Paint for thermal insulating outer wall

A technology for thermal insulation of external walls and thermal insulation materials, applied in the direction of anti-corrosion coatings, rosin coatings, coatings, etc., can solve the problems of inability to meet market demand, poor thermal insulation and other performance, and achieve enhanced anti-corrosion and crack resistance, excellent thermal insulation Good effect with sound insulation performance and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

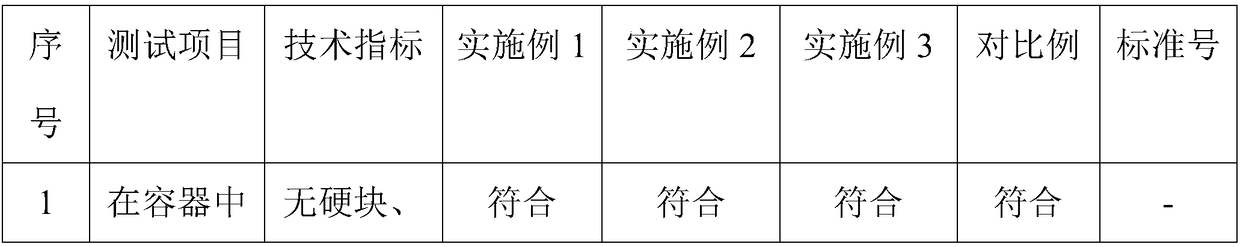

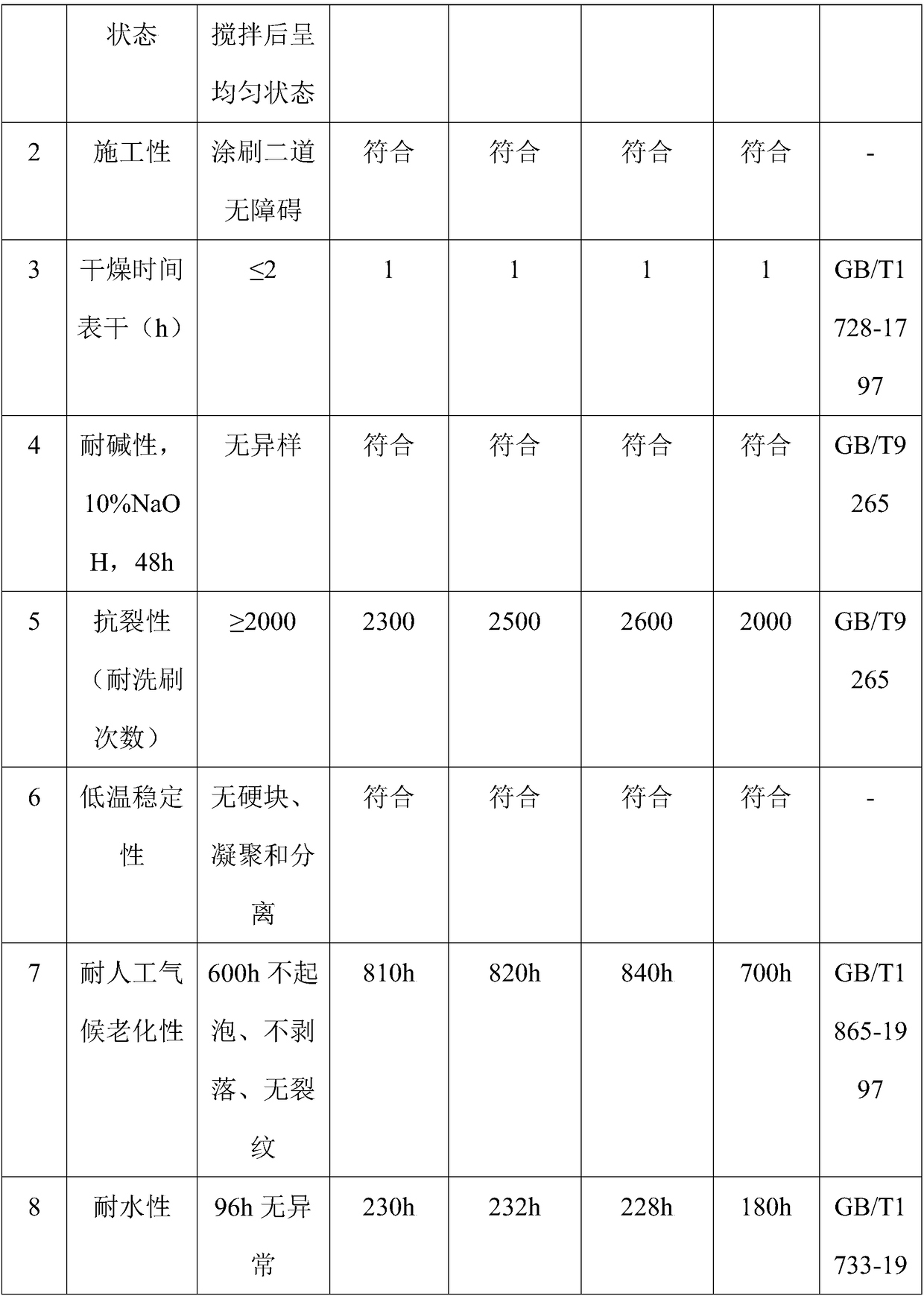

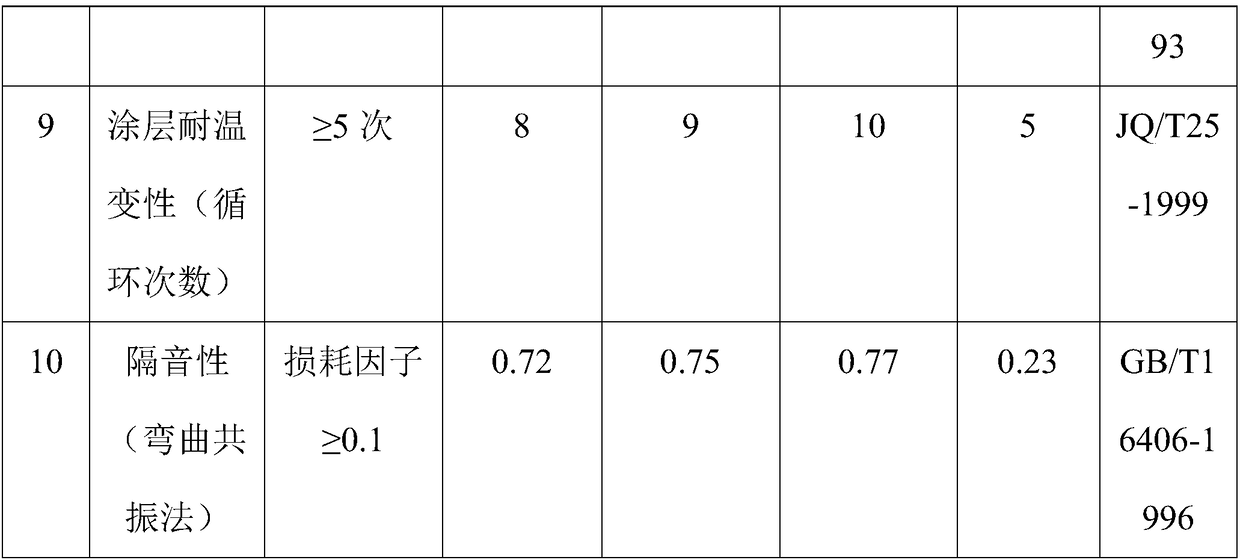

Examples

Embodiment 1

[0014] A coating for thermal insulation exterior walls, its raw materials include by weight: 25 parts of rosin resin, 2 parts of thermal insulation material, 10 parts of heavy calcium, 3 parts of nickel powder, 5 parts of vanillin, 1 part of zinc stearate, acrylic modified 15 parts of permanent resin latex, 4 parts of butyl acetate, 1 part of leveling agent, 6 parts of starch ether, and 90 parts of deionized water.

Embodiment 2

[0016] A kind of coating for thermal insulation exterior wall, its raw material comprises by weight: 10 parts of rosin resin, 7 parts of thermal insulation material, 5 parts of heavy calcium, 8 parts of nickel powder, 2 parts of vanillin, 4 parts of zinc stearate, acrylic modified 35 parts of permanent resin latex, 1 part of butyl acetate, 5 parts of leveling agent, 2 parts of starch ether, 60 parts of deionized water;

[0017] Wherein, the thermal insulation material includes fly ash, sulfuric acid, floating beads, basalt fiber, and coupling agent.

Embodiment 3

[0019] A kind of coating for thermal insulation exterior wall, its raw material comprises by weight: 17 parts of rosin resin, 5 parts of thermal insulation material, 7 parts of heavy calcium, 5 parts of nickel powder, 3.5 parts of vanillin, 3.5 parts of zinc stearate, acrylic modified 20 parts of permanent resin emulsion, 2.5 parts of butyl acetate, 3 parts of leveling agent, 4 parts of starch ether, 70 parts of deionized water;

[0020] Wherein, the thermal insulation material includes fly ash, sulfuric acid, floating beads, basalt fiber, and coupling agent;

[0021] The weight ratio of the fly ash, sulfuric acid, floating beads, basalt fiber and coupling agent is 1:1:0.6:0.5:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com