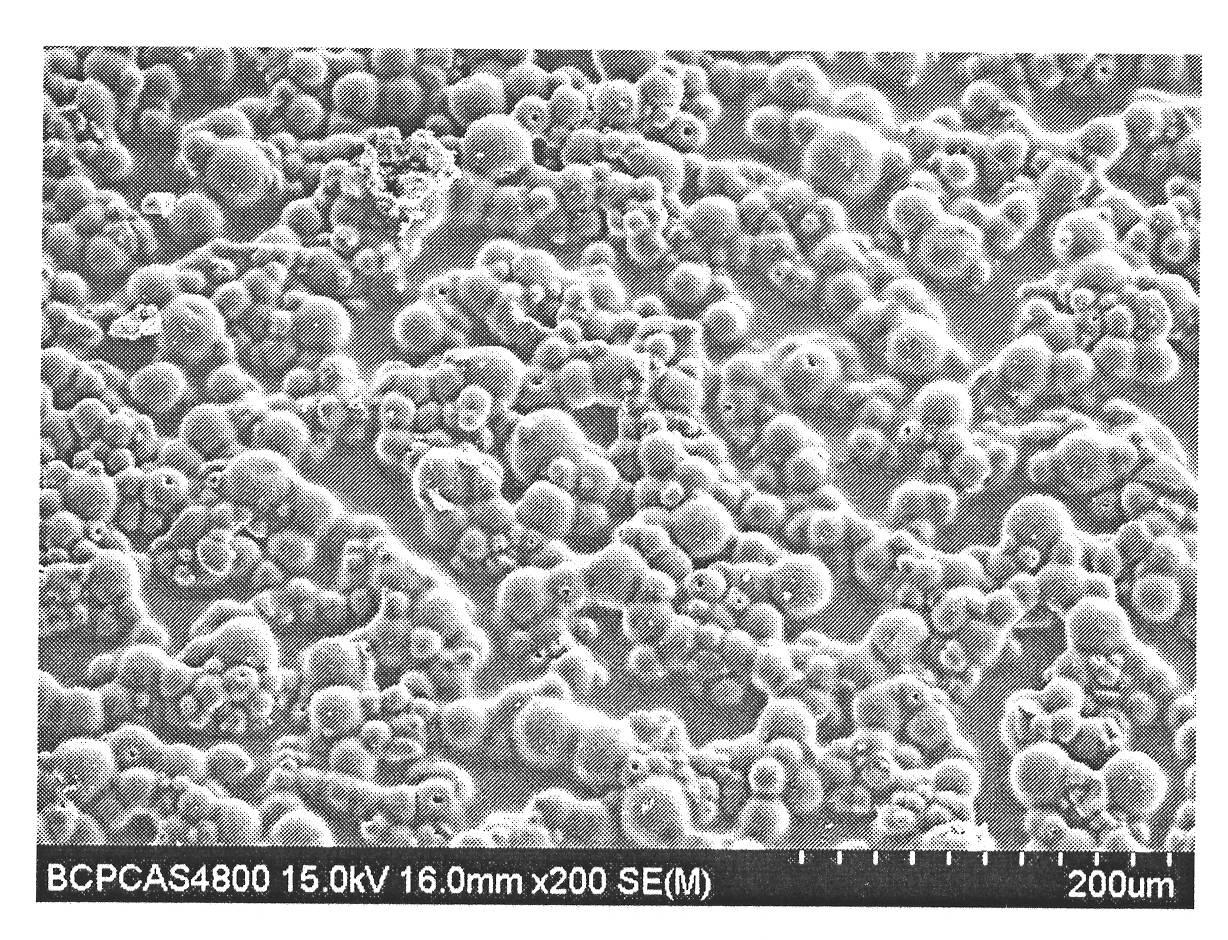

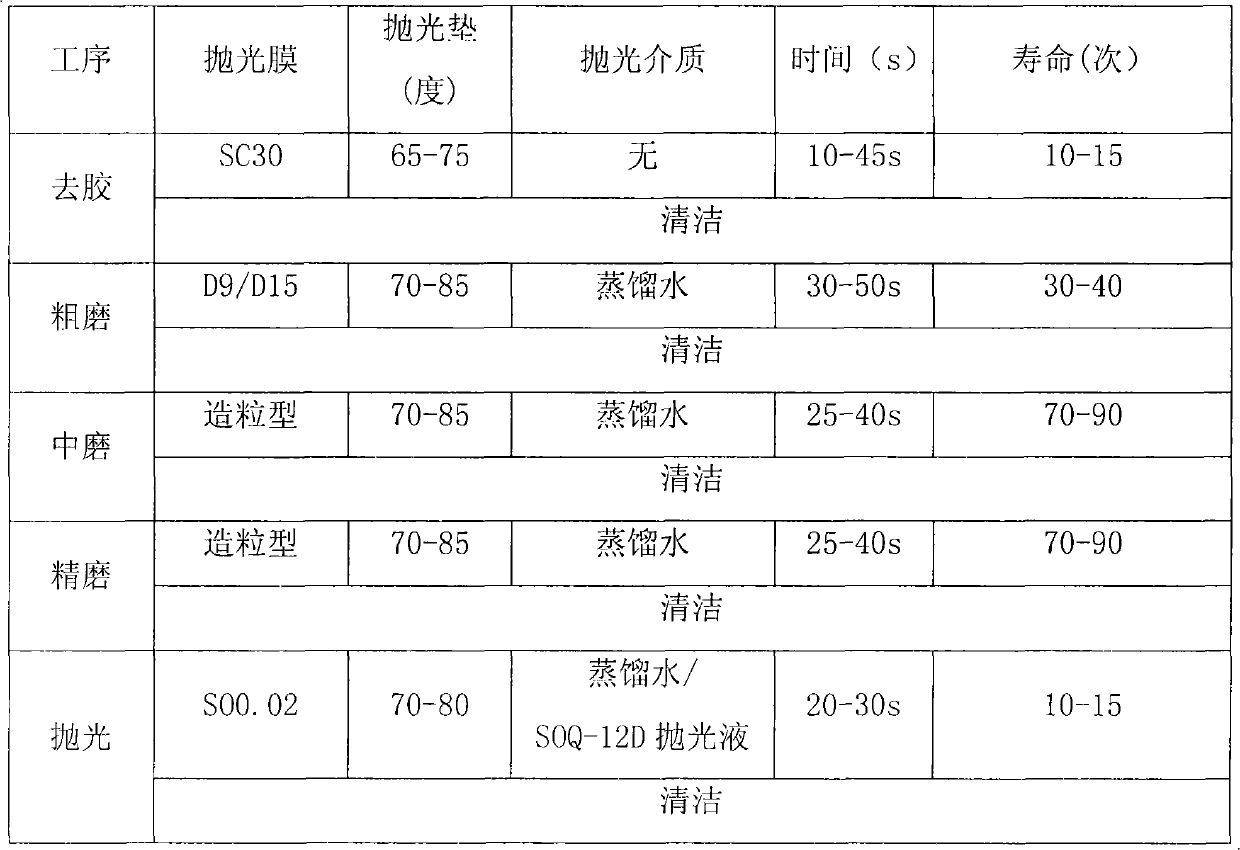

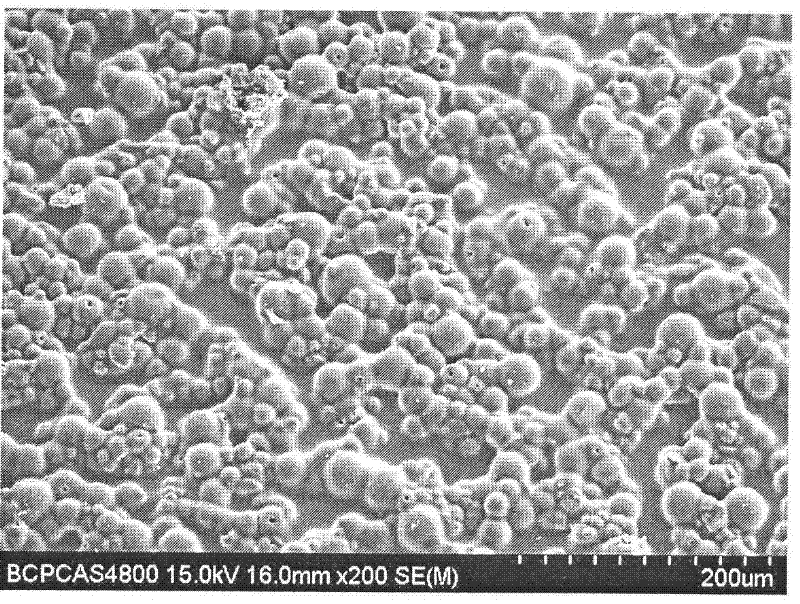

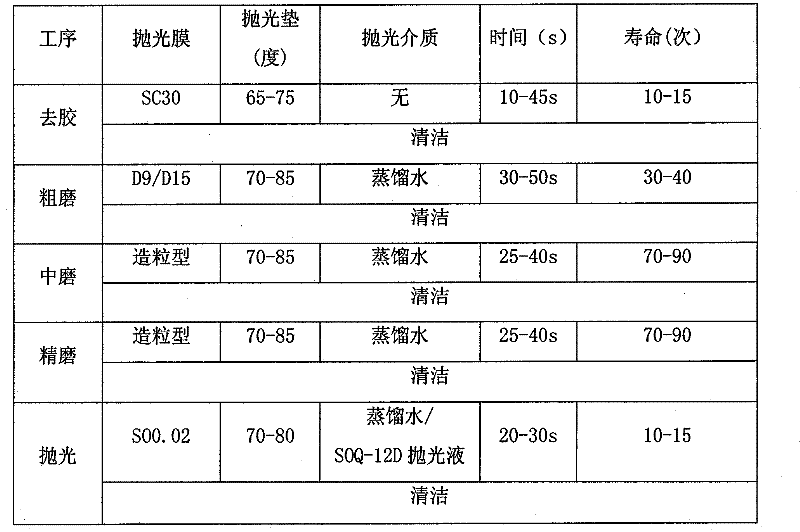

ActiveCN101767318AImprove surface roughnessImprove grinding efficiencyAbrasion apparatusGrinding machinesPolyesterEpoxy

The present invention provides a for the precise finish of an optical fiber connector with lasting abrasive power and high life time, a preparing method thereof and an application thereof, and can strengthen self-shaping. The granulation polishing film comprises base material and an abrasive layer coated at the surface of the base material, wherein the abrasive layer comprises resinoid bond and composite abrasive grains in global coacervate; the composite abrasive grains are global coacervates prepared by granulating abrasive powder distributed in the mixing liquid of metal oxide sol and organic or inorganic binder; the resinoid bond comprises epoxide resin and epoxide resin toughener, and also comprises one or several kinds of polyester, polyurethane, daiamid, acrylate and polyurea. The granulation polishing film is used for the grinding finish of the optical fiber connector and optical fiber arrays. The life time is one to two times longer than that of the traditional polishing film for the finish of the optical fiber connector, and the processing cost of the optical fiber connector is reduced.

Owner:BEIJING GRISH HITECH

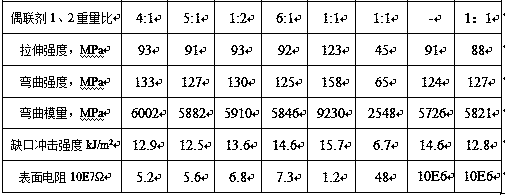

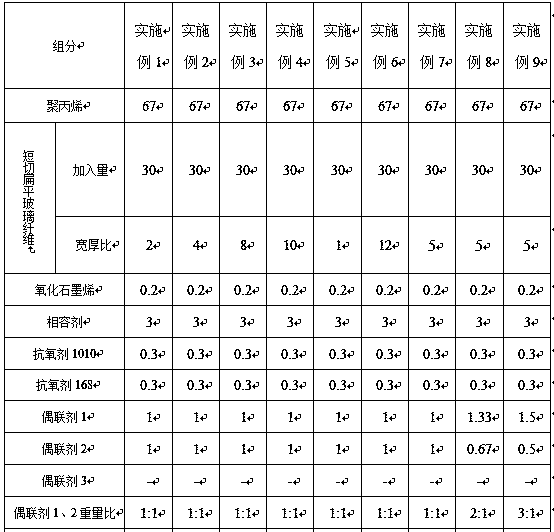

Glass fiber and graphene hybrid filler filled polypropylene composite material and preparation method thereof

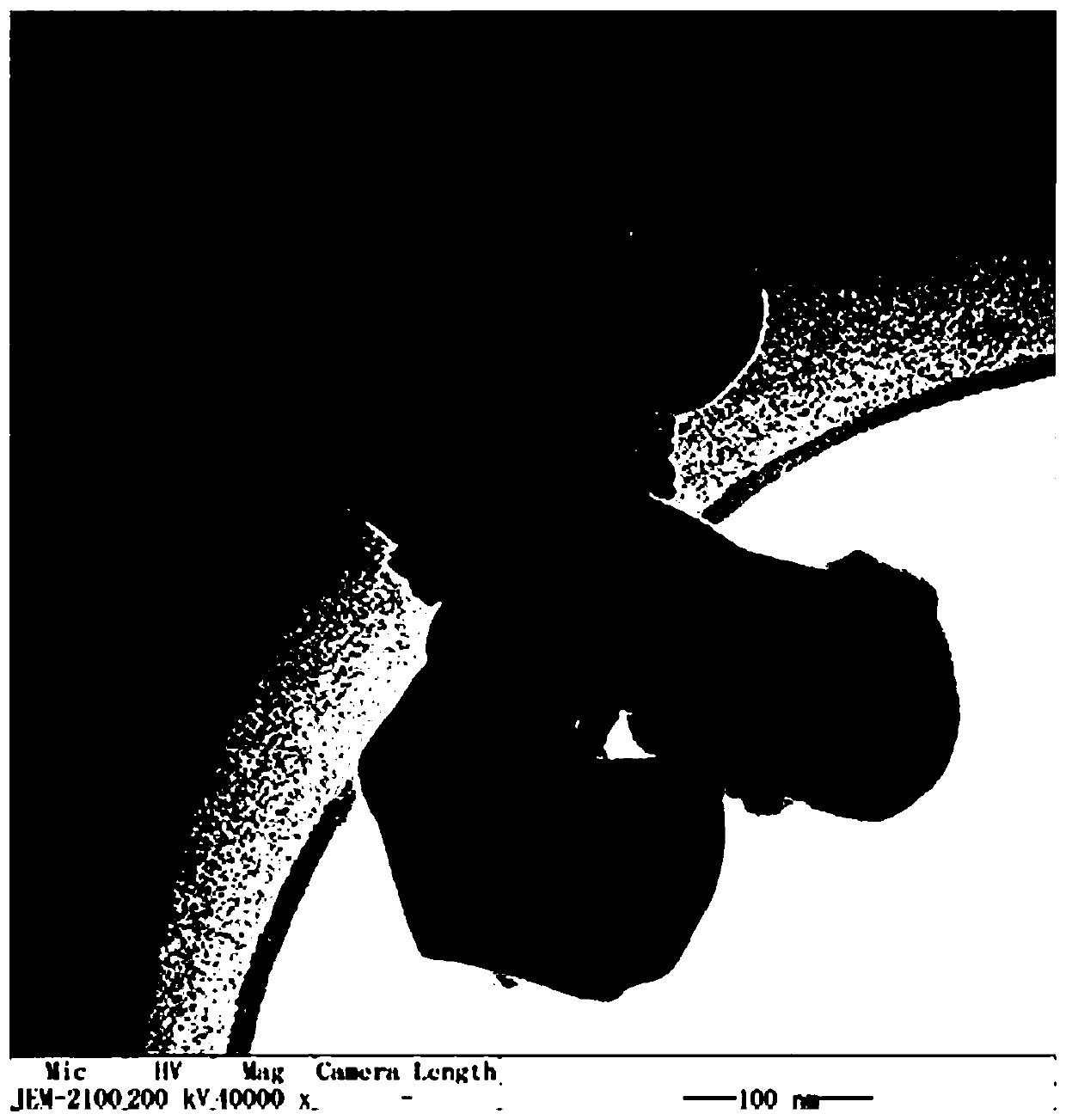

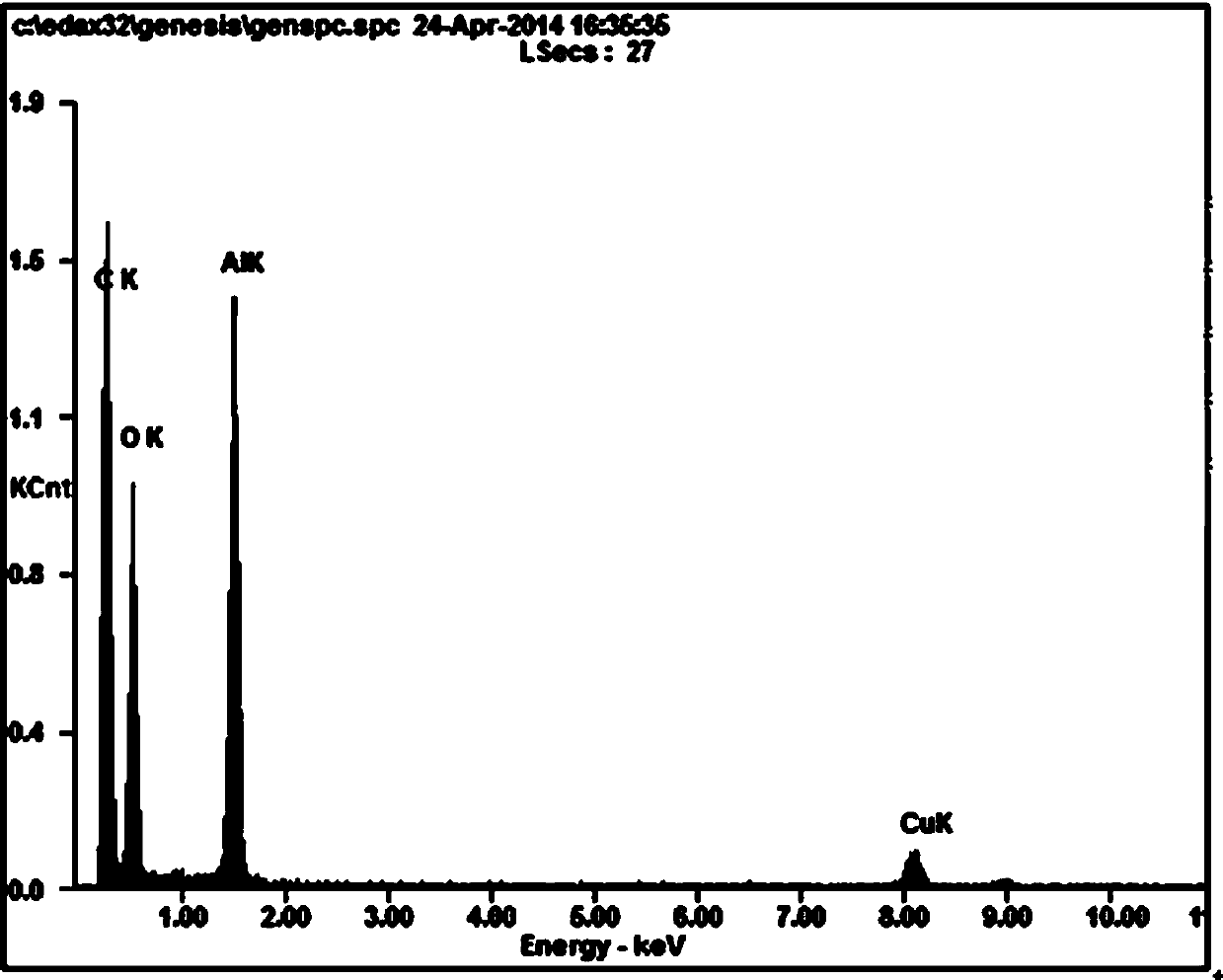

The invention relates to a glass fiber and graphene hybrid filler filled polypropylene composite material and a preparation method thereof. The glass fiber and graphene hybrid filler filled polypropylene composite material comprises the following components: 45-85 parts of polypropylene, r 10-50 parts of glass fiber, and 0.0001-1 part of graphene. The glass fiber is chopped glass fiber with a flatsection, and the width-to-thickness ratio of the section is 2-10. The preparation method utilizes electrostatic self-assembly principle to realize coating of glass fiber with graphene oxide, melt blending and in-situ reduction of graphene oxide can be realized synchronously. The invention has the advantages that: as the graphene carrier, glass fiber can realize even dispersion of a minute quantity of graphene in the matrix, a conductive network is formed to substantially lower the material surface resistance, an excellent antistatic effect can be achieved, and the stable physical and chemicalproperties of graphene endow the material with long-acting antistatic properties under moist, heating, insolation, vibration and other harsh conditions.

Owner:WUHAN JINFA TECH CO LTD +1

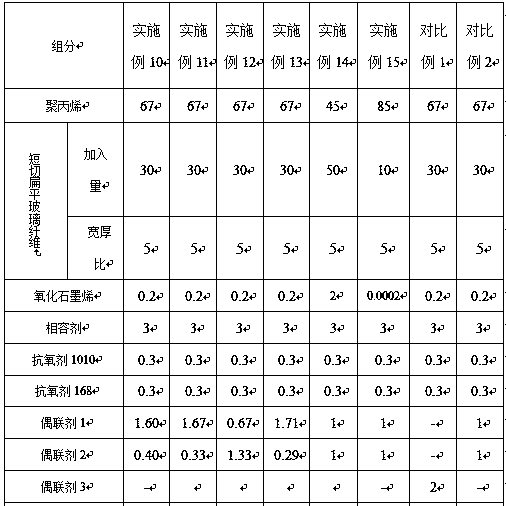

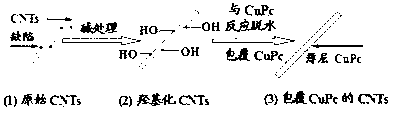

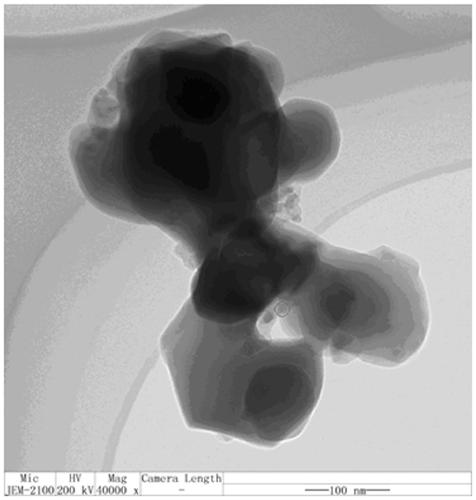

High-dielectric composite material, as well as preparation method and application thereof

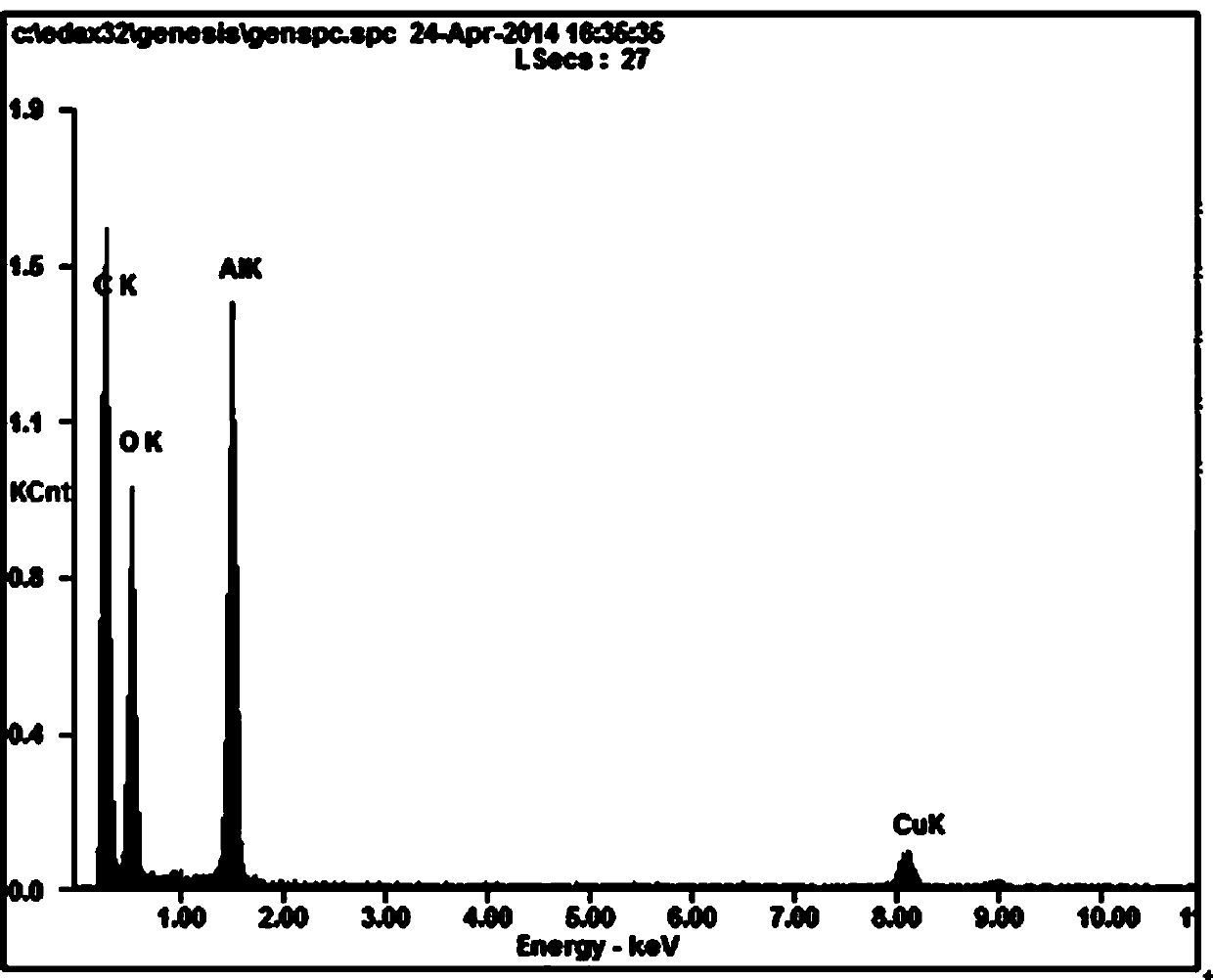

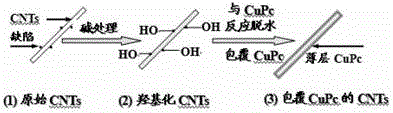

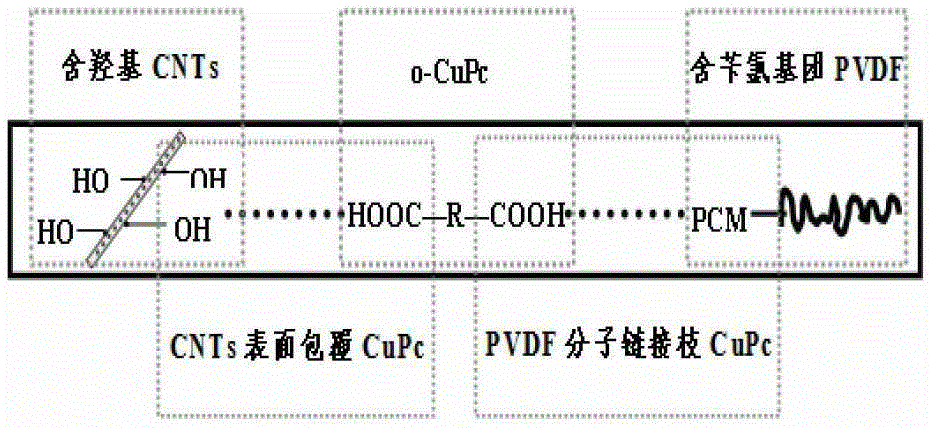

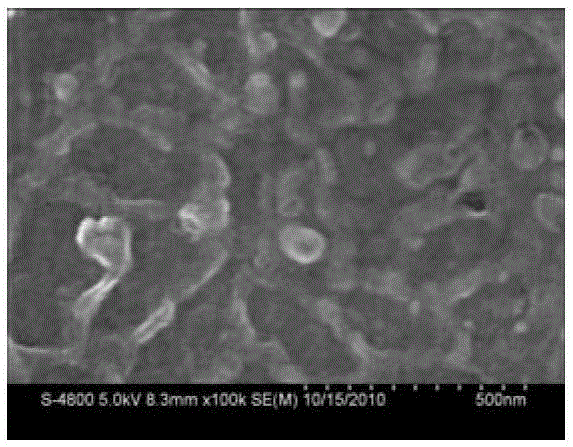

The invention relates to a high-dielectric composite material, as well as a preparation method and an application thereof. The composite material utilizes polyvinylidene fluoride as a basal body and a multi-walled carbon nanotube as a packing, a copper phthalocyanine oligomer is adopted to wrap the surface of the multi-walled carbon nanotube, and polyvinylidene fluoride is grafted, wherein the copper phthalocyanine oligomer plays a role of a flexible interface layer between the multi-walled carbon nanotube and the polyvinylidene fluoride so as to improve the compatibility of an interphase interface. Compared with an unmodified carbon nanotubes (CNTs) packing polymer composite material, the high-dielectric composite material adopts the copper phthalocyanine oligomer for the interphase interface, the dispersibility of the CNTs can be improved, the interface compatibility of organic / inorganic phases is also improved, and the interface polarization formation and transmission are benefited, so that the dielectric constant is increased, the breakdown field strength of the material is reduced, and the high-dielectric composite material is suitable for producing high-dielectric devices for electronic circuit boards.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

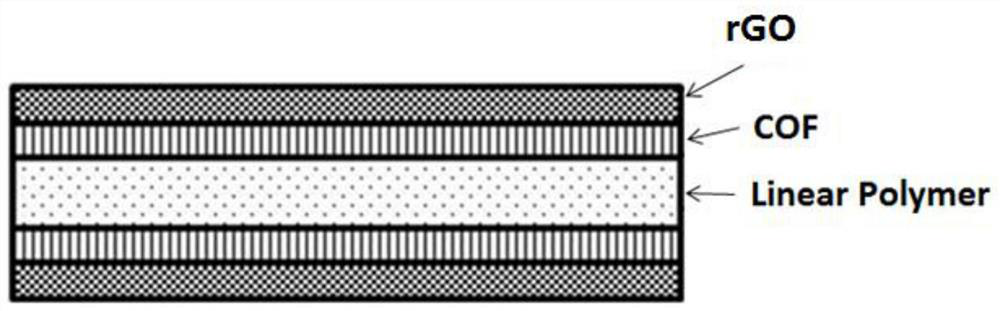

Novel Polymer-COF-rGO composite membrane and preparation method thereof

PendingCN112619704AEasy to separatePromote migrationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionPolymer sciencePolymer chemistry

The invention discloses a novel Polymer-COF-rGO composite membrane and a preparation method thereof. The preparation method comprises the steps that firstly, a COF monomer containing a polymer is prepared from a COF monomer and a linear Polymer, then the COF monomer, another COF monomer containing an amino group and graphene oxide (GO) are mixed and ground, DMF and acetic acid are added, then a heating reaction is conducted, and the novel Polymer-COF-rGO composite membrane is formed. In the synthesis reaction, two COF monomers form a COF material, added graphene oxide (GO) is reduced in-situ in a DMF solution and forms a covalent bond with amino in the COF material to be connected between rGO and COF at the same time under the heating condition, and in-situ growth of an rGO (reduced graphene oxide) membrane layer on the COF membrane layer is achieved. Due to the fact that the Polymer and the COF membrane layer are connected through covalent bonds, and the COF and the rGO membrane layer are connected through covalent bonds, the two types of 2D materials are effectively and tightly combined together, a bridging effect is achieved, and separation of COF photo-induced charges and migration of photo-induced electrons to rGO are improved.

Owner:嘉兴罗顿新材料科技有限公司

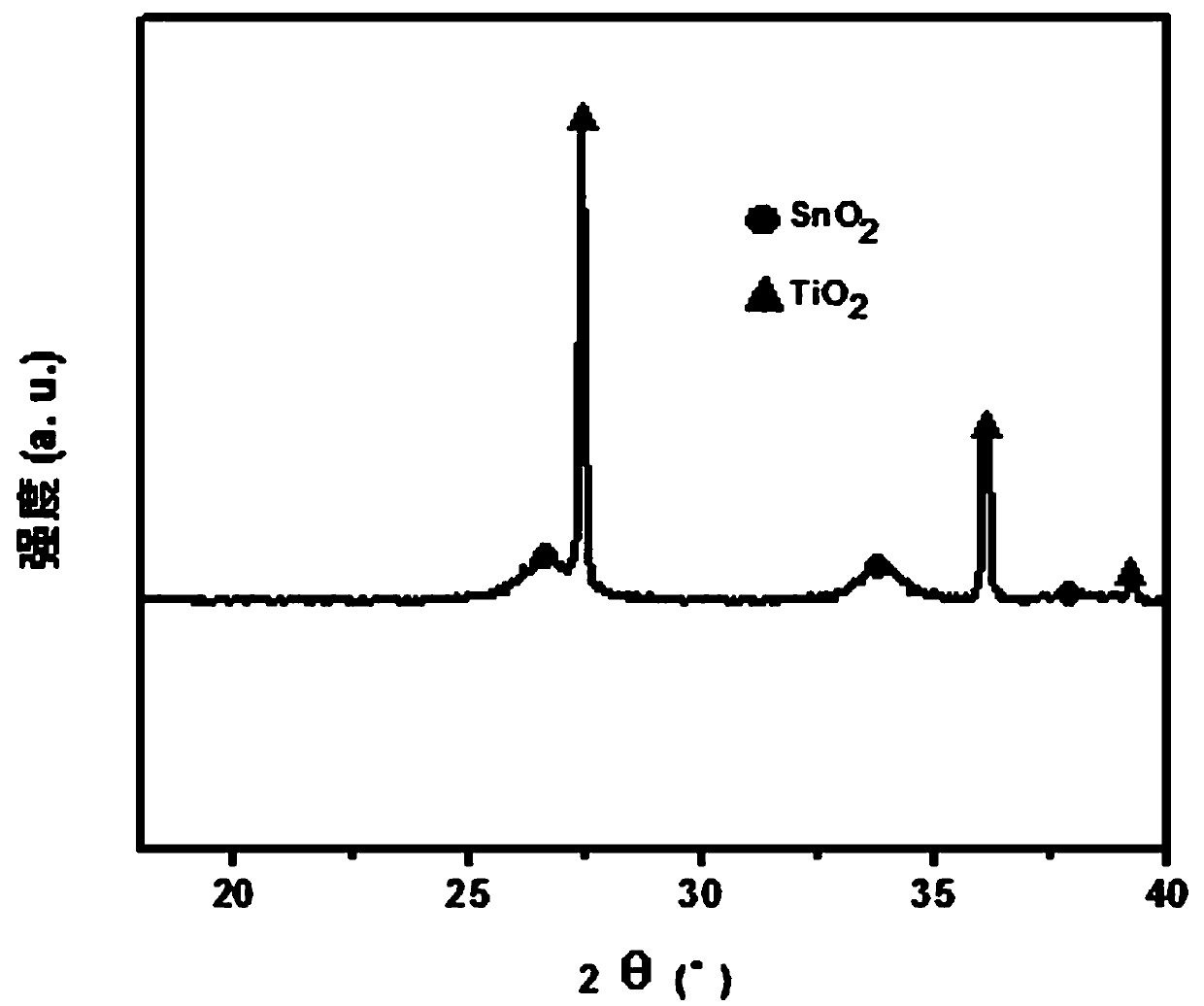

Preparation method of inorganic light-colored conductive titanium dioxide powder

ActiveCN107903664ACoated evenlyAdd lessPigment treatment with non-polymer organic compoundsTitanium dioxideTitanium

The invention provides a preparation method of inorganic light-colored conductive titanium dioxide powder. The preparation method includes the steps of firstly, dispersing gel ATO into water to obtaingel ATO aqueous dispersion, and adding a peptizing agent into the gel ATO aqueous dispersion until pH is 8-12 to obtain clear and transparent ATO hydrosol; secondly, adding titanium dioxide slurry into the ATO hydrosol prepared in the first step to form a mixed solution a, wherein the titanium dioxide slurry is prepared by dispersing titanium dioxide into water; thirdly, dropwise adding acid intothe mixed solution a obtained in the second step to regulate pH to 2-6 to form a mixed solution b; fourthly, drying the mixed solution b, crushing, and performing high-temperature sintering to obtainthe inorganic light-colored conductive titanium dioxide powder. The preparation method has the advantages that the method is simple to operate, and the prepared inorganic conductive titanium dioxidepowder is low in resistivity and light in color.

Owner:HENAN UNIVERSITY

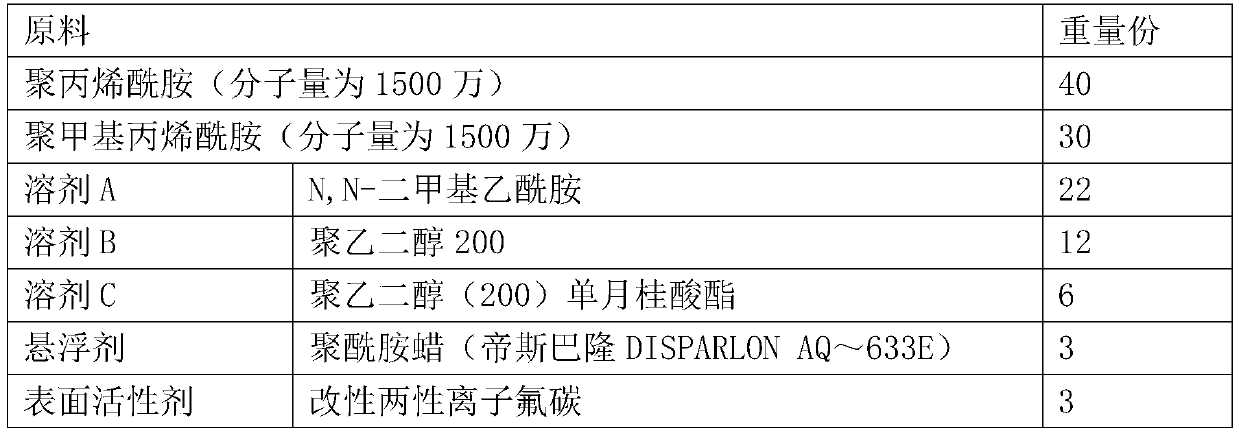

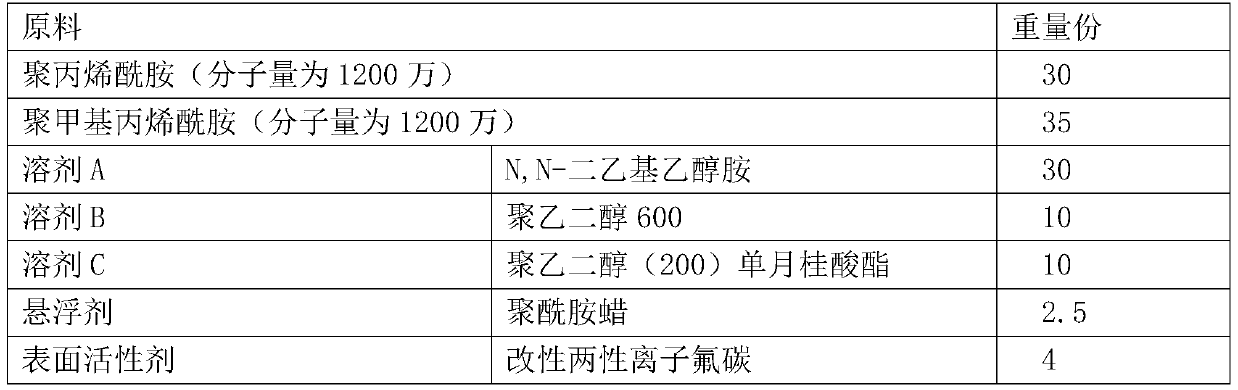

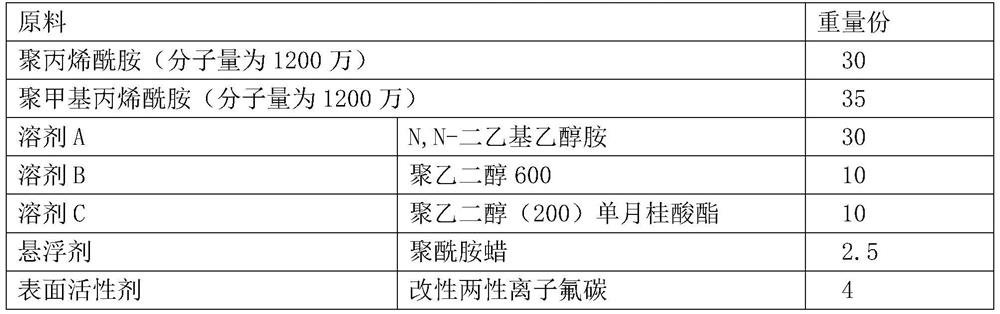

High-content water-based resistance reducing agent and preparation method thereof

ActiveCN111394085AEliminates slow dissolutionEliminate oil phase damage problemsFluid removalDrilling compositionMethacrylamideSolvent

The invention provides a high-content water-based resistance reducing agent and a preparation method thereof, and solves the technical problems in the prior art that a powder resistance reducing agentis low in hydration speed, oily residues exist after gel breaking of an oily suspension resistance reducing system, environmental friendliness is not achieved and the powder content of a water-basedresistance reducing suspension system is low. The preparation comprises the following raw materials in parts by weight: 20-50 parts of polyacrylamide; 20-40 parts of polymethacrylamide; 22-66 parts ofa solvent A; 4-12 parts of a solvent B; 6-18 parts of a solvent C; 1-3 parts of a suspending agent; and 3-6 parts of a surfactant, wherein the solvent A is alkyl amides; the solvent B is polyethyleneglycol; and the solvent C is polyhydric alcohol or polyhydric alcohol esters. The high-content water-based resistance reducing agent not only has the characteristics of high hydration speed, high powder content and good storage stability, but also can realize integrated operation and online blending.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD +1

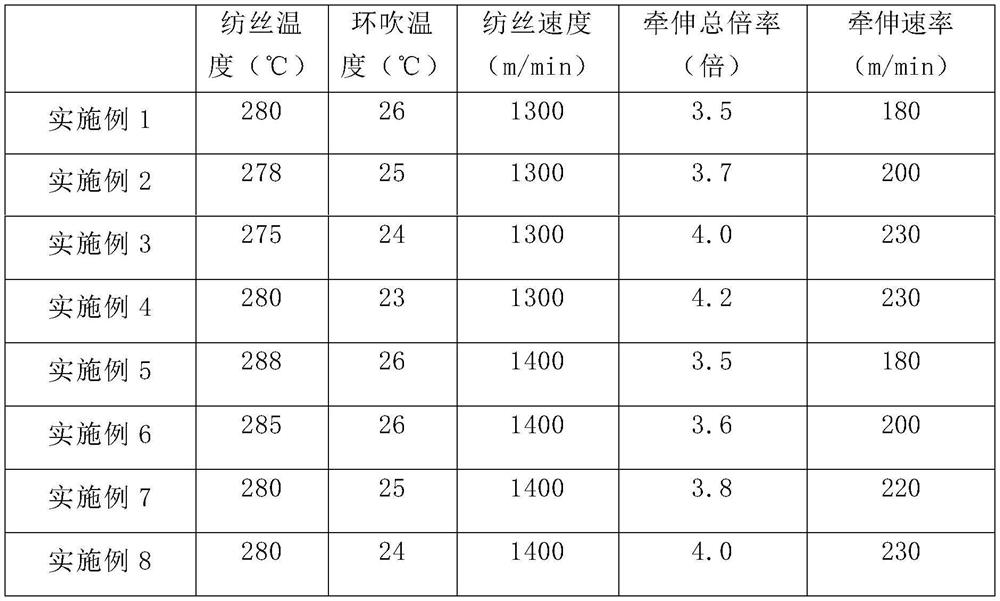

Polyester staple fibers and preparation method thereof

InactiveCN110747531AHigh glass transition temperatureReduce the interaction forceMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolymer science

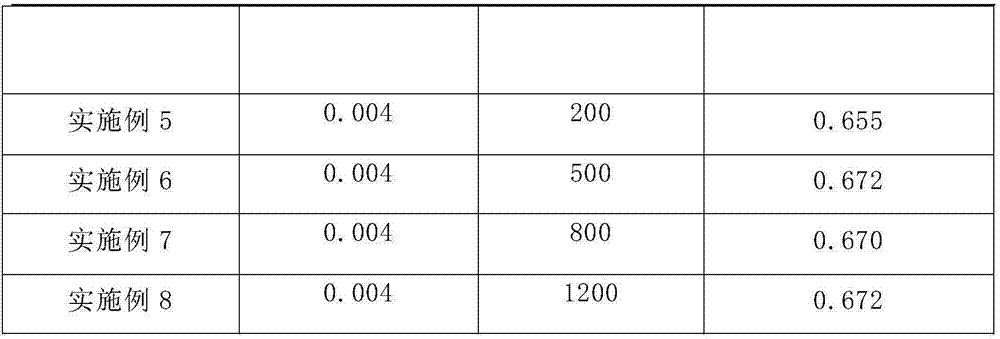

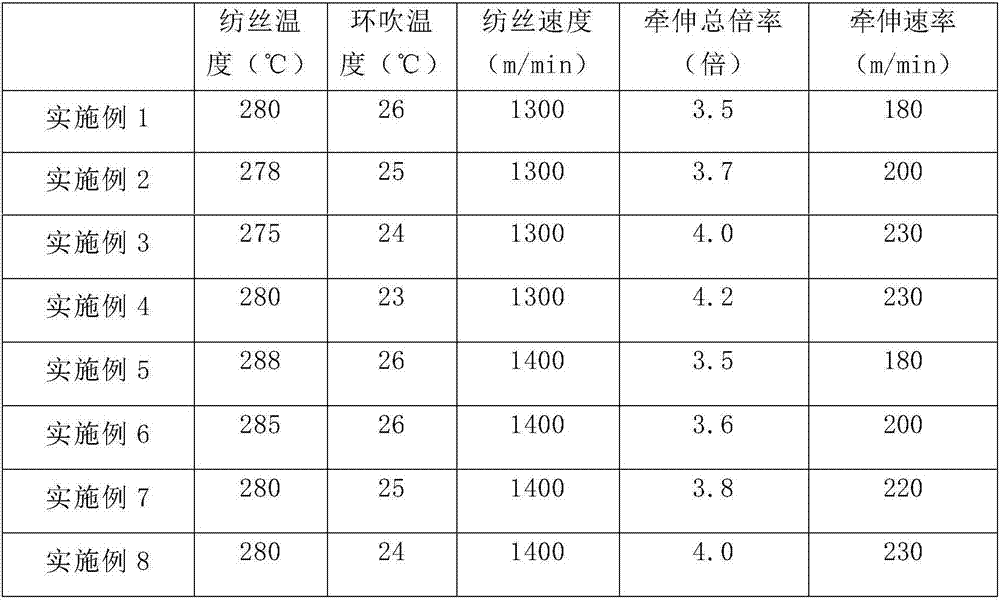

The invention provides polyester staple fibers and a preparation method thereof, and belongs to the technical field of polyester fibers. Polyethylene terephthalate contains a nucleating agent nano barium sulfate, the particle size of the nano barium sulfate is less than or equal to 100 nm, the concentration of the nano barium sulfate in the polyethylene terephthalate is 10-1000 ppm, and the specification of the staple fibers is 0.90-1.60 dtex*38 mm; nano polyethylene terephthalate composite is prepared by esterification and polycondensation of nano barium sulfate ethylene glycol suspension anda polyester monomer, and the nucleating agent nano barium sulfate is added in the form of ethylene glycol suspension before esterification, or before polycondensation after esterification. The polyester monomer is pure terephthalic acid, ethylene glycol or medium purity terephthalic acid. The special polyester staple fibers for sewing threads are low in production cost, good in glossiness, high in strength and low in dry heat shrinkage rate, and can meet the requirements of sewing thread spinning process and dyeing and finishing processing.

Owner:CIXI JIAJI CHEM FIBER

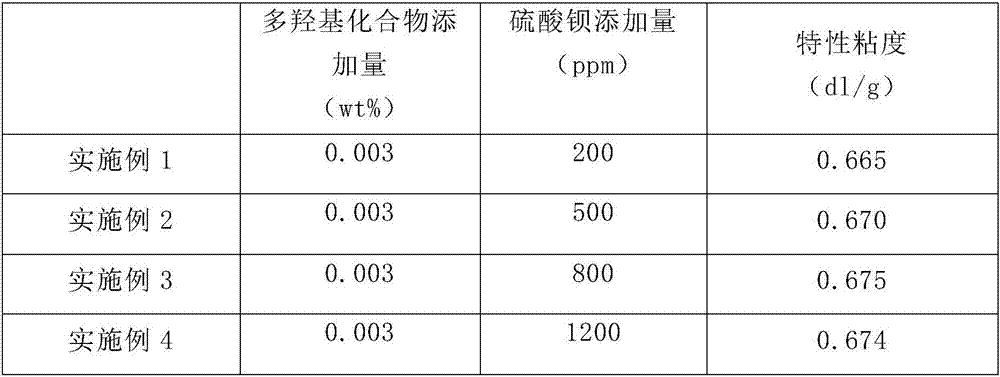

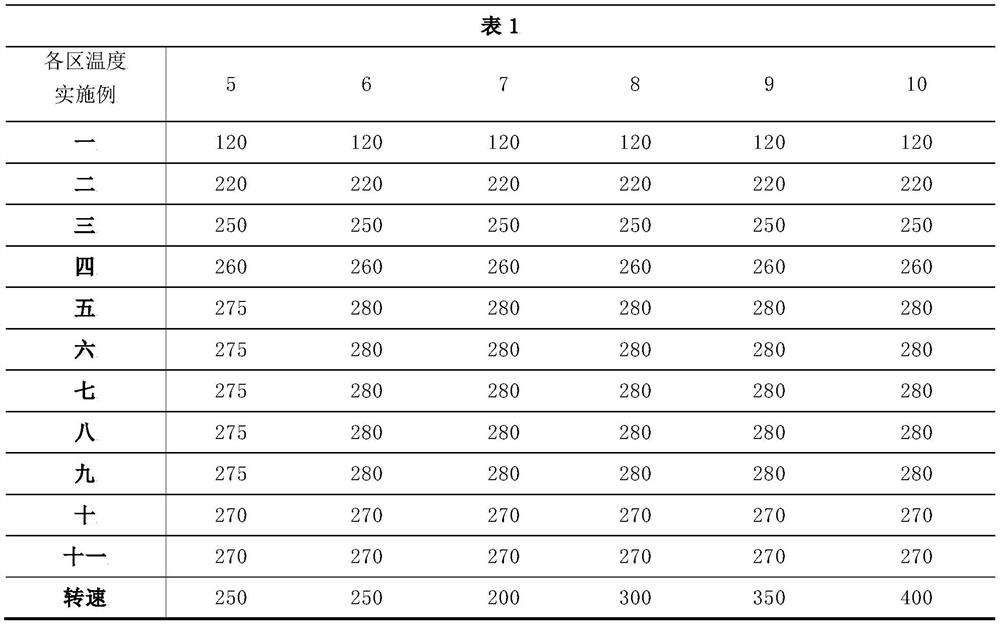

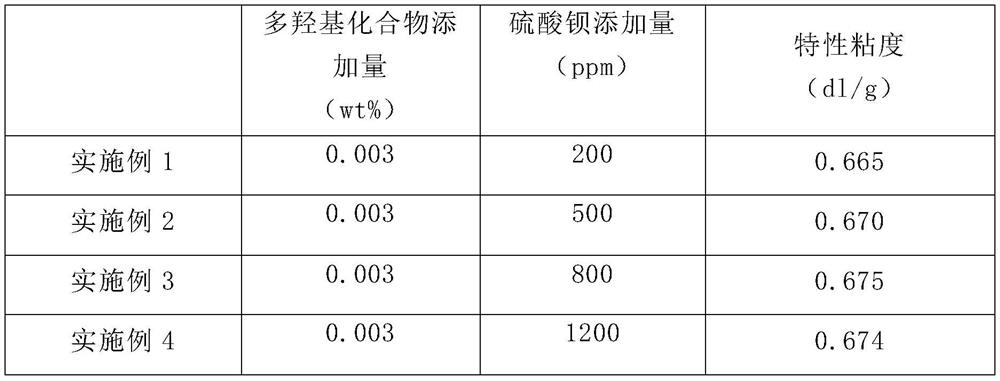

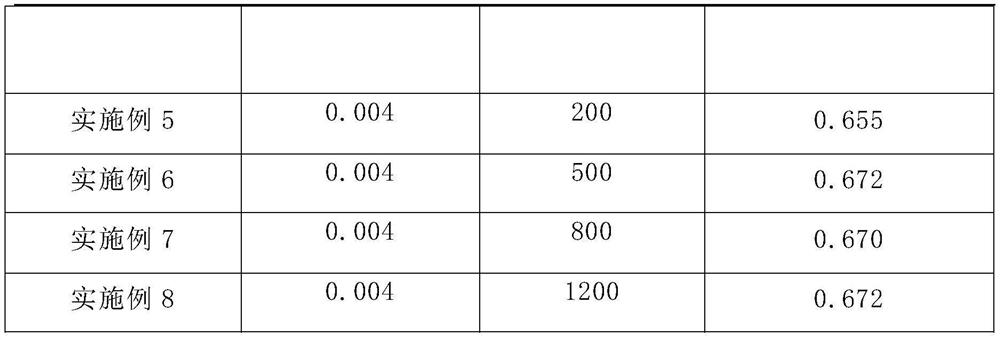

Direct spinning preparation method of glazed ultrahigh strength terylene high toughness polyester staple fibers

ActiveCN107881581AHigh glass transition temperatureImprove compactnessMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer sciencePapermaking

The invention discloses a direct spinning preparation method of glazed ultrahigh strength terylene high toughness polyester staple fibers. The preparation method comprises the following steps: mixingand stirring terephthalic acid, ethylene glycol, a polyhydroxy compound and a titanium series catalyst; carrying out an esterification reaction on the mixture; then carrying out further esterificationreaction and polycondensation reaction under the action of a catalyst ethanediol stibium; before the polycondensation reaction, adding barium sulfate to obtain a glazed polyester melt, the characteristic viscosity of which is 0.650-0.675dl / g; and spinning the melt to prepare the ultrahigh strength terylene high toughness polyester staple fibers. For the prepared fibers, the strength is greater than 6.40cN / dtex, the breaking elongation is 18-24%, and the dry heat-shrinkage at 180 DEG C is 3.5-6.0%. The fibers can meet the demands on products for manufacturing reinforcing materials such as top-grade sewing threads, papermaking and concrete.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite polylactic acid biomaterial and preparation method thereof

The invention relates to the technical field of orthopedic materials, and concretely relates to a composite polylactic acid biomaterial and a preparation method thereof. The composite polylactic acidbiomaterial comprises by weight, 10-15 parts of a chitosan compound, 5-8 parts of silk fibroin, 10-16 parts of hydroxyapatite, 0.2-5 parts of a compatibilizer, 50-65 parts of lactide and 0.5-0.8 partof a silane coupling agent, wherein chitosan compound is prepared by an electrospray process of chitosan and hyaluronic acid / carbon nanotube, and the hyaluronic acid / carbon nanotube is mainly preparedthrough a reaction of aminated hyaluronic acid and a carboxylated multiwalled carbon nanotube and dialysis. The composite polylactic acid biomaterial prepared in the invention has a good biocompatibility, meets the requirements of the mechanical performance of bones, has a service life fully meeting the needs of patients, and solves a problem that the service life of existing orthopedic materialscannot fully meet the needs of patients.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

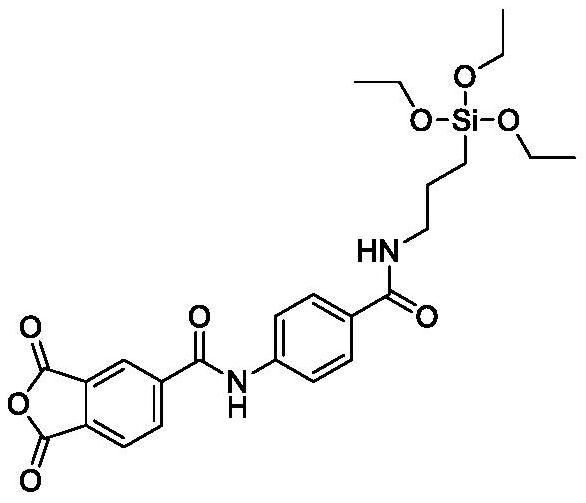

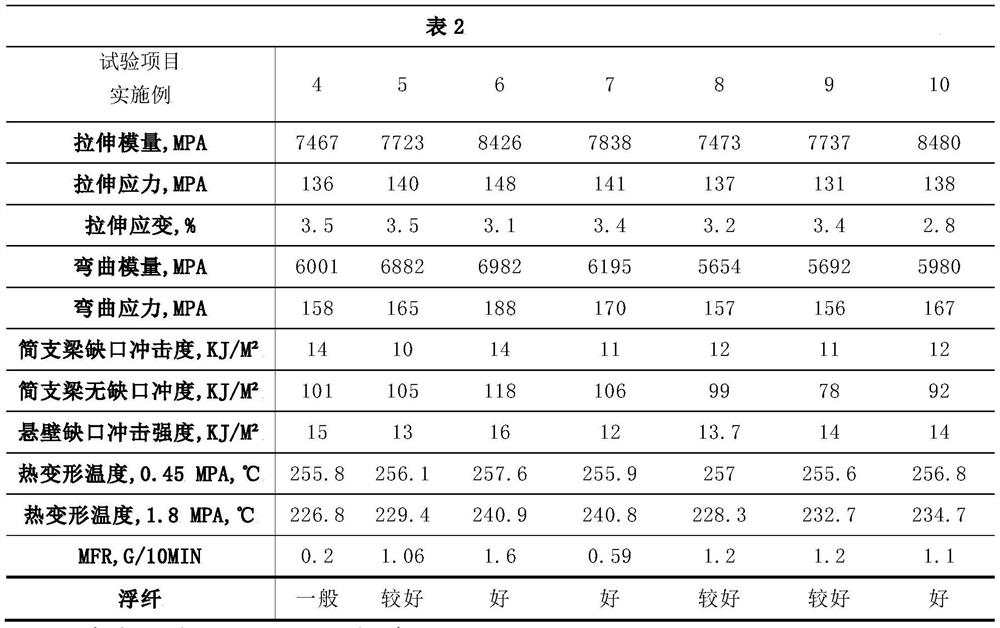

Floating-fiber-free glass fiber reinforced nylon composite material and preparation method thereof

The invention relates to a floating-fiber-free glass fiber reinforced nylon composite material and a preparation method thereof, and belongs to the field of engineering plastic composite materials and preparation processes thereof, the floating-fiber-free glass fiber reinforced nylon composite material comprises the following raw materials by weight: 40-90 parts of matrix polyamide resin, 5-55 parts of modified glass fiber, 0-40 parts of a flexibilizer, 0.1-1.5 parts of a heat stabilizer, and 0-5 parts of a lubrication dispersant. The glass fiber reinforced polyamide composite material is prepared by processing the matrix polyamide resin, the glass fiber and other additives according to a certain proportion, so that the two-phase interface bonding of the glass fiber and polyamide is good, the glass fiber on the surface of a product is not exposed, the surface smoothness of the product is good, and the material has the characteristics of higher tensile strength, higher bending modulus and better notch impact strength. The composite material has wide application prospects in the fields requiring high strength, high modulus and high dimensional stability, such as automobile engine covers, electric cutting machines, trunk accessories, pump impellers, cooling fans, precise instrument bottom shells, camera parts and the like.

Owner:ANHUI ZHONGDING RUBBER PLASTIC PROD CO LTD

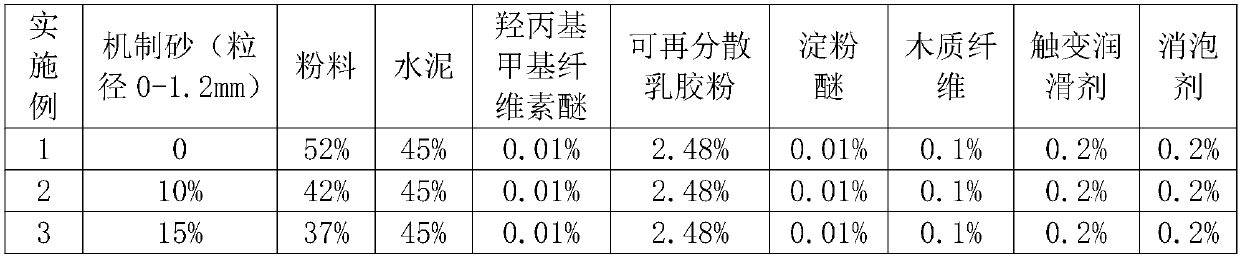

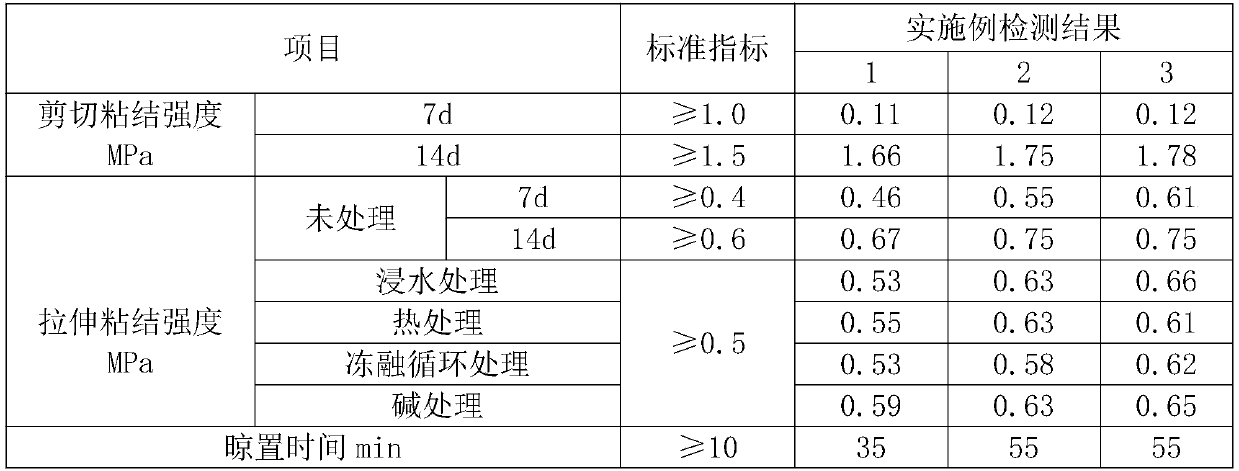

Interface agent for mechanized construction

The invention provides an interface agent for mechanized construction. The interface agent is prepared from the following components in percentage by mass: 0 to 15 percent of manufactured sand, 45 percent of cement, 37 to 52 percent of powder and the balance of an additive, wherein the grain diameter of the manufactured sand is 0 to 1.2mm. The additive is prepared from 0.01 percent of hydroxypropyl methylcellulose ether, 2.48 percent of redispersible latex powder, 0.01 percent of starch ether, 0.1 percent of woody fiber, 0.2 percent of a thixotropic lubricant and 0.2 percent of a de-foaming agent. By adopting the interface agent, the problem of a bonding force can be solved and a concrete wall surface and wall surfaces made of other wall materials also can synchronously absorb water in a mechanical construction process, so that synchronous initial setting of different wall materials is ensured and cracking and hollowing phenomena caused by the fact that the shrinkage of wall bodies isdifferent are avoided; and a work slowdown phenomenon of workers is reduced and the construction efficiency is improved.

Owner:杭州墨泰科技股份有限公司

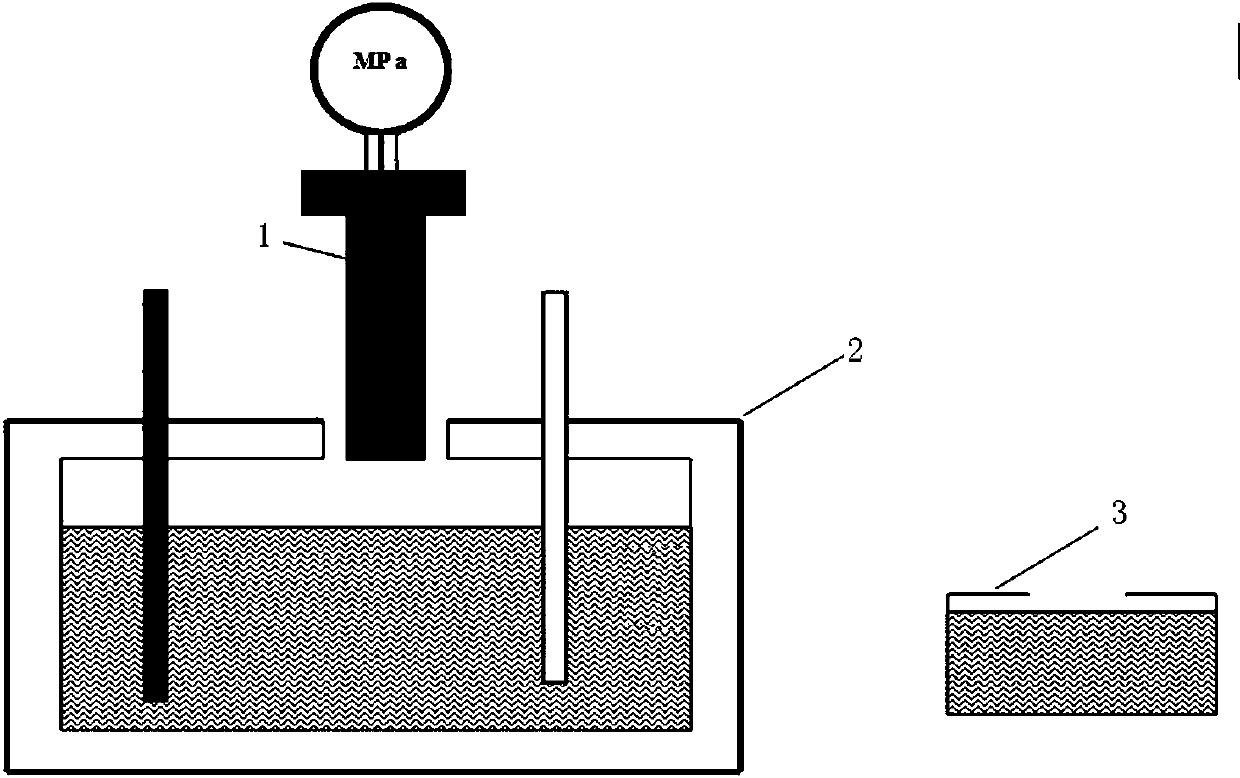

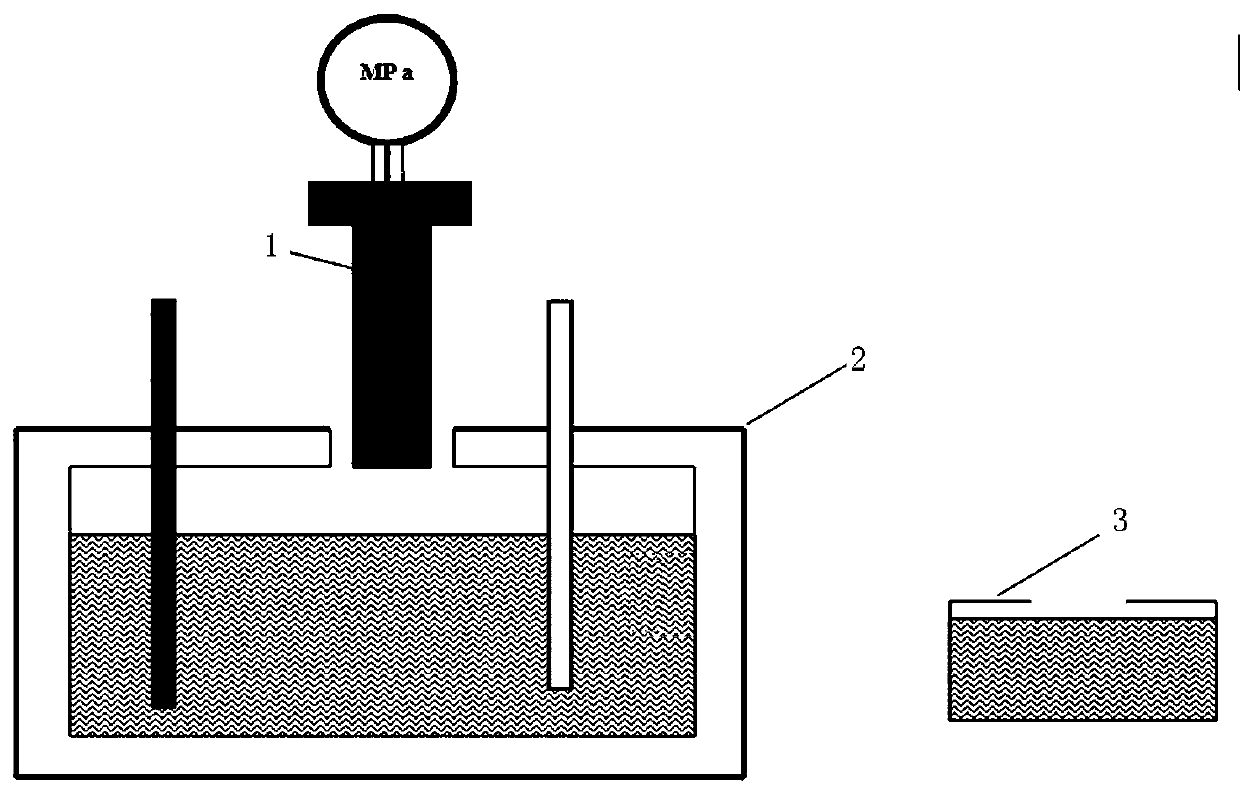

Method for modifying nanometer oxide through supercritical ethanol

ActiveCN107603279AReduce reunionUniform particle sizeBulk chemical productionPigment treatment with non-polymer organic compoundsTemperature controlIce water

The present invention belongs to the technical field of material modification, and particularly relates to a modification method for surface treatment of nanoparticles in a supercritical ethanol state. The modification method specifically comprises: 1, uniformly mixing ethanol and a nanometer oxide (particle size of 20-100 nm), placing in a reaction kettle with a pressure gauge, and strictly sealing; 2, placed the sealed reaction kettle in a heating furnace with a temperature control device, and heating at a temperature of 240+ / -1 DEG C; 3, observing the value of the pressure gauge on the reaction kettle, starting timing when the value of the pressure gauge achieves 6+ / -0.5 MPa, and carrying out a thermal insulation and pressure maintaining reaction for 5-10 min; 4, immediately placing thereaction kettle into a cooling pool, and cooling for 30-60 min, wherein cooling water is an ice water bath, and the temperature is 0 DEG C; and 5, taking out the treated nanoparticles, placing in a 130 DEG C vacuum oven, drying for more than 6 h, and grinding in a mortar after completely drying to obtain the surface-treated nanoparticles.

Owner:盘锦易立凯泰新材料有限公司

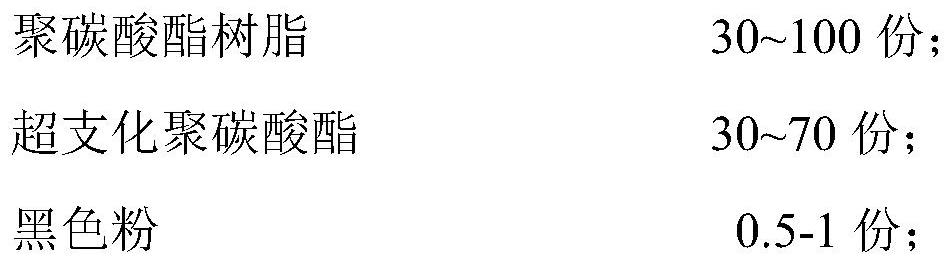

High-weather-resistance black PC resin composition as well as preparation method and application thereof

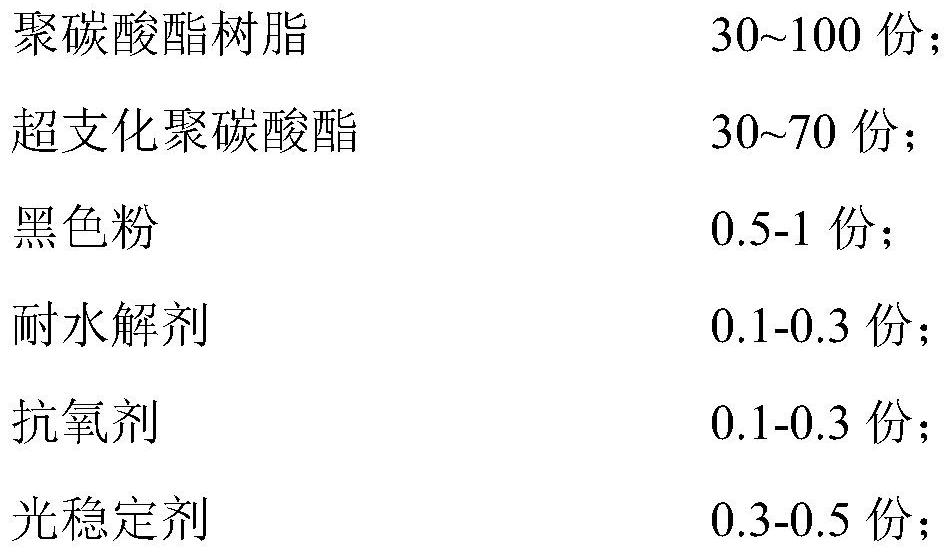

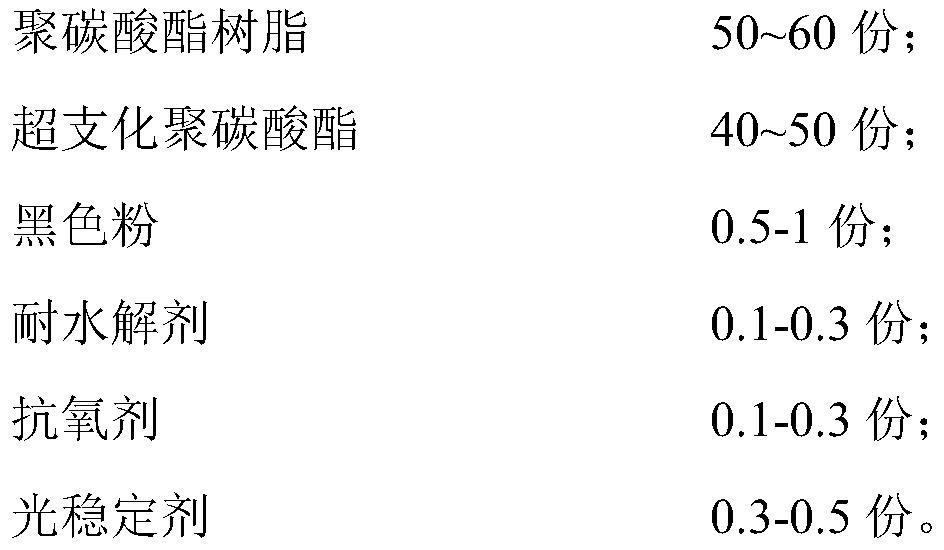

The invention provides a high-weather-resistance black PC resin composition as well as a preparation method and application thereof. The black PC resin composition with high weather resistance comprises the following components: polycarbonate resin, hyperbranched polycarbonate, black powder, a hydrolysis-resistant agent, an antioxidant and a light stabilizer, the branching degree of the hyperbranched polycarbonate is 0.3 to 0.5, and the weight-average molecular weight of the hyperbranched polycarbonate is 6400 to 12000. According to the high-weather-resistance black PC resin composition disclosed by the invention, hyperbranched polycarbonate is introduced and is matched with other auxiliaries, so that the water resistance of the black PC resin composition can be effectively improved. The weather resistance and the highlight black surface state can be further improved, and the alloy material can be applied to preparation of spraying-free plastic products and can replace common spraying PC / ABS alloy materials on parts such as automobile household appliances and the like.

Owner:WUHAN JINFA TECH CO LTD +1

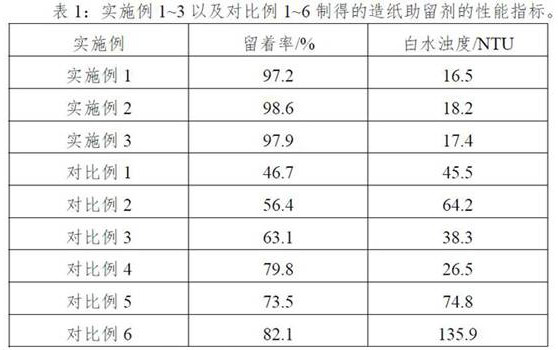

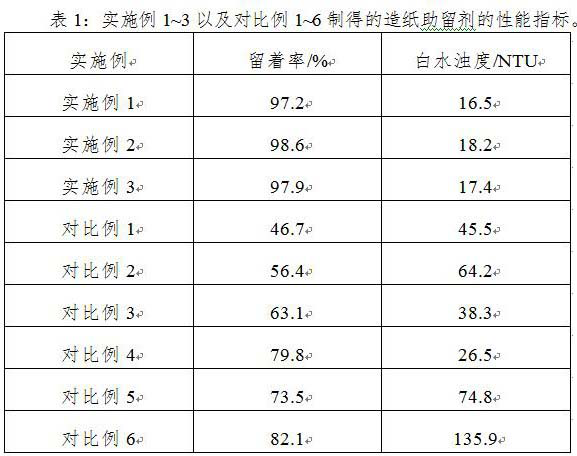

Papermaking retention aid, preparation method and application thereof

ActiveCN113248651AAct as a "patch"Play the role of "bridge"Paper/cardboardRetention agents additionFiberActive agent

The invention relates to a papermaking retention aid, a preparation method and application thereof, and belongs to the technical field of preparation of modified polyacrylamide. The method comprises the following steps: uniformly mixing acrylamide, a cationic monomer, a structure regulator, a hydrophobic monomer, N-vinylformamide and a cationic surfactant with water to obtain a mixed solution; introducing nitrogen into the mixed solution to remove oxygen, then adding a polymerization additive to initiate a polymerization reaction to obtain jelly, and then sequentially granulating, drying and crushing the jelly to obtain copolymer powder; preparing the copolymer powder into a copolymer powder aqueous solution by using water, and then sequentially adding liquid bromine and a sodium hydroxide aqueous solution for modification treatment to obtain a modified treatment solution; and adjusting the pH value of the modified treatment solution to 8-9, and then filtering through a filter membrane to obtain the papermaking retention aid. The papermaking retention aid prepared by the invention improves the retention rate of fine fibers, and when the papermaking retention aid is used in a papermaking process, the papermaking production efficiency can be improved, the blockage of a water filtering channel is avoided, and the turbidity of white water can be effectively reduced.

Owner:SHANDONG NUOER BIOLOGICAL TECH

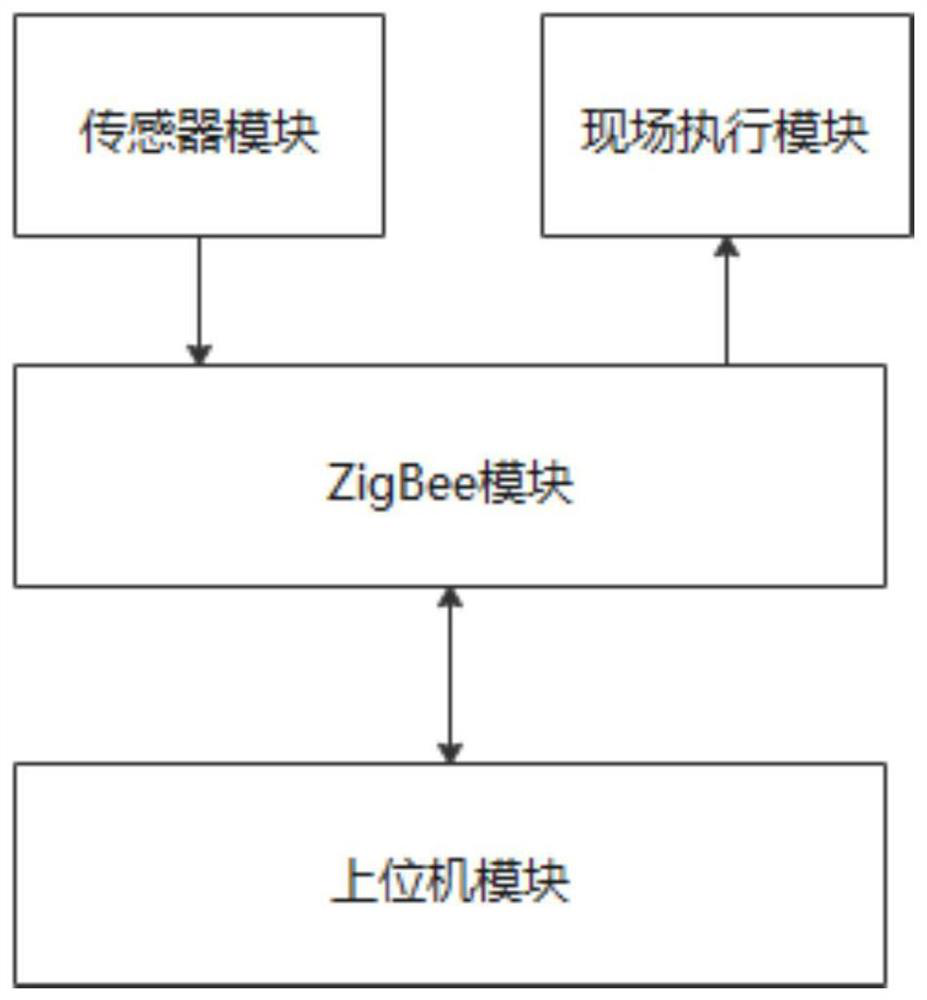

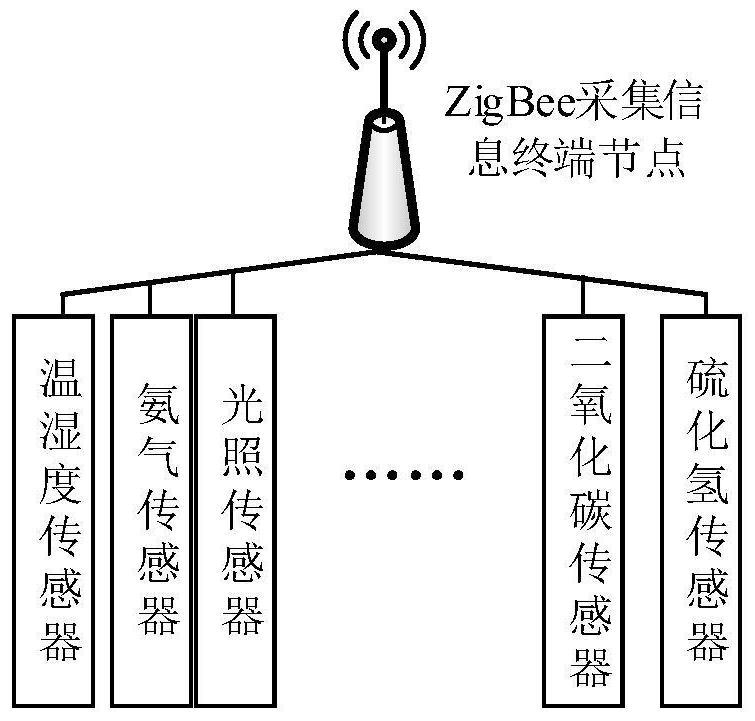

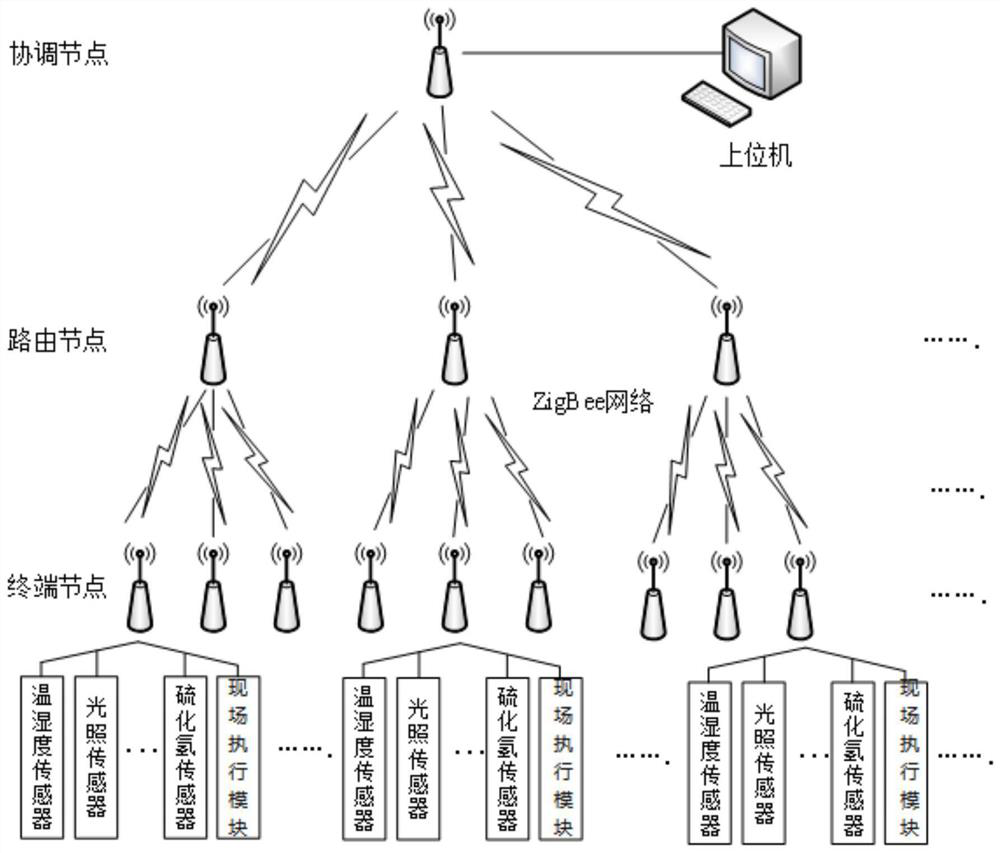

Breeding house environment monitoring system

ActiveCN113467558AImprove communication distanceEasy to set upSimultaneous control of multiple variablesThe InternetComputer module

The invention discloses a breeding house environment monitoring system. The system comprises a sensor module, a field execution module, a ZigBee module and an upper computer module, wherein the ZigBee module is in communication connection with the sensor module, the field execution module and the upper computer module. In order to solve the problems that in the prior art, the breeding environment cannot be monitored in real time and does not have the intelligent regulation and control function, the system adopts the technologies of the Internet of Things, artificial intelligence, Internet+ and the like, real-time monitoring and intelligent regulation and control of breeding house environment parameters are achieved, a user can conveniently detect and manage the breeding house environment in time, and the breeding quality is effectively improved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Sponge water-permeable brick and preparation method thereof

InactiveCN110451928APlay the role of "bridge"High strengthCeramic materials productionCeramicwareBrickSodium Bentonite

The invention discloses a sponge water-permeable brick and a preparation method thereof, and belongs to the technical field of a water-permeable brick. The sponge water-permeable brick is prepared from the following raw materials in parts by weight: 80 to 90 parts of sludge powder, 5 to 10 parts of modified polypropylene fiber, 3 to 5 parts of granite aggregate, 1 to 3 parts of expanded perlite, 15 to 20 parts of bentonite, 5 to 10 parts of coal ash and 5 to 10 parts of diatomite. The water-permeable brick prepared by the method has high compressive strength and high water permeability, has sound absorbing and noise reducing properties, accords with the industrial standard of Water-permeable Brick (CJ / T945-2005), is low in cost, can perform industrial production, responds to sponge city concept and can serve as an important building material in sponge city construction.

Owner:安徽新宇环保科技股份有限公司

A kind of high-content water-based drag reducing agent and preparation method thereof

ActiveCN111394085BHigh powder contentFast hydrationFluid removalDrilling compositionMeth-Active agent

The invention provides a high-content water-based resistance reducing agent and a preparation method thereof, and solves the technical problems in the prior art that a powder resistance reducing agentis low in hydration speed, oily residues exist after gel breaking of an oily suspension resistance reducing system, environmental friendliness is not achieved and the powder content of a water-basedresistance reducing suspension system is low. The preparation comprises the following raw materials in parts by weight: 20-50 parts of polyacrylamide; 20-40 parts of polymethacrylamide; 22-66 parts ofa solvent A; 4-12 parts of a solvent B; 6-18 parts of a solvent C; 1-3 parts of a suspending agent; and 3-6 parts of a surfactant, wherein the solvent A is alkyl amides; the solvent B is polyethyleneglycol; and the solvent C is polyhydric alcohol or polyhydric alcohol esters. The high-content water-based resistance reducing agent not only has the characteristics of high hydration speed, high powder content and good storage stability, but also can realize integrated operation and online blending.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD +1

A kind of method of supercritical ethanol modification nano-oxide

ActiveCN107603279BPlay the role of "bridge"Good compatibilityBulk chemical productionPigment treatment with non-polymer organic compoundsWater bathsIce water

Owner:盘锦易立凯泰新材料有限公司

A kind of sodium humate binder solution for iron ore pellets and its preparation method and application

The invention discloses a sodium humate binder solution for iron ore pellets and its preparation method and application. The solute of the sodium humate binder solution is composed of sodium humate, sodium hydroxide and a viscosity regulator, and the solvent It is water, and the viscosity modifier is one or more of the soluble salts of Al3+, Fe3+, Ca2+, Mg2+. The preparation method is to dissolve sodium humate in NaOH solution, then add the viscosity modifier and stir evenly, Promptly obtained; the preparation method of this sodium humate binder solution is simple to operate and low in cost, and the prepared sodium humate binder solution is added in the iron ore concentrate during the pelletizing process of the iron ore pelletizing process, which can effectively It improves the strength of green pellets and the total iron grade of finished pellets, and has the characteristics of less consumption and is suitable for pelletizing various iron concentrates.

Owner:CENT SOUTH UNIV

A kind of high dielectric composite material, its preparation method and application

The invention relates to a high-dielectric composite material, as well as a preparation method and an application thereof. The composite material utilizes polyvinylidene fluoride as a basal body and a multi-walled carbon nanotube as a packing, a copper phthalocyanine oligomer is adopted to wrap the surface of the multi-walled carbon nanotube, and polyvinylidene fluoride is grafted, wherein the copper phthalocyanine oligomer plays a role of a flexible interface layer between the multi-walled carbon nanotube and the polyvinylidene fluoride so as to improve the compatibility of an interphase interface. Compared with an unmodified carbon nanotubes (CNTs) packing polymer composite material, the high-dielectric composite material adopts the copper phthalocyanine oligomer for the interphase interface, the dispersibility of the CNTs can be improved, the interface compatibility of organic / inorganic phases is also improved, and the interface polarization formation and transmission are benefited, so that the dielectric constant is increased, the breakdown field strength of the material is reduced, and the high-dielectric composite material is suitable for producing high-dielectric devices for electronic circuit boards.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

A kind of direct spinning preparation method of bright ultra-high strength polyester high tenacity polyester staple fiber

ActiveCN107881581BHigh glass transition temperatureImprove compactnessMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer scienceSpinning

The invention discloses a direct spinning preparation method of bright ultra-high-strength polyester and high-toughness polyester staple fiber. In the present invention, after mixing and stirring terephthalic acid, ethylene glycol, polyhydroxy compounds and titanium-based catalysts, the esterification reaction is carried out first, and then the further esterification reaction and polycondensation reaction are carried out under the action of the catalyst ethylene glycol antimony. Barium sulfate is added before the reaction to obtain a bright polyester melt with an intrinsic viscosity of 0.650-0.675dl / g. The melt is prepared by spinning to obtain ultra-high strength and high tenacity bright polyester staple fiber. The strength of the prepared fiber is greater than 6.40cN / dtex, the elongation at break is 18-24%, and the dry heat shrinkage at 180°C is 3.5-6.0%, which can meet the product requirements for making high-end sewing threads and reinforcing materials such as papermaking and concrete.

Owner:CHINA PETROLEUM & CHEM CORP +1

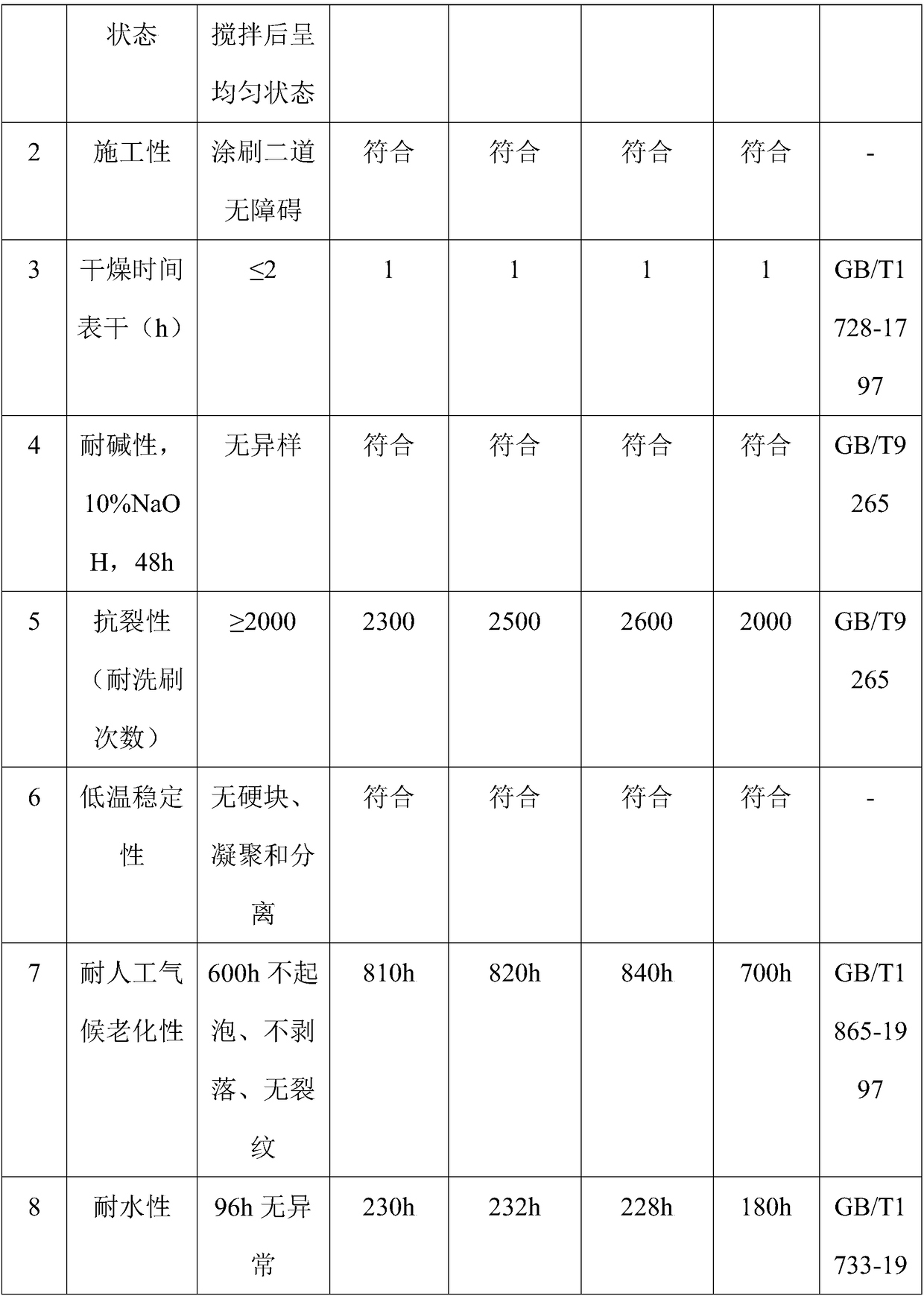

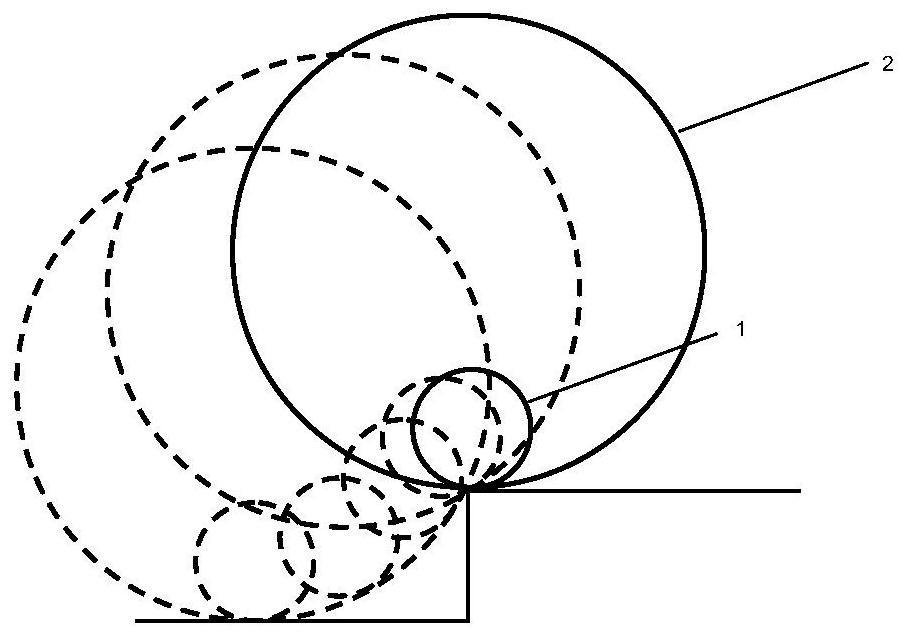

Paint for thermal insulating outer wall

InactiveCN108707421AImprove insulation effectImprove sound insulationRosin coatingsAnti-corrosive paintsThermal insulationEther

The invention discloses a paint for a thermal insulating outer wall. The paint for the thermal insulating outer wall is prepared from, by weight, 10-25 parts of rosin resin, 2-7 parts of thermal insulation material, 5-10 parts of coarse whiting, 3-8 parts of nickel powder, 2-5 parts of vanillin, 1-4 parts of zinc stearate, 15-35 parts of crylic acid modified resin latex solution, 1-4 parts of butyl acetate, 1-5 parts of flatting agent, 2-6 parts of starch ether and 60-90 parts of deionized water. The paint for the thermal insulating outer wall has the advantages of higher anti-corrosive performance, and excellent heat retaining, sound-proof and anti-cracking properties.

Owner:TIANCHANG JULONG TRAVEL PAINT

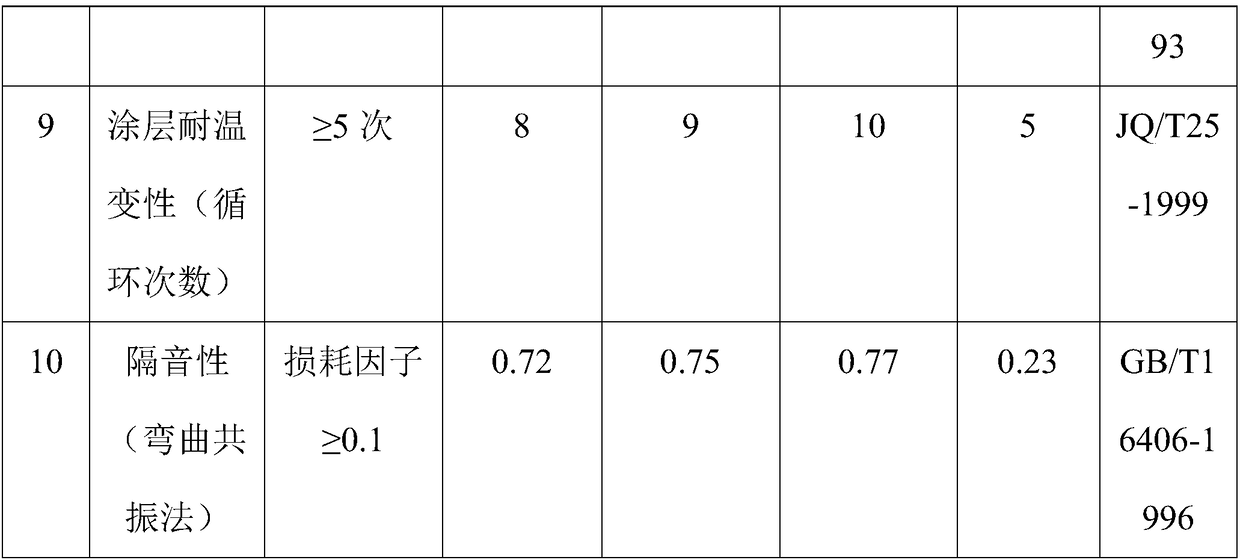

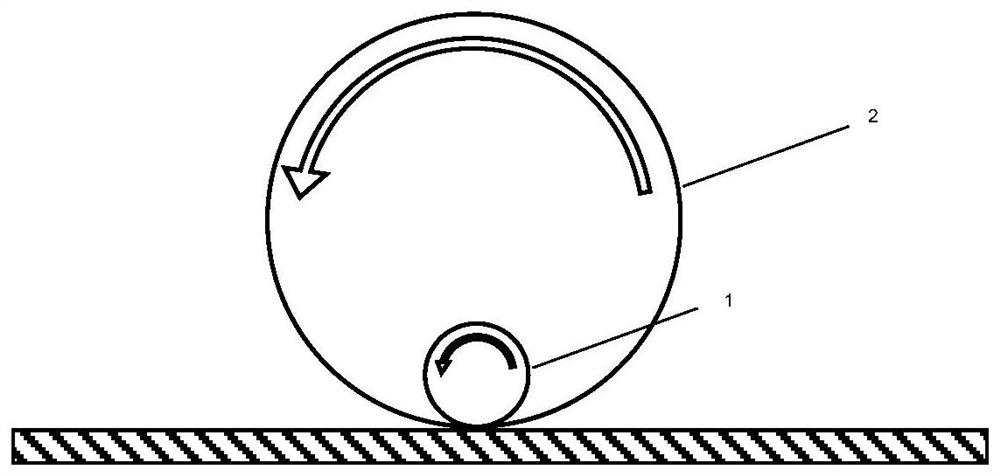

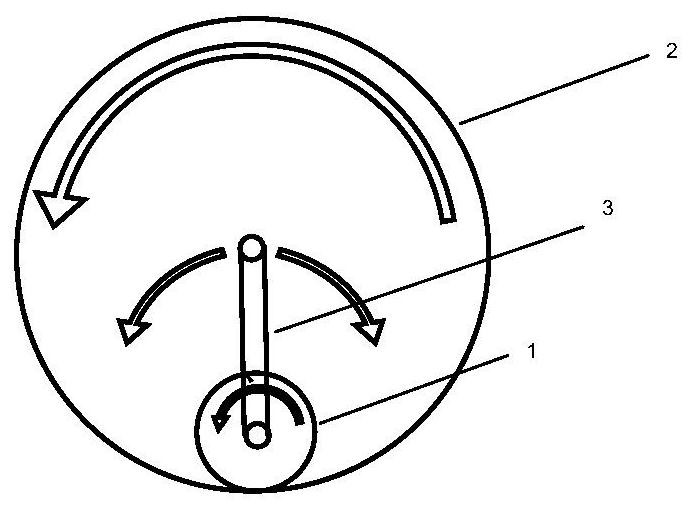

Smooth obstacle crossing walking mechanism

ActiveCN112660262APlay the role of "bridge"Avoid hypermutationVehiclesMultiple wheel assemblyDrive wheelControl theory

The invention belongs to the technical field of walking mechanisms, and provides a smooth obstacle crossing walking mechanism which can maintain small friction loss and high efficiency while providing high smooth obstacle crossing capacity and is suitable for most daily use situations. The smooth obstacle crossing walking mechanism comprises a driving wheel and a contact wheel. The driving wheel is small in diameter, the contact wheel is large in diameter, the driving wheel can autonomously rotate around the axis of the driving wheel under the action of driving force, the driving wheel is compressed with the inner edge of the contact wheel under the action of gravity, the contact wheel makes contact with the ground, and when the driving wheel actively rotates, the driving wheel walks along the inner edge of the contact wheel under the action of friction force between the driving wheel and the contact wheel. The contact wheel rolls forwards under the action of gravity and friction force of the driving wheel, and walking of the smooth obstacle crossing walking mechanism is achieved.

Owner:DALIAN UNIV OF TECH

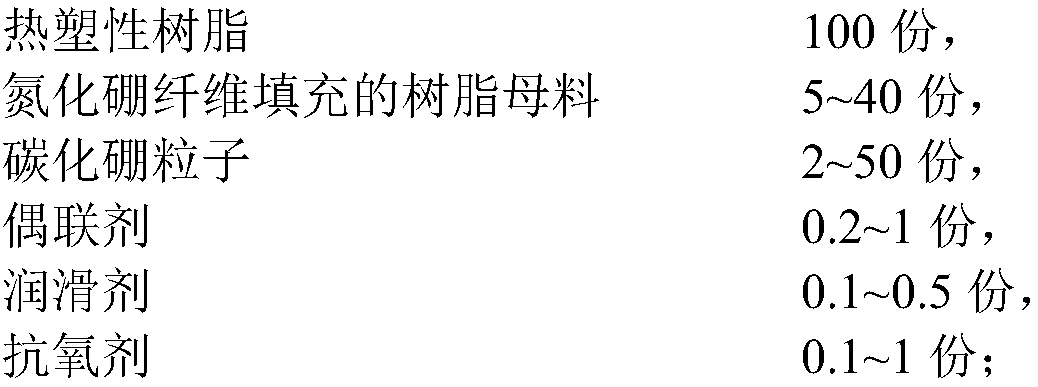

A kind of heat-conducting resin composition and preparation method thereof

The invention belongs to polymer composite materials and relates to a heat-conduction resin composition and a preparation method thereof. The heat-conduction resin composition is prepared from 100 parts by weight of a thermoplastic resin, 5-40 parts by weight of a resin mother material filled with boron nitride fibers, 2-50 parts by weight of boron carbide particles, 0.1-0.5 parts by weight of a lubricant and 0.1-1 part by weight of an anti-oxidant. The heat-conduction resin composition has high thermal conductivity and high mechanical strength. The heat-conduction resin composition can be used for easy preparation of a high-thermal conductivity member and especially for preparation of members in electrical and electronic parts. The boron nitride heat-conduction fibers has bridge effects in the heat-conduction resin composition, can bond heat conduction filler particles individually dispersed in the base resin and can connect isolated heat conduction units to form a large heat-conduction network so that the filler components easily form a communication network and thus thermal conductivity is greatly improved.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

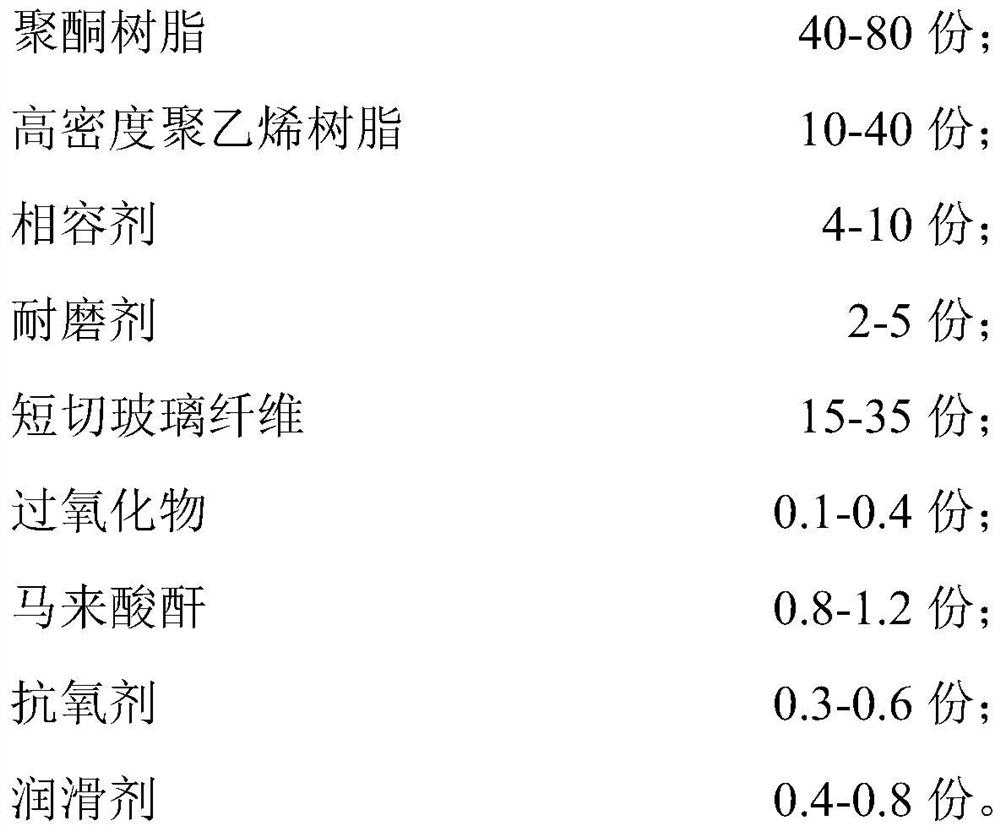

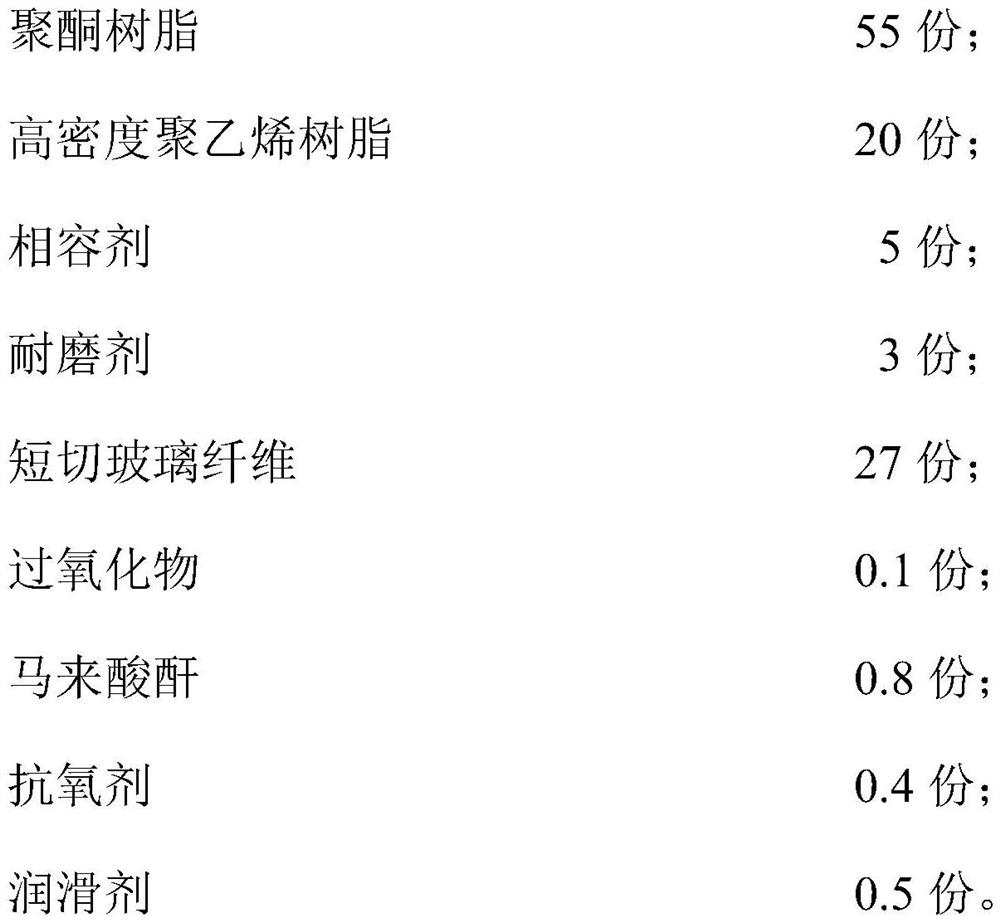

High-impact wear-resistant glass fiber reinforced POK-HDPE composite material and preparation method thereof

ActiveCN112175345ANot easy to rub offImprove impact strengthMaleic anhydrideHigh-density polyethylene

The invention belongs to the technical field of high polymer materials, and discloses a high-impact wear-resistant glass fiber reinforced POK-HDPE composite material and a preparation method thereof.The high-impact-resistance wear-resistant glass fiber reinforced POK-HDPE composite material is prepared from polyketone resin, high-density polyethylene resin, a compatilizer, a wear-resistant agent,chopped glass fibers, peroxide, maleic anhydride, an antioxidant and a lubricant. The POK-HDPE composite material prepared by the invention has the advantages of high normal-temperature / low-temperature impact strength, low water absorption, good wear resistance and the like, and can be widely applied to parts with severe condition requirements such as high-temperature high-humidity wear resistance, normal-temperature / low-temperature impact resistance, wear resistance and the like.

Owner:横店集团得邦工程塑料有限公司

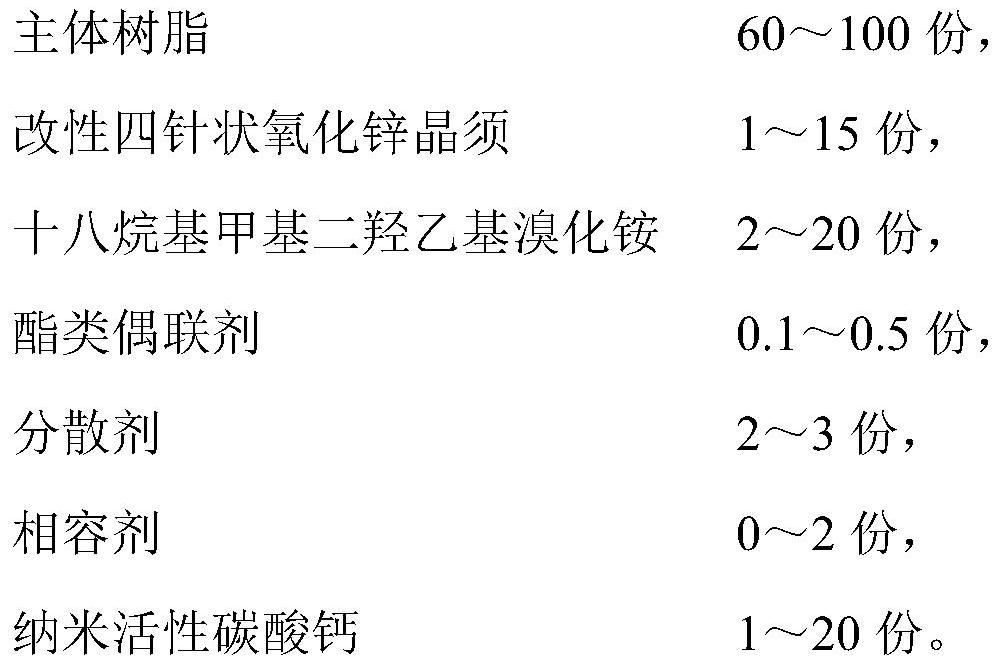

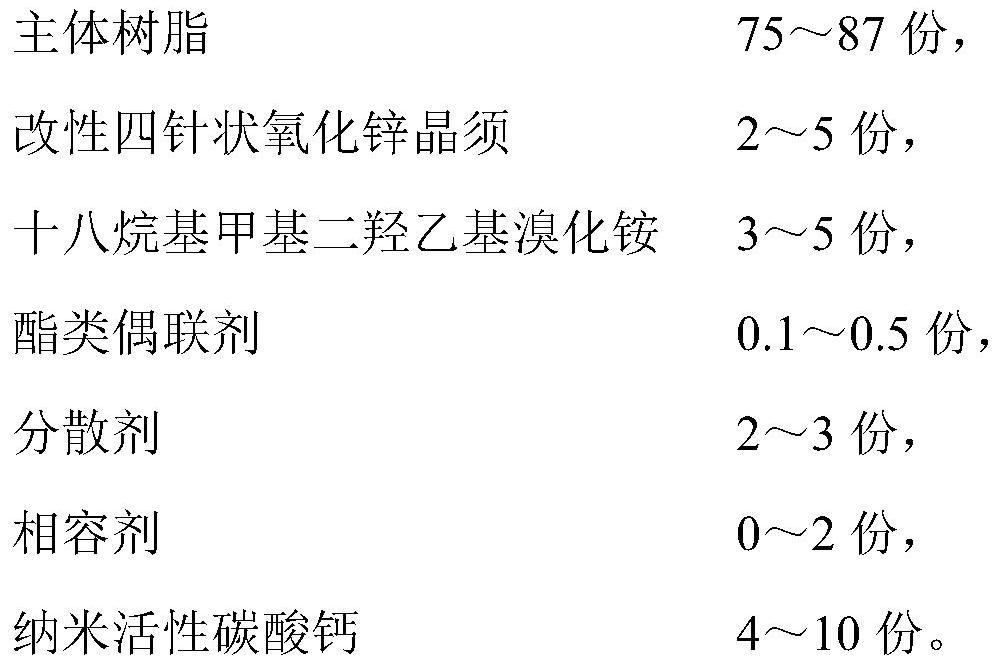

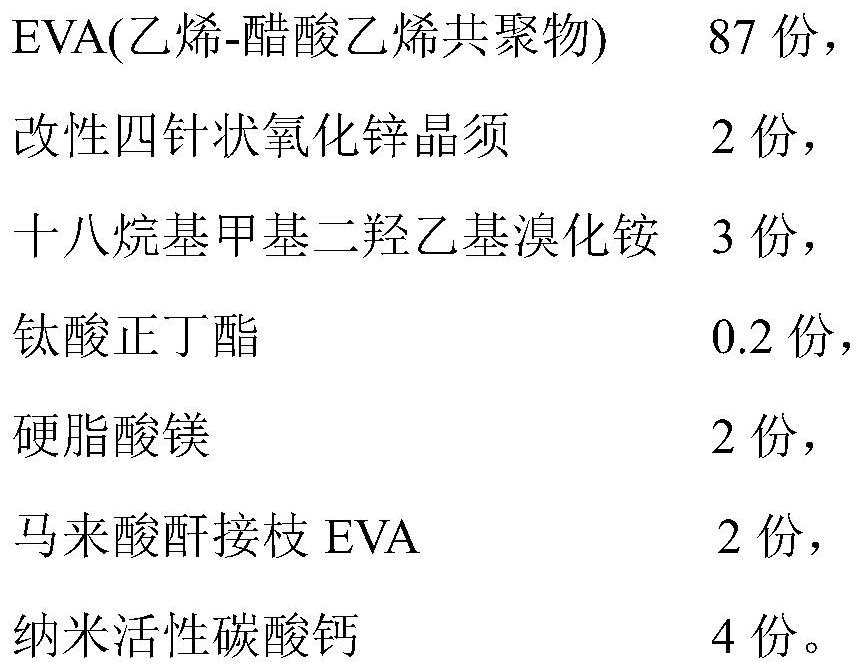

A kind of antibacterial plastic based on microwave synthesis of quaternary ammonium salt and preparation method thereof

ActiveCN110256758BReduce production energy consumptionIncrease productivityOrganic compound preparationAmino compound preparationEngineeringMethyl palmoxirate

Owner:GUANGZHOU UNIVERSITY

Granulation polishing film, preparing method thereof and application thereof

ActiveCN101767318BImprove surface roughnessImprove grinding efficiencyAbrasion apparatusGrinding machinesPolyesterEpoxy

The present invention provides a for the precise finish of an optical fiber connector with lasting abrasive power and high life time, a preparing method thereof and an application thereof, and can strengthen self-shaping. The granulation polishing film comprises base material and an abrasive layer coated at the surface of the base material, wherein the abrasive layer comprises resinoid bond and composite abrasive grains in global coacervate; the composite abrasive grains are global coacervates prepared by granulating abrasive powder distributed in the mixing liquid of metal oxide sol and organic or inorganic binder; the resinoid bond comprises epoxide resin and epoxide resin toughener, and also comprises one or several kinds of polyester, polyurethane, daiamid, acrylate and polyurea. The granulation polishing film is used for the grinding finish of the optical fiber connector and optical fiber arrays. The life time is one to two times longer than that of the traditional polishing filmfor the finish of the optical fiber connector, and the processing cost of the optical fiber connector is reduced.

Owner:BEIJING GRISH HITECH

A kind of composite polylactic acid biological material and preparation method thereof

The present invention relates to the technical field of orthopedic materials, in particular to a composite polylactic acid biological material and a preparation method thereof. The composite polylactic acid biological material comprises the following raw materials in parts by weight: 10-15 parts of chitosan complex, 5-parts of silk fibroin 8 parts, 10-16 parts of hydroxyapatite, 0.2-5 parts of compatibilizer, 50-65 parts of lactide and 0.5-0.8 parts of silane coupling agent. Among them, the chitosan complex is prepared by electrospraying chitosan and hyaluronic acid / carbon nanotubes, and the hyaluronic acid / carbon nanotubes are mainly composed of aminated hyaluronic acid and carboxylated multi-walled carbon nanotubes. Tube reaction, obtained by dialysis. The composite polylactic acid biomaterial prepared by the invention not only has good biocompatibility, but also meets the requirements of bone mechanical properties, and its service life can fully meet the needs of patients, which solves the problem that the service life of existing orthopedic materials cannot fully meet the needs of patients.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

A papermaking retention aid and its preparation method and application

ActiveCN113248651BAct as a "patch"Play the role of "bridge"Paper/cardboardRetention agents additionFiberActive agent

The invention relates to a papermaking retention aid and its preparation method and application, belonging to the technical field of preparation of modified polyacrylamide. The method is as follows: uniformly mix acrylamide, cationic monomer, structure regulator, hydrophobic monomer, N-vinyl formamide and cationic surfactant with water to obtain a mixed solution; nitrogen and deoxygenate the mixed solution, and then add The polymerization aid initiates the polymerization reaction to obtain a colloidal substance, and then the colloidal substance is granulated, dried and crushed in sequence to obtain a copolymerized powder; the copolymerized powder is prepared into an aqueous solution of the copolymerized powder with water, and then liquid bromine and The sodium hydroxide aqueous solution is modified to obtain a modified treatment solution; the pH of the modified treatment solution is adjusted to 8-9, and then filtered through a filter membrane to obtain a paper-making retention aid. The papermaking retention aid prepared by the invention improves the retention rate of fine fibers, and when used in a papermaking process, can improve papermaking production efficiency, avoid blocking of water filtration channels, and effectively reduce white water turbidity.

Owner:SHANDONG NUOER BIOLOGICAL TECH

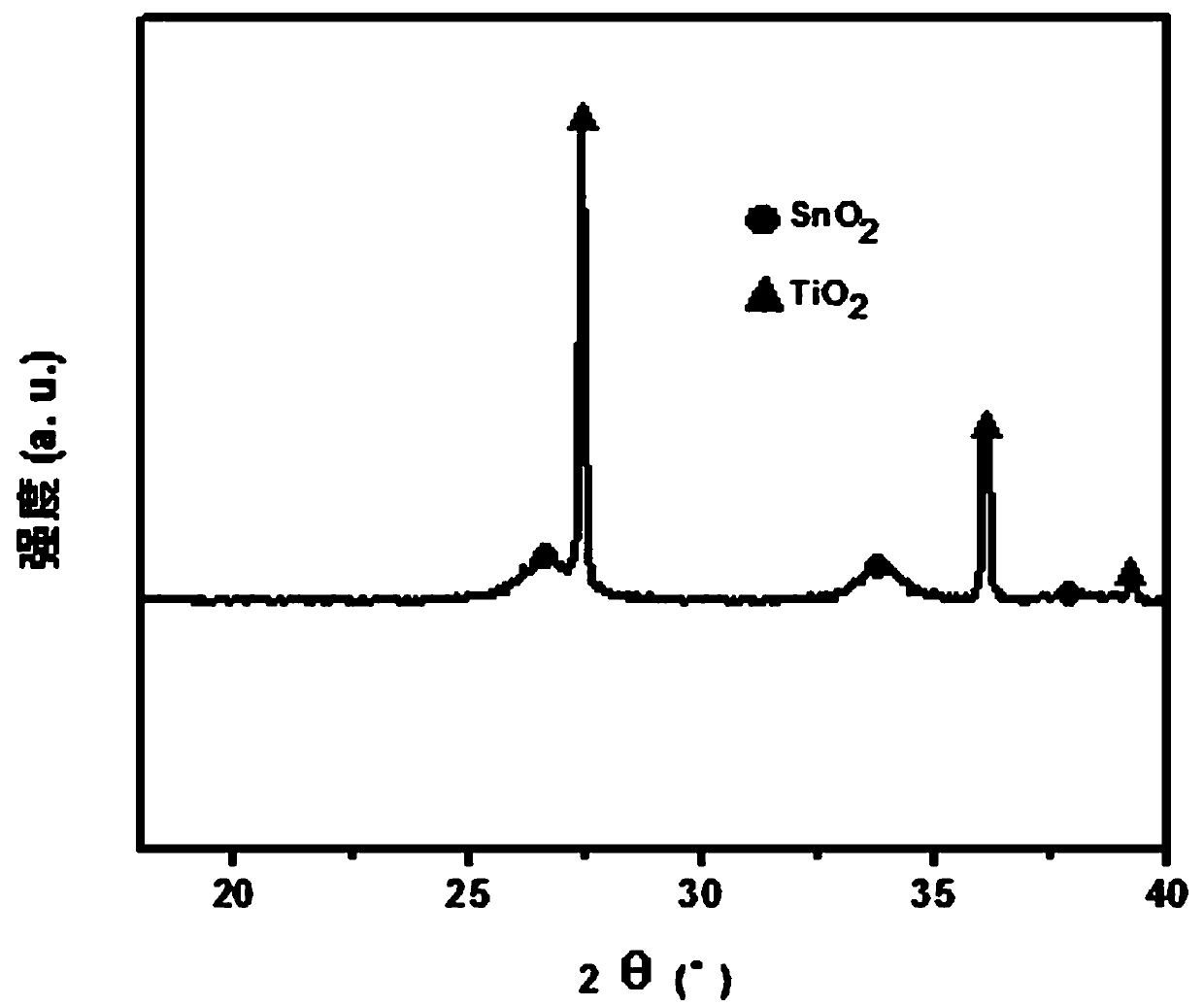

A kind of preparation method of inorganic light-color conductive titanium dioxide powder

ActiveCN107903664BPlay the role of "bridge"Promote dissolutionPigment treatment with non-polymer organic compoundsSlurryTitanium oxide

The invention provides a preparation method of inorganic light-colored conductive titanium dioxide powder. The preparation method includes the steps of firstly, dispersing gel ATO into water to obtaingel ATO aqueous dispersion, and adding a peptizing agent into the gel ATO aqueous dispersion until pH is 8-12 to obtain clear and transparent ATO hydrosol; secondly, adding titanium dioxide slurry into the ATO hydrosol prepared in the first step to form a mixed solution a, wherein the titanium dioxide slurry is prepared by dispersing titanium dioxide into water; thirdly, dropwise adding acid intothe mixed solution a obtained in the second step to regulate pH to 2-6 to form a mixed solution b; fourthly, drying the mixed solution b, crushing, and performing high-temperature sintering to obtainthe inorganic light-colored conductive titanium dioxide powder. The preparation method has the advantages that the method is simple to operate, and the prepared inorganic conductive titanium dioxidepowder is low in resistivity and light in color.

Owner:HENAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com