Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

384results about "Multiple wheel assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

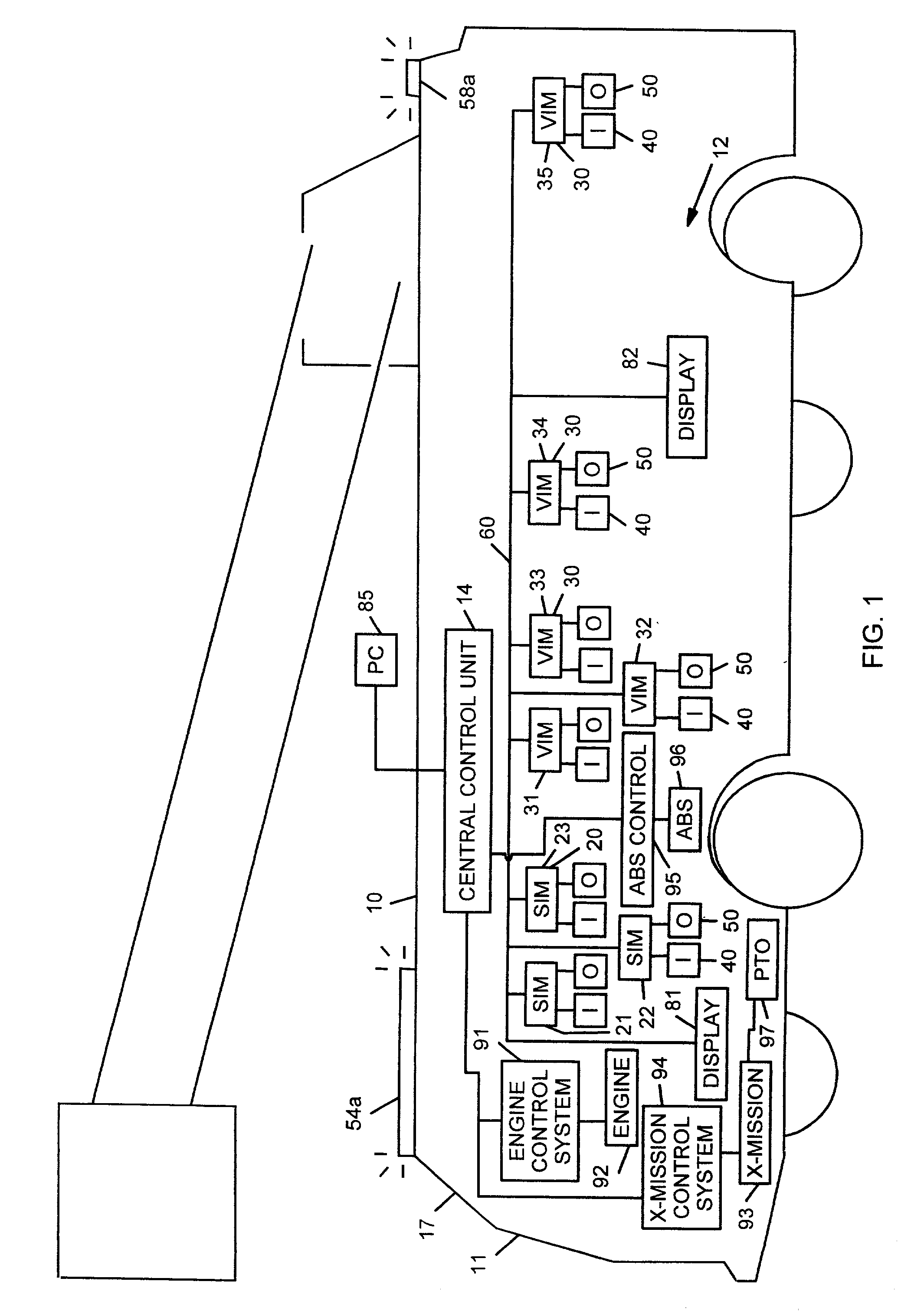

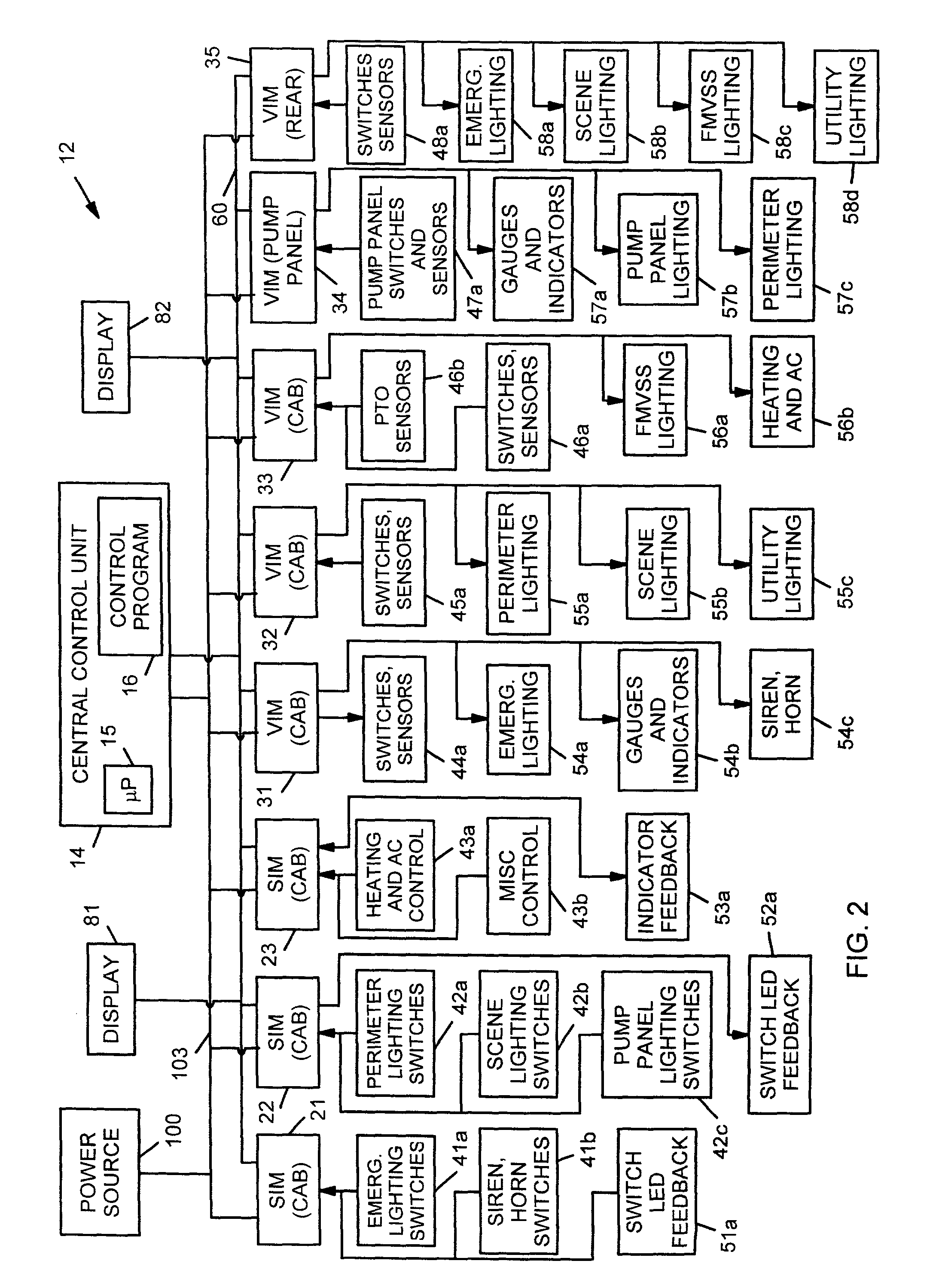

Control system and method for an equipment service vehicle

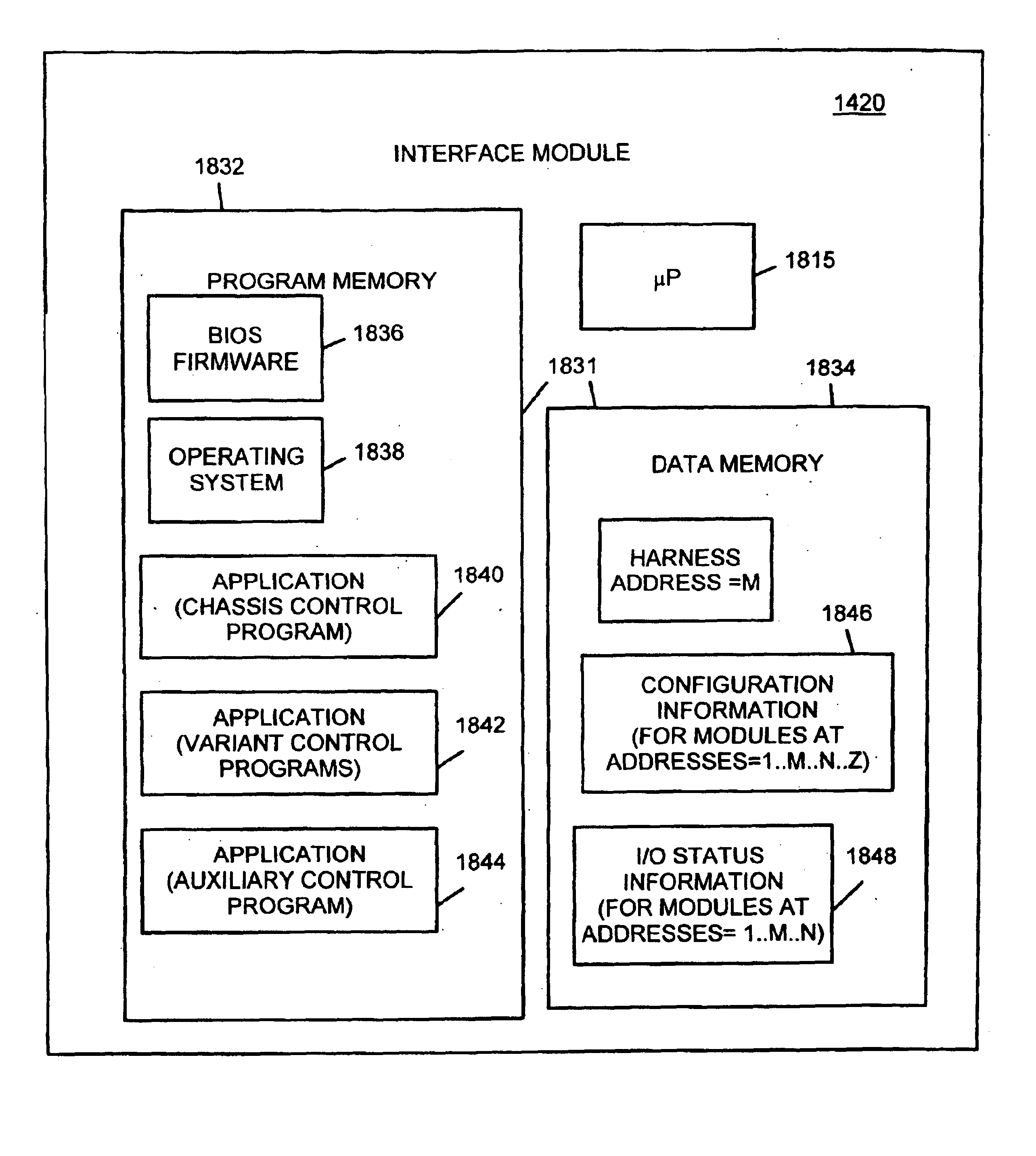

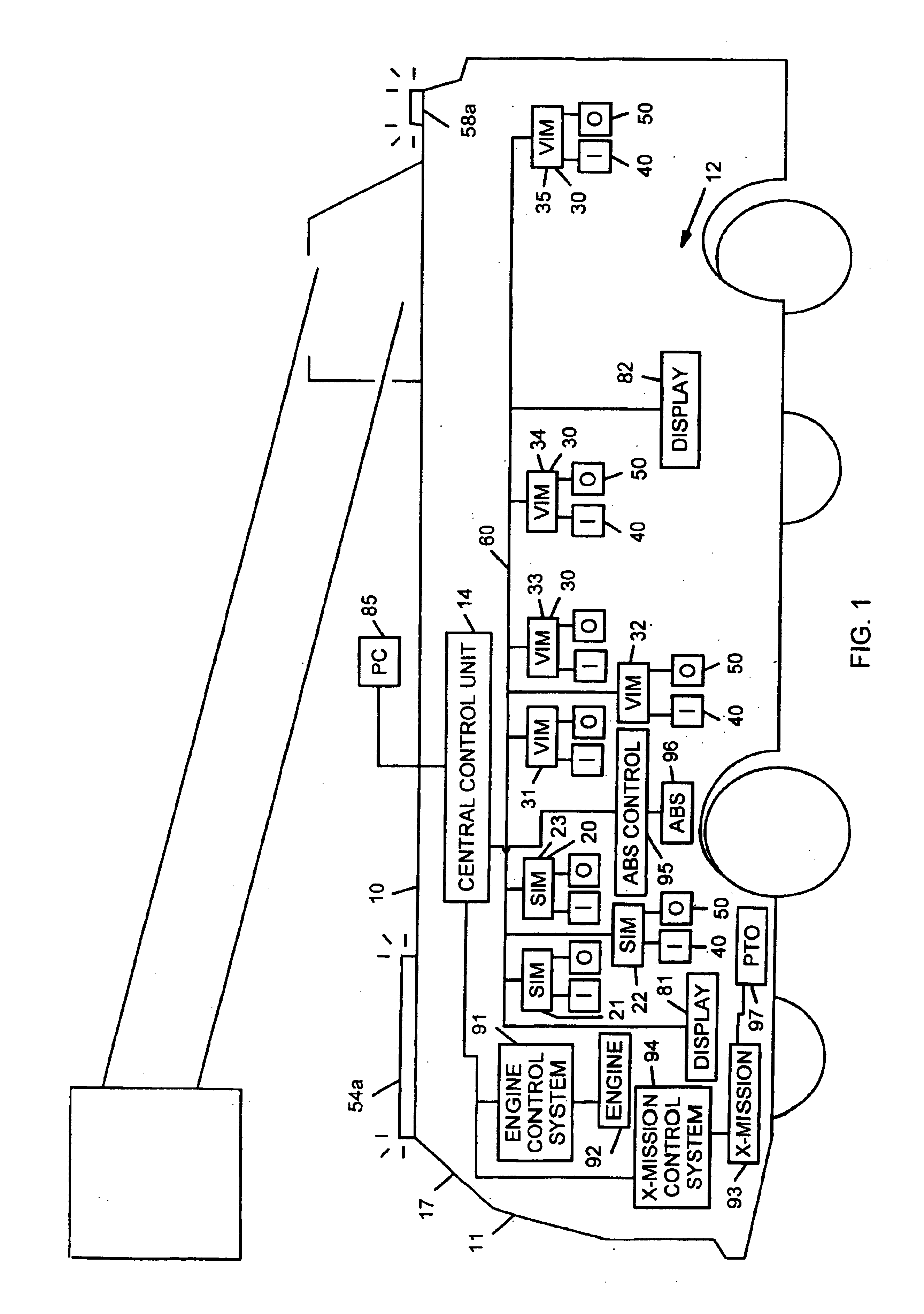

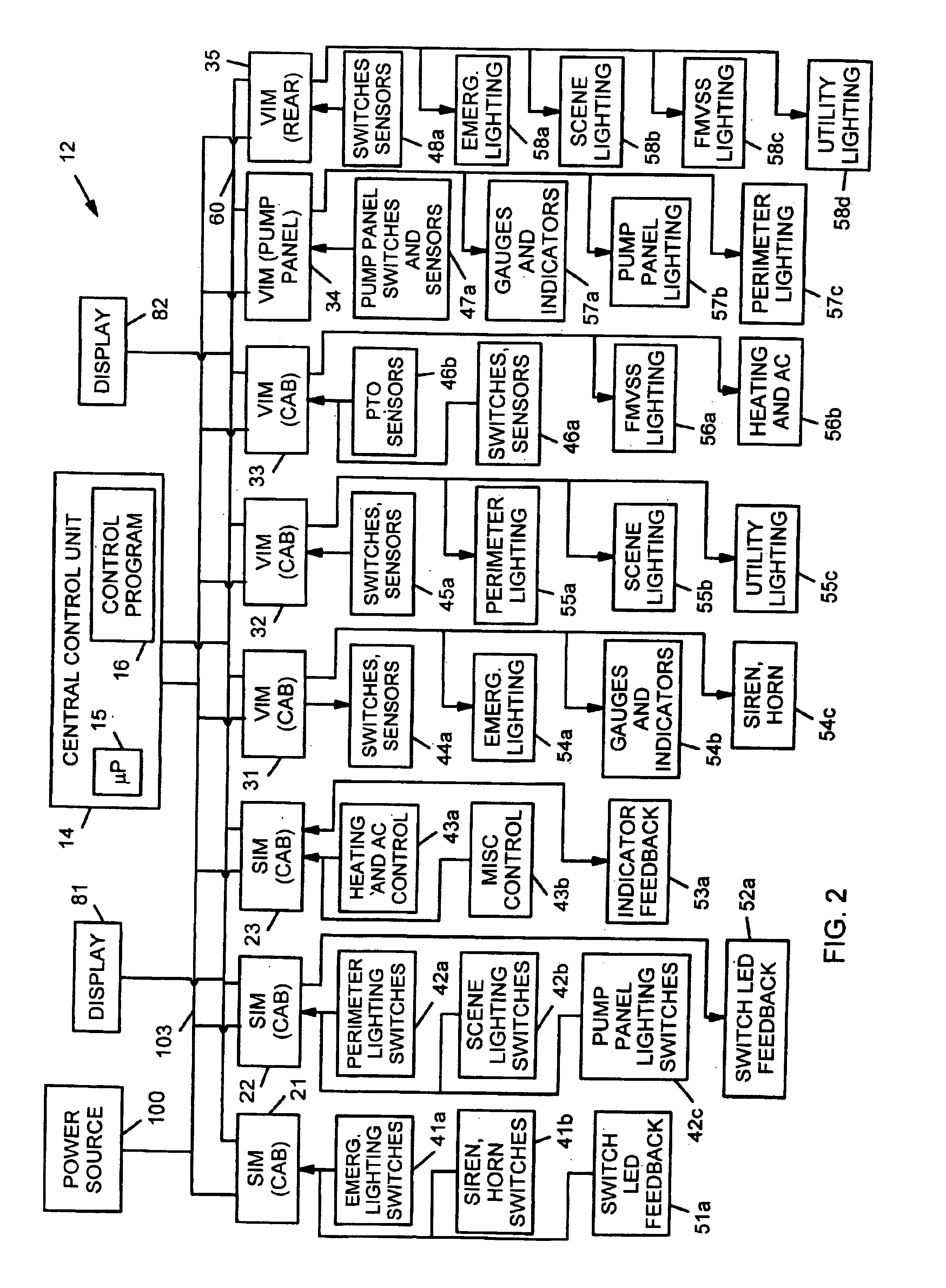

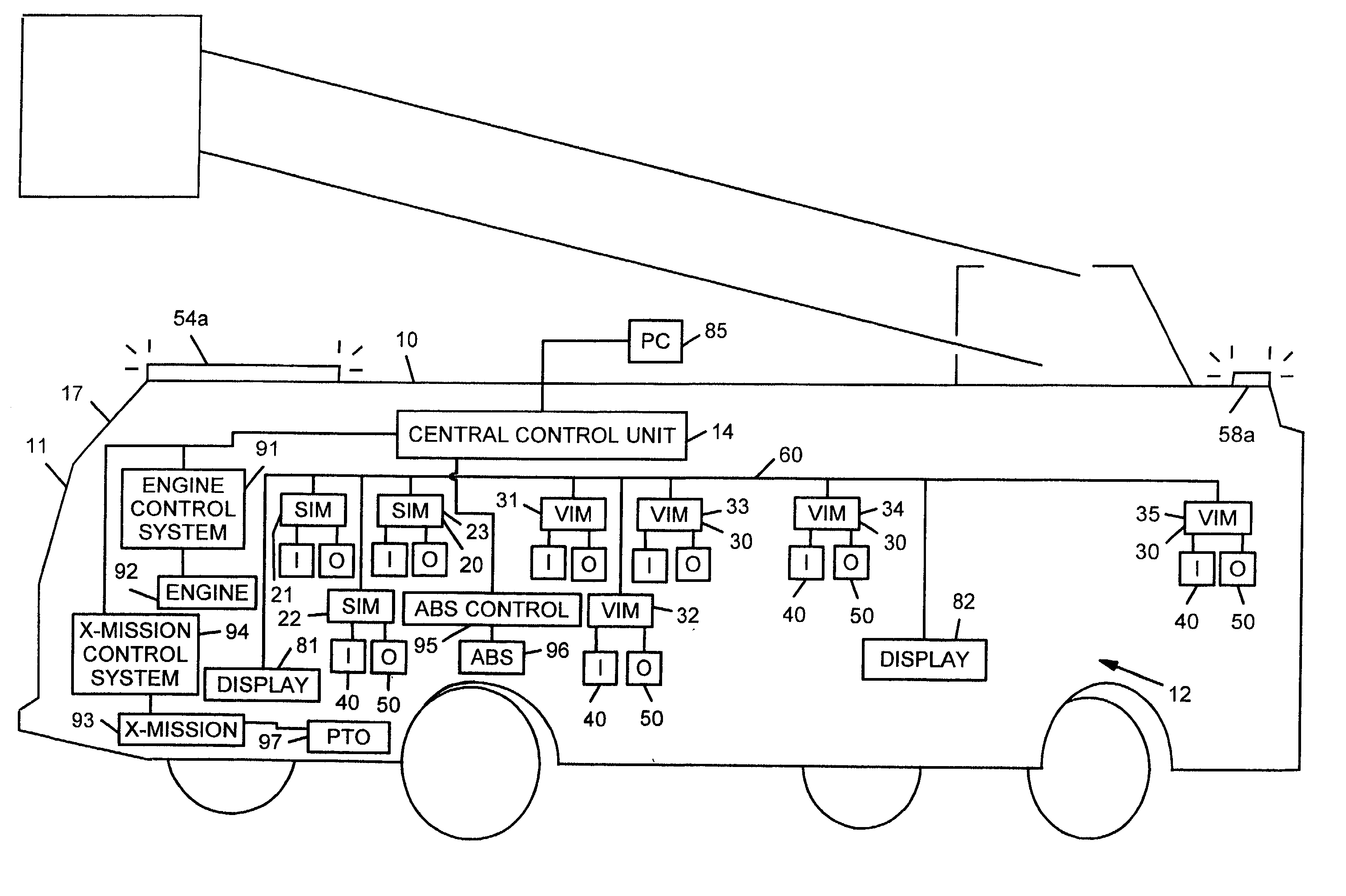

A control system for a vehicle comprises a power source, a power transmission link, a plurality of input and output devices, a plurality of microprocessor-based interface modules, and a communication network that interconnects the interface modules. The interface modules are also each coupled to respective local subsets of the input and output devices. Each of the interface modules collects input status information from the respective local subset of the input devices and transmits the input status information over the communication network to the remaining interface modules.

Owner:OSHKOSH CORPORATION

Military vehicle having cooperative control network with distributed I/O interfacing

A power distribution and control system for a military vehicle comprises a power source, a power transmission link, a plurality of input and output devices, a plurality of microprocessor-based interface modules, and a communication network that interconnects the interface modules. The interface modules are also each coupled to respective local subsets of the input and output devices so as to permit distributed data collection from the input devices and distributed power distribution to the output devices. Each of the interface modules collects input status information from the respective local subset of the input devices and broadcasts the input status information over the communication network to each of the remaining ones of the interface modules. Each of the remaining ones of the interface modules receive the input status information and locally store the input status information.

Owner:OSHKOSH CORPORATION

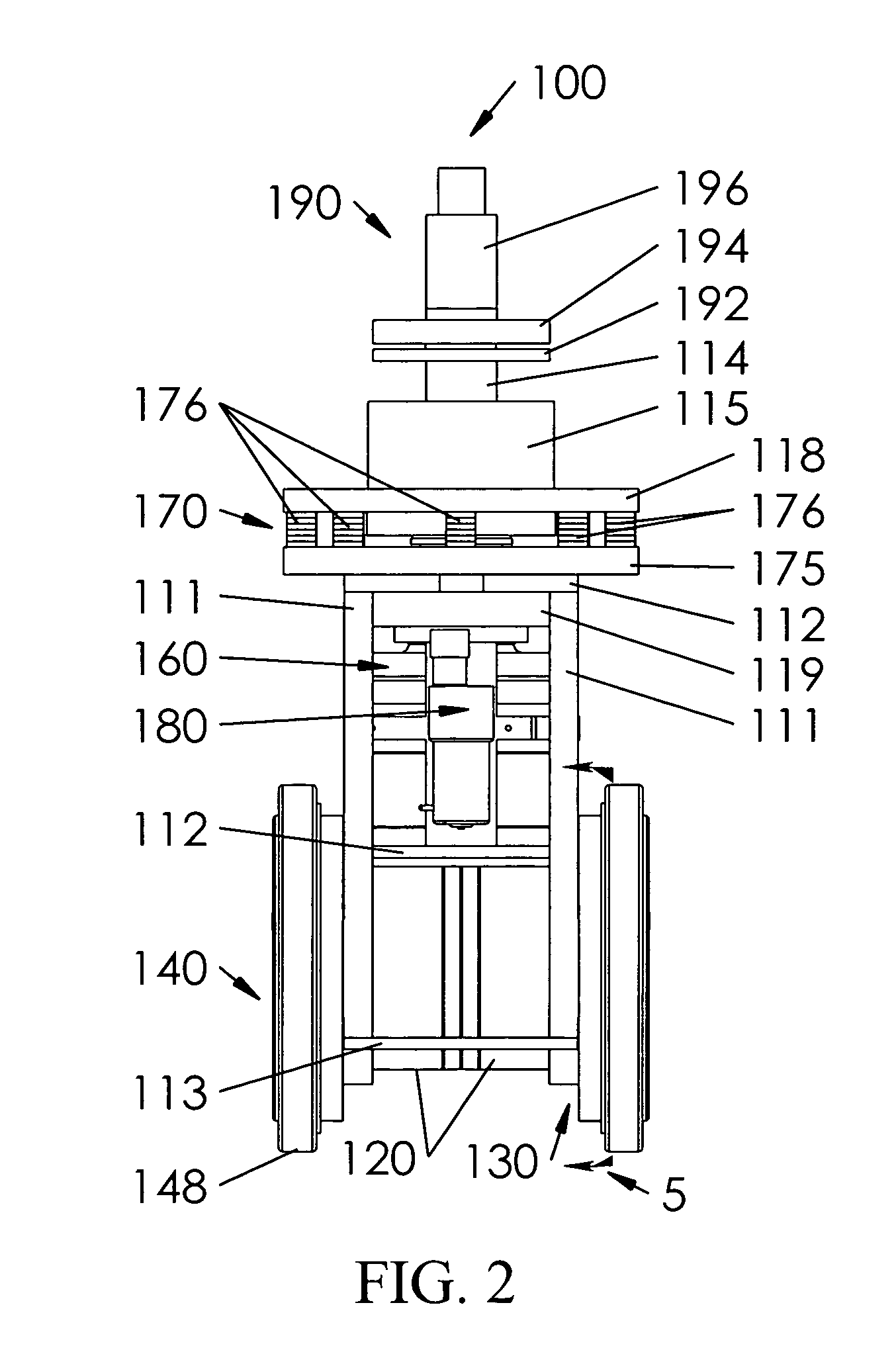

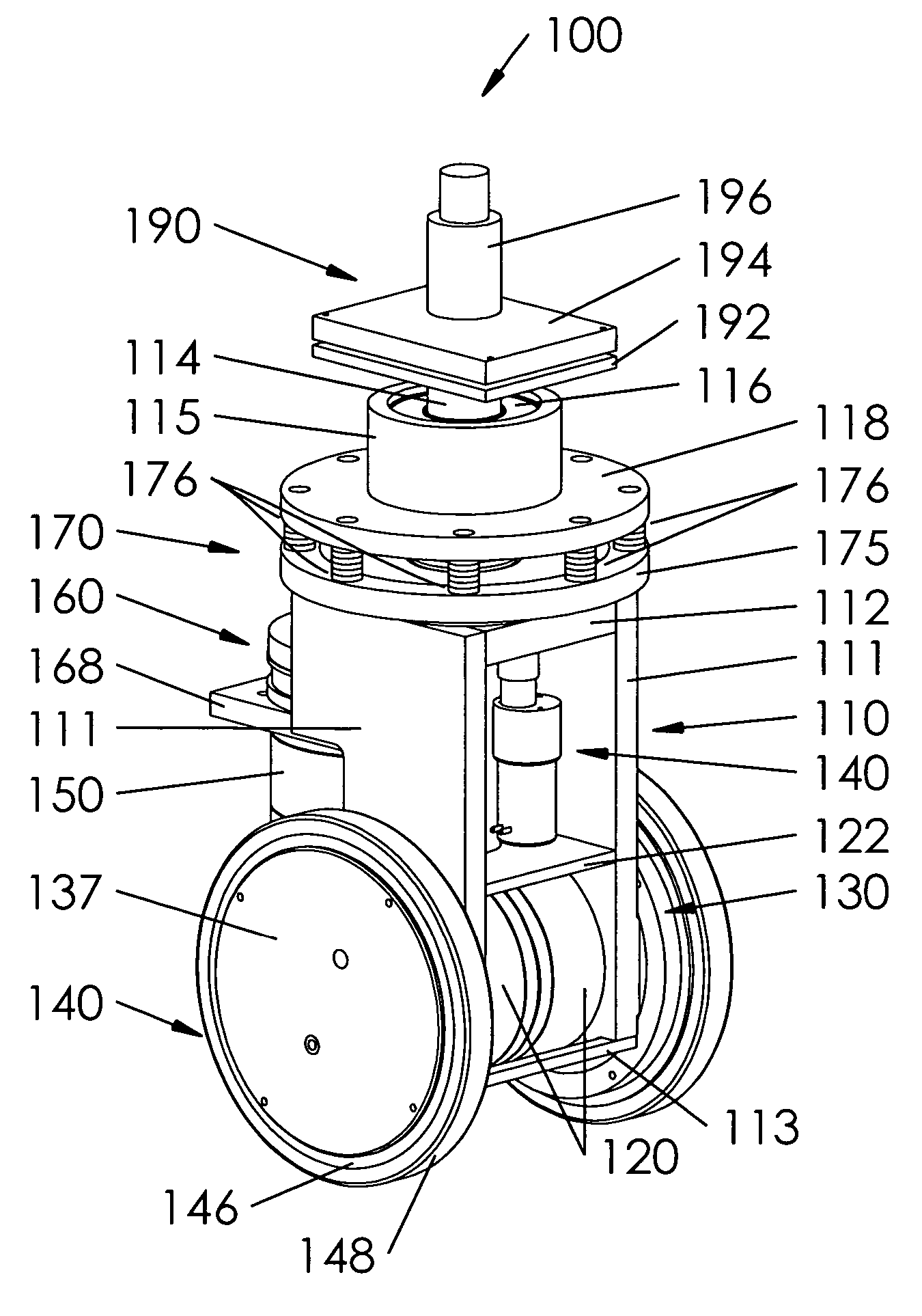

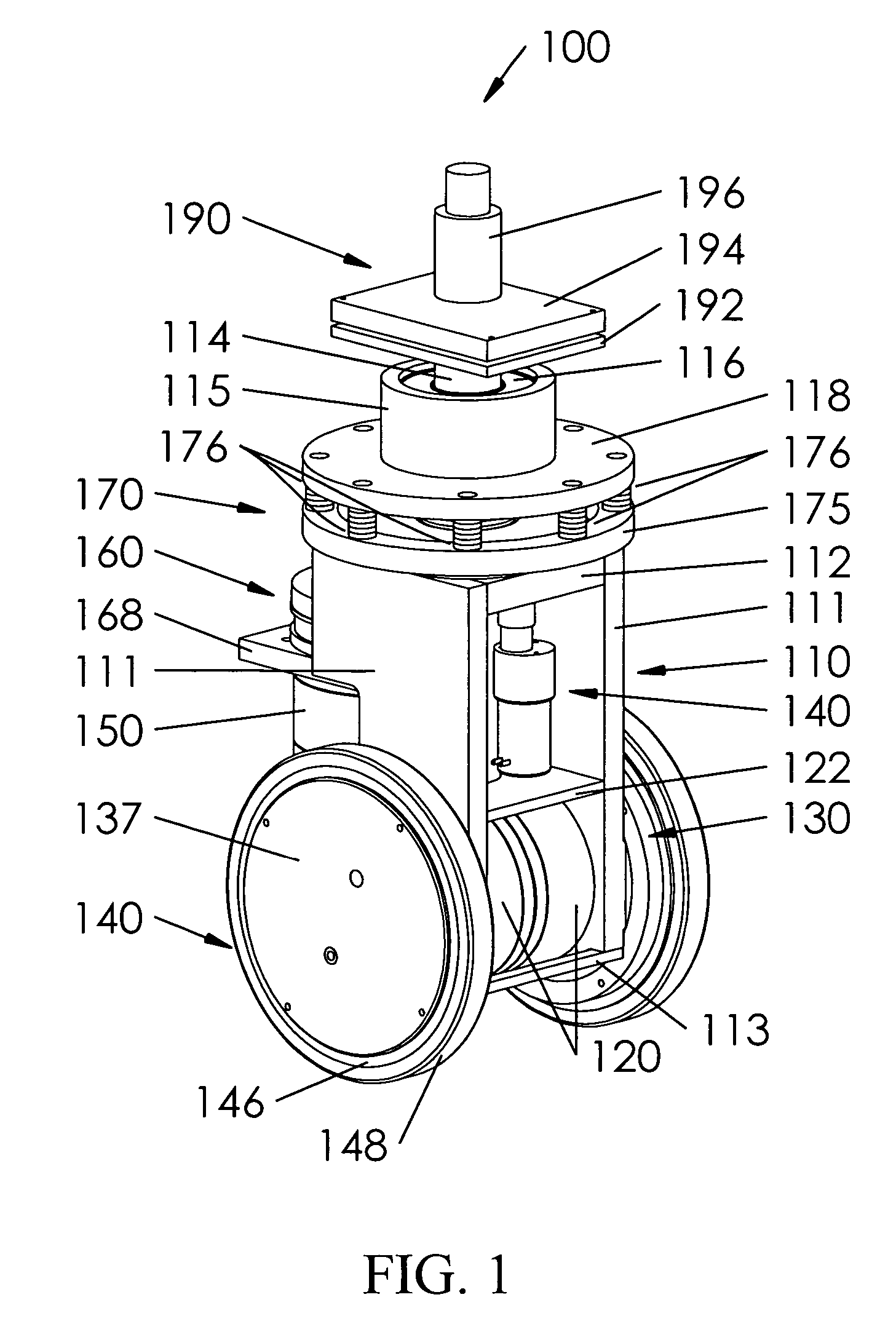

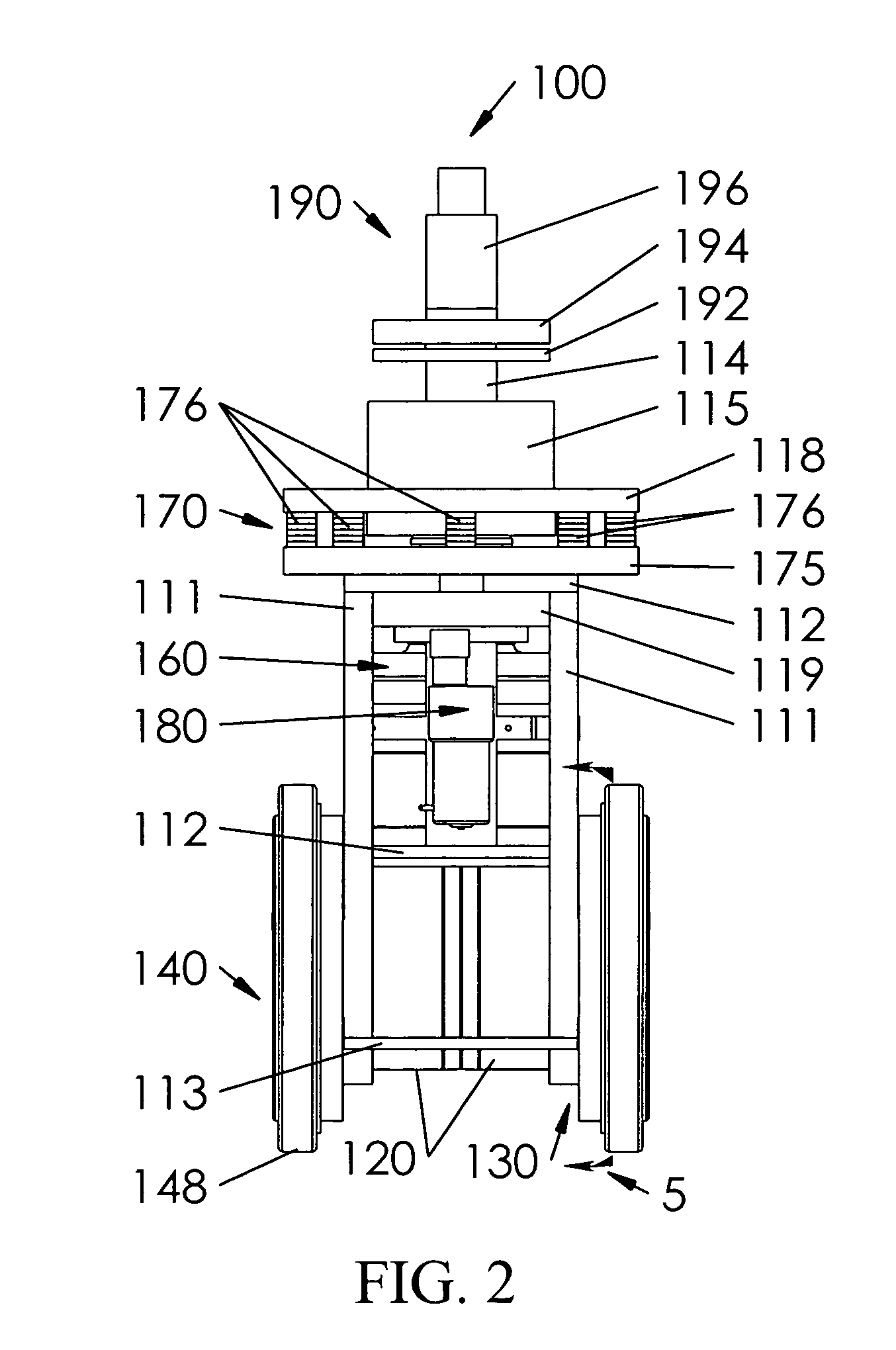

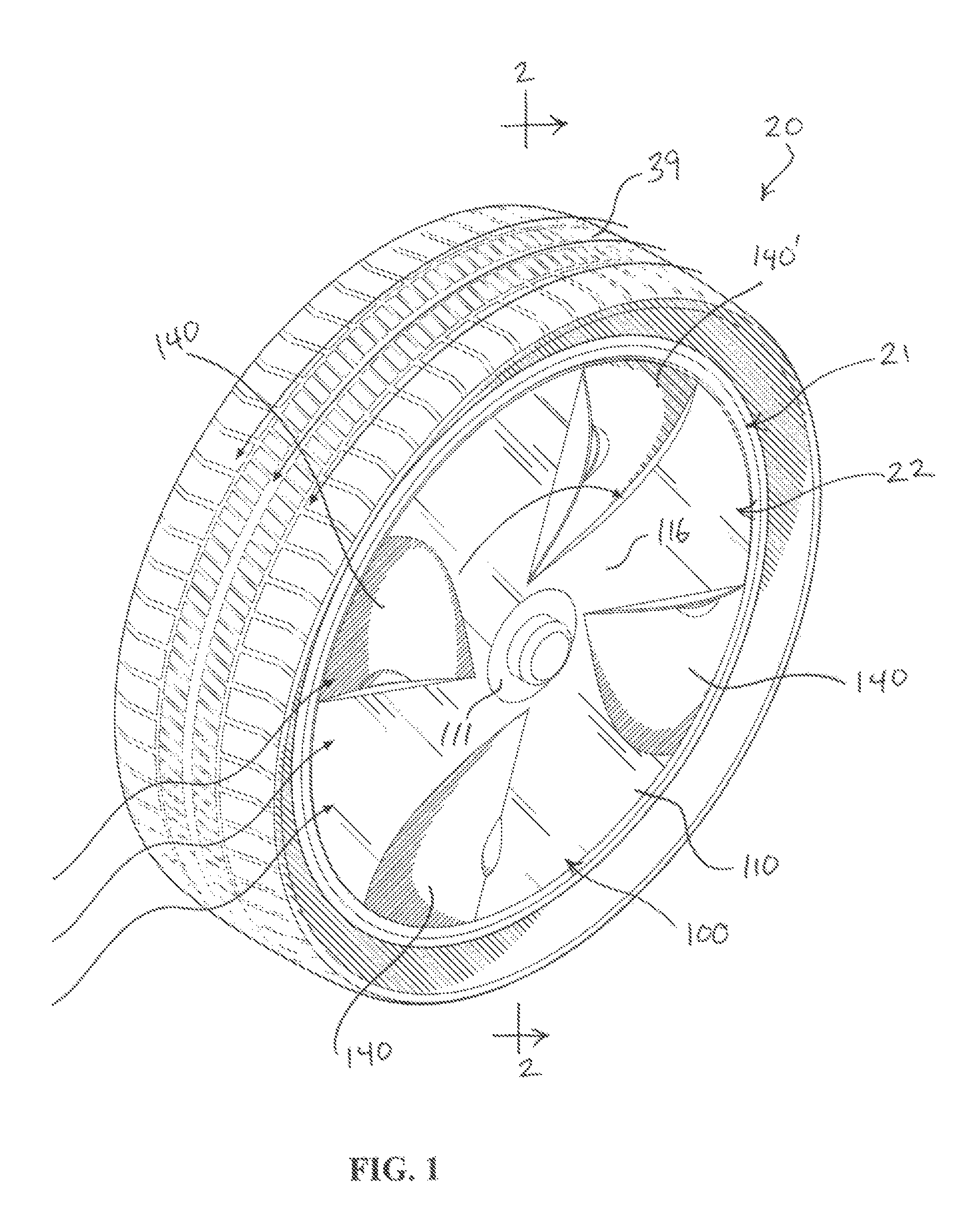

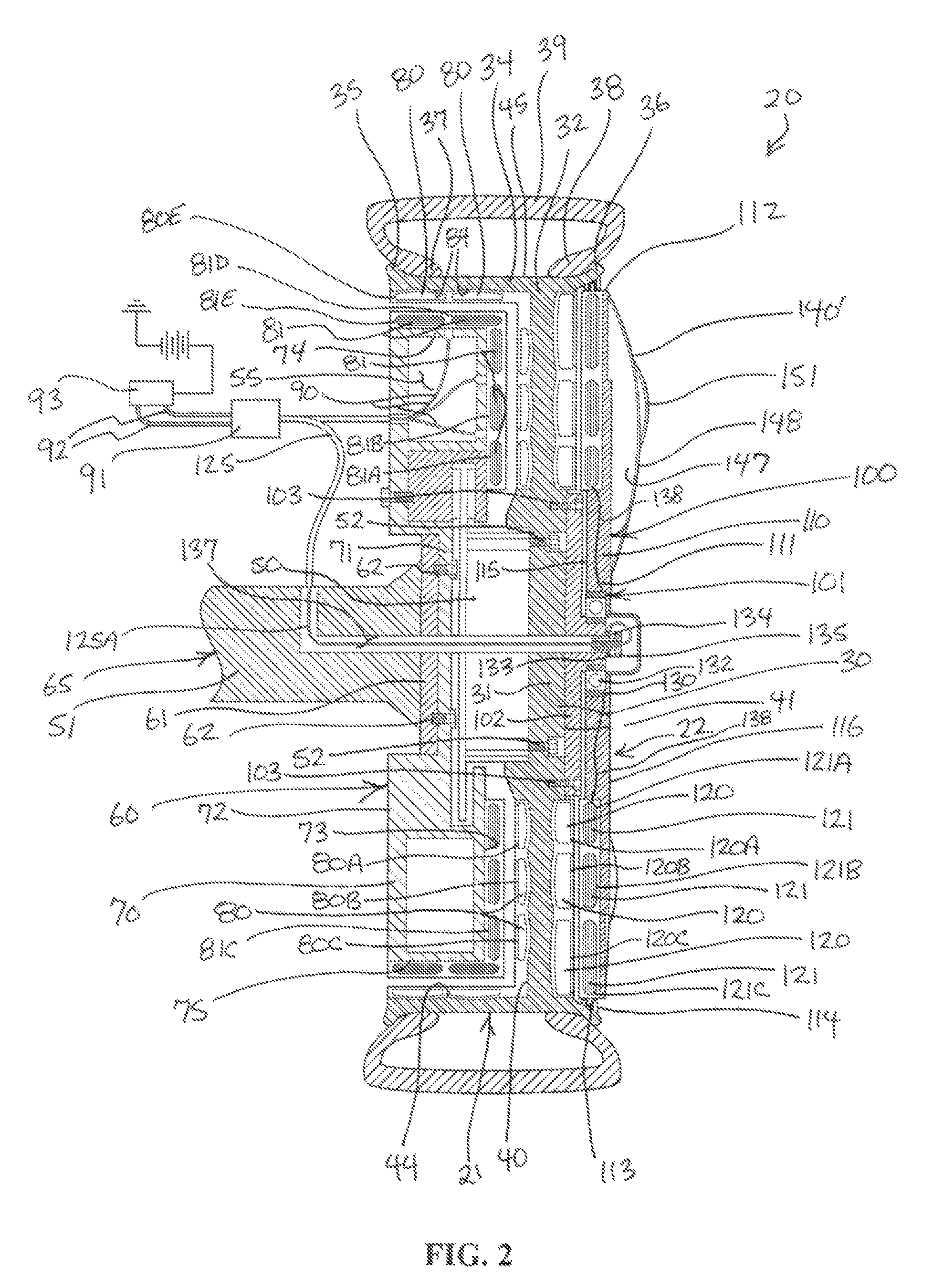

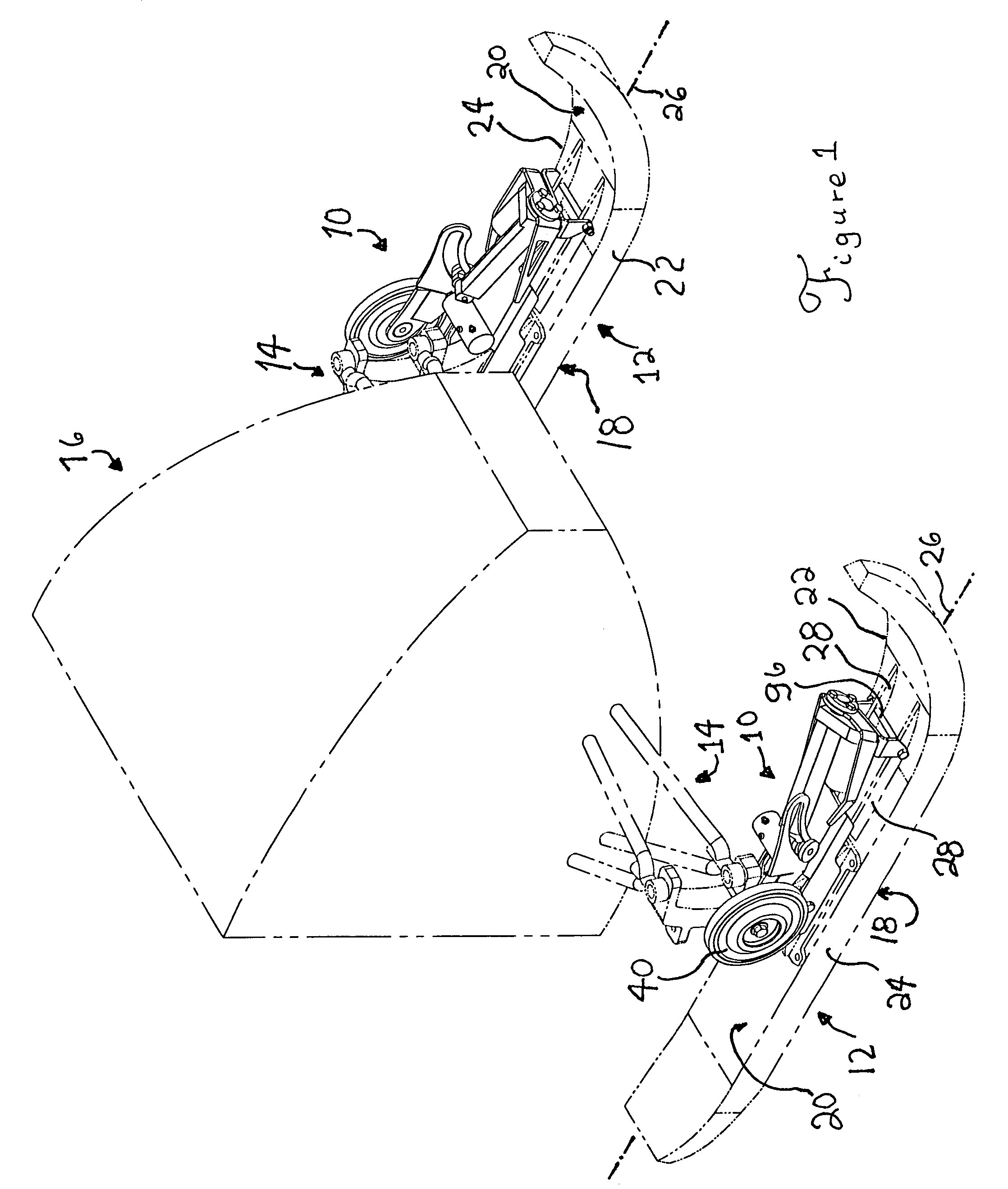

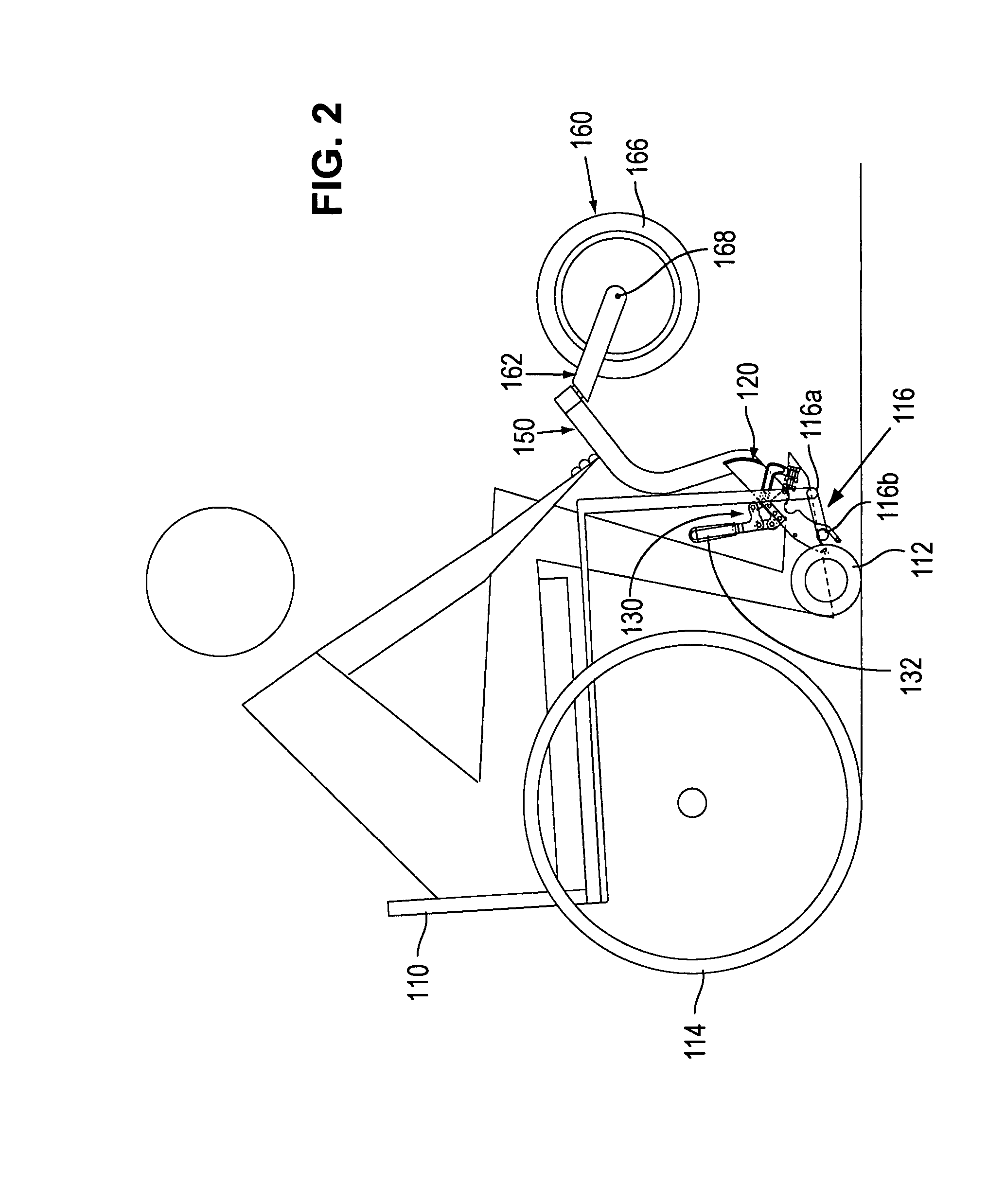

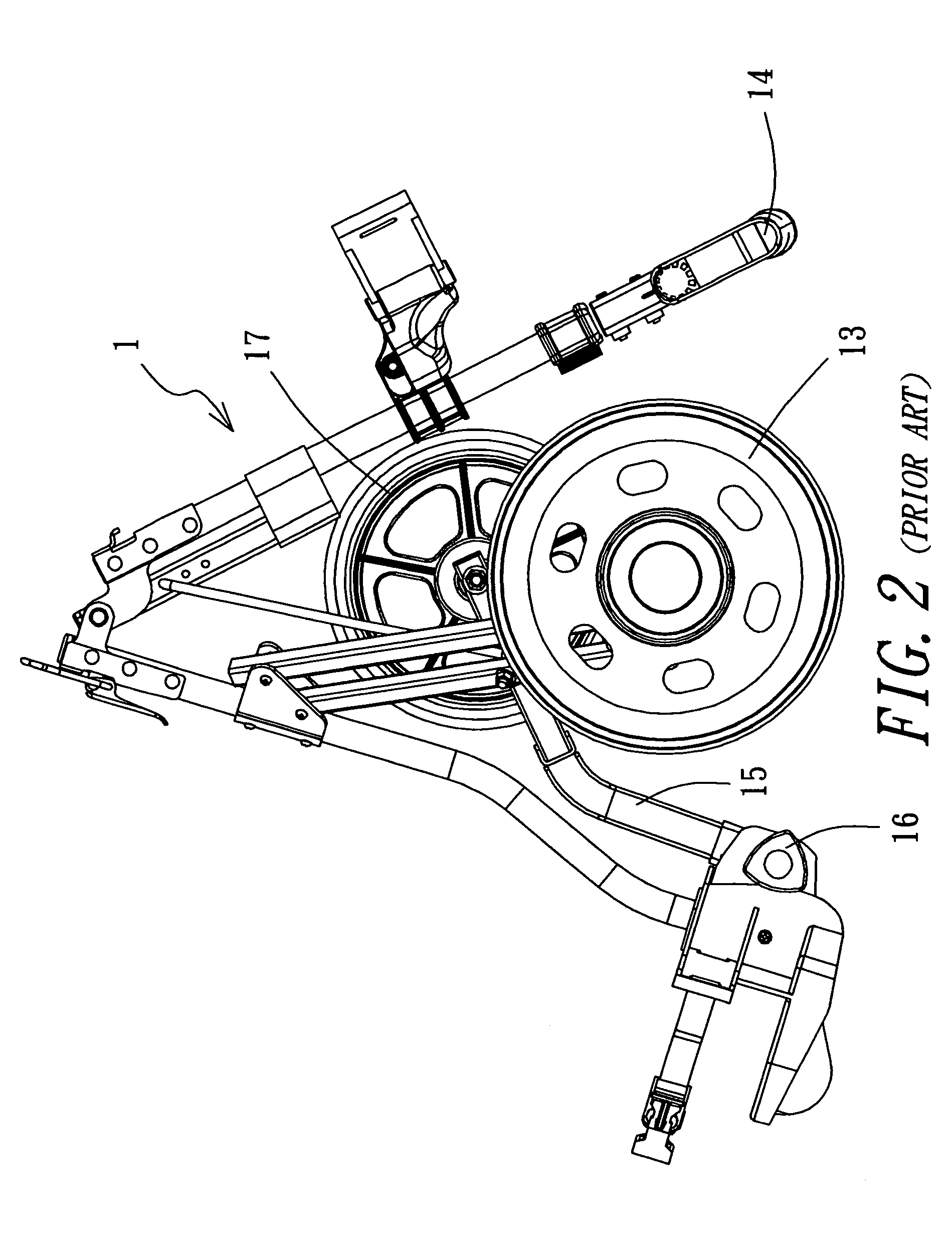

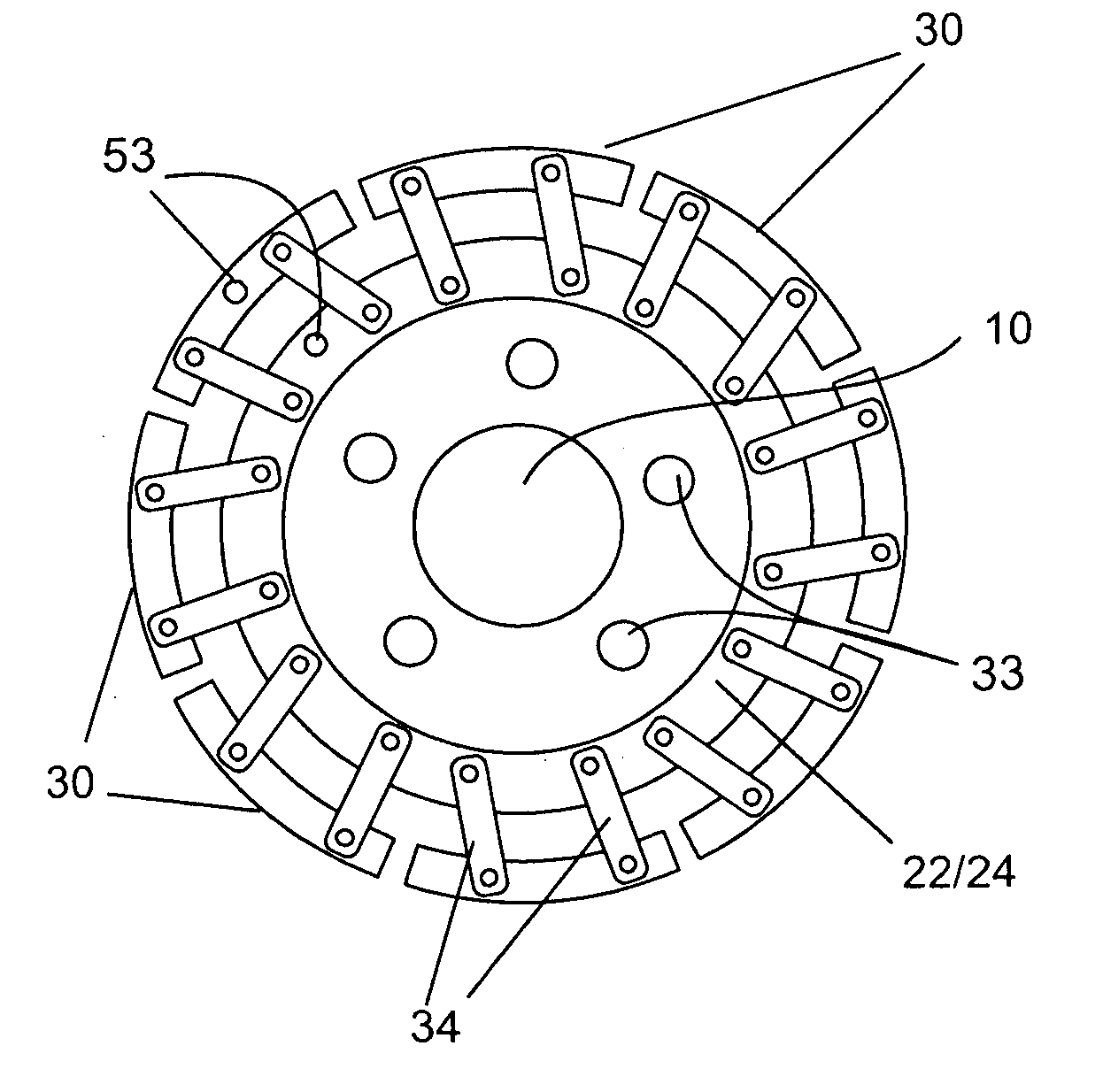

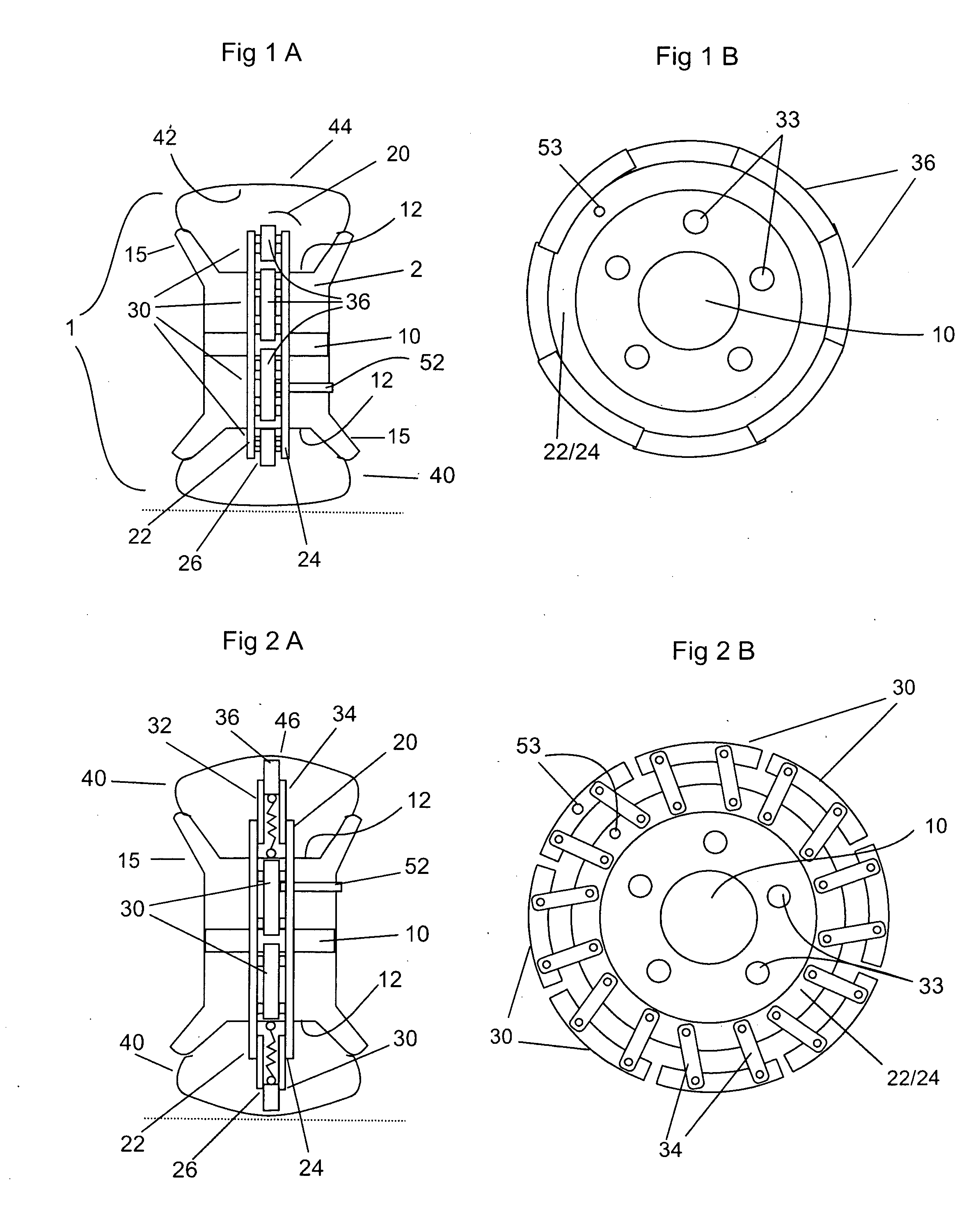

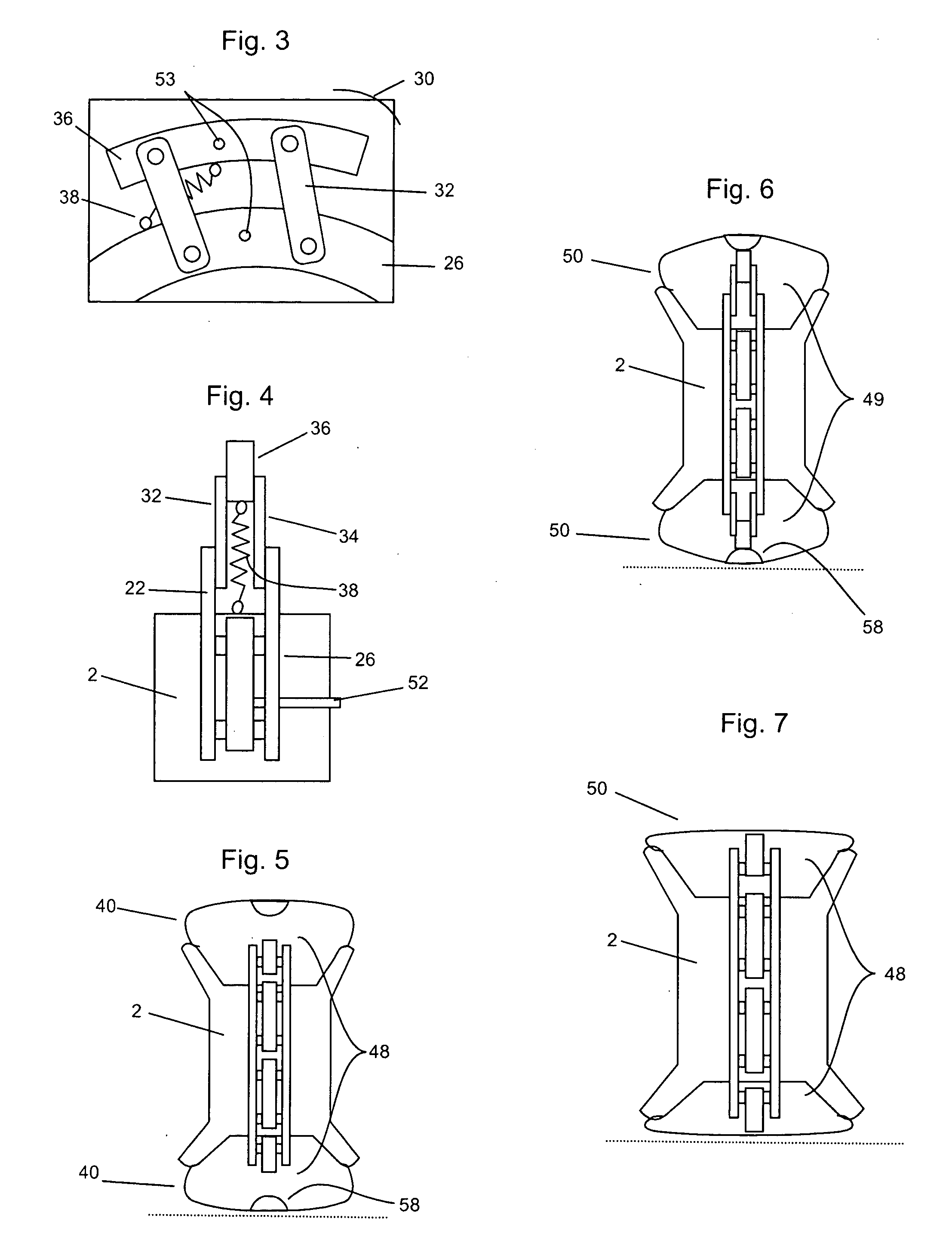

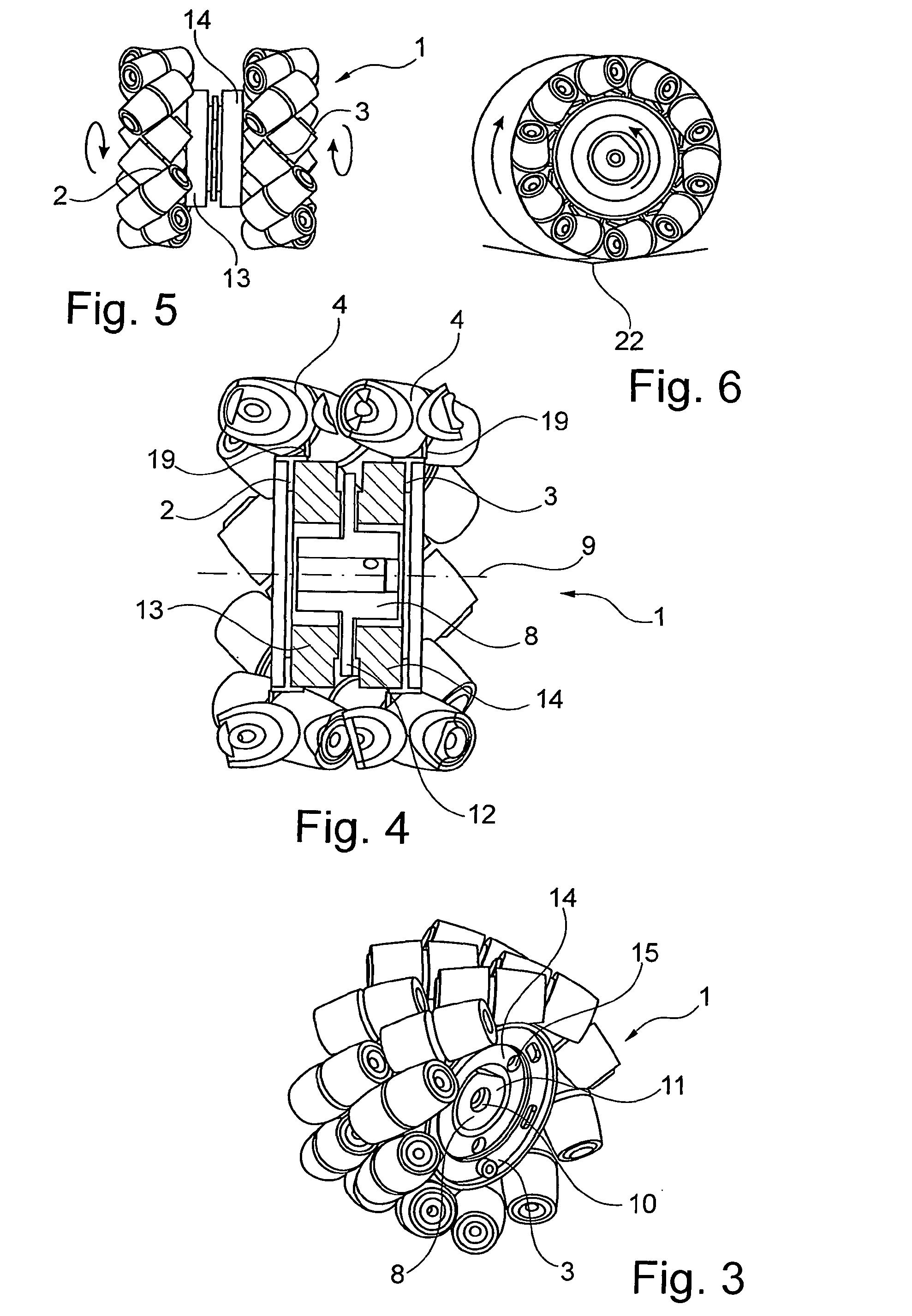

Modular dual wheel drive assembly, wheeled devices that include modular dual wheel drive assemblies and methods for moving and/or maneuvering wheeled devices using modular dual wheel drive assemblies

ActiveUS20070080000A1Improved load weight distributionHubsSteering linkagesRotational axisDrive wheel

A wheel assembly for a small-scale machine includes a pair of opposing, individually-driven wheels, associated motors and possibly one or more gear assemblies. The motors receive separate drive signals from a control electronics subsystem of the wheel assembly. The motors can be connected to the wheels via the gear assemblies. Because the wheels are separately driven, driving the two wheel assemblies at similar or different speeds drives the wheel assembly over straight or curved paths. An orientation assembly allows the orientation of the wheels to the machine to be controllably altered. A height adjusting assembly allows the distance between the wheels and a point on the machine where the wheel assembly is attached to be adjusted. The rotational axis that the wheel assembly rotates about when re-oriented need not pass through either wheel of the wheel assembly. The wheels can be driven by control signals generated by on-board control electronics.

Owner:CYCOGS

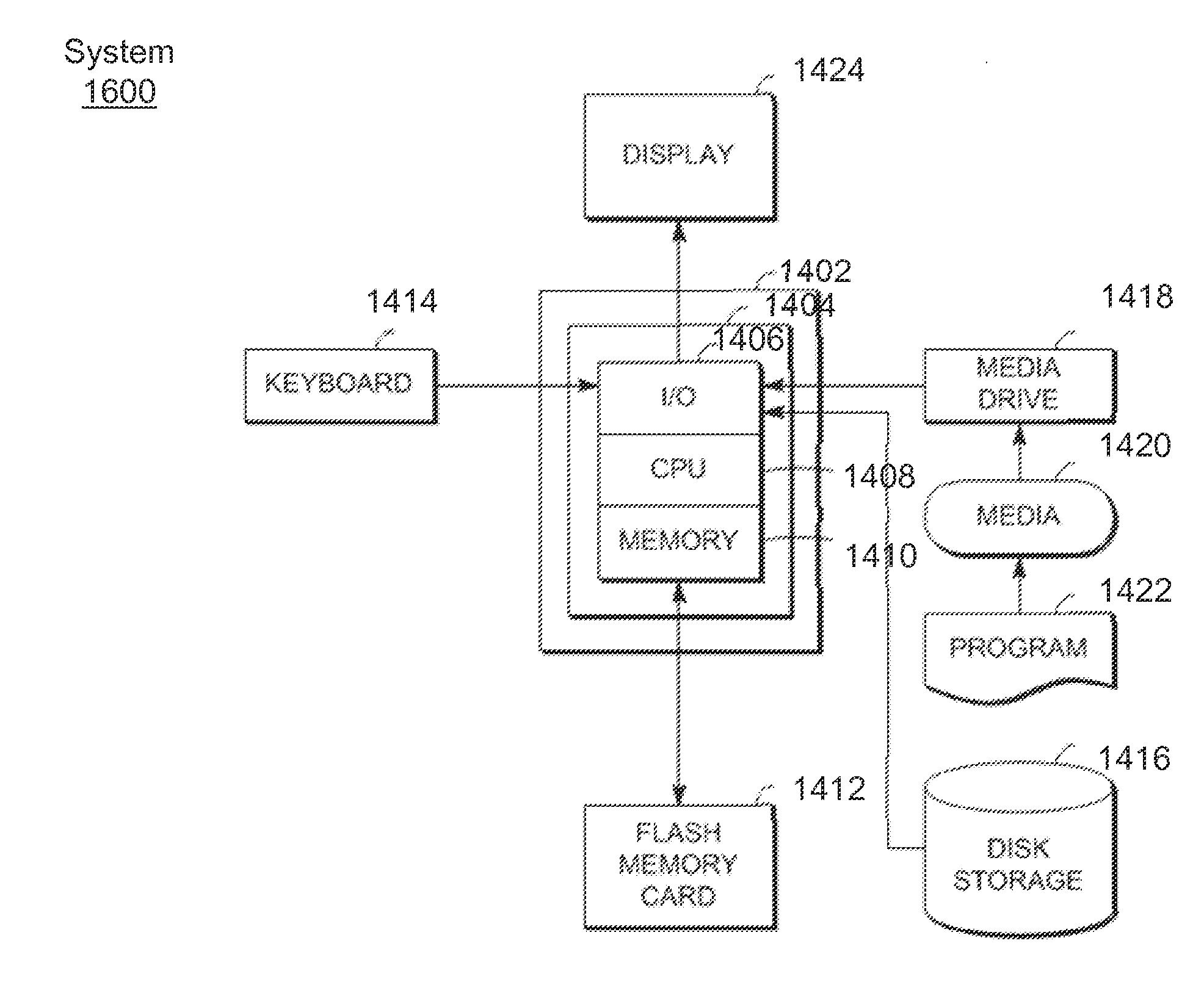

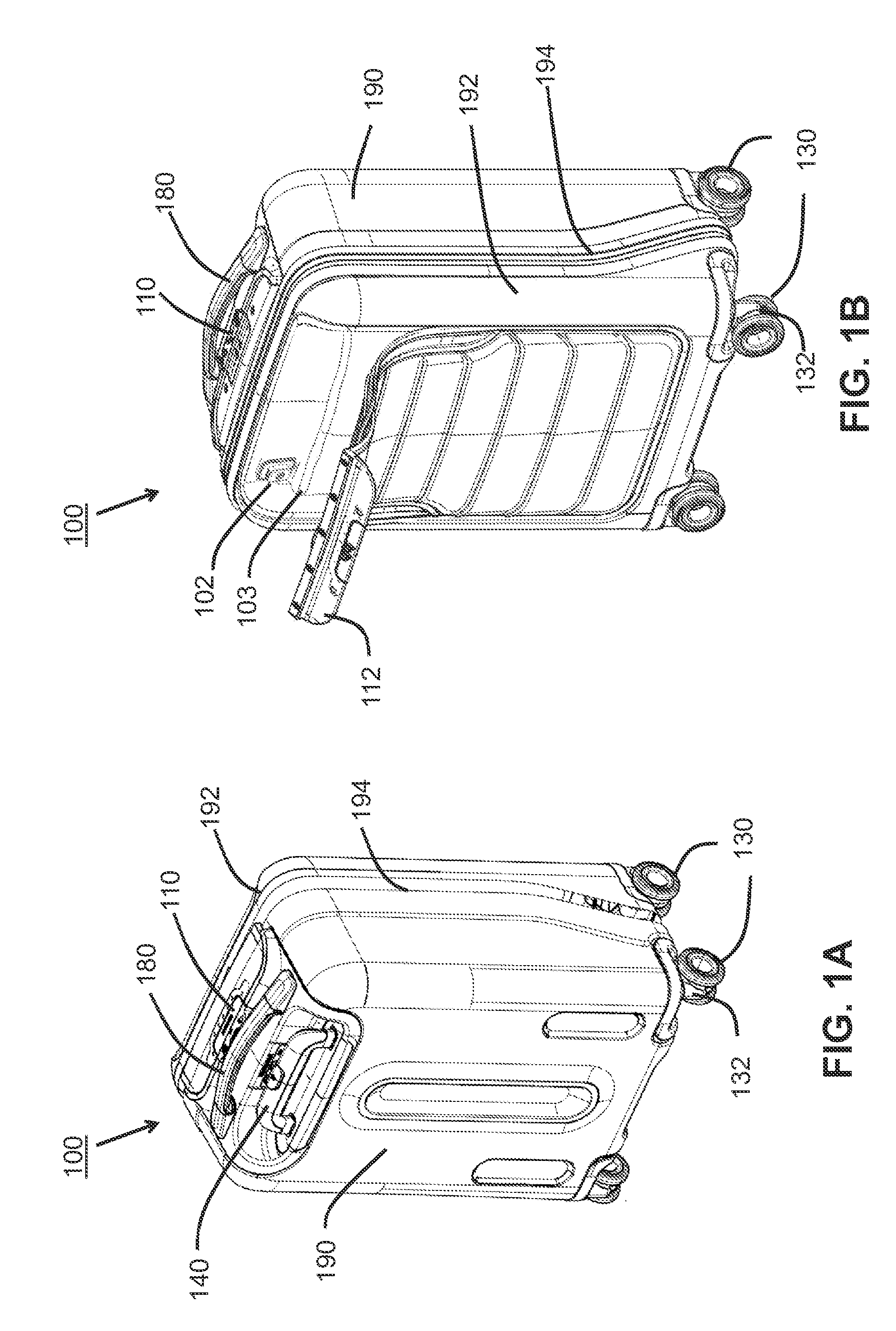

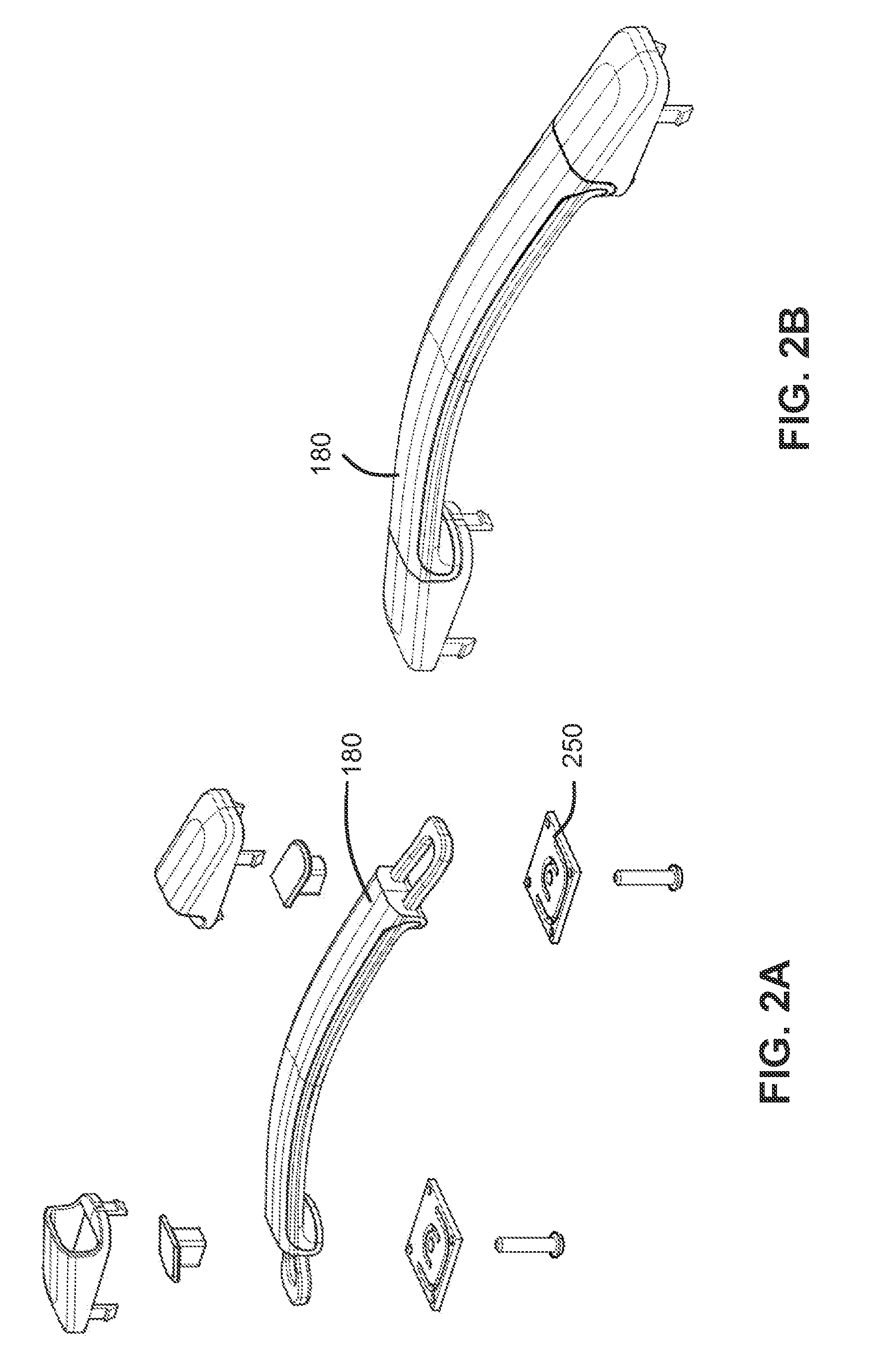

Active container

A multi-functional active container (e.g., luggage or suitcase) with a plurality of sensors and actuators is described. The container may include a body defining an enclosure and having at least one opening. The container may include a processor, a wireless receiver, and an electronically controllable lock. The processor can selectively lock or unlock the electronically controllable lock based on signals received via a wireless receiver (e.g., via Wi-Fi or BLUETOOTH connections). In some examples, a distance between the active container and a remote device (e.g., a smart phone) can be determined (e.g., based on relative GPS signals or connection strength) and if the distance exceeds a threshold, the electronically controllable lock can be activated to secure the container. Further, the container may include a rechargeable power source for powering external devices and an integrated weight sensor for detecting the weight of the container.

Owner:TRAVELPRO BSI INC

Modular dual wheel drive assembly, wheeled devices that include modular dual wheel drive assemblies and methods for moving and/or maneuvering wheeled devices using modular dual wheel drive assemblies

A wheel assembly for a small-scale machine includes a pair of opposing, individually-driven wheels, associated motors and possibly one or more gear assemblies. The motors receive separate drive signals from a control electronics subsystem of the wheel assembly. The motors can be connected to the wheels via the gear assemblies. Because the wheels are separately driven, driving the two wheel assemblies at similar or different speeds drives the wheel assembly over straight or curved paths. An orientation assembly allows the orientation of the wheels to the machine to be controllably altered. A height adjusting assembly allows the distance between the wheels and a point on the machine where the wheel assembly is attached to be adjusted. The rotational axis that the wheel assembly rotates about when re-oriented need not pass through either wheel of the wheel assembly. The wheels can be driven by control signals generated by on-board control electronics.

Owner:CYCOGS

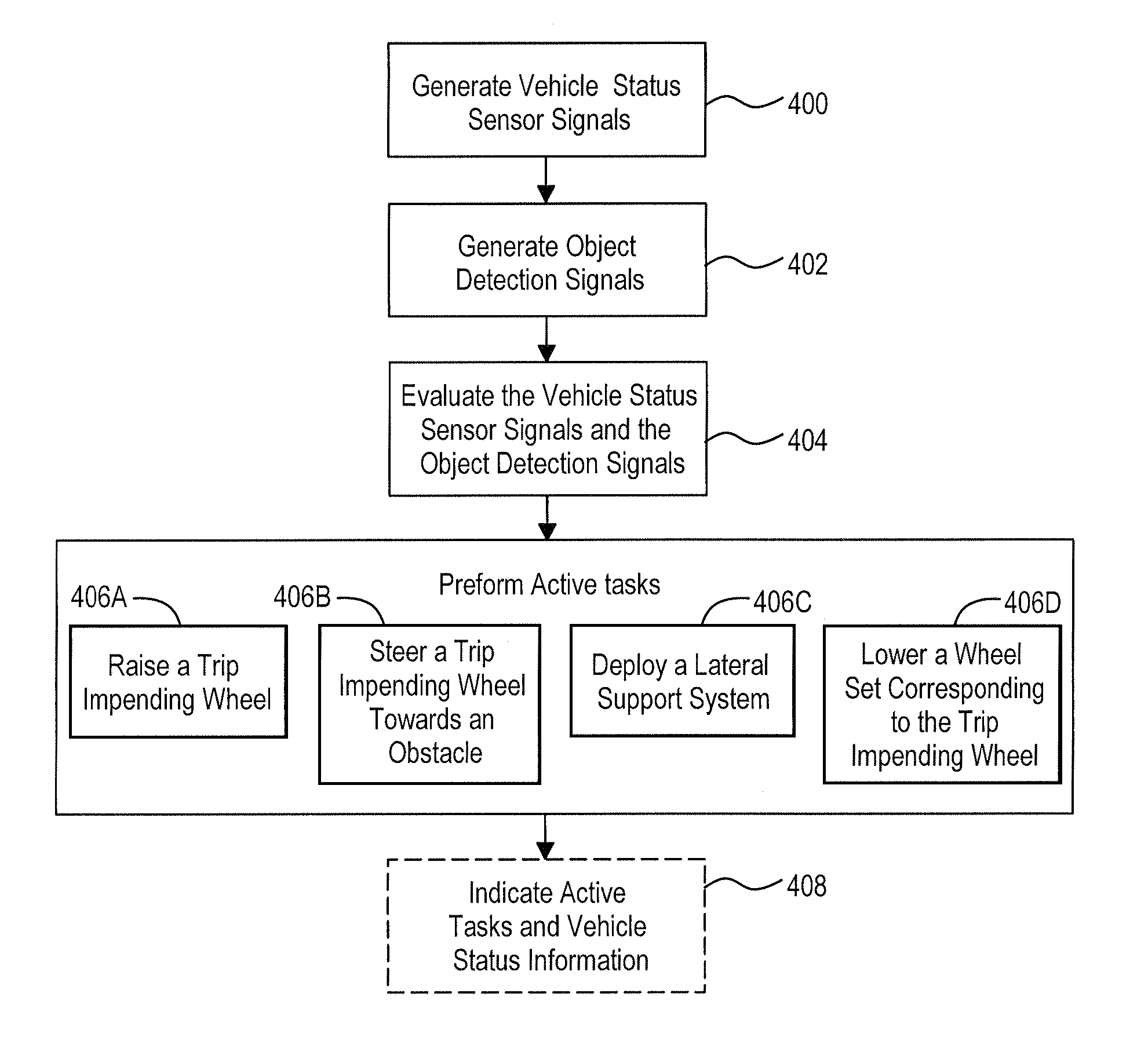

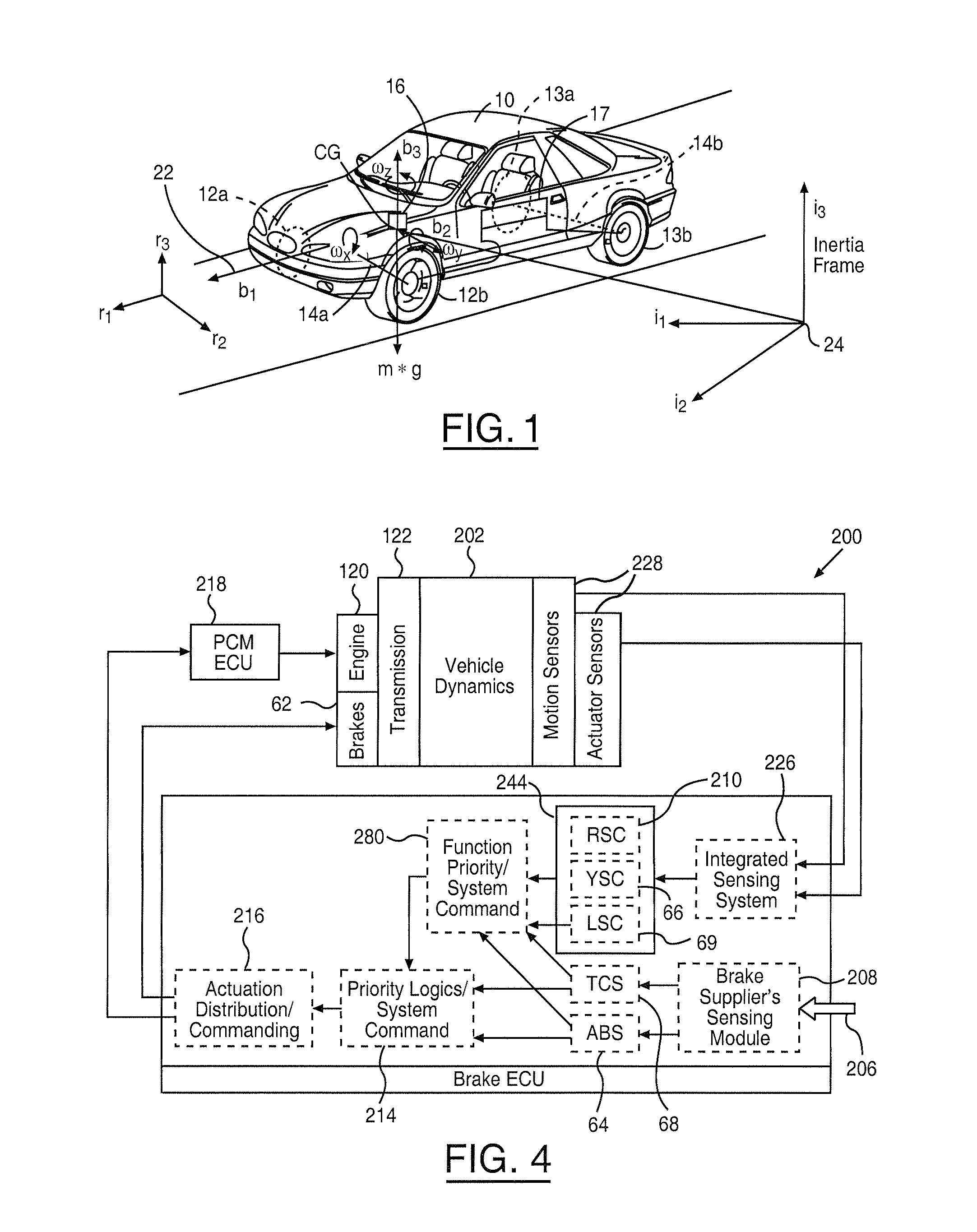

Tripped rollover mitigation and prevention systems and methods

InactiveUS20080119984A1Avoid rapid collisionsDigital data processing detailsAnimal undercarriagesSupporting systemRollover

A rollover stability control system for a vehicle may include an object information device. An active suspension or an active steering system may be coupled to a wheel of the vehicle. The rollover system may include a lateral support system. A controller determines that an obstacle is an imminent tripping obstacle and raises or steers the wheel, to prevent the wheel from colliding with the obstacle, or deploys the lateral support system in response to a rollover notification signal and the determination. A rollover stability control system for a vehicle may include a chassis and a driving surface wheel. A wheel assembly is coupled to the chassis inward from the driving surface wheel relative to a longitudinal centerline of the vehicle. The wheel assembly contacts the driving surface when a roll angle of the vehicle is greater than a predetermined level.

Owner:FORD GLOBAL TECH LLC

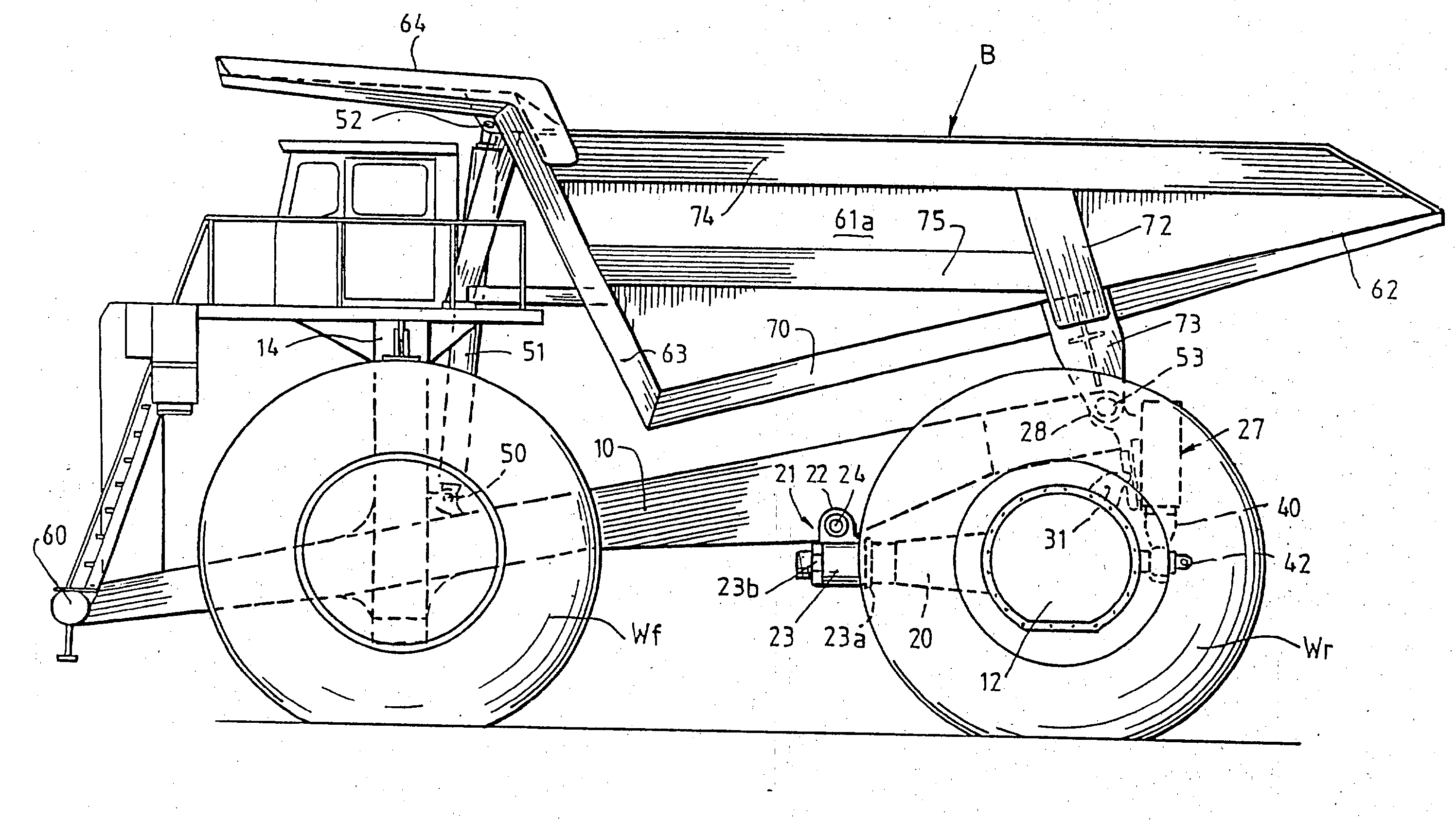

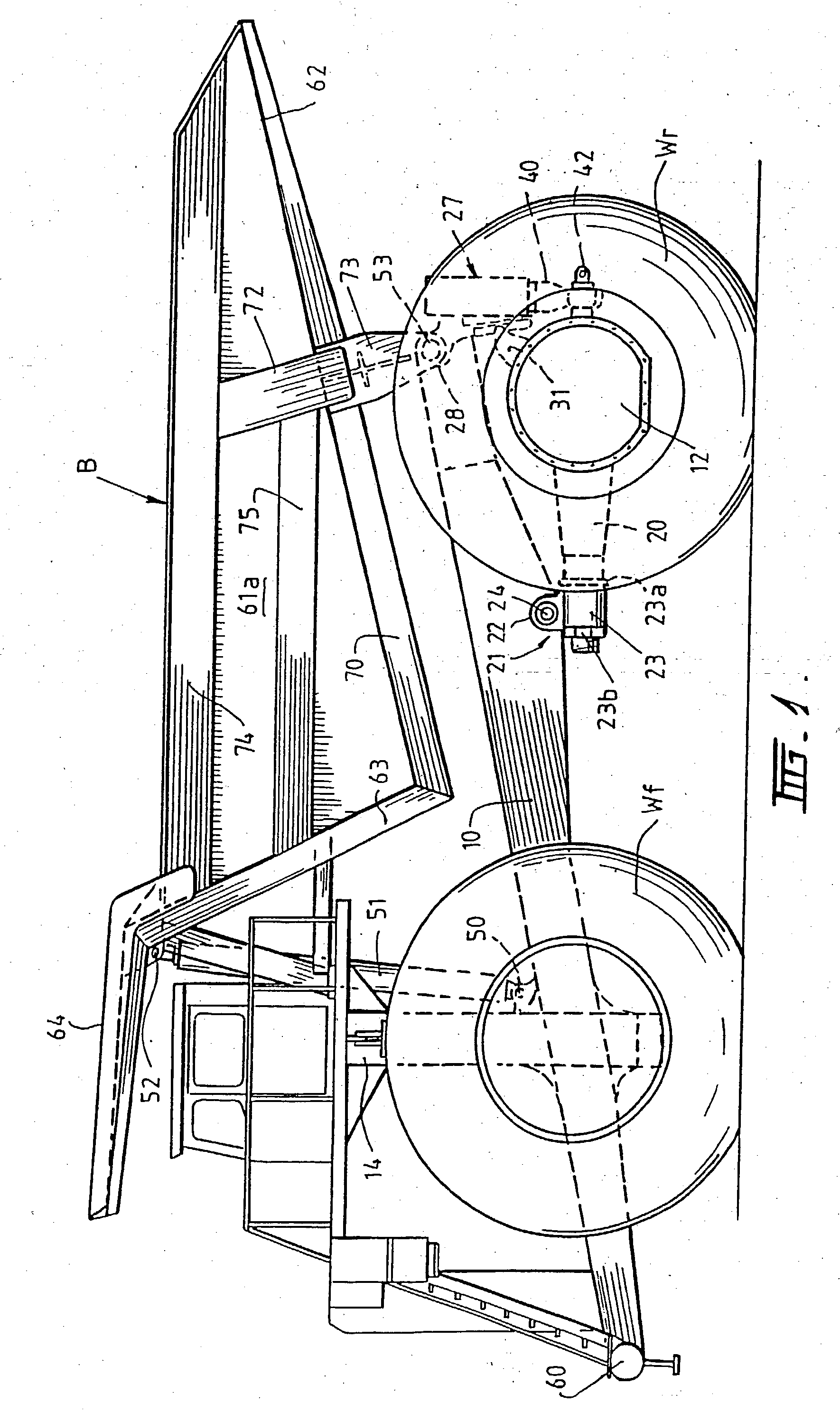

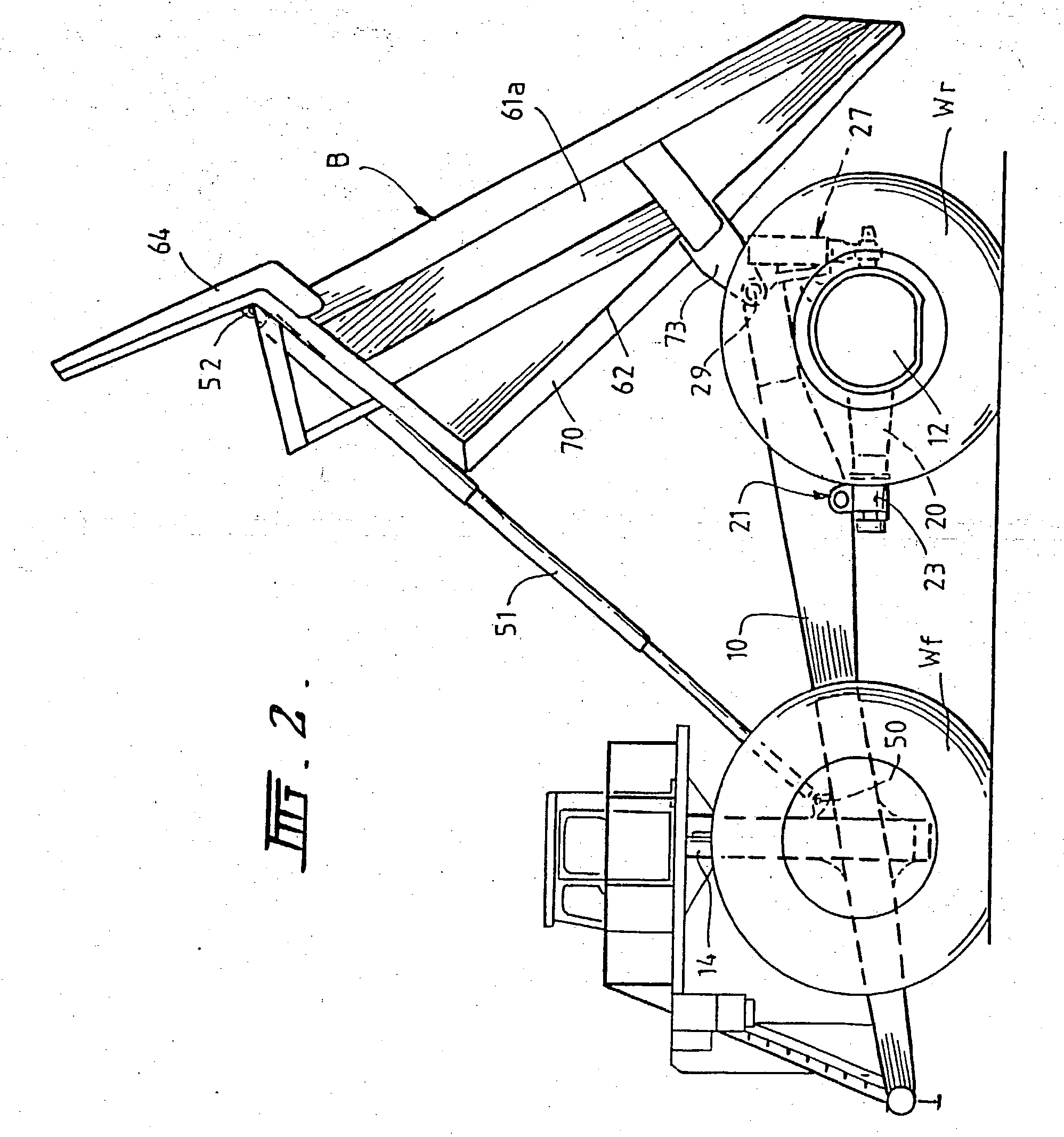

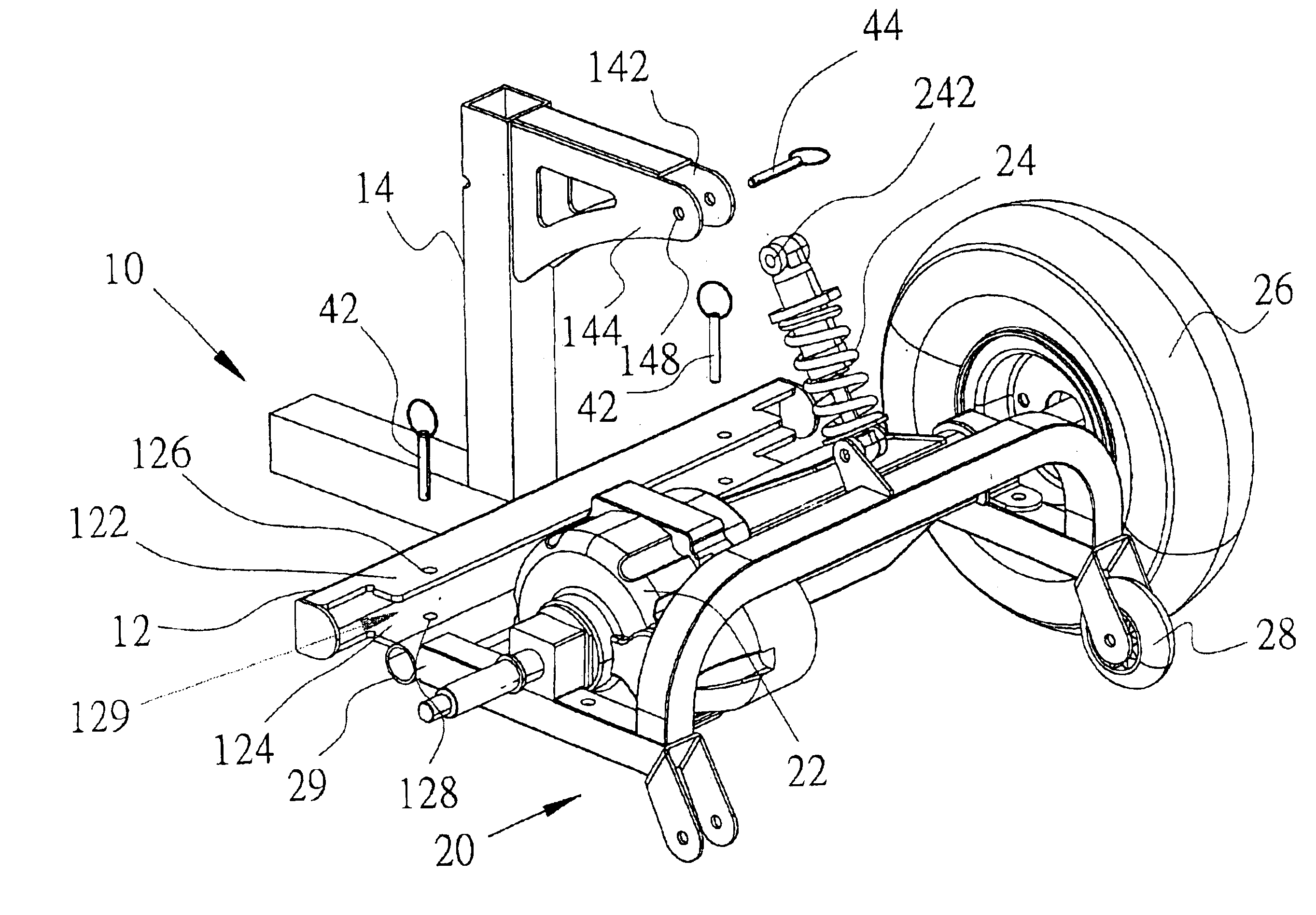

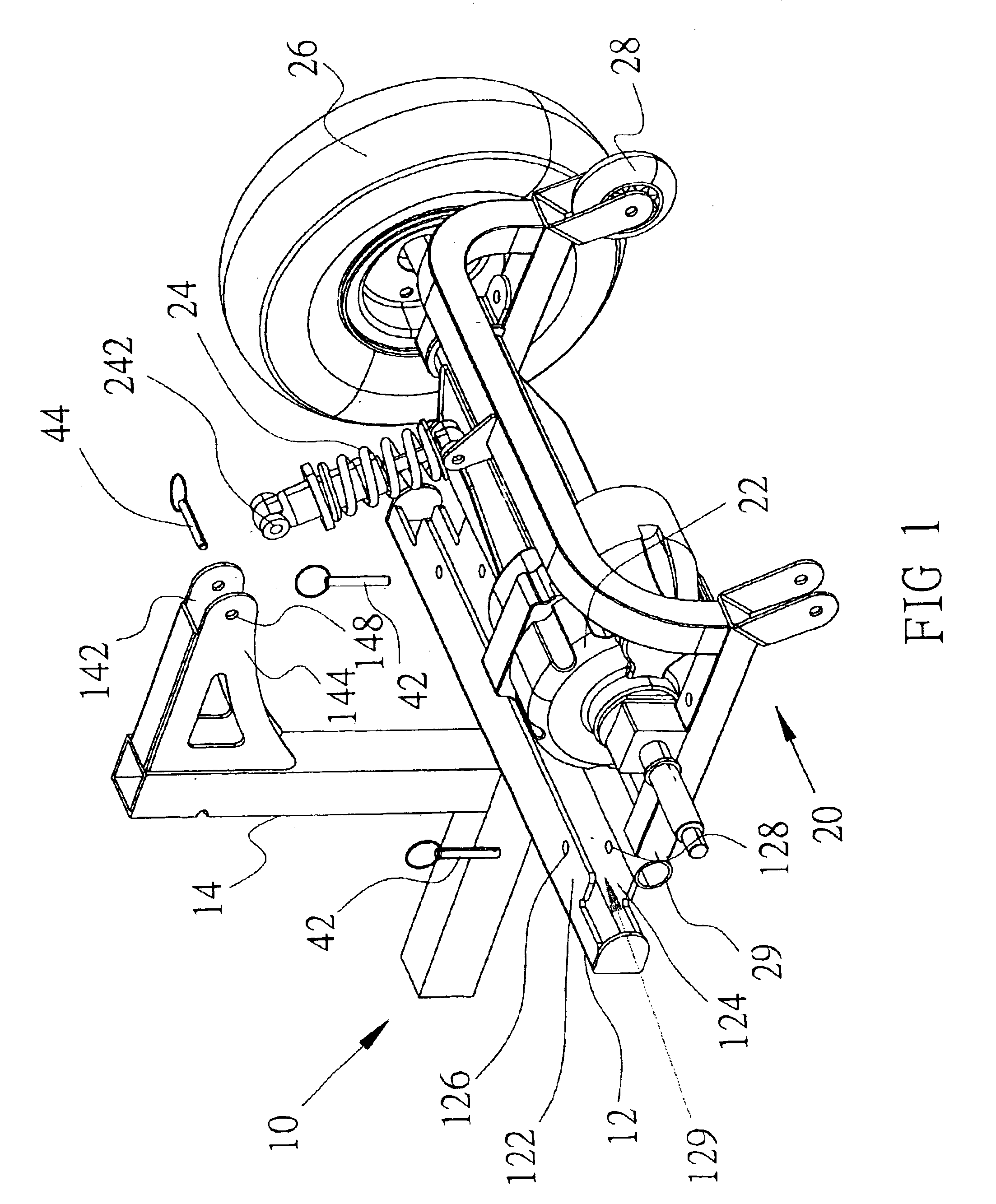

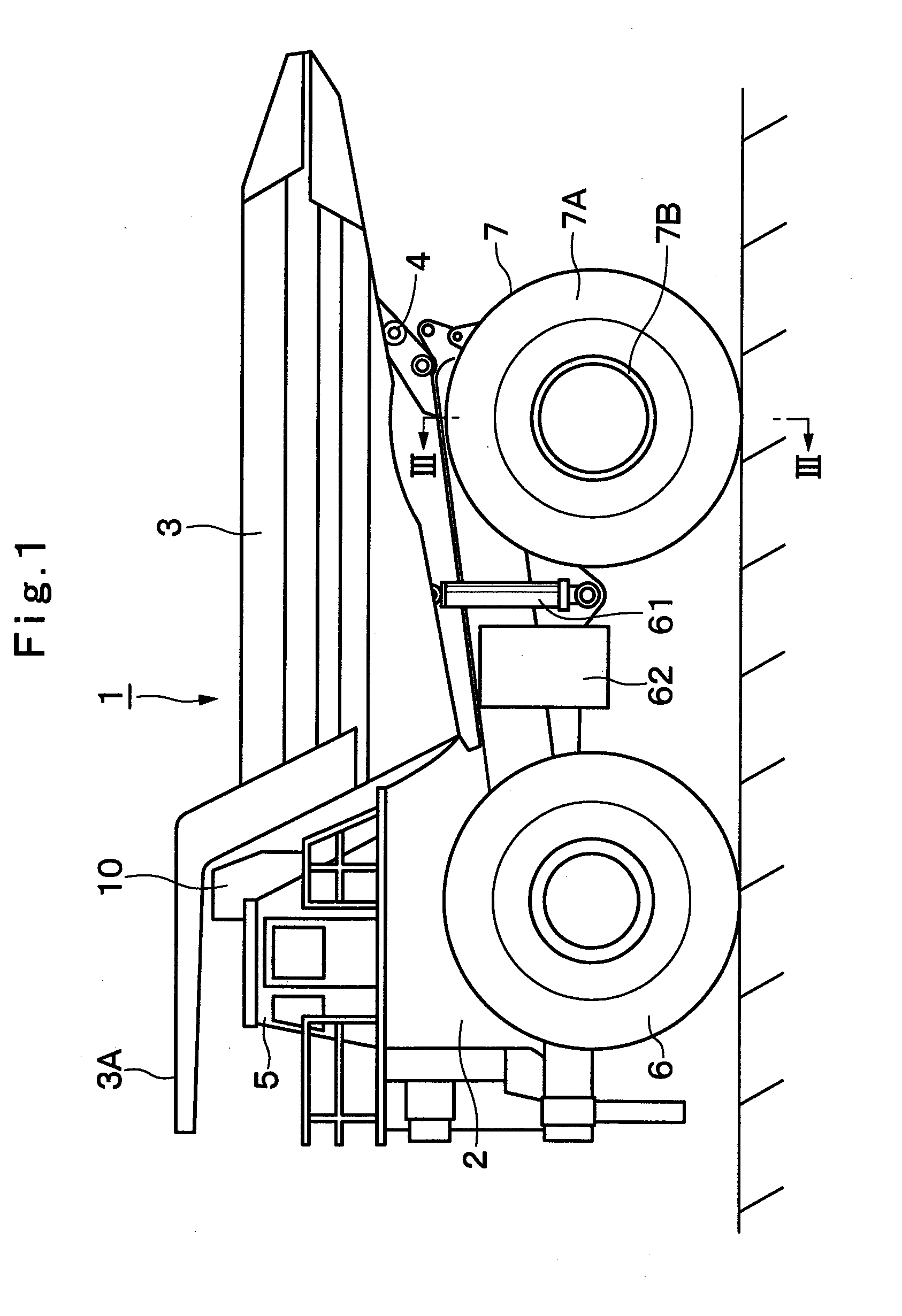

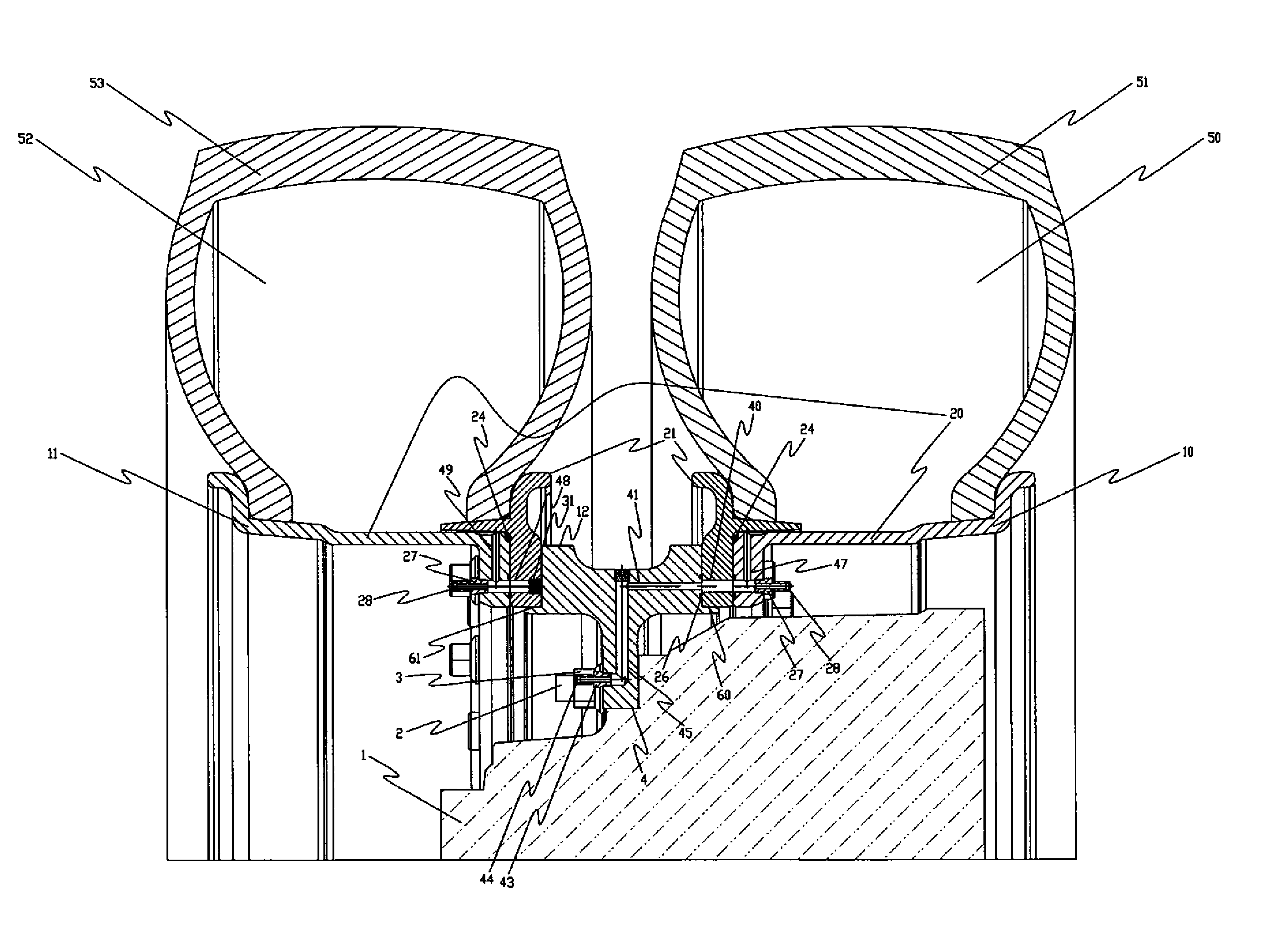

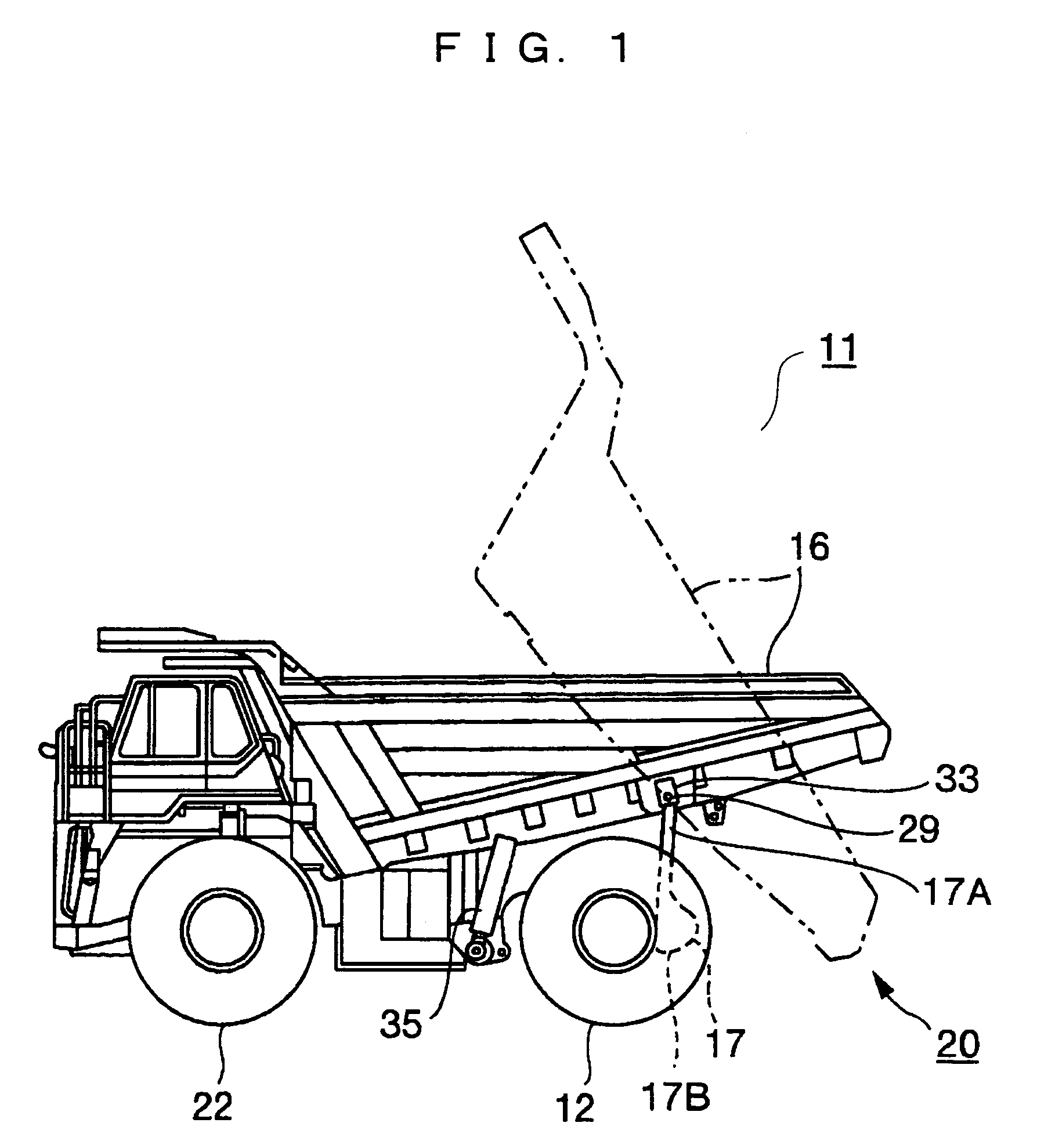

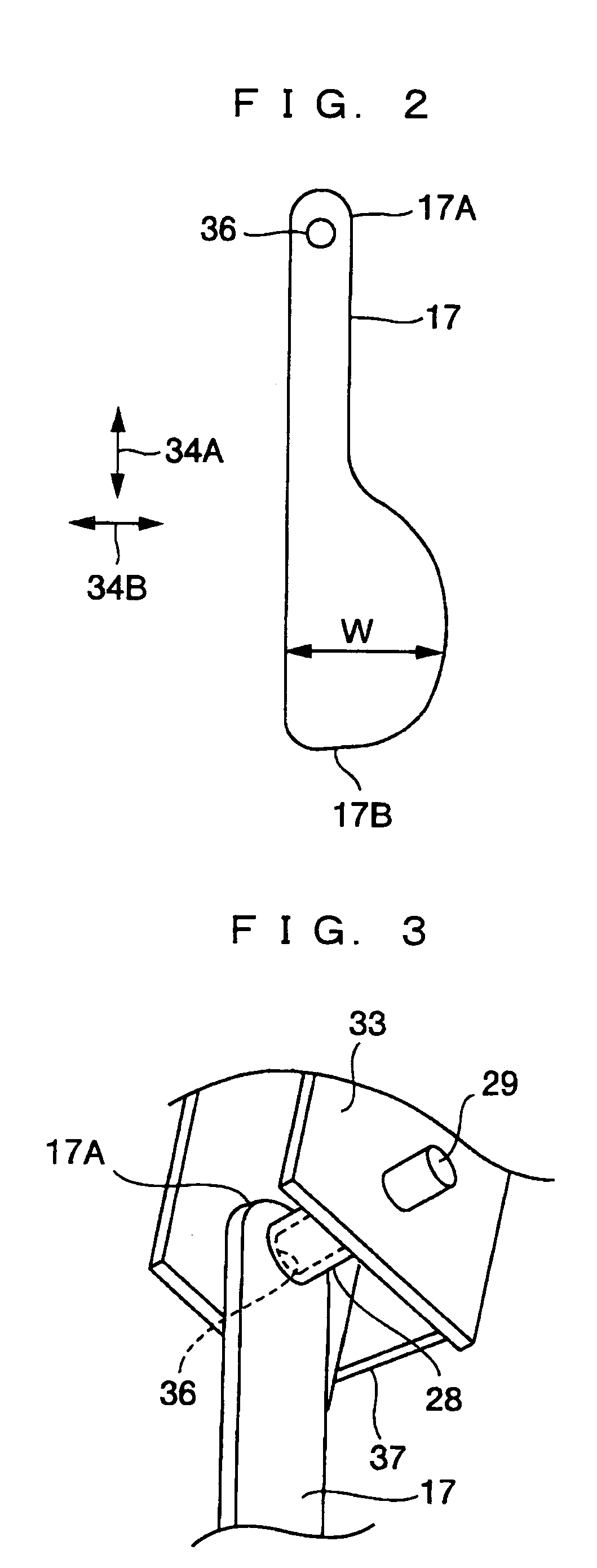

Suspension system and body for large dump trucks

InactiveUS20040036245A1Easy dischargeWear minimizationElectric propulsion mountingInterconnection systemsTransverse axisVehicle frame

A suspension system for the main frame of a large dump truck having laterally spaced frame members (10) each associated with a wheel mounting hub (12) the system comprising, for each hub (12), a hollow forward attachment arm (20) supported by a bearing block (21) having a longitudinal journal (23) and a transverse journal (22), the longitudinal journal (23) receiving the attachment arm (20) and the transverse journal (22) receiving the ends of a shaft rigidly secured to the frame members (10) and extending therebetween to define a cross member and a vertically compliant suspension strut comprising a cylinder (41) rigidly attached to a support (28) secured to the frame member (10) and receiving a piston (40) attached to a rear extension (42) from the hub (12) via a bearing which allows each hub (12) to rotate about longitudinal and transverse axes relative to the respective frame member (10). Also disclosed is dump truck body (B) having side walls (61), a floor (62) and an end wall (63), the floor (62) being reinforced by longitudinal reinforcing beams and by only one transverse beam (72). The side walls (61) slope inwardly, the floor (62) slopes downwardly and forwardly and the width of the floor (62) increases towards the rear of the body (B).

Owner:LIEBHERR WERK BIBERACH

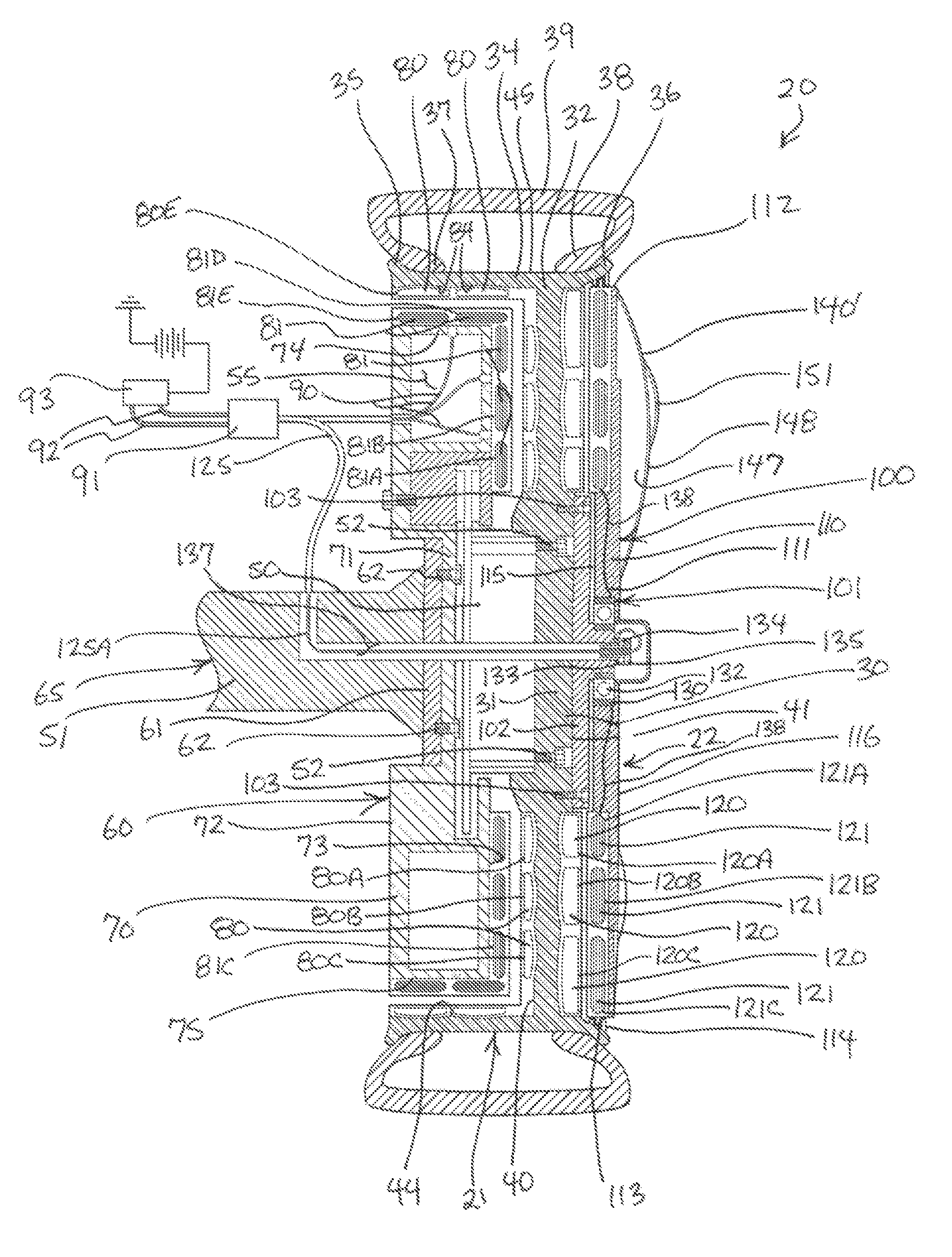

Wheel assembly with electric power generator

A wheel assembly includes a carrier and a wheel mounted adjacent to the carrier for rotation relative to the carrier. A first array of magnets is carried by one of the first side of the wheel and the carrier, and a first array of coils is carried by the other of the wheel and the carrier corresponding to the first array of magnets. A spinner is mounted adjacent to the wheel for rotation relative to the wheel. A second array of magnets is carried by one of the wheel and the carrier, and a second array of coils is carried by the other of the wheel and the spinner corresponding to the second array of magnets.

Owner:VANCEA PETER

Travel drive apparatus for a working vehicle

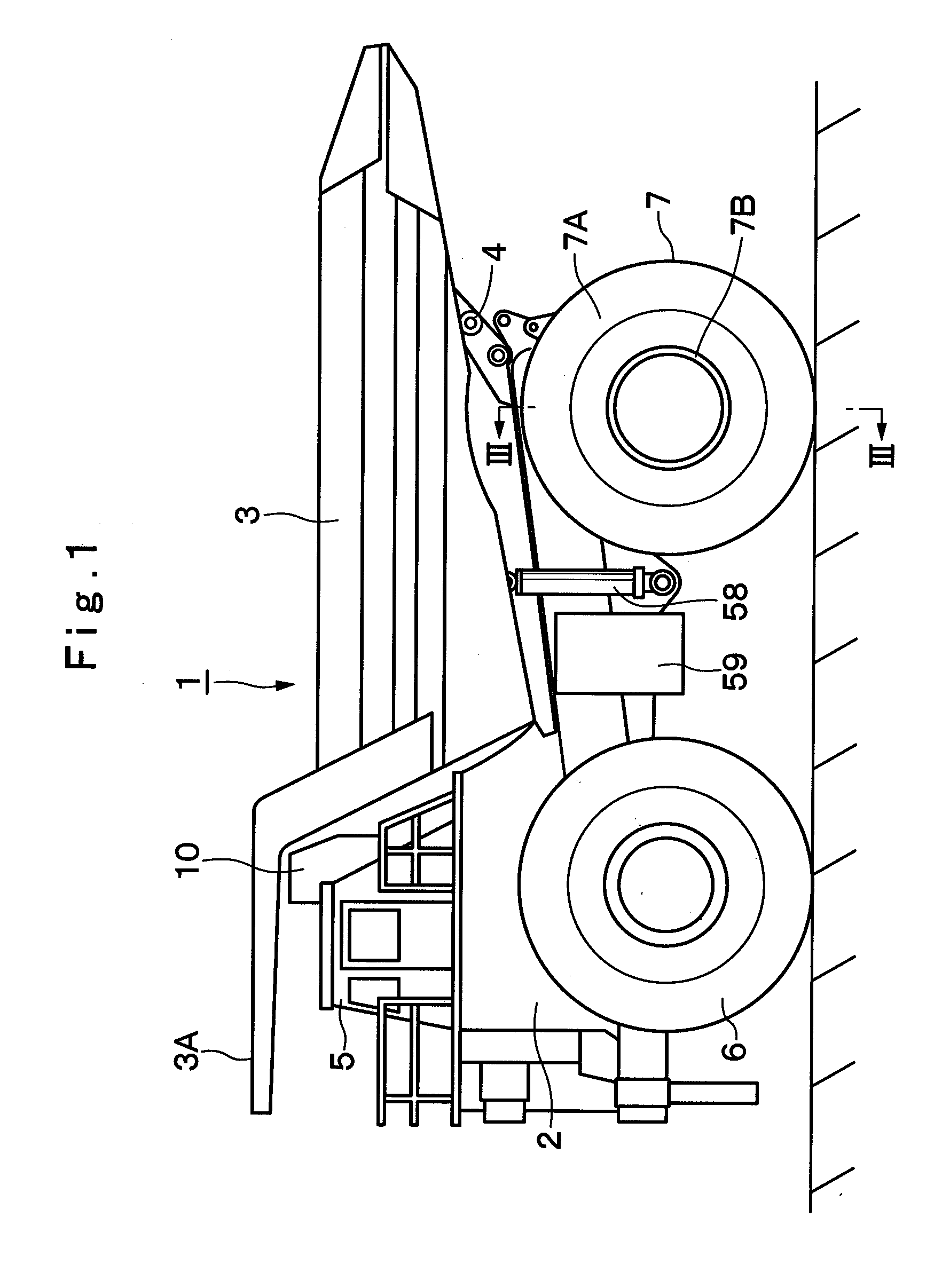

ActiveUS20100191417A1Prolong lifeImprove reliabilityHybrid vehiclesGearboxesTemperature differenceEngineering

When the drive of a lubricant pump (46) is stopped to prevent the lubricant pump (46) from assuming an idling state, a determination is made as to whether or not a temperature difference (ΔT) between the temperature (T) of a lubricant oil detected earlier by a temperature sensor (51) and a warning temperature (Toh) is equal to or lower than a predetermined threshold value (α). When the temperature difference (ΔT) is within the threshold value (α), an “overheat” warning is issued to an operator of a dump truck (1). In consequence, even in a case where a temperature sensor (51) is provided on the output side of the lubricant pump (46) by being located on an outer side of a wheel mounting case (19), planetary gear reduction mechanisms (23), (31) inside the wheel mounting case (19) can be prevented from overheating by warning the operator of the vehicle.

Owner:NIHON KENKI CO LTD

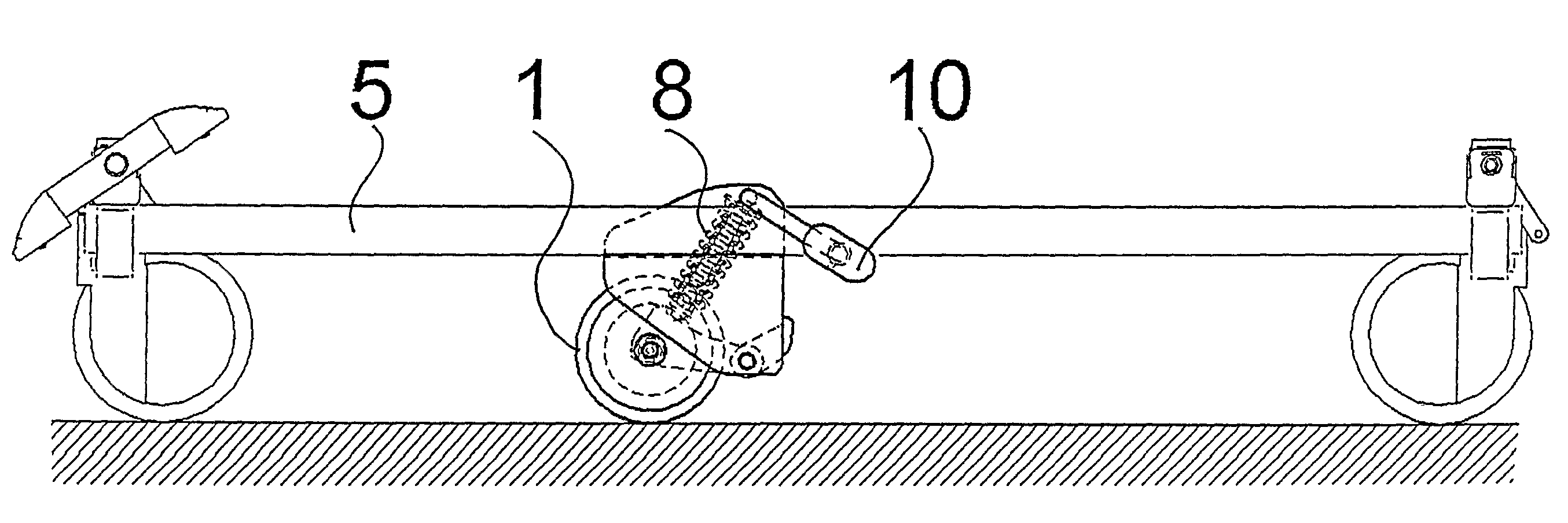

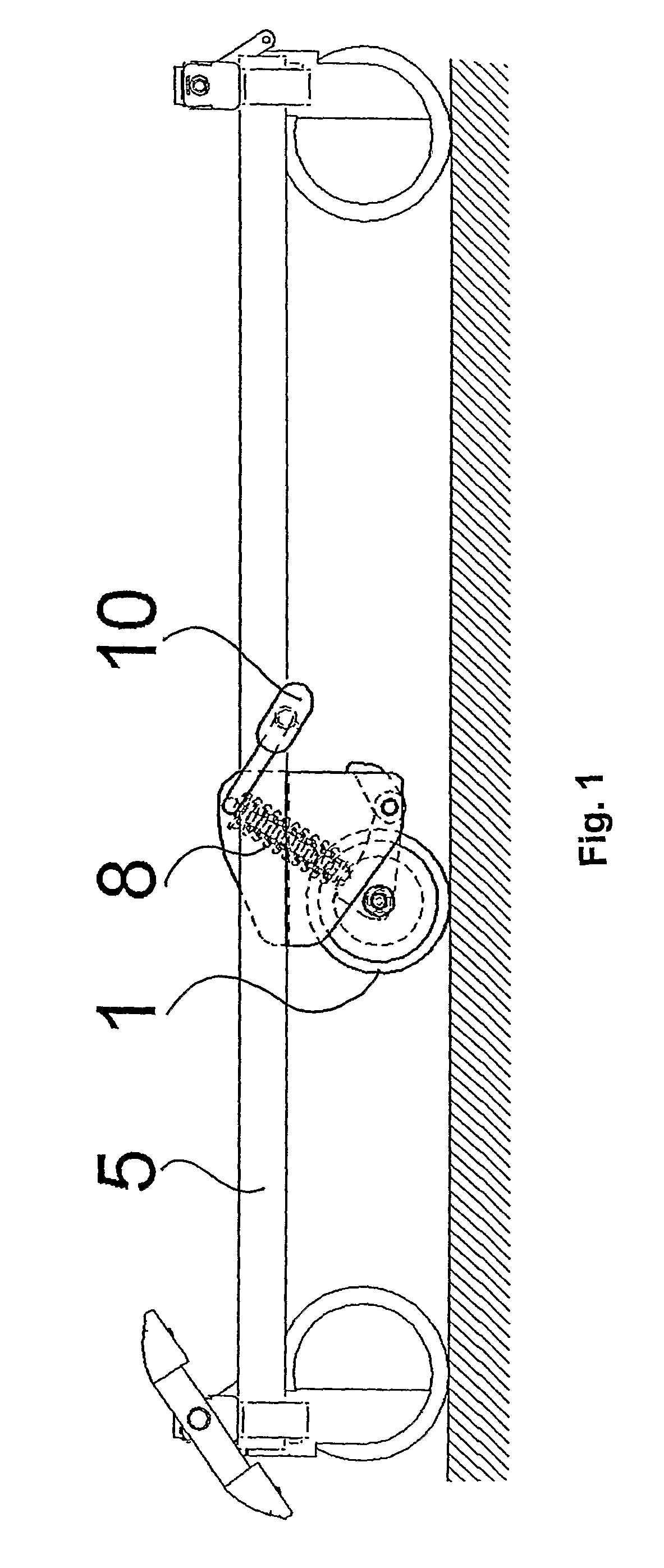

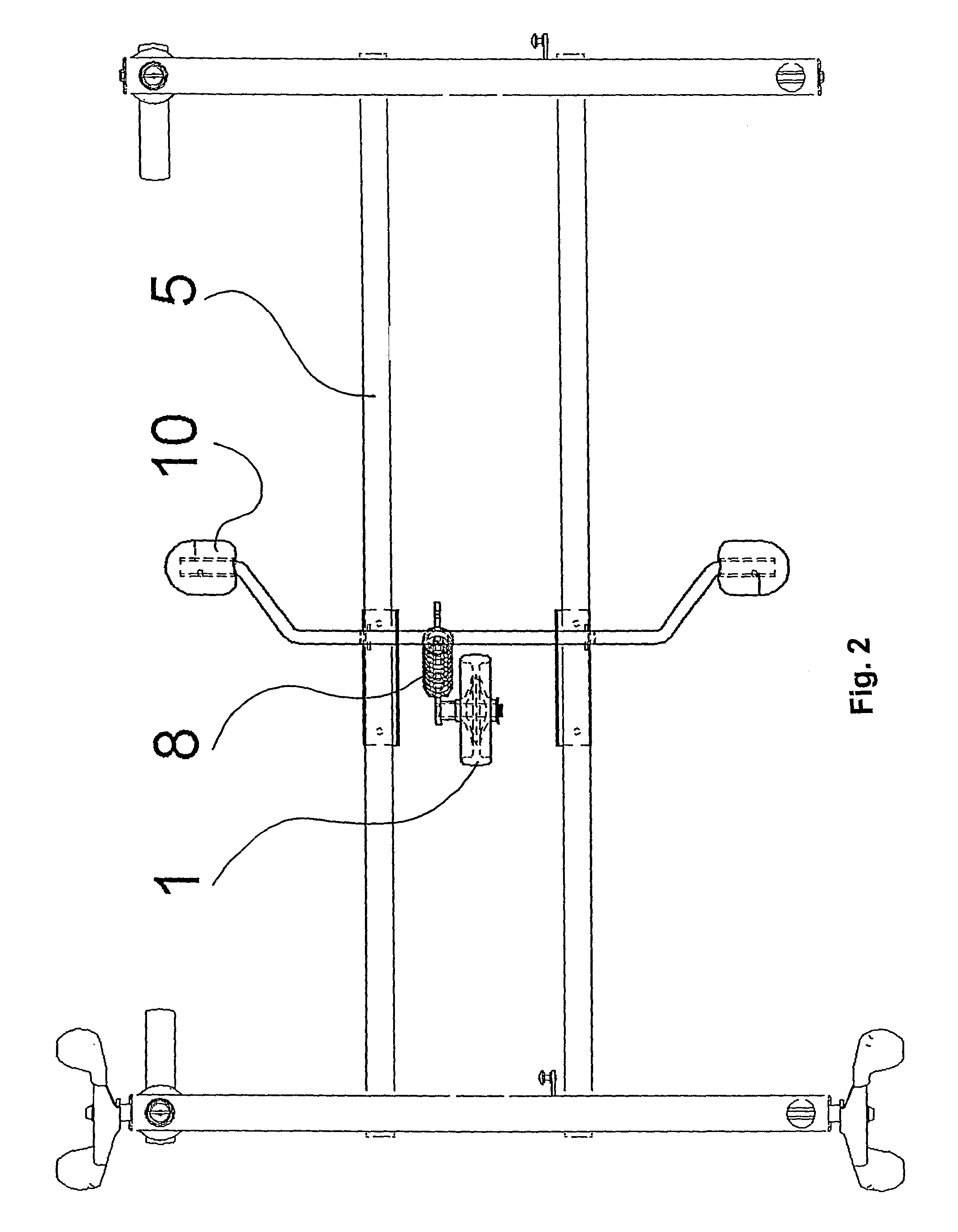

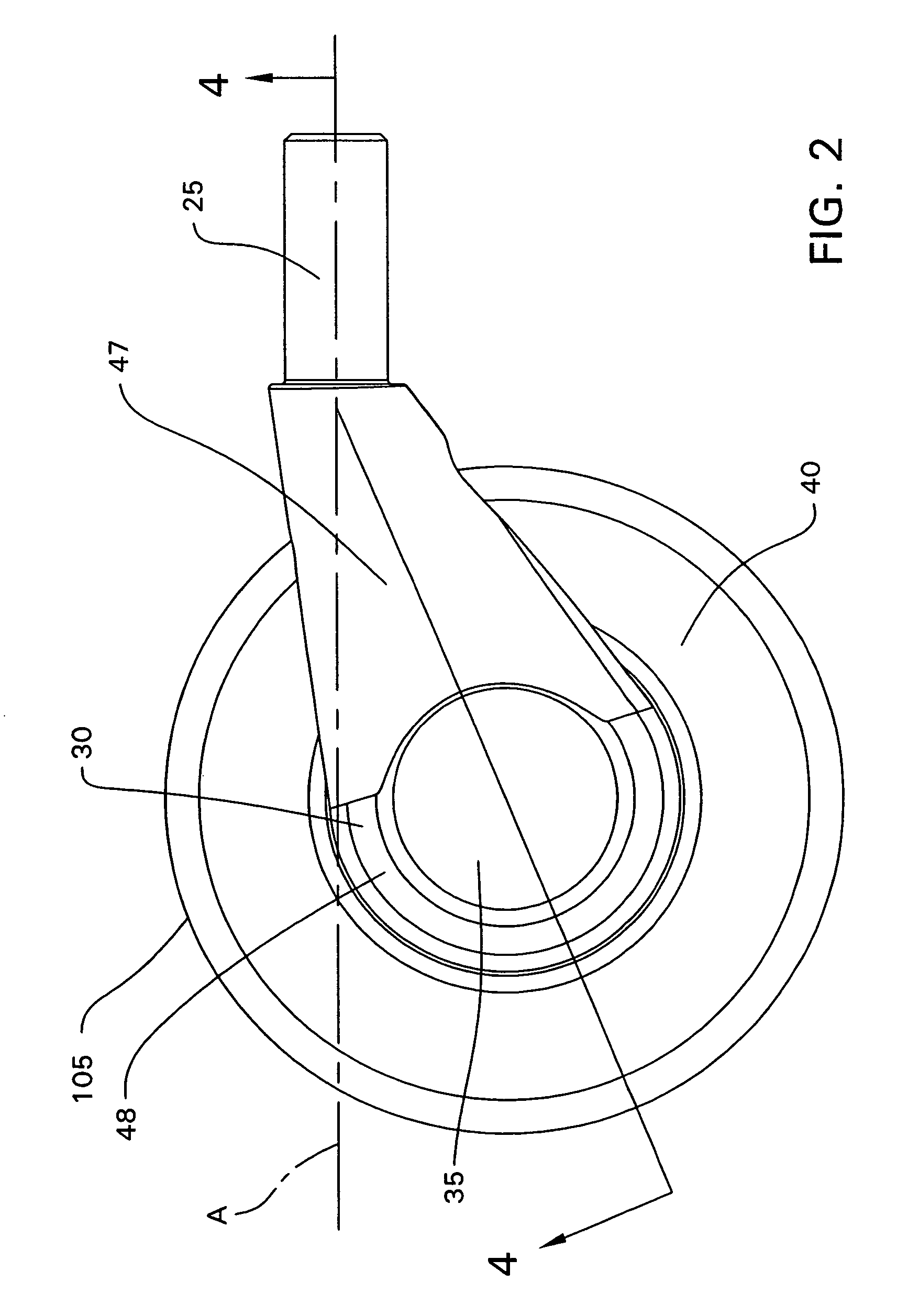

Guiding wheel assembly, especially for a hospital bed

InactiveUS8109525B2Simple equipmentSimple supplyCastorsUnderstructuresVertical planeMechanical engineering

A guiding wheel assembly, mainly for a hospital bed, including a wheel (1) with a horizontal rotation axis (6) installed on an arm (7) that is fixed to the frame (5) with the use of an axis (4) allowing swinging in the vertical plane. The wheel (1) is firmly fixed in the straight direction. The arm (7) is provided with a track (3), against which a pressing element (8) leans. The pressing element (8) is fixed with a pin (9) to the frame (5) in a swinging way.

Owner:LINET SPOL

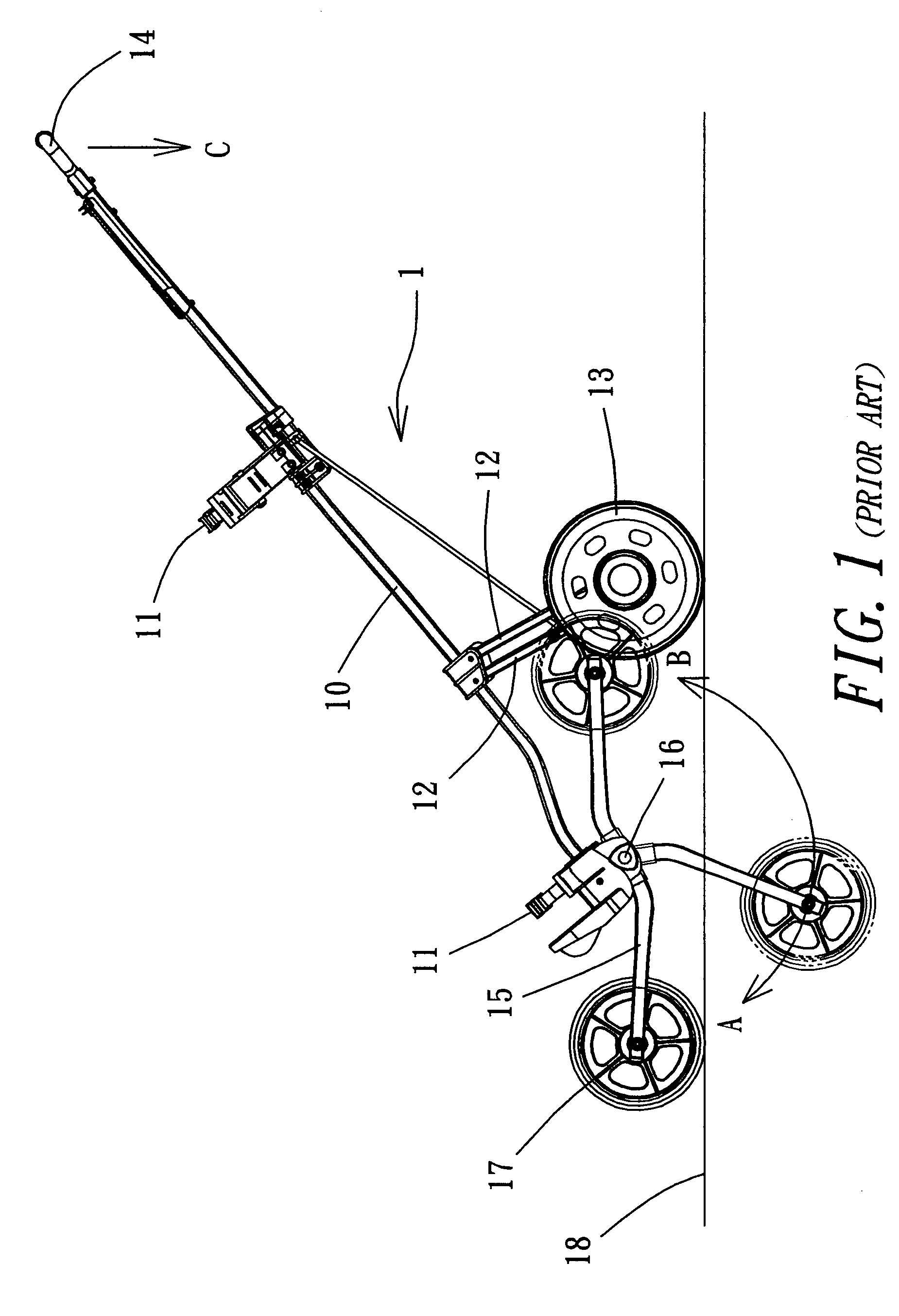

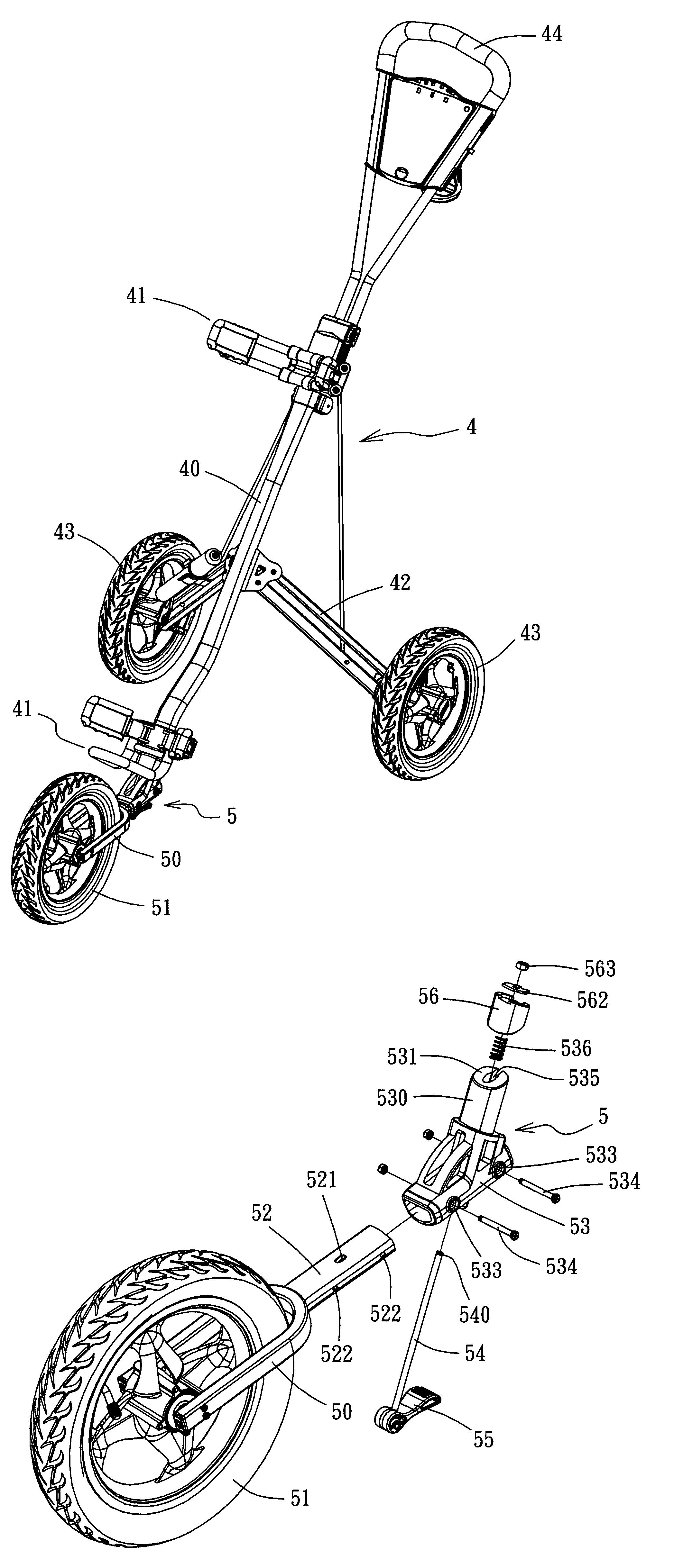

Third wheel collapsing device for a golf club cart

A third wheel collapsing device for a golf club cart includes a third wheel support frame having a U-shaped frame fixed pivotally with a third wheel and a hollow support arm fitted therein with a fit block. The support arm and the fit block respectively have insert holes and connecting holes. A support base assembled on the support arm has a pivotal shaft under the bottom and a threaded hole before the pivotal shaft for receiving an elastic lock member, which has an engage rod biased by a compression coil spring and controlled by a user. The support base has a fastening frame fixed with the lower end of the main frame of a golf club cart. When the engage rod is pulled and removed from the first insert hole of the support arm and the first connecting hole of the fit member, the third wheel support frame can be transversely collapsed.

Owner:UNIQUE PRODS & DESIGN

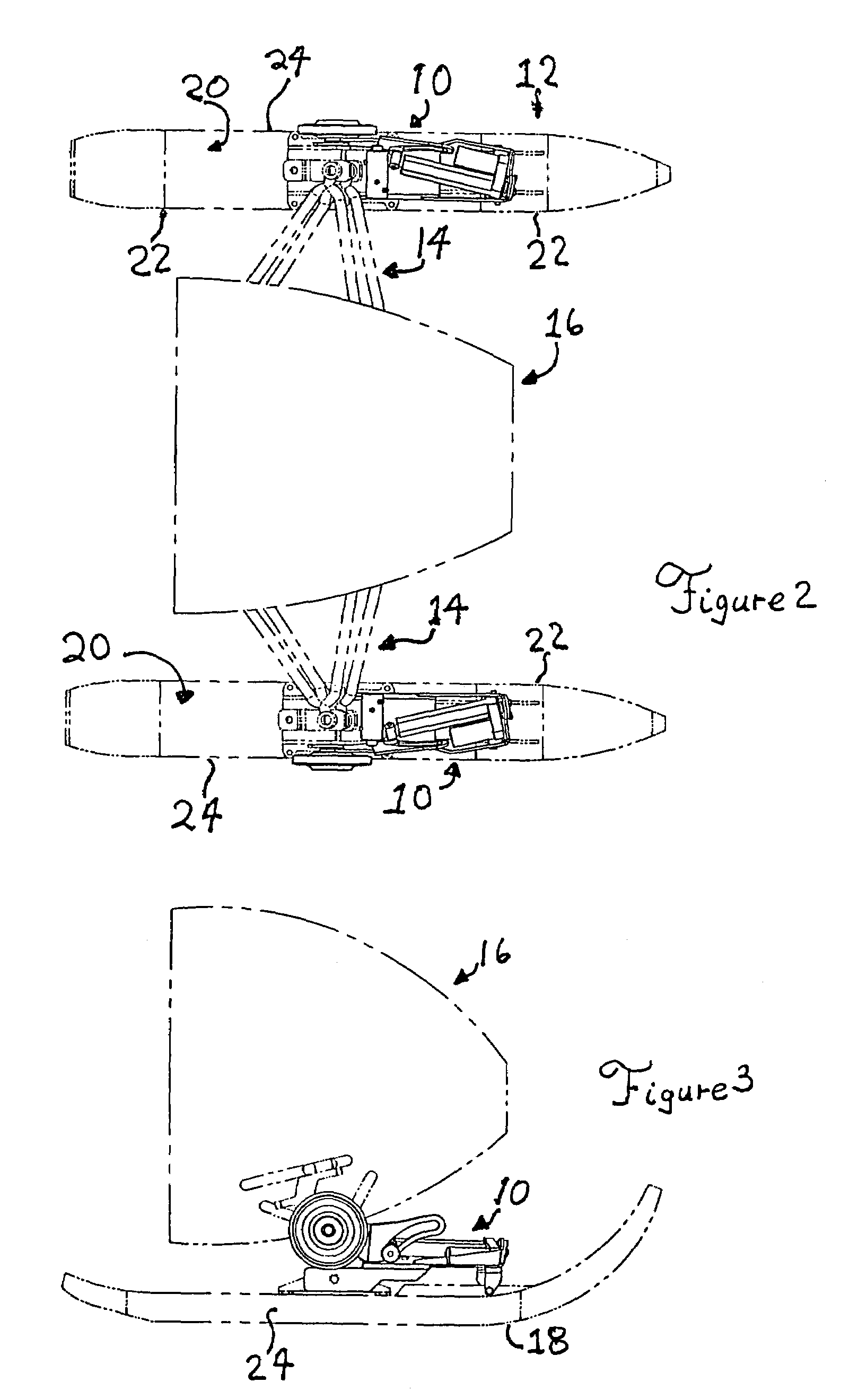

Wheel unit for ski-mounted vehicle

InactiveUS7290774B2Reduce riskLarge sustentation baseCarriage/perambulator accessoriesSledgesEngineeringActuator

A wheel unit mountable on a ski of a ski-mounted vehicle includes an actuating plate defining a wheel attachment section and a piston attachment section The actuating plate is pivotally attached to the ski intermediate the wheel and piston attachment sections for pivotal movement about a plate pivotal axis. A wheel attachment assembly is provided for rotatably attaching the wheel to the wheel attachment section. An actuator is operatively coupled to the actuating plate for selectively pivoting the actuating plate about the plate pivotal axis between a plate deployed configuration and a plate retracted configuration wherein in the plate deployed configuration the position of the actuating plate is such that the wheel protrudes at least partially below the ski gliding surface for engaging the ground surface and in the plate retracted configuration the position of the actuating plate is such that the wheel is retracted above the ski gliding surface for preventing the wheel from engaging the ground surface. A plate transversal moving assembly is operatively coupled to the actuating plate for selectively moving the actuating plate substantially transversally relative to the ski.

Owner:DESPRES JEAN

Tripped rollover mitigation and prevention systems and methods

InactiveUS8108104B2Avoid rapid collisionsDigital data processing detailsAnimal undercarriagesRolloverSupporting system

A rollover stability control system for a vehicle may include an object information device. An active suspension or an active steering system may be coupled to a wheel of the vehicle. The rollover system may include a lateral support system. A controller determines that an obstacle is an imminent tripping obstacle and raises or steers the wheel, to prevent the wheel from colliding with the obstacle, or deploys the lateral support system in response to a rollover notification signal and the determination. A rollover stability control system for a vehicle may include a chassis and a driving surface wheel. A wheel assembly is coupled to the chassis inward from the driving surface wheel relative to a longitudinal centerline of the vehicle. The wheel assembly contacts the driving surface when a roll angle of the vehicle is greater than a predetermined level.

Owner:FORD GLOBAL TECH LLC

Wheeled vehicle having a detachable rear frame

InactiveUS6896084B2Easy to assembleEasy to foldWheelchairs/patient conveyanceUnderstructuresEngineeringShock absorber

Owner:LO CHIU HSIANG

Travel drive apparatus for a working vehicle

ActiveUS20100187044A1Improve the lubrication effectImprove cooling effectHybrid vehiclesAnalogue computers for trafficEngineeringDrive motor

In case a temperature (T) of a lubricant oil (G) cannot be detected by an oil temperature sensor (51) provided on an output side of a lubricant pump (46), the temperature (Tm) of a wheel drive motor (17) is detected by using a motor temperature sensor (53) provided on the wheel drive motor (17). By estimating the temperature (T) of the lubricant oil (G) from the temperature (Tm) of the wheel drive motor (17), monitoring is carried out as to whether or not the temperature (Tm) has risen to a predetermined temperature (Tms) at which the cooling of the lubricant oil (G) by forced circulation is deemed necessary. The drive of a lubricant pump (46) by a pump drive motor (47) is stopped until the motor temperature (Tm) rises to a level exceeding the predetermined temperature (Tms).

Owner:NIHON KENKI CO LTD

All terrain adapter for a wheelchair

ActiveUS7735847B2Improve stabilityEasy to install and removeWheelchairs/patient conveyanceMultiple wheel assemblyTerrainWheelchair

An all terrain adapter for a wheelchair that removably clamps onto the foot support of the wheelchair and supports a relatively large diameter, slightly inclined swivelling nose gear wheel at an extended distance from the foot support to stabilize the wheelchair when it is being pushed over soft or uneven surfaces and which swivels around when the wheelchair is moved forward to lift the front wheels of the wheelchair clear of the ground.

Owner:DOUGHERTY PATRICK S

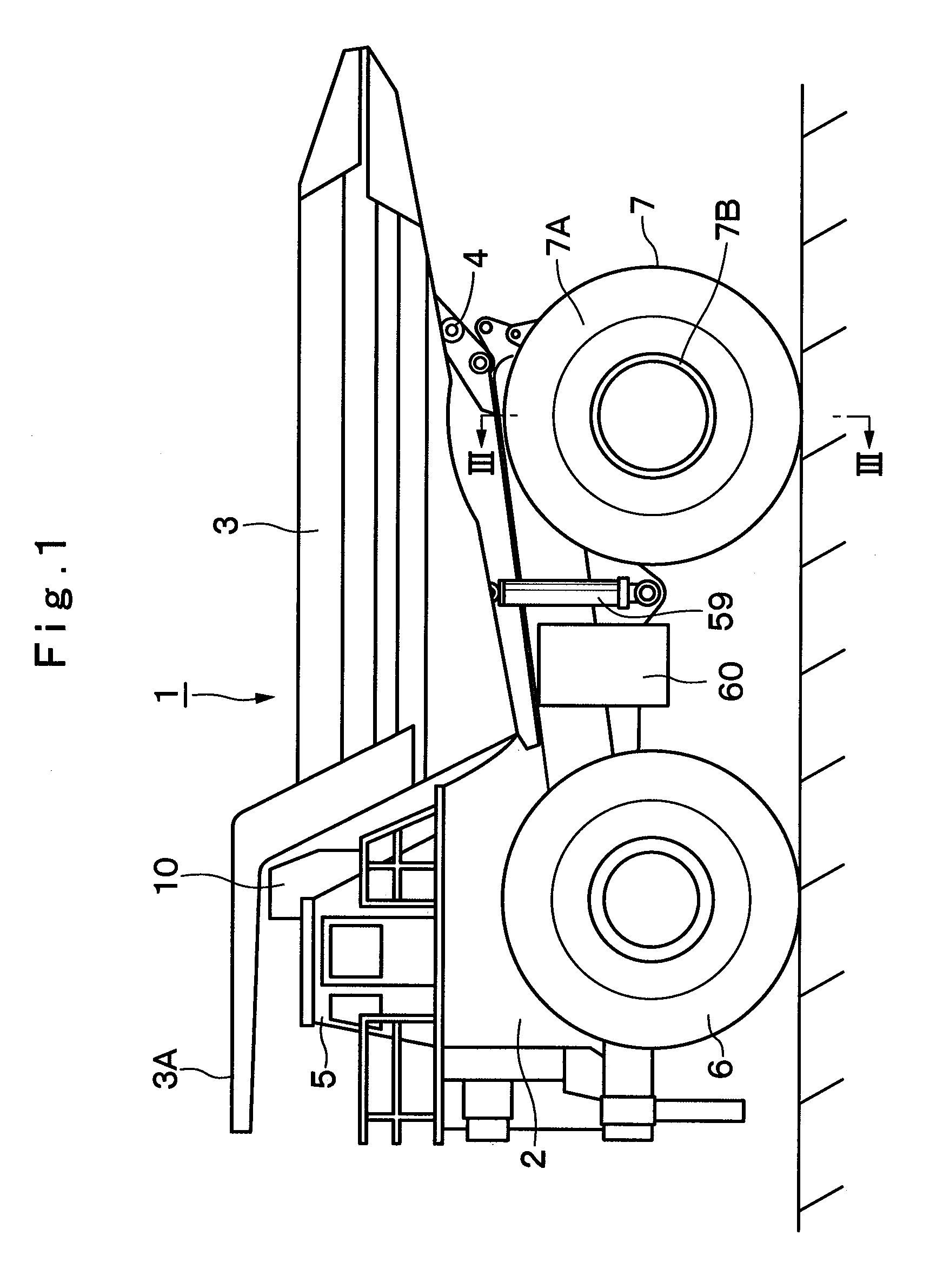

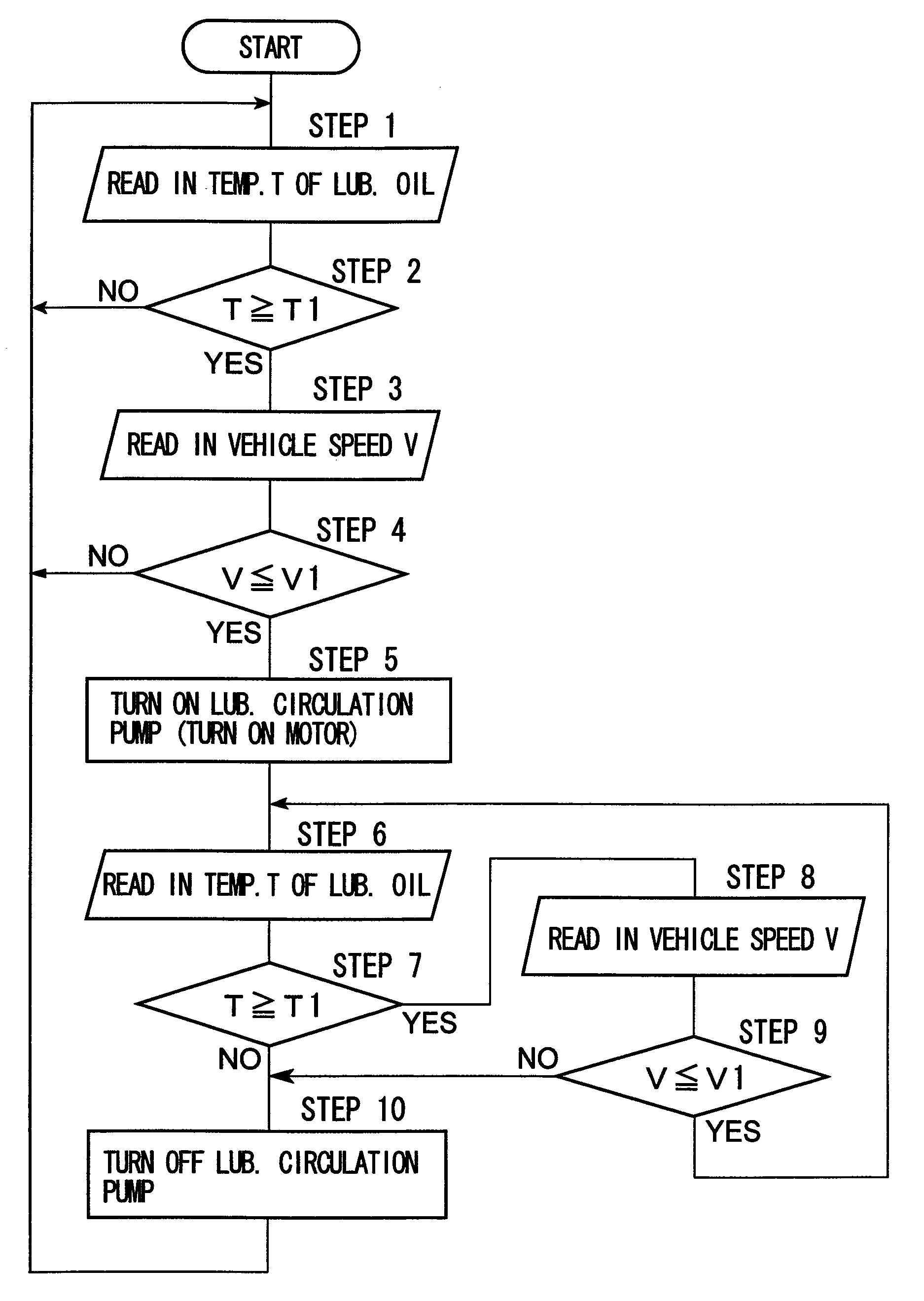

Traveling drive unit for working vehicle

ActiveUS20100140020A1Preventing dry idling operationEasy to useGearboxesDigital data processing detailsCentrifugal forceCirculating pump

A lubricant circulation pump (46) which is driven by an electric motor (47) is provided in the course of a circulation path (41A, 41B) for circulating lubricant oil to a wheel mounting case (19) which is rotated together with a rear wheel (7). Turning on and off the lubricant circulation pump is controlled according to rotational speed of the rear wheel. When lubricant oil in the wheel mounting case sticks on inner peripheral surfaces thereof under the influence of centrifugal force as a result of the increased vehicle speed, the electric motor is turned off to suspend operation of the lubricant circulation pump. Consequently, the lubricant circulation pump does not suck lubricant oil in the wheel mounting case through an inlet opening (42A) of an intake pipe (42), thereby preventing the lubricant circulation pump from being put in a dry idling operation.

Owner:NIHON KENKI CO LTD

Third wheel collapsing device for a golf club cart

A third wheel collapsing device for a golf club cart includes a third wheel support unit consisting of a connect base having a fitting member with an upper inclined surface, and a lock block on the upper inclined surface. A spring chamber is continually formed in both the fitting member and the lock block for receiving a spring therein. A control rod is movably fitted in a center hole of both the fitting member and the lock block and through the spring, and has its lower end pivotally connected with an eccentric plate. The eccentric plate is swung up or down to move down or move up the control rod so that the lock block is also moved down to alters its position a little to firmly contact with an inner surface of a main frame of a golf club cart or to separate from the main frame, assembling or disassembling the third wheel support unit with or from the main frame.

Owner:UNIQUE PRODS & DESIGN

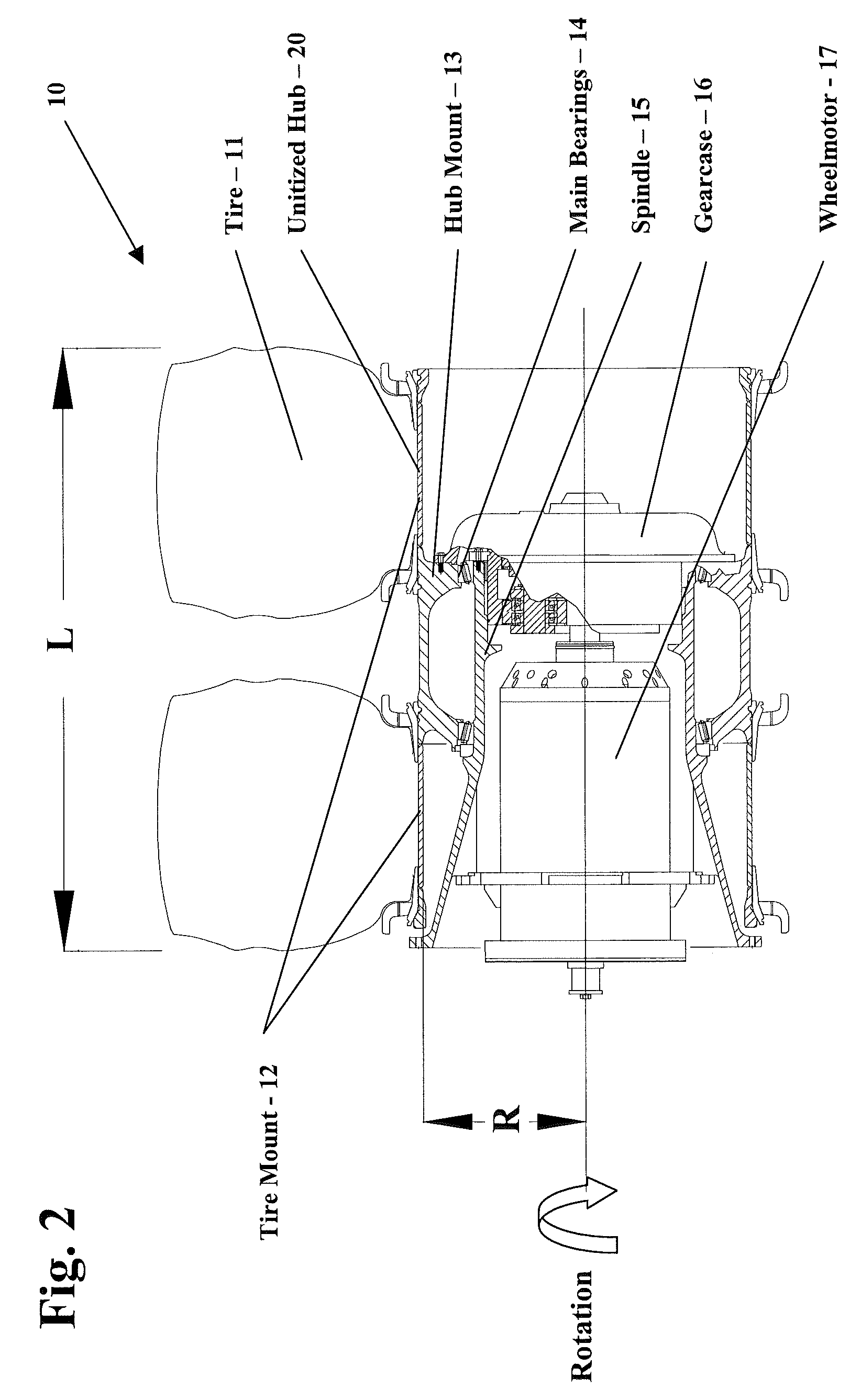

Unitized hub and rim for off-road vehicles

A hub for mounting a plurality of wheels of a vehicle, the hub including: an annular cylinder including at least two tire mounts disposed about a circumference of an outer surface of the cylinder, each of the mounts including at least one set of mounting features for receiving mounting hardware and retaining the tire. A dual wheel assembly and a vehicle are also disclosed.

Owner:BUCYRUS MINING EQUIP

Centrifugal wheel

InactiveUS20100141018A1Improve fuel economyReduce frictionRimsHigh resiliency wheelsAutomotive engineeringCentripetal force

A centrifugal wheel apparatus for a vehicle having a plurality of pivoting elements attachable to an interior of a vehicle wheel that, when subjected to centripetal force, pivot away from the vehicle wheel and toward a pneumatic tire attached to the vehicle wheel to reshape the pneumatic tire into a dome thereby decreasing surface contact between the vehicle and a surface so that the vehicle may travel with less resistance and increased economy.

Owner:MCCUE FAMILY TRUST

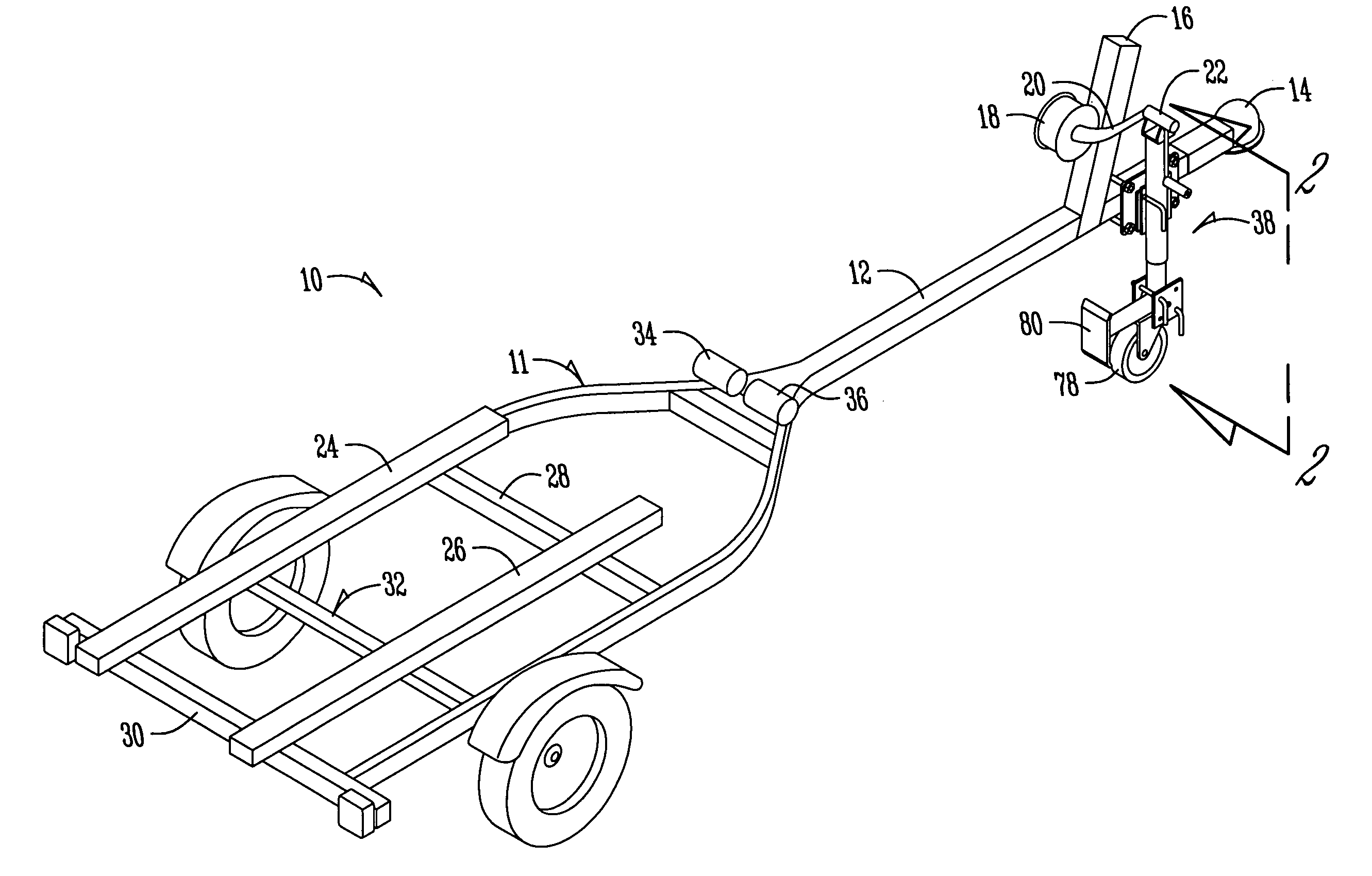

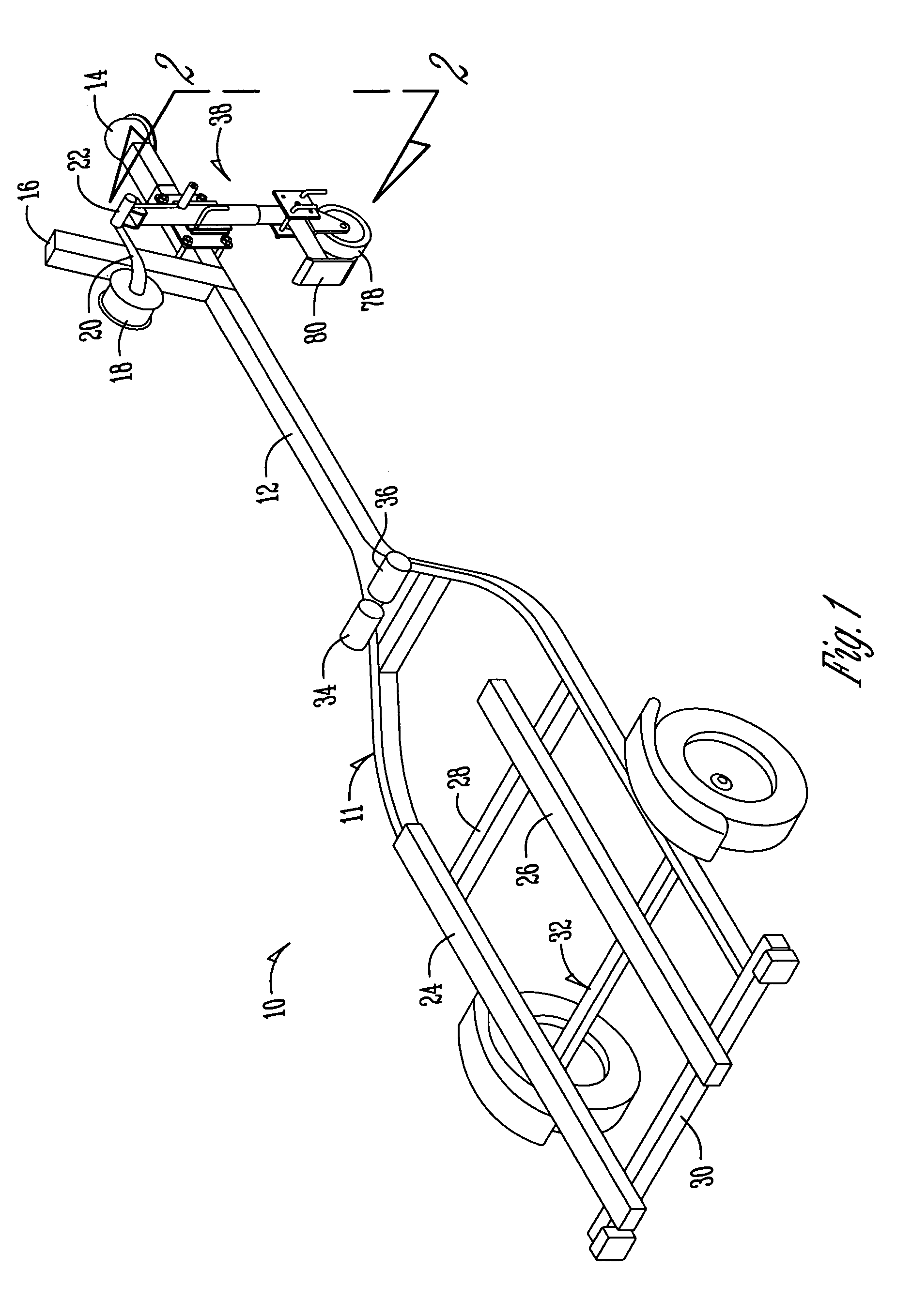

Jack stand assembly for boat trailers

InactiveUS7425012B1Vehicle fittings for lifting and manoeuvringVehicle fittings for liftingJackscrewEngineering

Owner:SEASE ANDREW E

Convertible low profile roller and support base

A low profile roller includes a wheel mounted on a hollow hub and having a roller ball mounted within the hollow hub. The roller is configured to function in a first, low profile operating mode when the roller ball is in contact with a support surface and in a second, high profile mode when the wheel is in contact with the support surface. A base for a movable support platform includes a base frame and a pivot sleeve rotatably mounted to the base frame and non-rotatably mounted to an arm connected to the hub. The pivot sleeve is configured to rotate the low profile roller from between the first mode and the second mode. A butterfly foot pedal is operably connected to the pivot sleeve.

Owner:STRYKER CORP

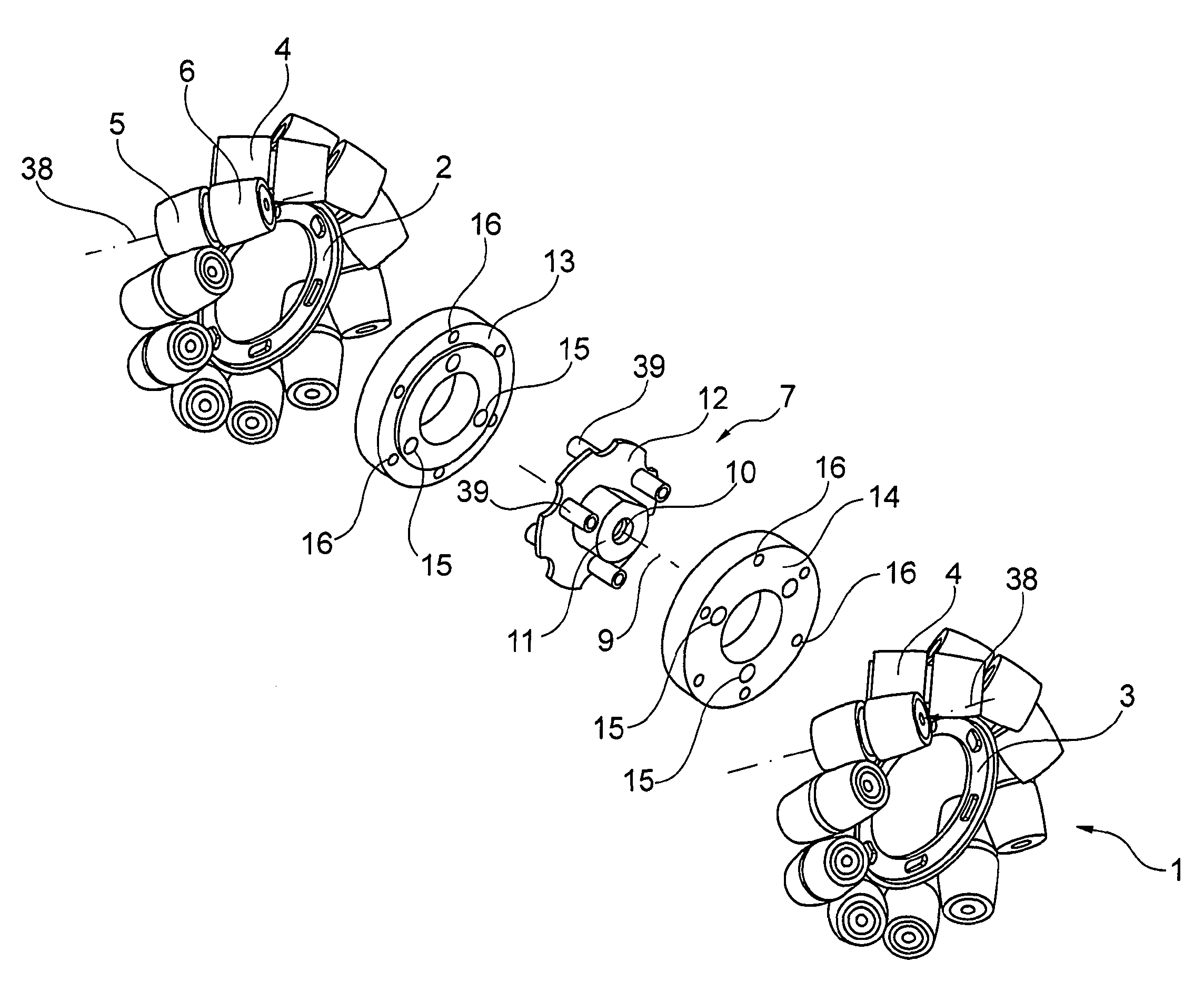

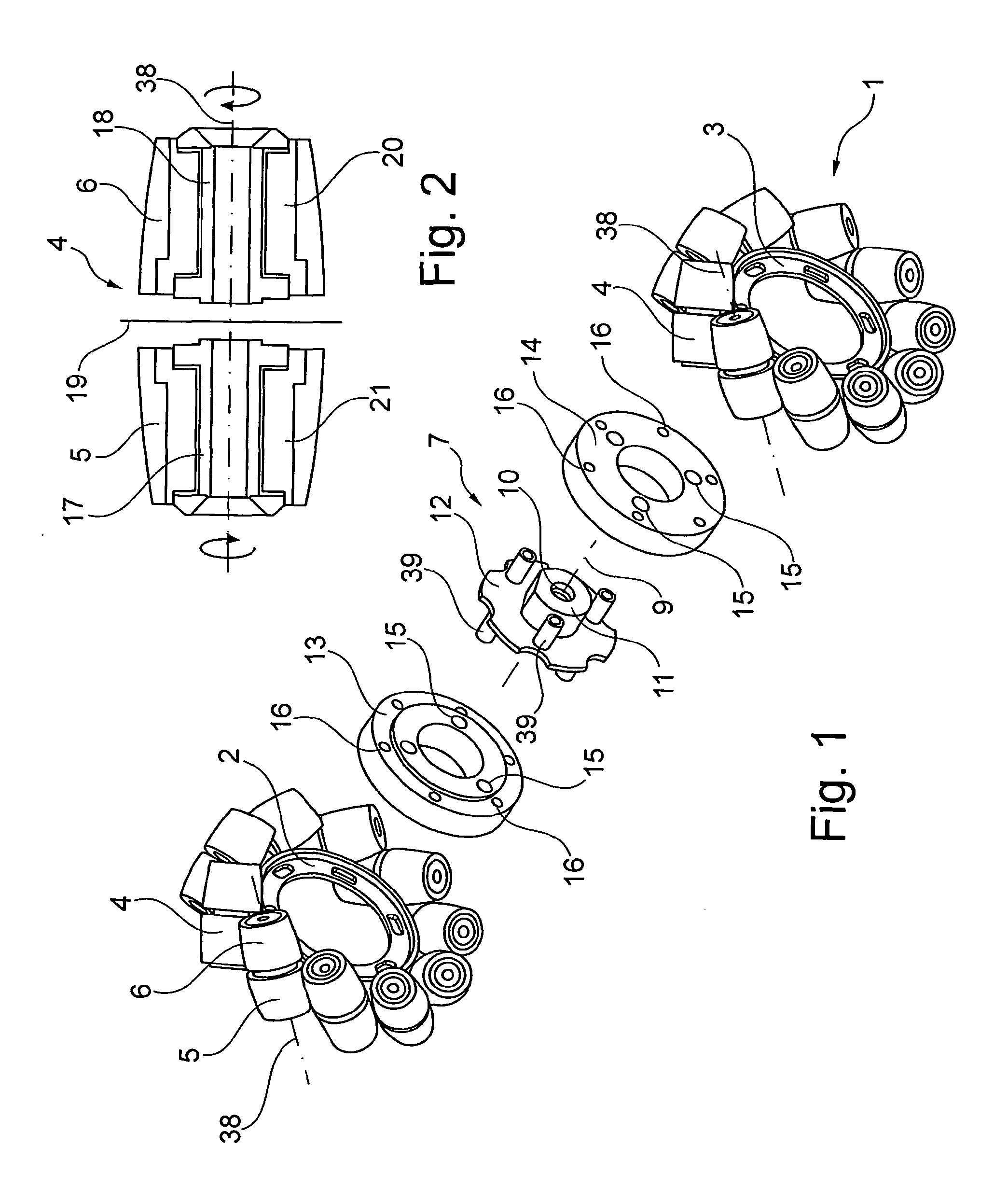

Mecanum wheel and mecanum-wheeled vehicle

A Mecanum wheel having a first wheel rim (2) which bears a multiplicity of rollers (4) which are arranged adjacent to one another in a circumferential direction and which are in each case mounted so as to be rotatable about a roller axis of rotation (38) arranged at an angle with respect to a first wheel rim axis of rotation (24), wherein said Mecanum wheel is characterized by a second wheel rim (3) which can be driven together with the first wheel rim (2) by means of a common drive shaft (33) and which bears a multiplicity of rollers (4) which are arranged adjacent to one another in a circumferential direction and which are in each case mounted so as to be rotatable about a roller axis of rotation (38) arranged at an angle with respect to a second wheel rim axis of rotation (25), which second wheel rim is connected to the first wheel rim (2) via damping means (7) formed so as to permit a limited relative movement of the first and the second rim (3) relative to one another. It is provided according to the invention that the damping means (7) are formed so as to permit a damped, limited relative movement between the first and the second wheel rim (2, 3) in the circumferential direction and / or perpendicular to a Mecanum wheel axis of rotation (9) and / or perpendicular to the first and / or to the second wheel rim axis of rotation (25) and / or at a tilt angle relative to one another.

Owner:OMNIROLL

All terrain adapter for a wheelchair

ActiveUS8152192B2Improve stabilityEasy and safe installation and removalWheelchairs/patient conveyanceMultiple wheel assemblyWheelchairFoot supports

An all terrain adapter for a wheelchair that removably clamps onto the foot support of the wheelchair and supports a relatively large diameter, slightly inclined swivelling nose gear wheel at an extended distance from the foot support to stabilize the wheelchair when it is being pushed over soft or uneven surfaces and which swivels around when the wheelchair is moved forward to lift the front wheels of the wheelchair clear of the ground.

Owner:DOUGHERTY PAT

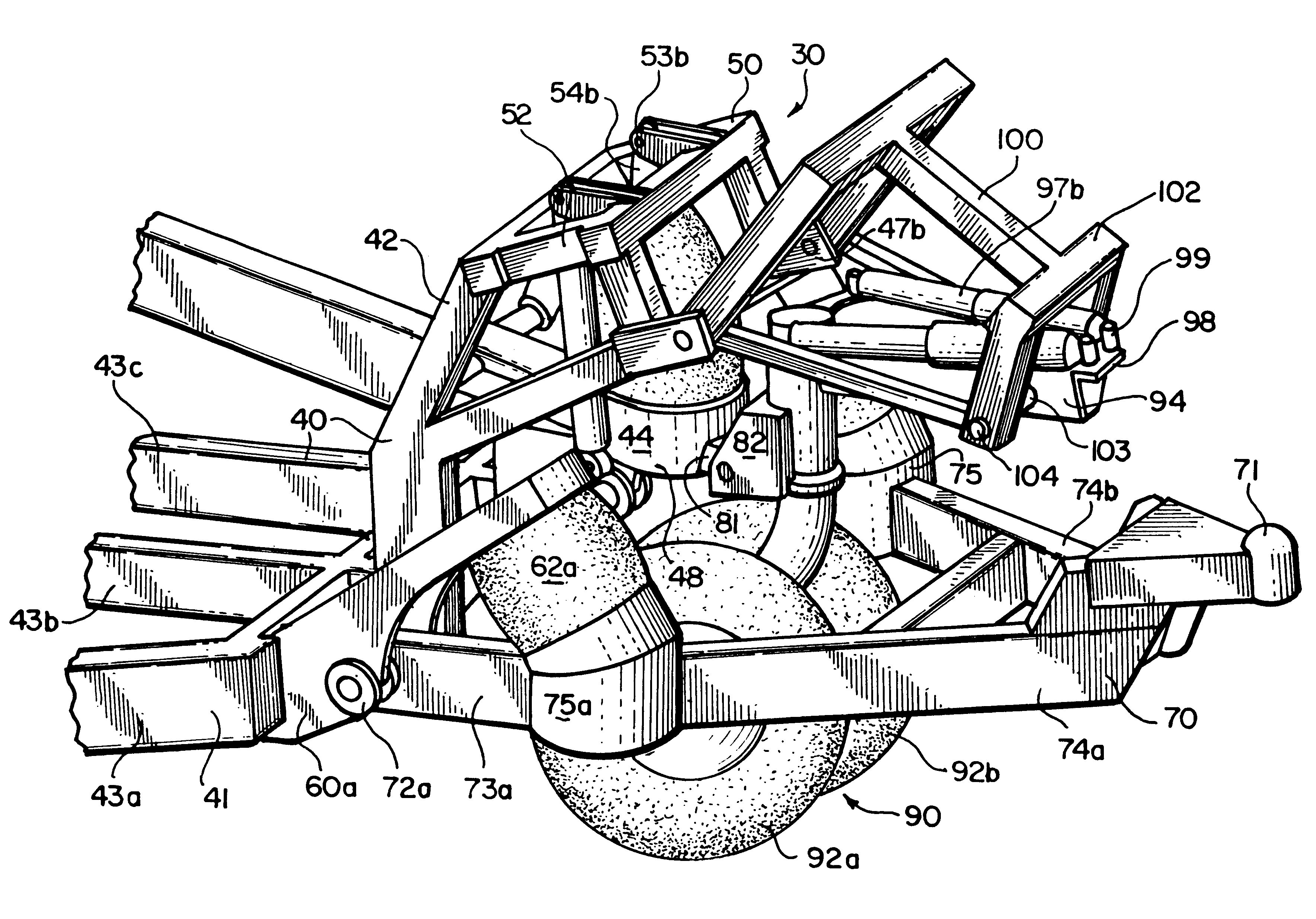

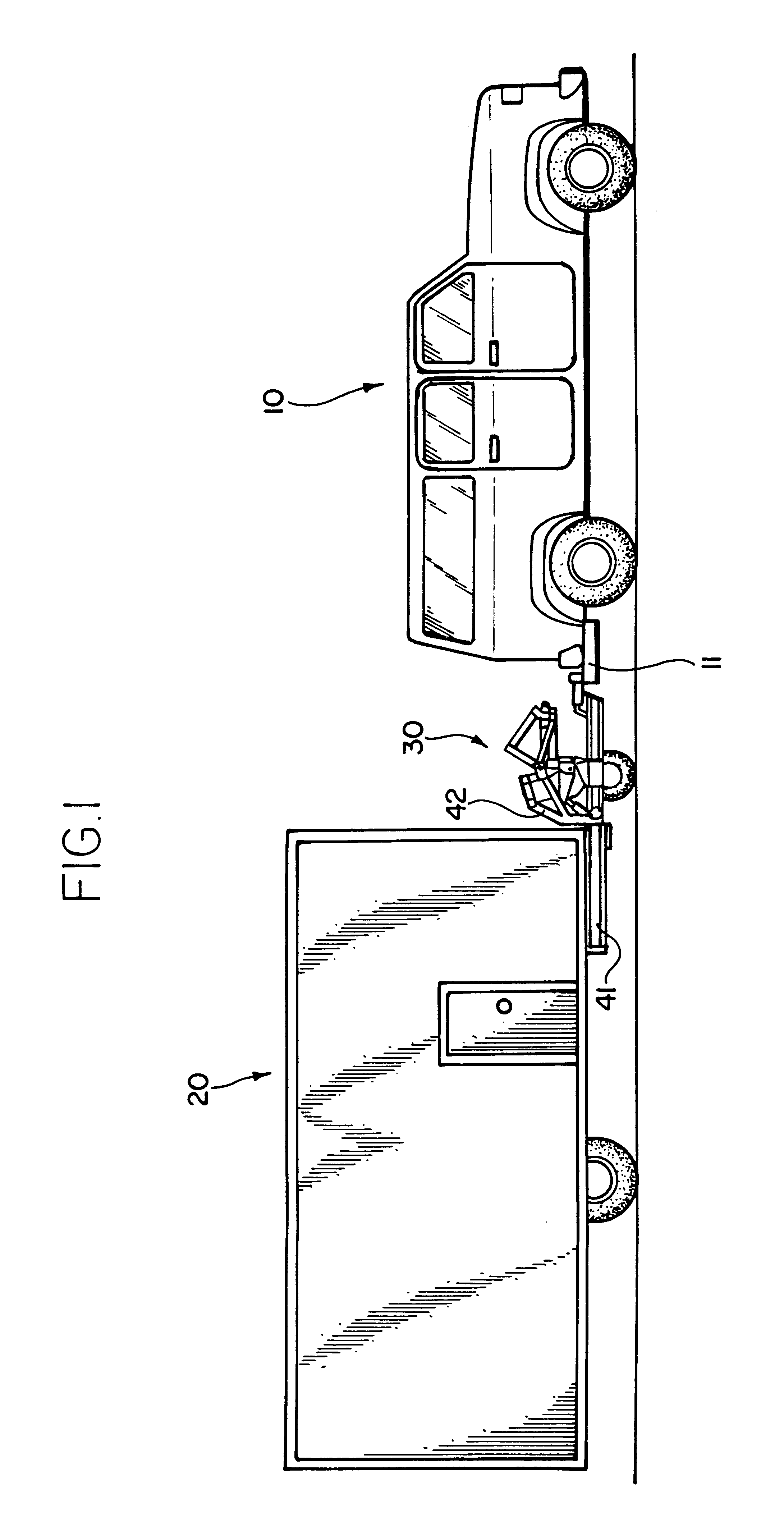

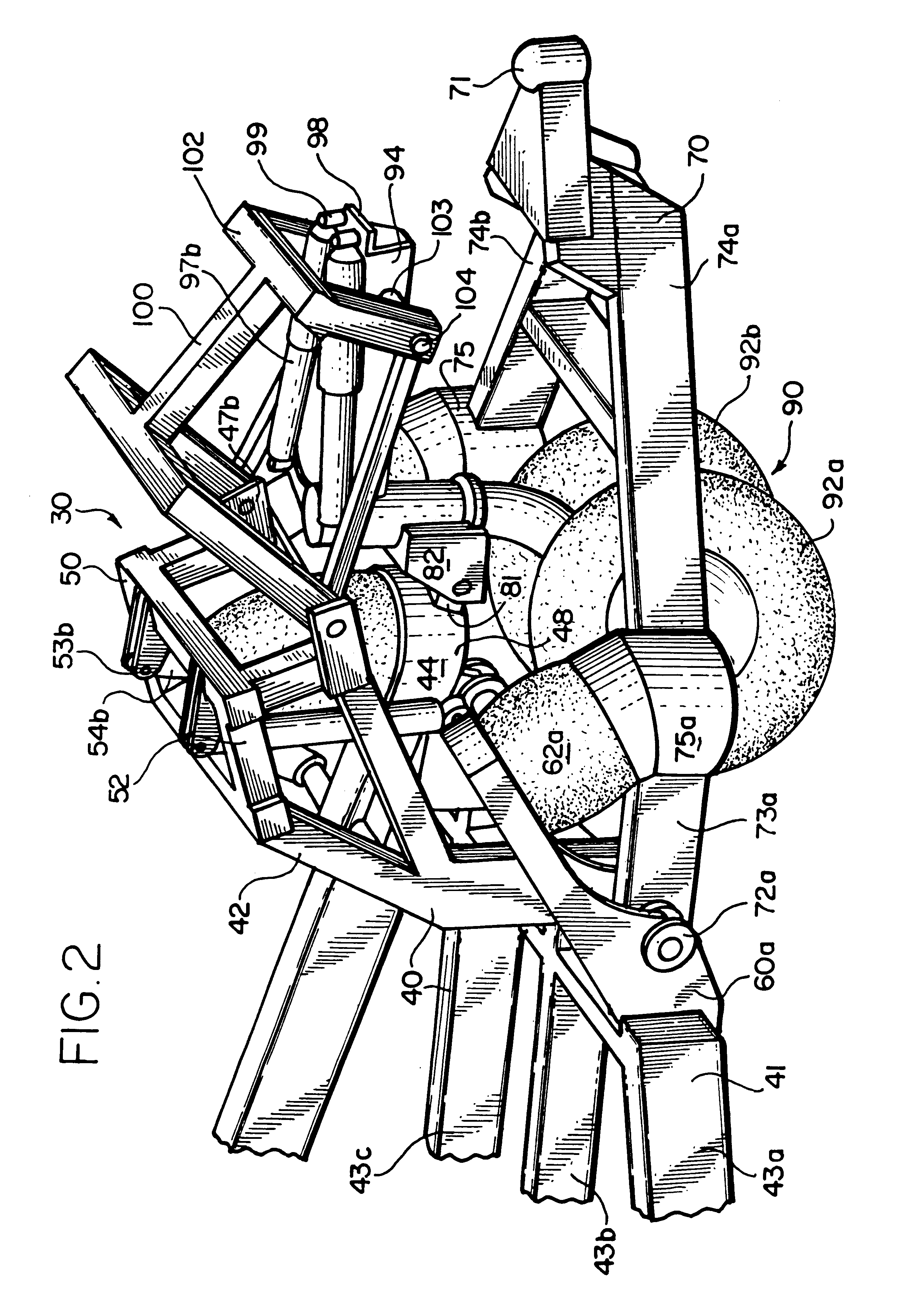

Trailer hitch assembly

InactiveUS6182997B1Easy to adjustEasy to liftTractor-trailer combinationsTowing devicesConstant loadEngineering

Towing apparatus for connecting a trailer with a towing vehicle. The towing apparatus is adapted to bear part of the weight of the trailer, thus lessening the load on the towing vehicle. This is accomplished by providing a wheel assembly on the towing apparatus which is operatively connected to an adjustable main spring which supports most of the weight of the trailer which would normally bear on the hitch of the towing vehicle. Unlike conventional towing systems, wherein the trailer tongue is rigidly attached to the trailer, the towing apparatus of the present invention employs a pivotally-mounted trailer tongue which is maintained in a horizontal position by an adjustable secondary spring or springs. The use of main and secondary springs presents a relatively constant load to the trailer hitch, even when the trailer is being towed across rough or uneven surfaces.

Owner:EZ TOW A DELAWARE

Traveling drive unit for working vehicle

ActiveUS8155834B2Preventing dry idling operationEasy to useGearboxesDigital data processing detailsCentrifugal forceCirculating pump

A lubricant circulation pump (46) which is driven by an electric motor (47) is provided in the course of a circulation path (41A, 41B) for circulating lubricant oil to a wheel mounting case (19) which is rotated together with a rear wheel (7). Turning on and off the lubricant circulation pump is controlled according to rotational speed of the rear wheel. When lubricant oil in the wheel mounting case sticks on inner peripheral surfaces thereof under the influence of centrifugal force as a result of the increased vehicle speed, the electric motor is turned off to suspend operation of the lubricant circulation pump. Consequently, the lubricant circulation pump does not suck lubricant oil in the wheel mounting case through an inlet opening (42A) of an intake pipe (42), thereby preventing the lubricant circulation pump from being put in a dry idling operation.

Owner:NIHON KENKI CO LTD

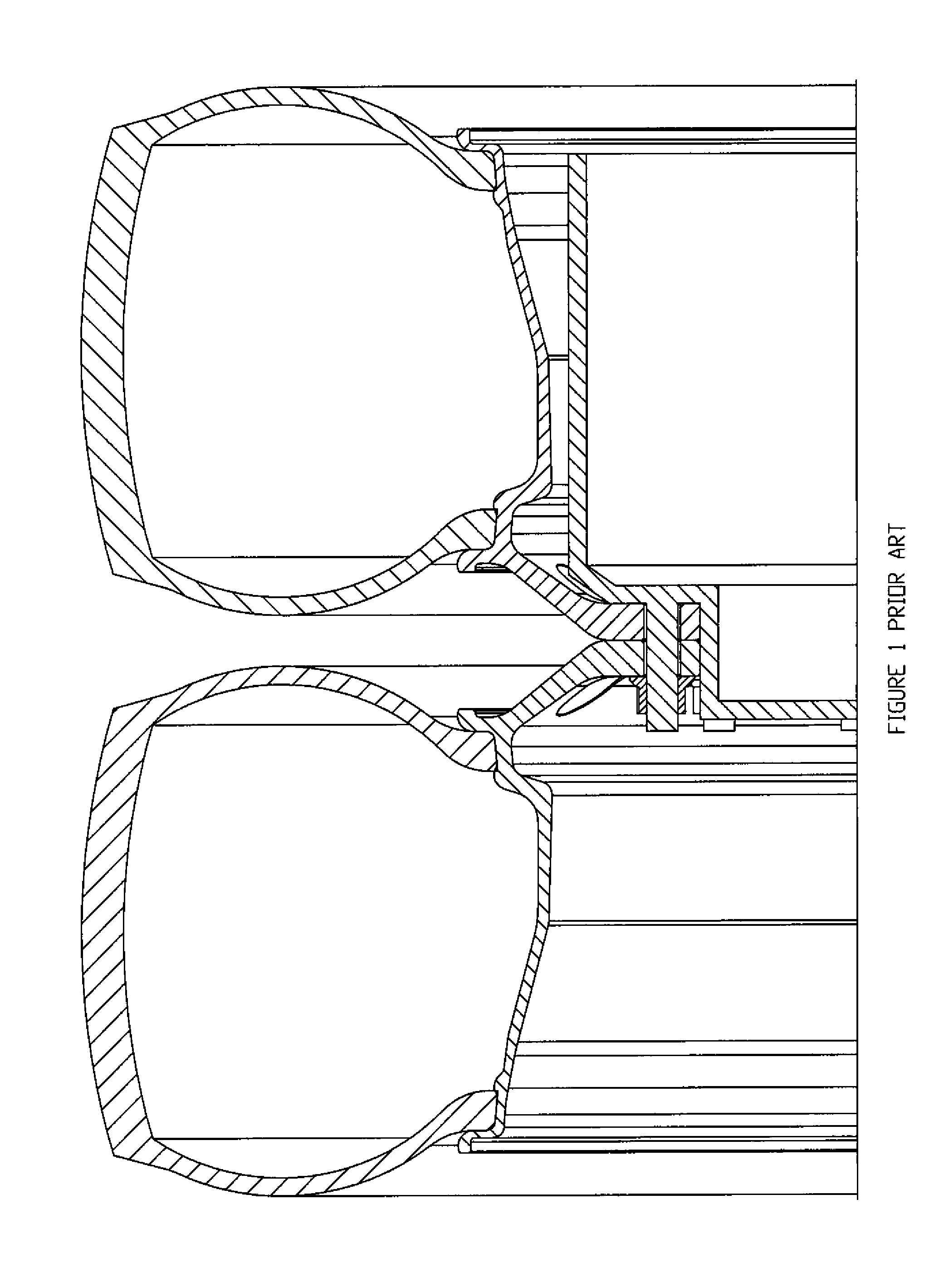

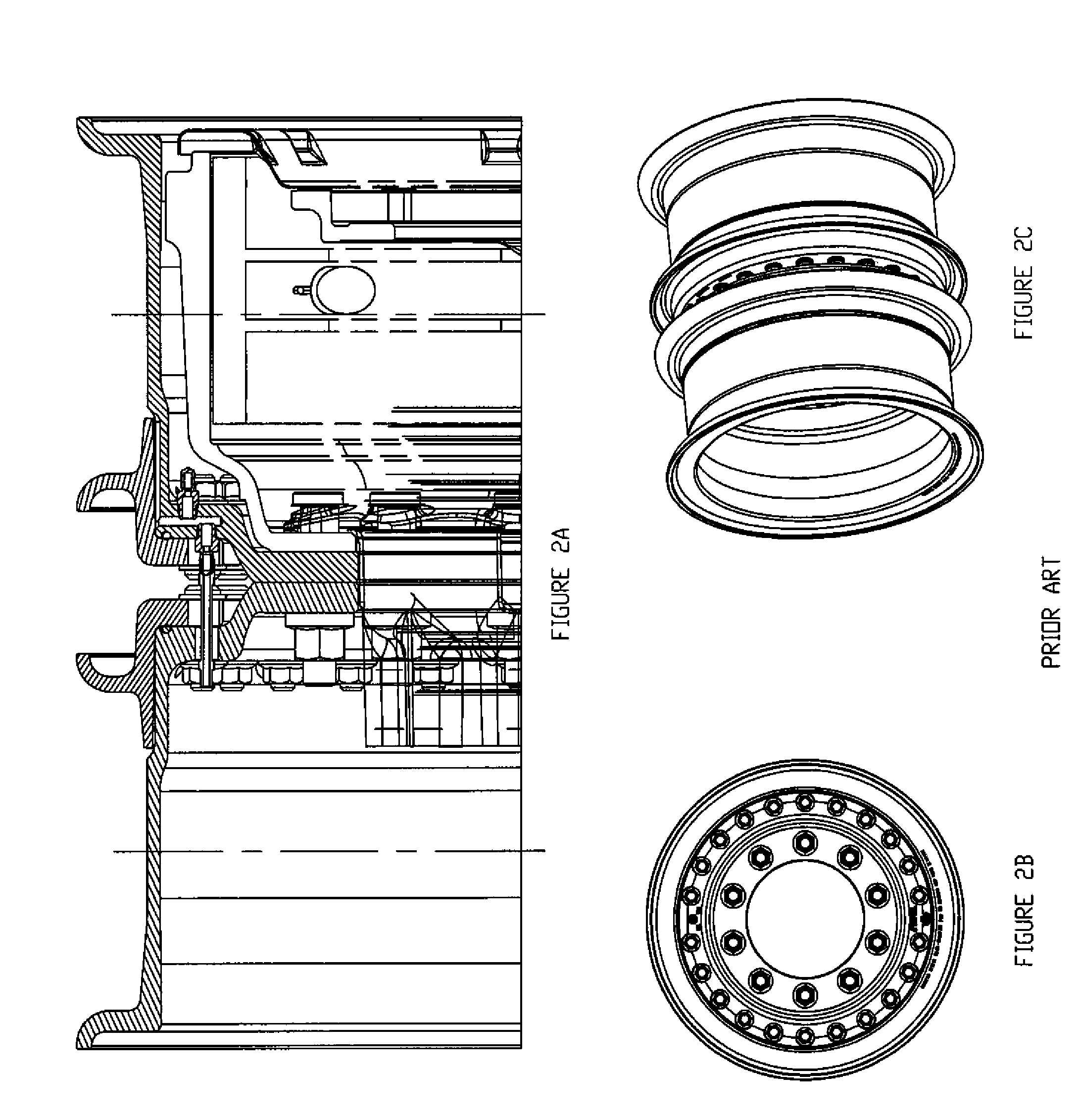

Dual wheels with common hub adapter

A dual wheel assembly for a vehicle having a common hub adapter. The assembly includes an inner wheel having an inner rim; an outer wheel having an outer rim; and a hub portion having a central cylindrical portion disposed between first and second end face portions, wherein the inner rim is mounted to the first end portion, and the outer rim is mounted to the second end face portion. The assembly may further include radially spaced apart holes disposed on the central cylindrical portion, wherein the spaced apart holes have end openings on opposite sides thereof and first and second fasteners extending in opposite directions in an alternating arrangement from the first and second end portions of the hub portion. Each of the first fasteners extends through an end opening of a spaced apart hole and the inner rim, and each of the second fasteners extends through an end opening of a spaced apart hole and the outer rim.

Owner:HUTCHINSON SA

Foreign matter removing device

InactiveUS7131670B2Reliable removalGood removal effectVehicle cleaningMultiple wheel assemblyForeign matterExtremity Part

A foreign matter removing device which is capable of reliably removing foreign matter from between a double tire includes at least one foreign matter removing member interposed in a space of at least one double tire. A dimension in a width direction of the foreign matter removing member in a vicinity of a tip end portion thereof is larger than a dimension in a diameter direction from an outer peripheral portion of a hub, on which the double tire is fitted, to an outer peripheral portion of a rim of at least the one double tire.

Owner:KOMATSU LTD

Freestanding self-propelled device for moving objects

InactiveUS6938711B2Eliminate strainEasy to operateWheelchairs/patient conveyanceTractorsMotor driveDrive wheel

A freestanding self-propelled device for moving objects. The device includes a chassis having lower frame portions and upright frame portions. A single motor-driven drive wheel is centrally located between the lateral ends of the chassis and coupled to the chassis so as to be pivotable about a substantially vertical axis. The drive wheel is located between sets of support wheels coupled to the lower frame portion of the chassis. In combination, the drive wheel and the support wheels result in the device being freestanding. The drive wheel projects below the sets of support wheels so that the device is supported by the drive wheel and by only one of each set of support wheels at any given time, thereby establishing a three-point contact with the surface supporting the device. A tiller equipped with controls is pivotably coupled to the drive wheel for pivoting the drive wheel about its vertical axis.

Owner:PIPP MOBILE STORAGE SYST

Dual wheelend for a vehicle

An axle assembly for a vehicle comprising a stationary spindle and a rotatable axle shaft. An intermediate hub is supported on the spindle. Adjacent inner and outer wheel hubs are supported on the intermediate hub. A differential mechanism interconnects the inner and outer wheel hubs for driving both of the wheel hubs and for permitting relative rotation between the wheel hubs. At least one differential bushing is disposed between the differential mechanism and the intermediate hub. A gear reduction system interconnects the intermediate hub and the axle shaft for providing torque multiplication. A wet disc brake device is coupled between the spindle and the intermediate hub.

Owner:AXLETECH INT IP HLDG

Popular searches

Registering/indicating working of vehicles Monocoque constructions Special data processing applications Propulsion unit arrangements Passenger vehicle superstructures Loading-carrying vehicle superstructures Electric devices Error detection/correction Pedestrian/occupant safety arrangement Wing accessories

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com