Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "No bloating issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

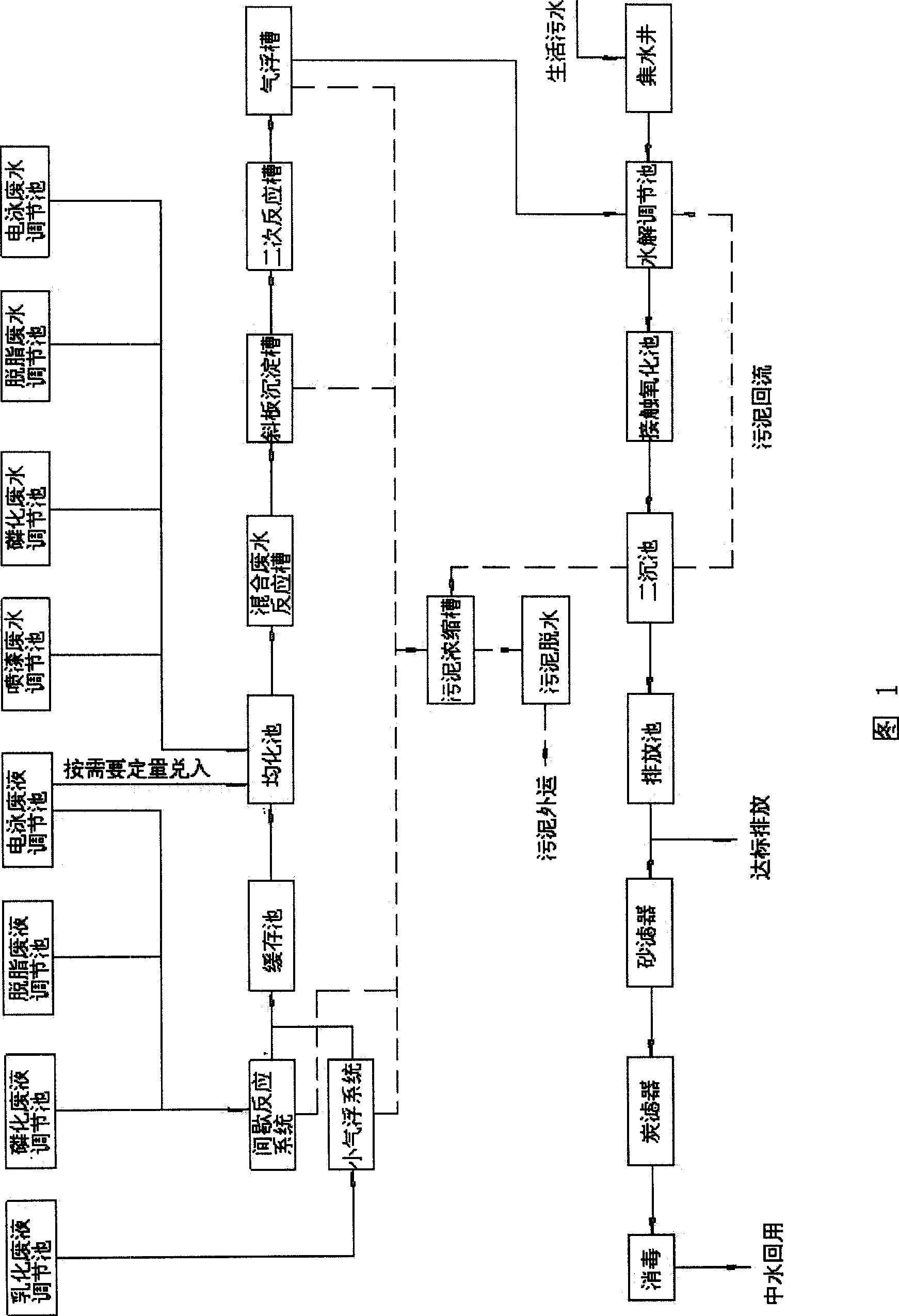

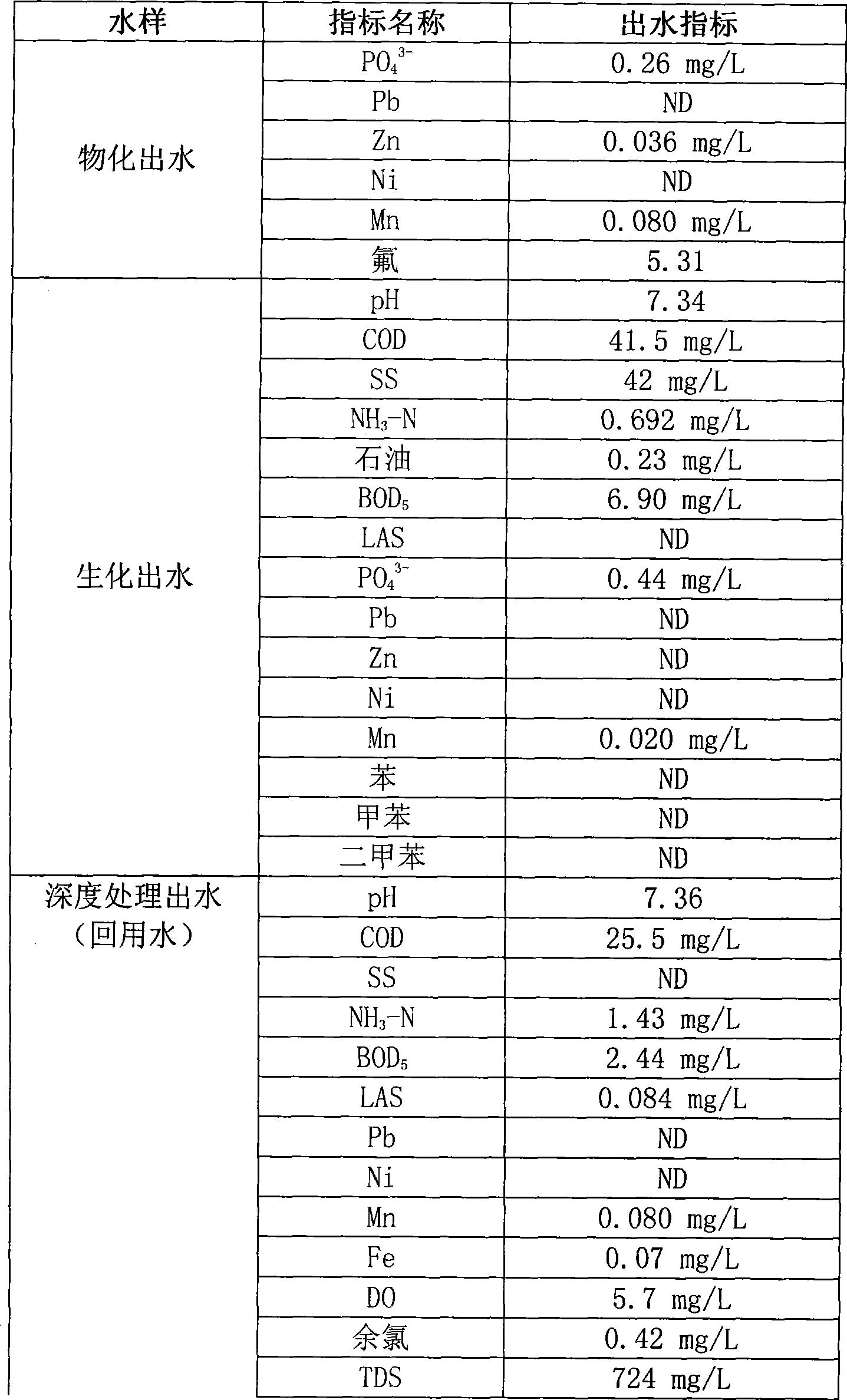

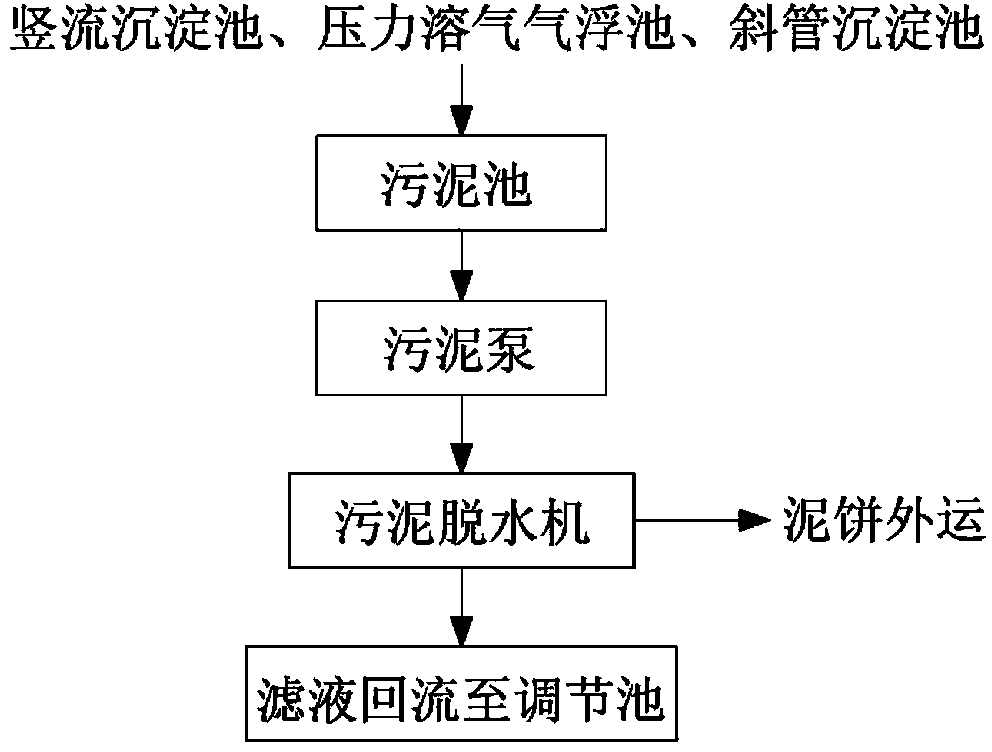

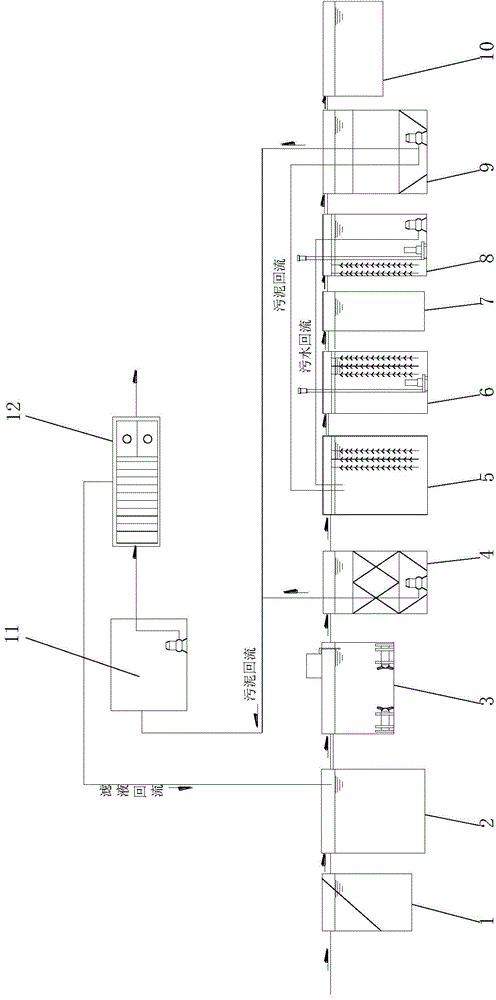

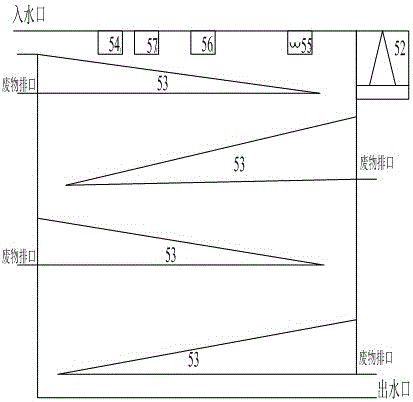

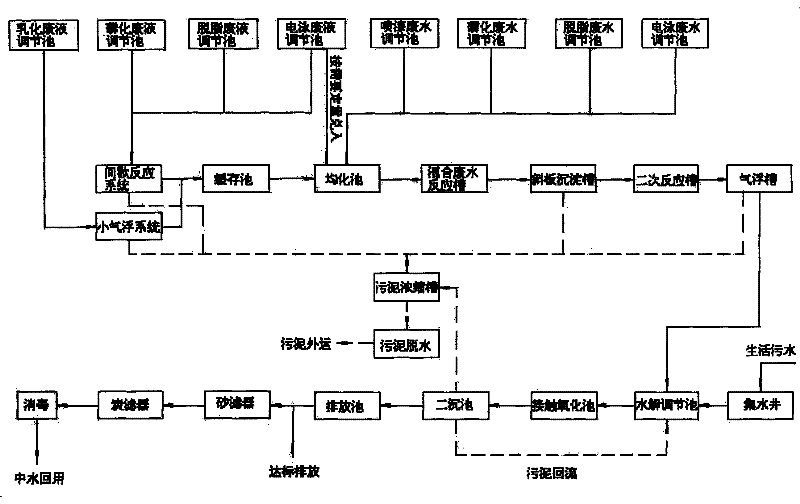

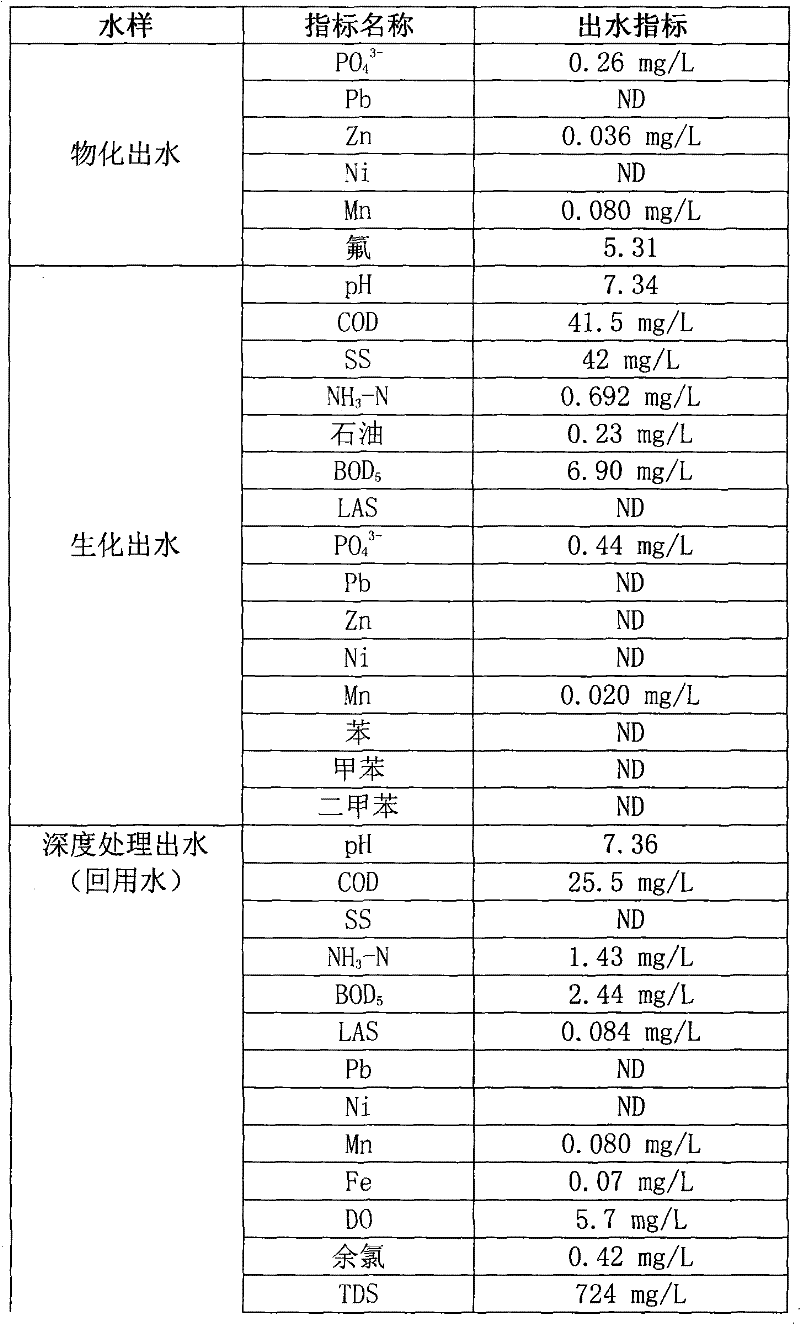

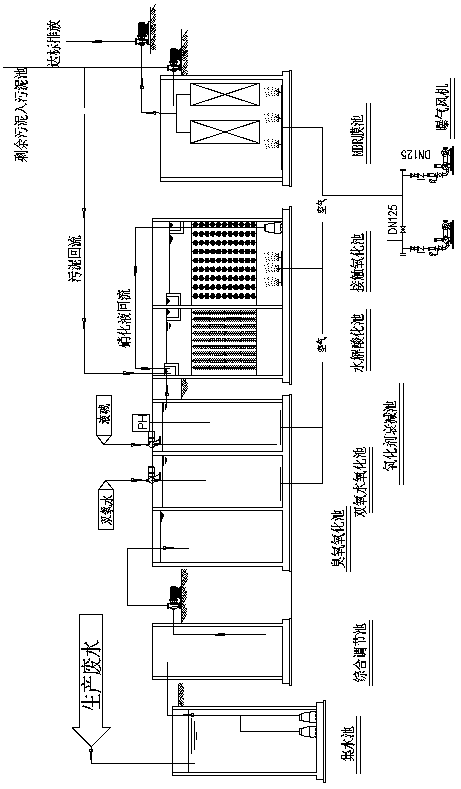

Automobile manufacturer wastewater treatment method

ActiveCN101456647AEasy to handleHigh activityTreatment using aerobic processesDispersed particle separationOperational costsIndustrial waste water

The invention relates to a method for treating wastewater and discloses a method for treating wastewater in an automobile manufacturing plant. A method of pretreatment, two-stage physicochemical treatment, biochemical treatment and advanced treatment is adopted to treat wastewater. The method for treating wastewater in the automobile manufacturing plant has little investment, small occupied area and low operating cost and has good integrated treatment effect on industrial wastewater and domestic sewage discharged from the automobile manufacturing plant.

Owner:SHANGHAI YIKE GREEN ENG

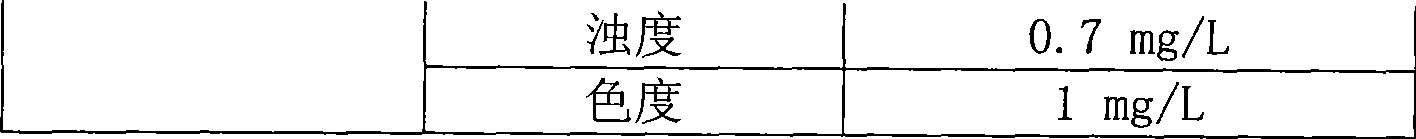

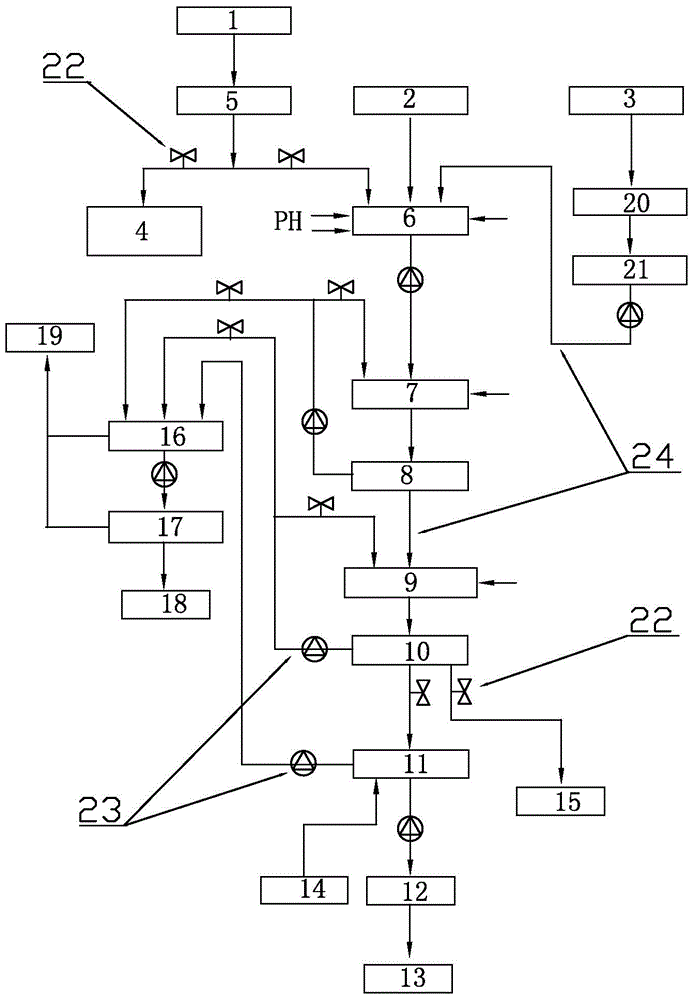

Kitchen waste filtrate treatment equipment and method

ActiveCN103435235AImprove CODHigh oil contentFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSludgeFiltration

The invention discloses kitchen waste filtrate treatment equipment and method. The treatment method comprises the steps that the kitchen filtrate firstly enters an oil separation tank used for separating oil substances from water substances; the water after separation is converged into a regulating tank and the water quality and quantity are regulated; the effluent enters a reaction tank, PAC (polyaluminium chloride) and PAM (polyacrylamide) are added to the effluent, so that fine particles in the water form a plenty of alum flocs, and then the alum flocs precipitate to be separated in a precipitation tank, thus removing most oil and scum; the effluent from the precipitation tank automatically flows into a neutralization tank, the pH value is regulated to neutral and then the effluent enters a pressure dissolved air floatation tank used for removing the scum formed by the flocculated suspended matter particles or oil particles brought on the water surface from the wastewater; then the pollutants such as organic matters, ammonia nitrogen and the like are removed by the pretreatment+anaerobic+aerobic precipitation+sand filtration technology of an exclusively added backflow sludge contact reactor; finally the wastewater reaches discharge standard.

Owner:裕英(北京)生物科技有限公司

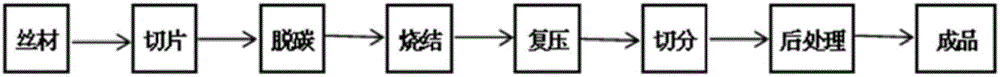

Preparation technology of high-braded-rate vertical fiber silver graphite electric contact

ActiveCN106098443ANo bloating issuesImprove anti-burn performanceElectric switchesElectricityCarbon layer

The invention discloses a preparation technology of a high-braded-rate vertical fiber silver graphite electric contact, which comprises the working procedures of (1) slicing a silver graphite wire material containing vertical fibers; (2) carrying out decarburization; (3) loading the decarburized vertical fiber silver graphite material into a sintering furnace; (4) re-pressing; (5) cutting an embossed vertical fiber silver graphite sheet into two parts so as to acquire a vertical fiber silver graphite contact with one side being a vertical fiber silver graphite surface and the other side being a decarburized silver layer; (6) grinding the cut vertical fiber silver graphite contact in a grinder into which an abrasive is added, polishing and dewatering; and (7) drying the dewatered vertical fiber silver graphite contact by using a drying oven so as to acquire a final finished product. The technology disclosed by the invention can enable the decarburized layer of the vertical fiber silver graphite to be sintered, so that the structure of the decarburized layer is changed, air holes generated inside the decarburized layer because of decarburization are eliminated, and the welding quality of decarburized silver graphite products is greatly improved under the same welding condition.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

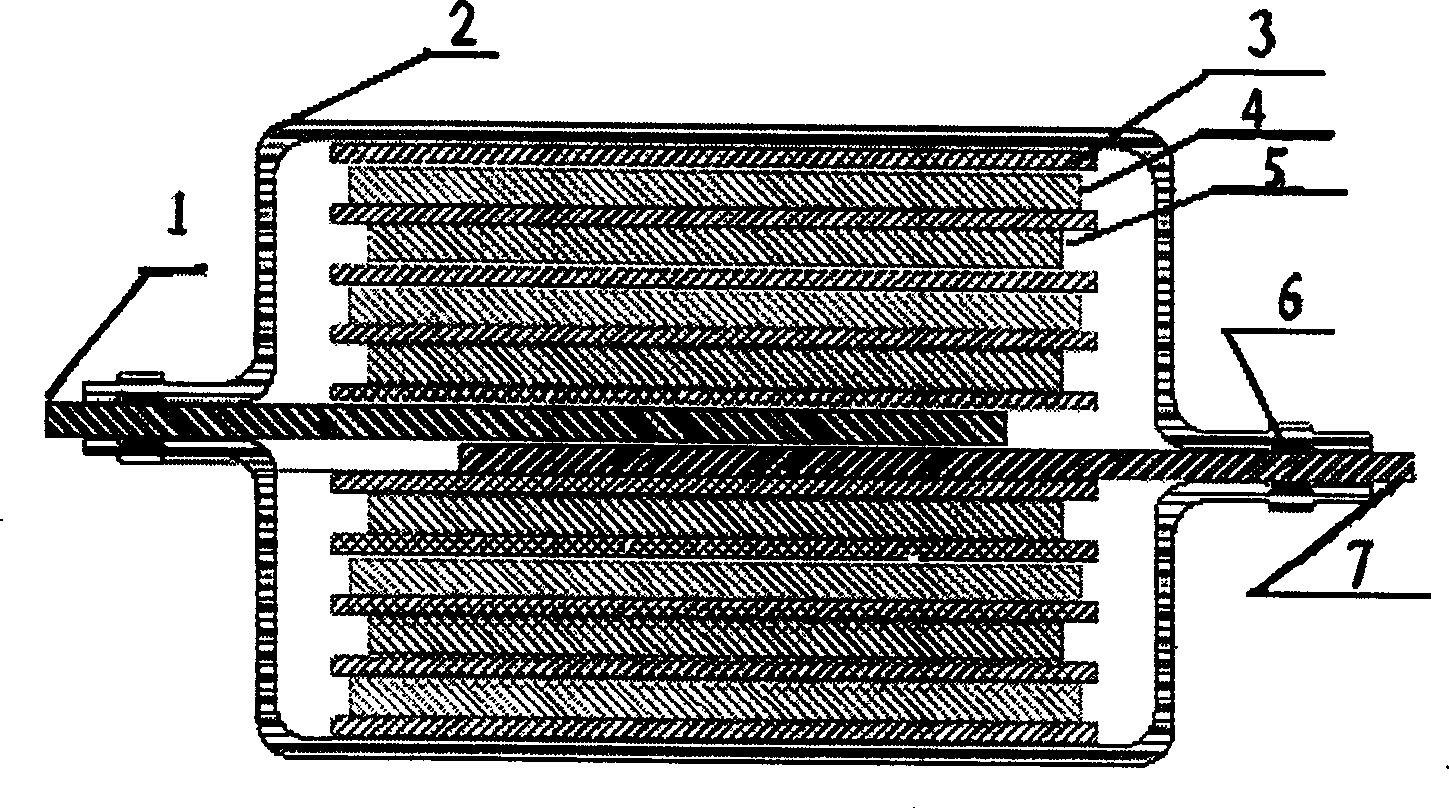

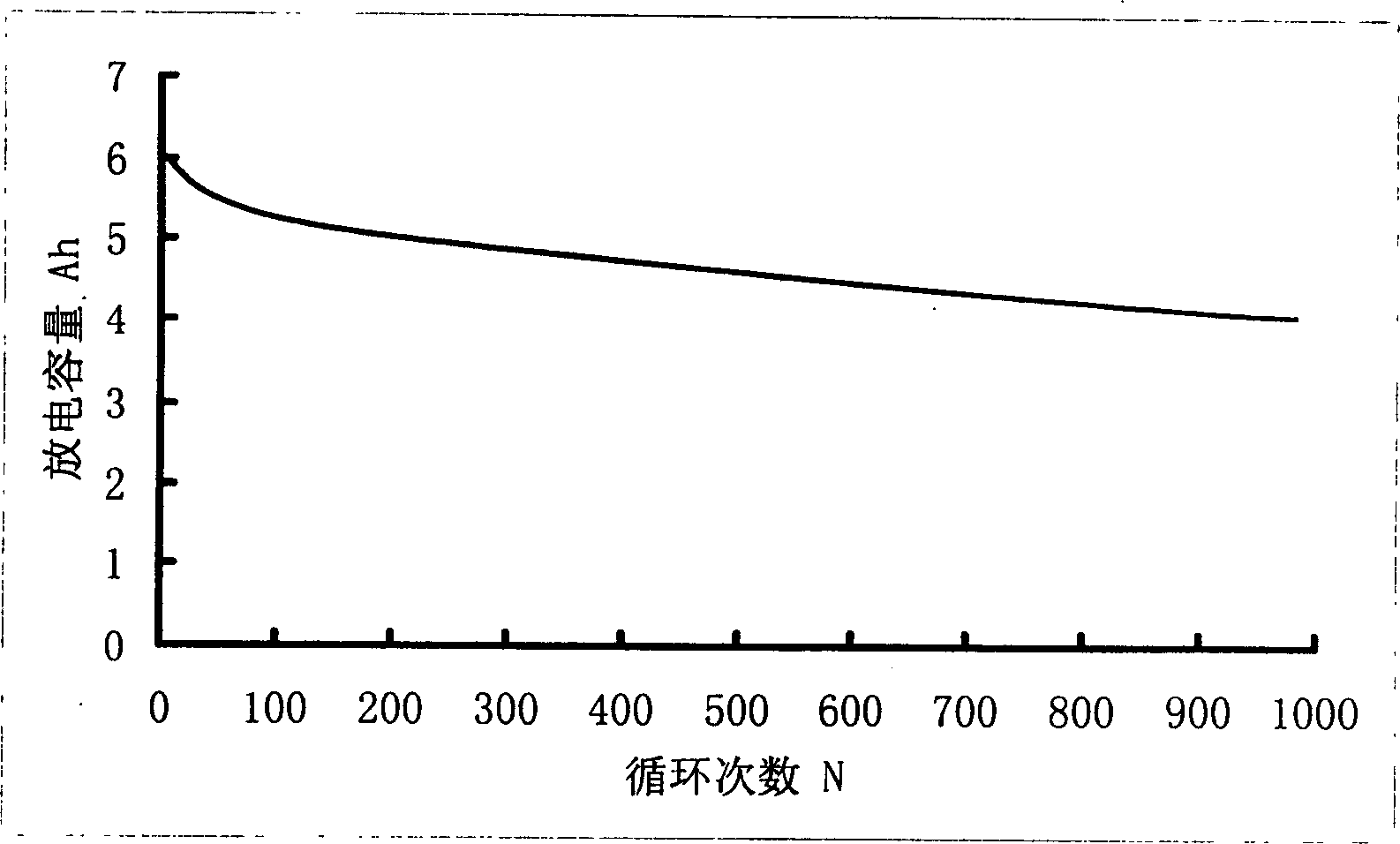

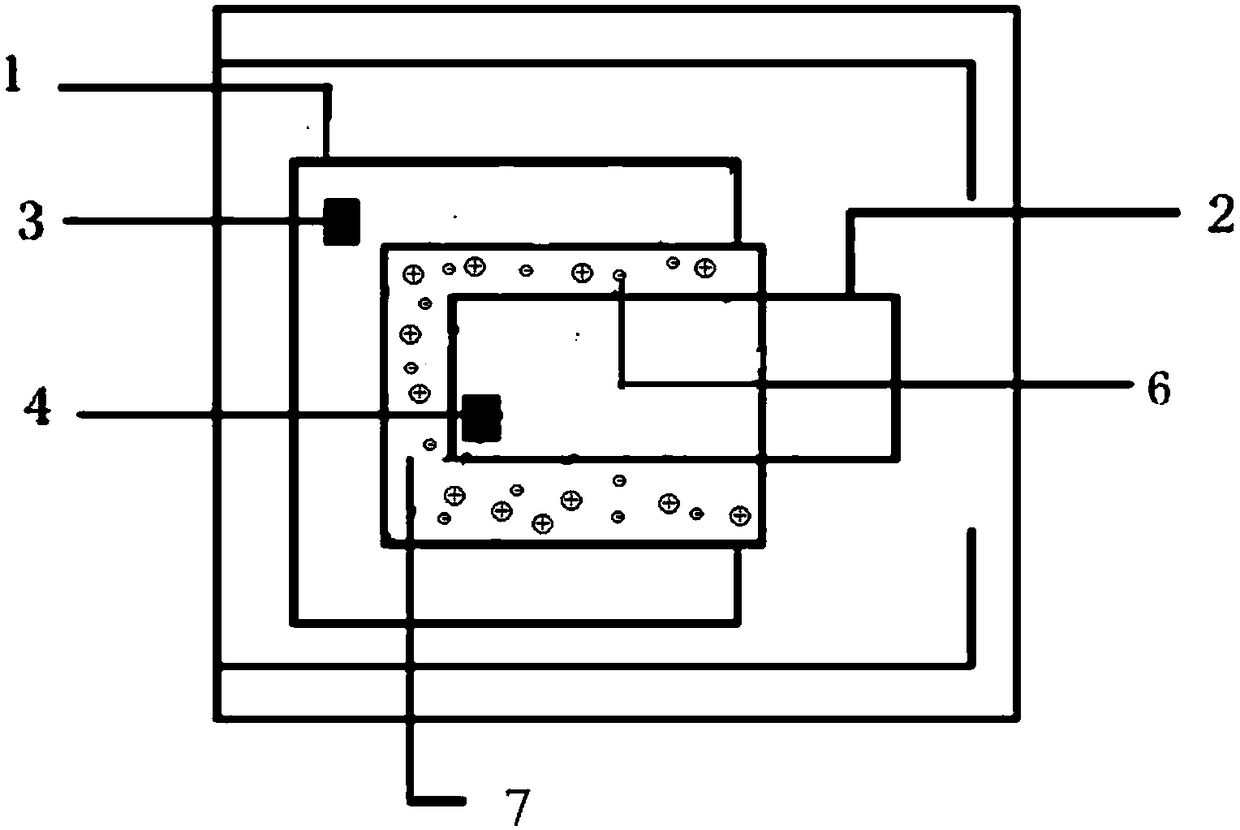

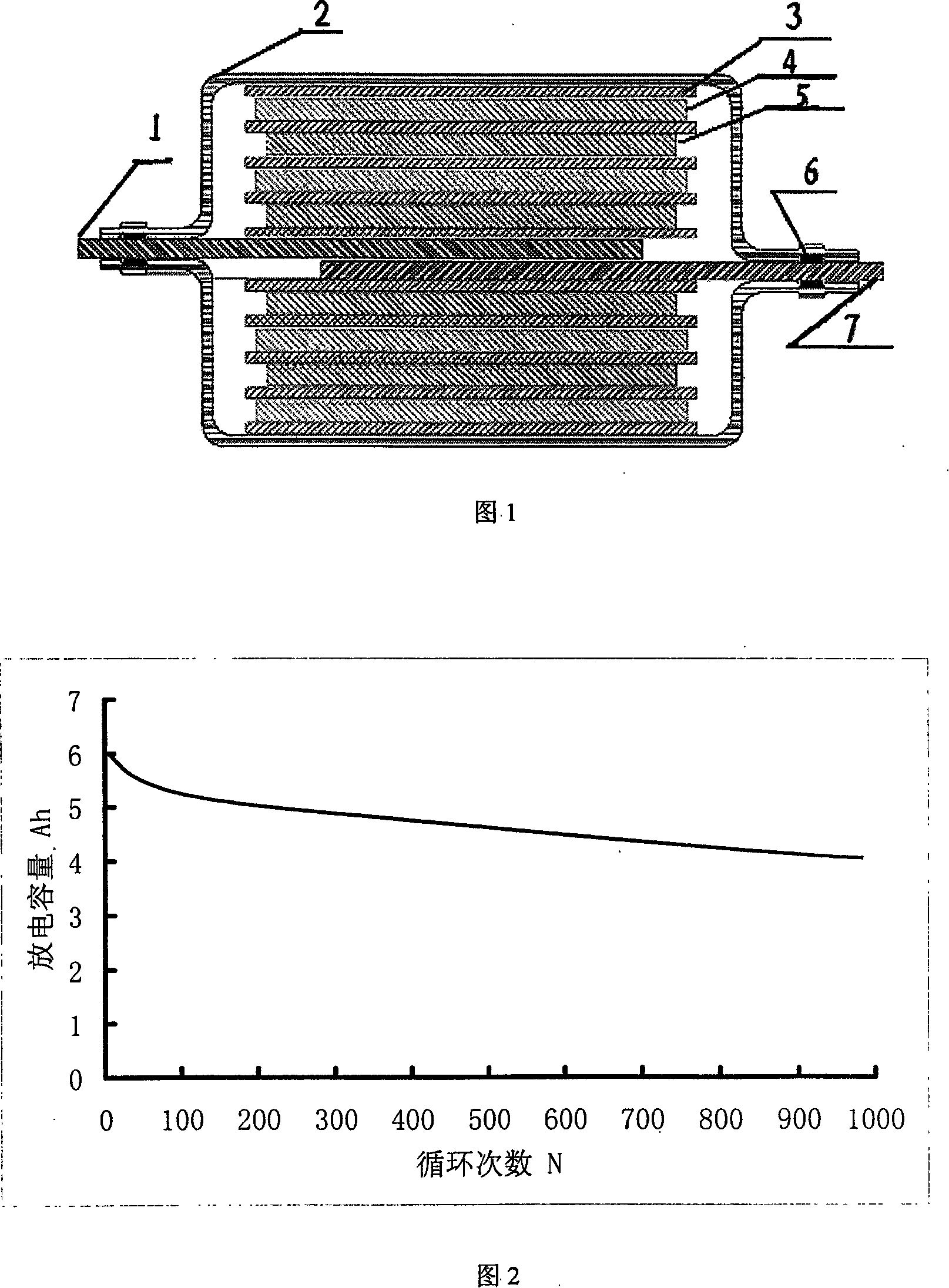

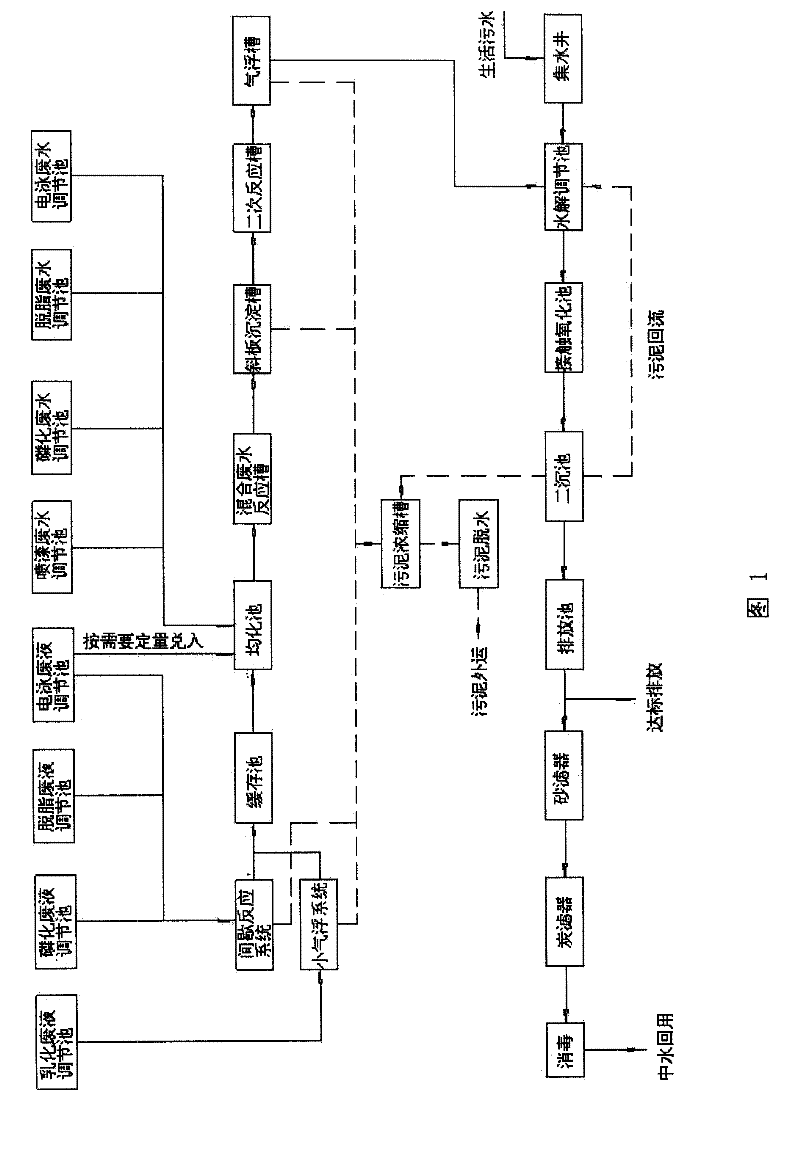

Cylindrical flexible packed lithium ion storage cell with aluminum-plastic composite film

InactiveCN1808760AExtended service lifeImprove use reliabilityFinal product manufactureSmall-sized cells cases/jacketsComposite filmMaterials science

This invention relates to one column polyethylene laminated film flexible lithium ion accumulator, which is characterized by the following: the shell is of polyethylene compound film packing column part; using compound metal oxidation and its compound as positive electrode materials free of imbedded lithium ion; using imbedded and removed lithium ion materials and its compound materials as negative materials and using aluminum foil as positive slice and carbide as negative materials and copper and nickel as negative slices; overlapping the isolated film, negative slices to form one column electrode board core and its outside fixed band; two end positive and negative electrode handles are parallel at one central line.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH

Sewage treatment method in garment production process

InactiveCN104016550ASimple processing methodEasy to manageMultistage water/sewage treatmentFlocculationSewage

The invention discloses a sewage treatment method in a garment production process. The sewage treatment method comprises the following steps: filtering, adjusting of water quality and water quantity, flocculation reaction, solid-liquid separation, hydrolytic acidification, first biodegradation, reducing of dissolved oxygen concentration, second biodegradation, solid-liquid separation and discharging. The sewage treatment method in the garment production process is simple and practical, convenient to manage, strong in operation stability, small in maintenance work, and good in sewage treatment effect, meets the standard requirements, and simultaneously can adapt to large change in sewage quality and quantity.

Owner:福建省佩吉服装股份有限公司

Sodium carboxymethyl cellulose production wastewater treatment process

InactiveCN105314794AImproved biodegradability and solubilityImprove biodegradability and solubilityMultistage water/sewage treatmentNature of treatment waterChemistrySodium carboxymethylcellulose

The invention discloses a sodium carboxymethyl cellulose production wastewater treatment process. The treatment process comprises a pretreatment section, an anaerobic treatment section, a preliminary precipitation section, a biological oxidation section, a biological precipitation section, a sludge treatment section and a membrane separation section; sodium carboxymethyl cellulose production wastewater, cleaning wastewater and domestic sewage are subjected to process design, and BVR evaporation desalting, anaerobic, preliminary precipitation, biological aerobic, biological precipitation and MBR (Membrane Bioreactor) treatment processes are adopted, so that the operating cost of sewage treatment is greatly reduced; various properties of equipment are thoroughly optimized and tapped, so as to enable the equipment to have a relatively high processing load; the adaptability to the sudden change of water quality and water volume is relatively high; the treatment efficiency of each section is stable, and the overall treatment effect is stable; and after technical treatment, the treated water reaches the sewage takeover standard of a sewage treatment plant, and partial water meets the requirements of enterprises on sewage recycling and then is recycled.

Owner:SUZHOU BAIYUN ENVIRONMENTAL PROTECTION PROJECT & EQUIP

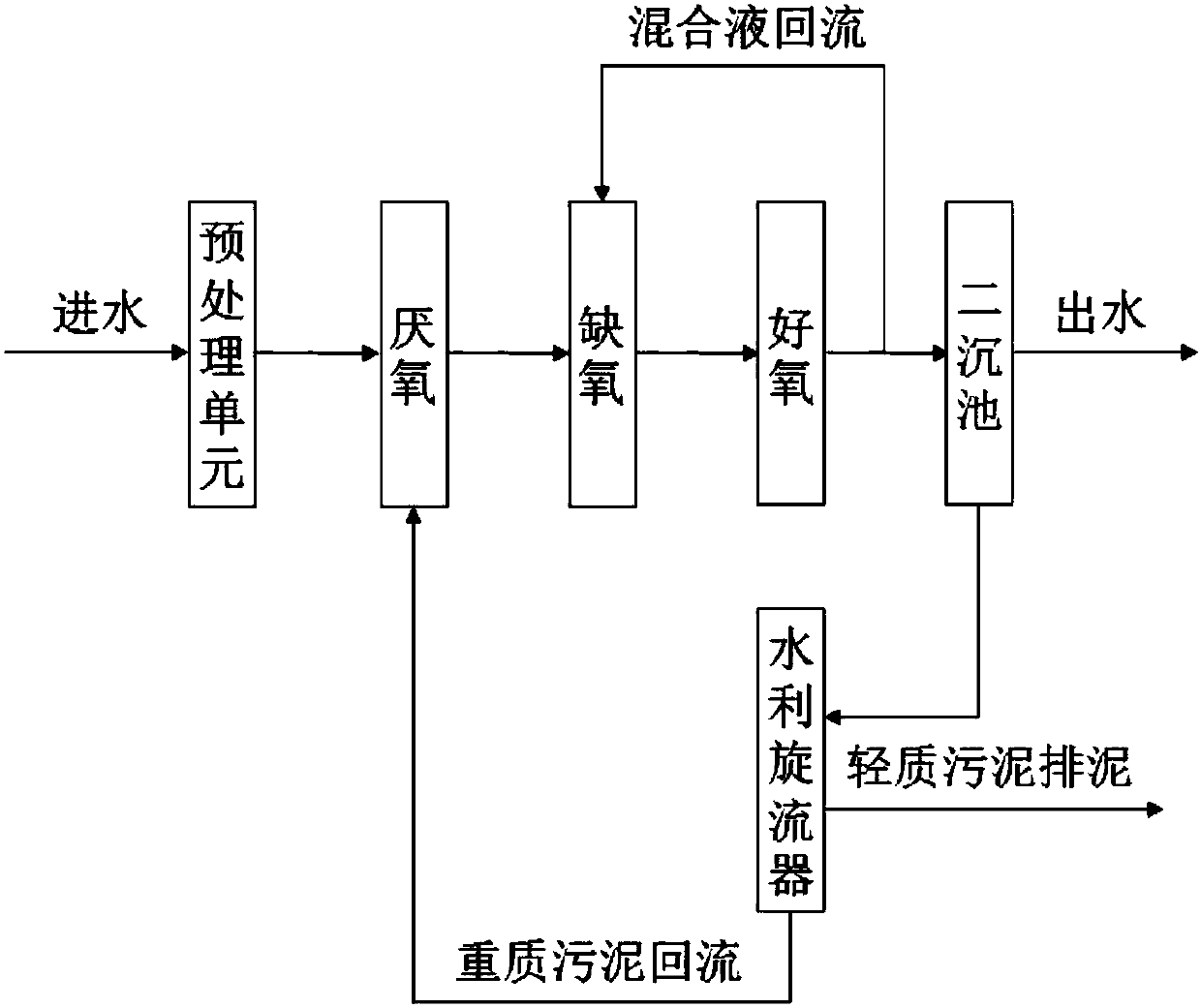

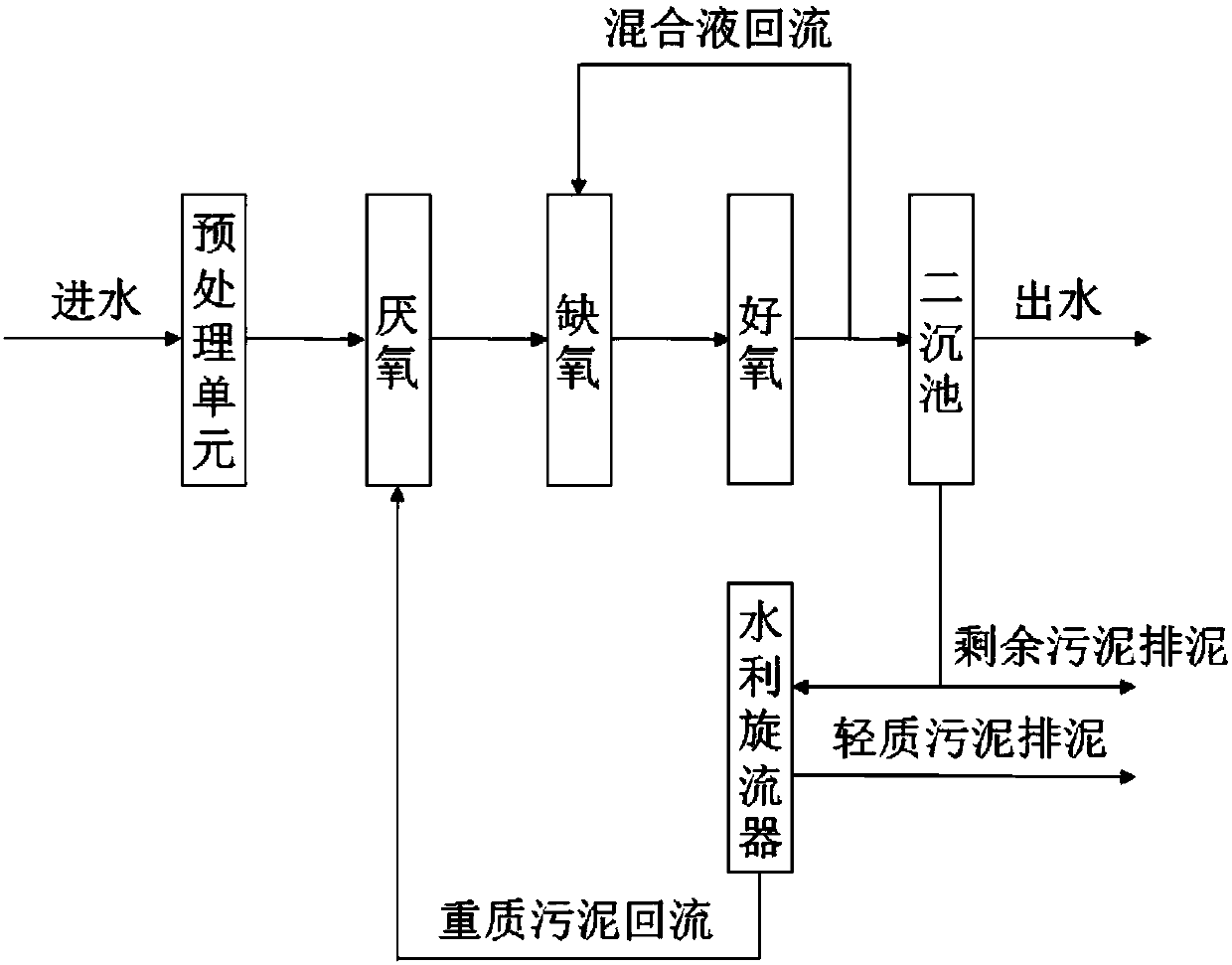

Method for recycling heavy sludge and enhancing nitrogen and phosphorus removal

InactiveCN107585951AAccelerated settlementProportionally largeMultistage water/sewage treatmentCycloneSludge

The invention provides a method for recycling heavy sludge and enhancing nitrogen and phosphorus removal, wherein the method comprises the following steps: (1) successively introducing sewage passingthrough a pretreatment unit into an anaerobic pool, an anoxic pool and an aerobic pool; (2) making the mixed liquid treated by the aerobic pool partially flow back to the anoxic pool, and introducingthe remaining part into a secondary sedimentation pool; and (3) introducing all or a part of sludge produced by the secondary sedimentation pool into a hydrocyclone or a centrifuge, carrying out cyclone or centrifugal treatment, allowing heavier sludge to flow back to the anaerobic pool by a heavy sludge reflux pipeline, allowing lighter sludge to enter a sludge treatment system through sludge discharge, and discharging a supernatant generated by the secondary sedimentation pool through a water outlet pipeline. The method overcomes the problem that the sludge concentration of a traditional active sludge treatment method is limited by sludge sedimentation performance of the secondary sedimentation pool and cannot be improved further, has good adaptability to water quality, and has strong anti-shock loading capability; and the wastewater treatment method does not have the problem of sludge expansion.

Owner:上海同济普兰德生物质能股份有限公司

Integrated device and method for enhancing deep denitrification of A/O (anoxic-oxic) technology by introducing AMX (anammox) bacteria

InactiveCN108585199ANo bloating issuesEasy to manageWater treatment parameter controlWater contaminantsRefluxMunicipal sewage

The invention discloses an integrated device and a method for enhancing deep denitrification of an A / O (anoxic-oxic) technology by introducing AMX (anammox) bacteria for partial denitrification coupled with anammox, and belongs to the technical field of municipal sewage treatment. The device consists of a high-efficiency tank, and auxiliary equipment and biological filler in the high-efficiency tank, wherein the high-efficiency tank mainly adopts the A / O technology. The method comprises the following steps of introducing the AMX bacteria to generate the partial denitrification coupled with anammox at the non-aeration area of the multistage A / O high-efficiency tank; removing organic matters, and denitrifying; then, performing anoxic synchronous nitrification and denitrification in the aeration area to further denitrify; after reaction is completed, sending drained water into a clean water tank to recycle, or draining. The device and the method have the advantages that the immobilized biological filler is used for providing a carrier for the AMX bacteria with longer growth and propagation period; the stable reaction conditions are provided for the partial denitrification coupled withanammox by controlling the gas stripping reflux, aeration amount, C / N (carbon to nitrogen) ratio and HRT (hydraulic retention time), so as to complete deep denitrification of domestic sewage at a lowC / N ratio.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Intensive type rural domestic sewage treatment system

InactiveCN106495410AGood water qualityLarge specific surface areaTreatment using aerobic processesSpecific water treatment objectivesSpecial effectsSmall footprint

The invention belongs to the technical field of sewage treatment and relates to an intensive type rural domestic sewage treatment system which comprises composition units including a grid, a regulating pond, a biochemical pond, precipitation and filtration integration equipment and the like. Sewage enters the regulating pond after passing through the grid firstly and then enters the biochemical pond; the biochemical pond can be rapidly started by adding a composite new bacterium by one time; in a contact process of the sewage and a biofilm, organic matters in water are adsorbed and decomposed through a special effect aerobic bacterium to produce CO2 and H2O; ammonia nitrogen is effectively and rapidly treated under the action of bacterial flora including an aerobic ammonifier to produce N2; and effluent of the biochemical pond enters a precipitation and filtration integration device, so that mud and water are separated from each other to enable the effluent to be further clarified, and the effluent subjected to treatment reaches the emission requirements and can be drained or reused. The intensive type rural domestic sewage treatment system is small in occupied area, little in investment, good in quality of the effluent and stable and convenient to run, can be rapidly started, can effectively treat rural domestic sewage and effectively protects a rural water resource environment.

Owner:辽宁清澄环境工程有限公司

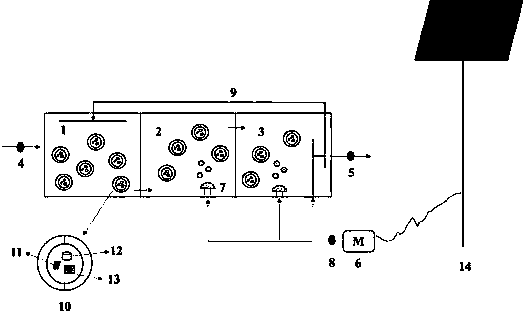

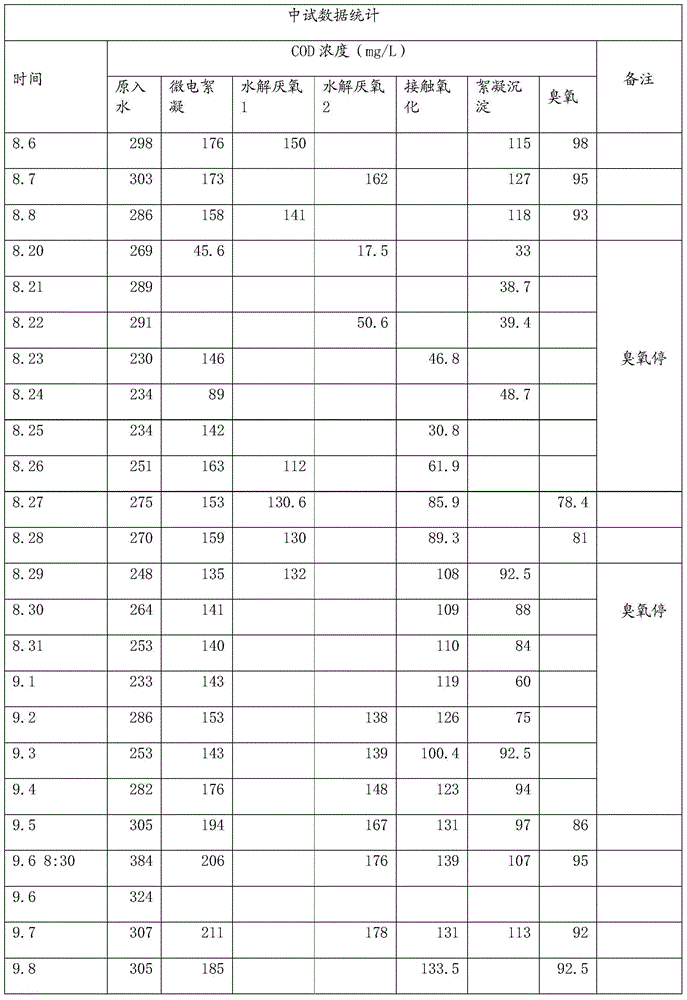

Microelectrolysis treatment system for treating acrylon wastewater

InactiveCN104986920AEfficient removalEase of emission complianceMultistage water/sewage treatmentNature of treatment waterSludgeFenton reagent

The invention discloses a microelectrolysis treatment system for treating acrylon wastewater. The system sequentially comprises a microelectrolysis reaction unit, a neutralization and sedimentation unit and a biological treatment unit, wherein the microelectrolysis reaction unit comprises a plurality of independent microelectrolysis reaction tanks which are connected in series into one or more groups of microelectrolysis reaction units; each group of the microelectrolysis reaction tanks can operate independently; each independent microelectrolysis reaction tank adopts a bottom-inlet and top-outlet water inlet and outlet manner; a water distribution pipeline is arranged at the bottom of each microelectrolysis reaction tank, and used for driving water to move up spirally; a plurality of support layers are arranged in each microelectrolysis reaction tank; an acid microelectrode material is arranged on each support layer; an aeration and sludge discharging system is arranged at the bottom of each microelectrolysis reaction tank. The microelectrolysis treatment system has the advantages that ferrous sulfate generated in a microelectrolysis reaction can be utilized skillfully, hydrogen peroxide is added to obtain a Fenton reagent, so as to effectively remove various organic substances from the wastewater; moreover, as the microelectrode materials are arranged in a hydrolysis tank, an anaerobic tank and a contact oxidation tank, the difficulty of biochemical treatment is further reduced, and sludge loading is reduced.

Owner:广东灵捷制造化工有限公司

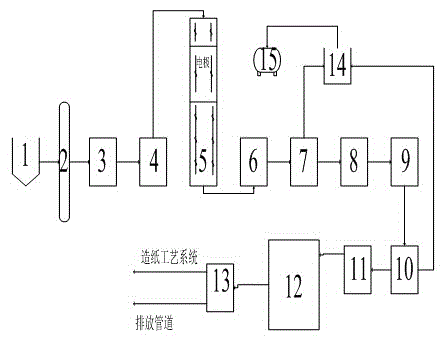

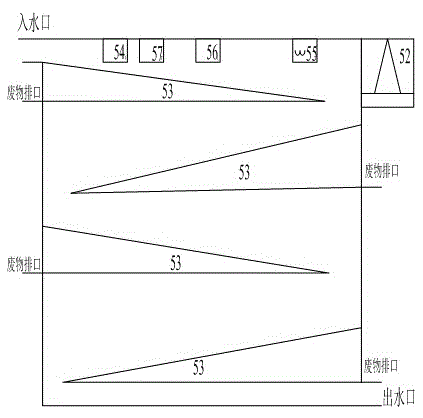

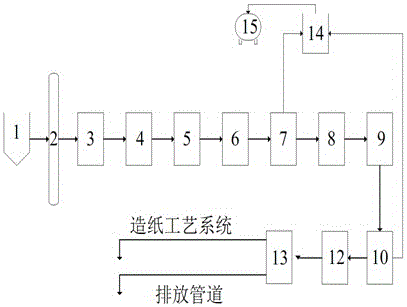

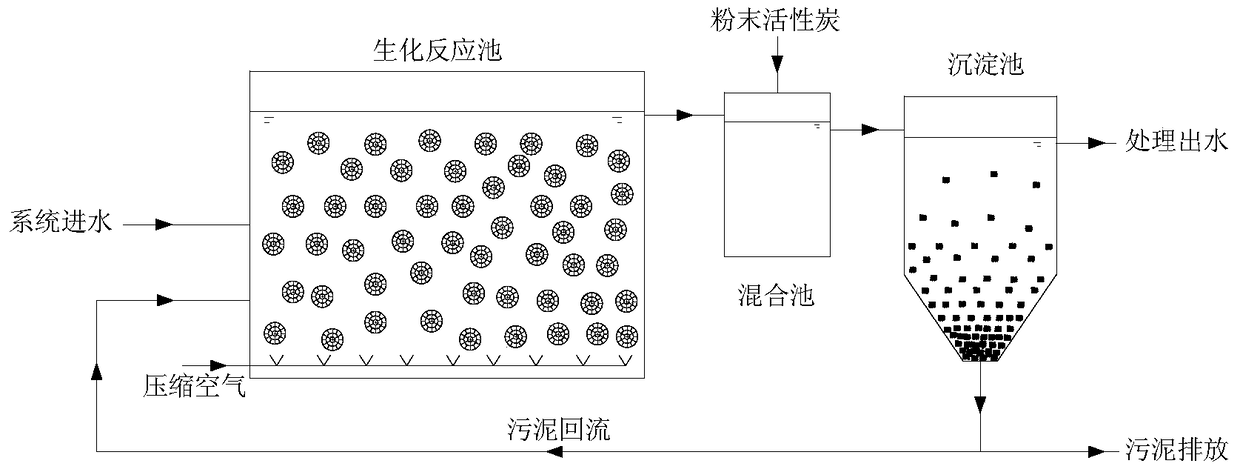

Industrial waste-water treating system for paper making factory

ActiveCN104986924AGood removal effectReduce equipment investment costsMultistage water/sewage treatmentWaste water treatment from plant processingRefluxSedimentation

The invention discloses an industrial waste-water treating system for a paper making factory. The industrial waste-water treating system comprises a pretreatment water collecting tank, a grating, a grit tank, a physical filter tank, an ice grating, an electromagnetic adsorption tank, an air floating tank, an acidification tank, a contact oxidation tank, a secondary sedimentation tank, a reflux treating tank, an artificial wetland treating system, a recirculation storage tank, a sludge storage tank, and a belt pressure filter, wherein the temperature in ice grating equipment is minus 2-10 DEG C. The waste-water treating system adopts environment-friendly ice grating equipment with low energy consumption, and the ice grating equipment is applied for the waste-water treating technology in paper making for the first time; the waste-water treating system has an obvious removing effect on organic matters and small-sized solid suspended matters, which are unique and difficult to remove, in paper-making waste water, and chemical reagents are not added. In the paper-making waste water treated by the waste-water treating system, the removal rate of chemical oxygen demands is 98.1%; the removal rate of total nitrogen is 97.2%; the removal rate of five-day biochemical oxygen demands is 95.1%; the removal rate of suspended matters is 96.1%; the removal rate of chroma is 90.1%; the removal rate of turbidity is 98.8%.

Owner:江苏富星纸业有限公司

Paper mill production wastewater treatment method

ActiveCN105060626AGood removal effectNo addedMultistage water/sewage treatmentWaste water treatment from plant processingConstructed wetlandGrating

The invention discloses a paper mill production wastewater treatment method. Wastewater sequentially goes through a pretreatment water collection pool, a grating, a sand basin, a physical filtering pool, an ice gate, an electromagnetic adsorption pool, an air floatation pool, an acidifying pool, a contact oxidation pool, a secondary sedimentation pool, a constructed wetland treatment system, a recirculation storage pool, a mud storage pool and a belt filter press. The low energy consumption and environmental protection ice gate is adopted in the invention, is used in the papermaking wastewater treatment process for the first time, and has obvious removal effects on small solid suspension and unique organic matters difficult to remove in papermaking wastewater without adding chemical reagents. In the papermaking wastewater treated through the method, the removal rate of chemical oxygen demand is 98.1%, the removal rate of total nitrogen is 97.2%, the removal rate of five-day biochemical oxygen demand is 95.1%, the removal rate of suspensions is 96.1%, the chroma removal rate is 90.1%, and the turbidity removal rate is 98.8%.

Owner:浙江兴舟纸业有限公司

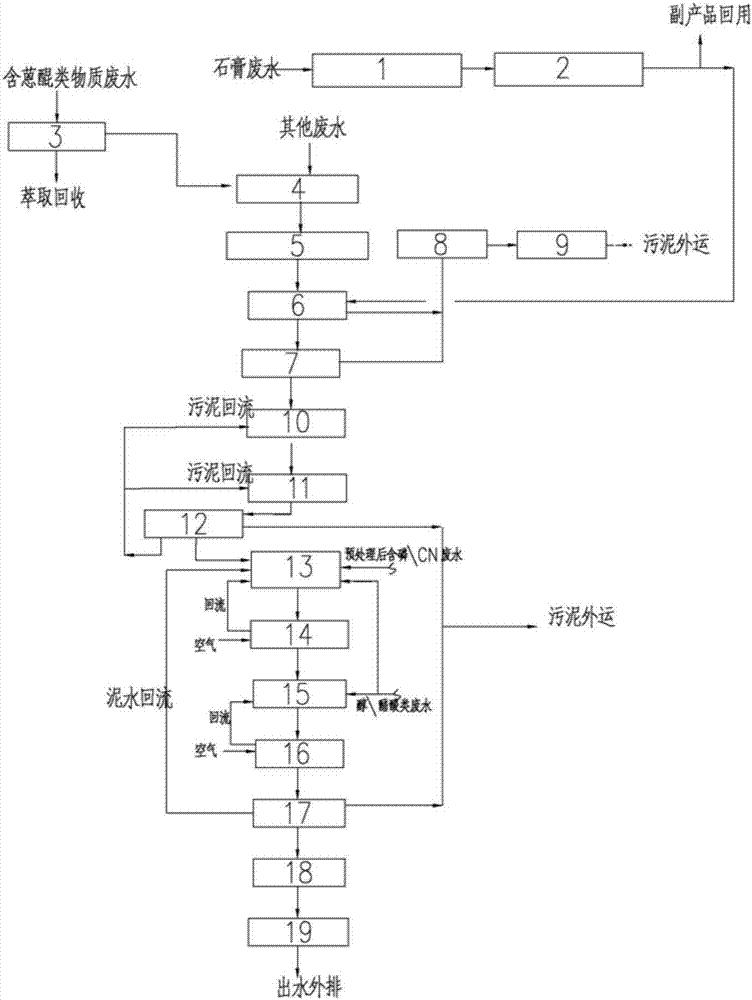

Dye wastewater treatment apparatus and method thereof

ActiveCN107010794AImprove processing efficiencyImprove the efficiency of COD (Chemical Oxygen Demand) removalTreatment using aerobic processesWater contaminantsAnthraquinonesAcetic acid

The invention discloses a dye wastewater treatment apparatus and a method thereof. Phosphorus / cyanogen (CN)-containing wastewater, gypsum wastewater, anthraquinone substance-containing wastewater and alcohol / acetic acid degradable wastewater are classified from the source, enters different devices in the apparatus according to different water properties and are treated to eliminate the pollution from the source, and the method is improved to increase the resource utilization efficiency, greatly reduce the instability and the toxicity of raw water, reduces the impact of wastewater to a biochemical system and realize strong adaptation to the sudden change of the water quality and the water volume, less residual sludge and the recycling and the long-period stable running of the apparatus. The apparatus and the method have the advantages of small investment, high treatment efficiency, stable outlet water quality, and convenience in operation.

Owner:宁波德欣科技有限公司

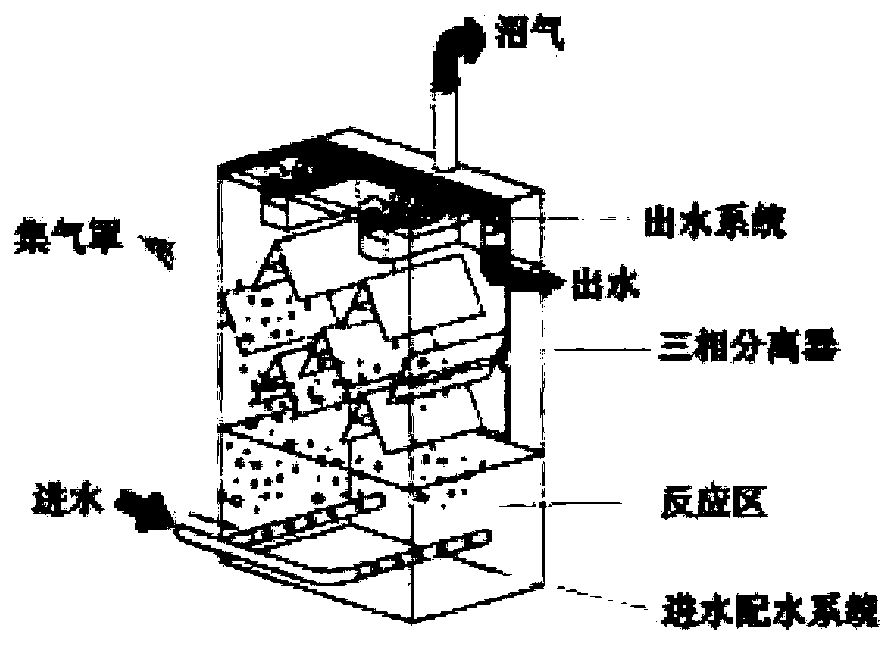

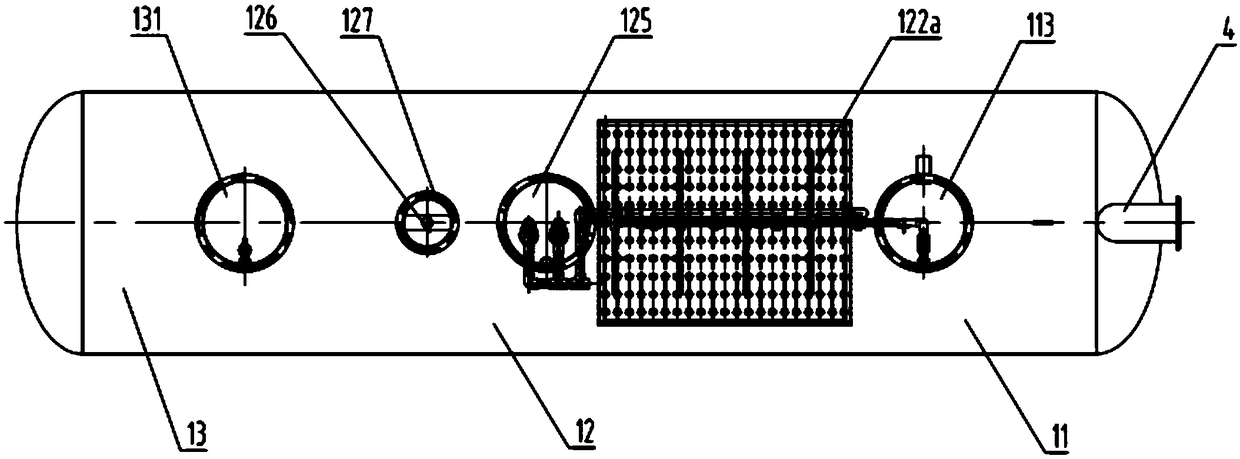

Biological membrane multistage reaction equipment

PendingCN108689494AEasy to handleImprove efficiencyTreatment with aerobic and anaerobic processesNitrogen removalBiochemical engineering

The invention relates to biological membrane multistage reaction equipment which comprises a comprehensive integrated device and a vertical multistage biochemical device. The vertical multistage biochemical device comprises a precipitation tank and one or multiple biochemical tanks. Sewage sequentially enters the comprehensive integrated device, one or multiple biochemical tanks and the precipitation tank, and one or multiple biochemical tanks are serially or parallelly connected between the comprehensive integrated device and the precipitation tank. When multiple biochemical tanks are serially connected between the comprehensive integrated device and the precipitation tank, identical or different fillers are sequentially put into different biochemical tanks according to sewage treatment requirements, aerobic and anaerobic treatment can be performed on the sewage repeatedly, and alternate cycling of multistage nitration and denitrification is realized, so that nitrogen removal efficiency of a system is improved greatly, and finally discharged sewage can reach national standards of Class I B and Class I A; when the biochemical tanks are parallelly connected, a lot of sewage can be treated at the same time, so that sewage treatment scale and efficiency are improved greatly.

Owner:北京海斯顿水处理设备有限公司

Sewage treatment method for medical institutions

InactiveCN102464428ANo bloating issuesReduce power consumptionMultistage water/sewage treatmentMedicineMunicipal sewage

The invention relates to a sewage treatment method for medical institutions, which comprises the steps of sewage pretreatment, anaerobic treatment, aerobic treatment, precipitation treatment and disinfection treatment. The sewage treatment method for the medical institutions has low operation cost, is stable to operate and has high sewage treatment efficiency. Effluent continuously reaches the standard and is discharged in a qualified state. The pollution to the environment is effectively controlled. Therefore, not only is the environment improved, but also the load of a domestic wastewater treatment plant is relieved.

Owner:扬州龙锦涂装环保设备有限公司

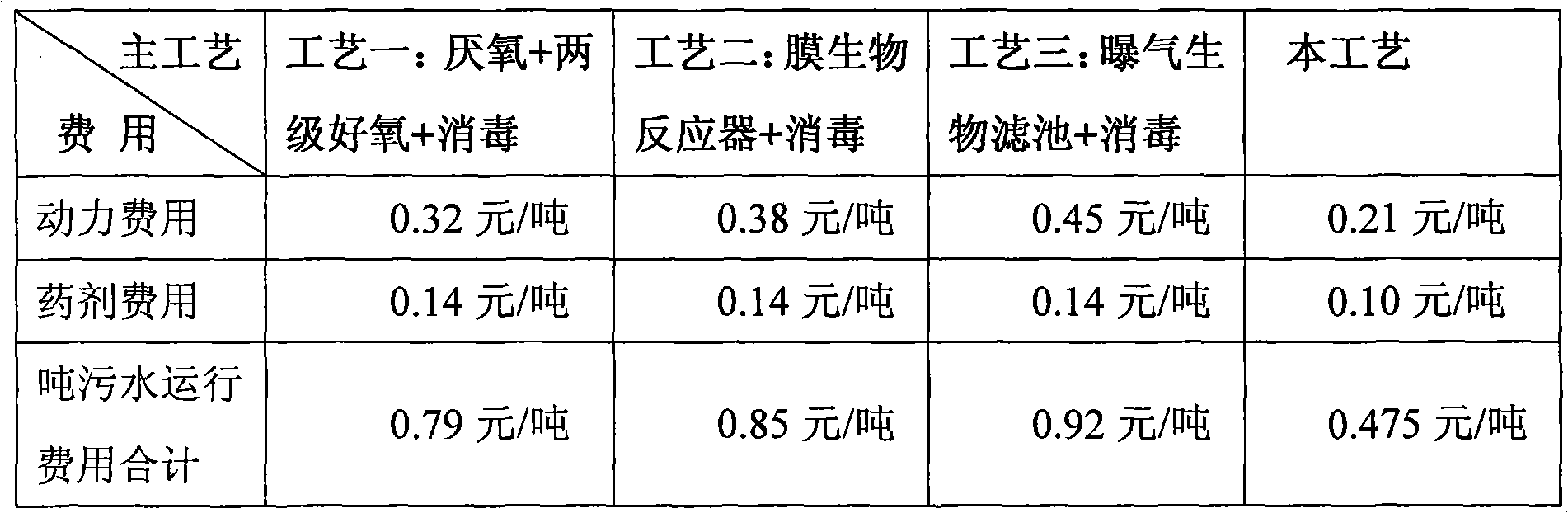

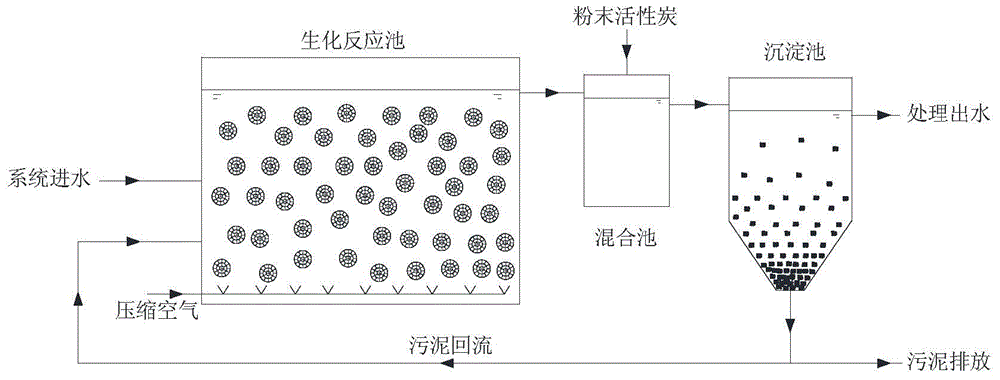

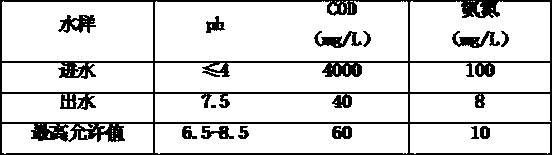

Method for treating wastewater by using carrier fluidized biomembrane reactor

ActiveCN105621780AImprove settlement performanceEasy to handleMultistage water/sewage treatmentActivated carbonWater discharge

The invention discloses a method for treating wastewater by using a carrier fluidized biomembrane reactor. The method comprises the following steps: sequentially treating wastewater to be treated in a biochemical reaction tank, a mixing tank and a precipitation tank, discharging a supernatant in the precipitation tank, and returning at least parts of sludge at the bottom of the precipitation tank to the biochemical reaction tank, wherein active carbon is added to water discharged from the biochemical reaction tank, and the active carbon and the discharged water are uniformly mixed in the mixing tank. The method can effectively reduce the content of suspensions in water finally obtained after treatment, and also has the advantages of excellent wastewater treatment effect, fast biomembrane formation speed, strong impact resistance, good treatment effect, and convenient running and management.

Owner:CHINA PETROLEUM & CHEM CORP +1

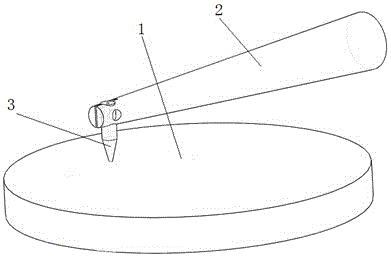

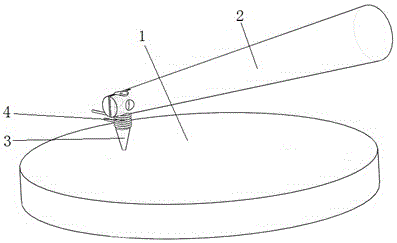

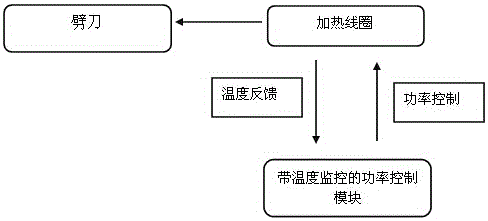

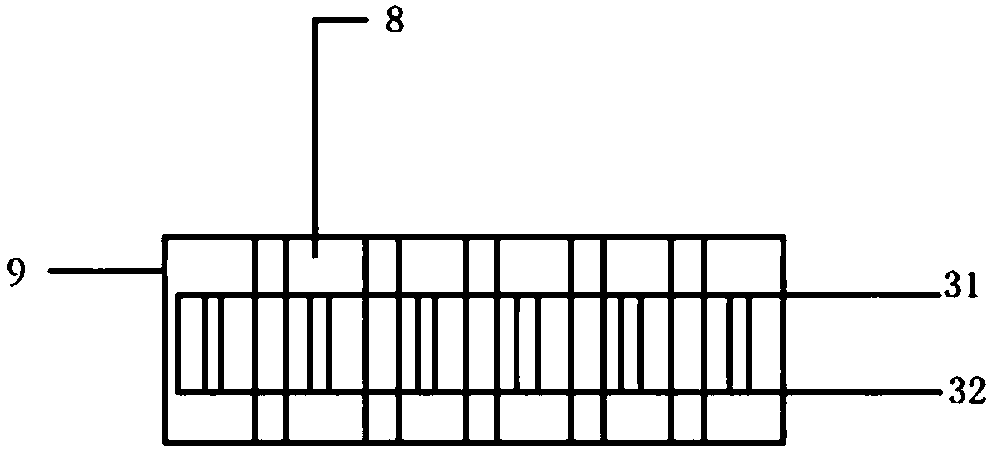

Wafer hot-pressing ultrasonic ball planting device and process

InactiveCN106098576AEliminates the risk of burnsShorten heating timeSolid-state devicesSemiconductor/solid-state device manufacturingTemperature controlComputer module

The invention discloses a wafer hot-pressing ultrasonic ball planting device and a process thereof. The ball planting device comprises a heating table, an ultrasonic rod and a chopper. A heating coil is wound on the chopper. The heating coil is connected with a power supply through a switch. A temperature measuring device is connected with a power control module. The power control module is connected with the power supply. The power control module controls the power of the power supply according to the head temperature of the chopper detected by the temperature measuring device, so that the head temperature of the chopper is maintained at a desired level. According to the technical scheme of the invention, the chopper is heated to a required process temperature by the heating coil, and a golden wire in the chopper is also heated. Meanwhile, the ultrasonic energy is transmitted to the chopper through the ultrasonic rod. Under the combined action of the friction heat and the heat transferred from the heating coil to the golden wire, the golden wire is melted and the ball planting process is completed. According to the technical scheme of the invention, the chip burning problem on the wafer can be solved. Meanwhile, the displacement of patterns on the wafer is avoided, and the ball planting efficiency is high.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

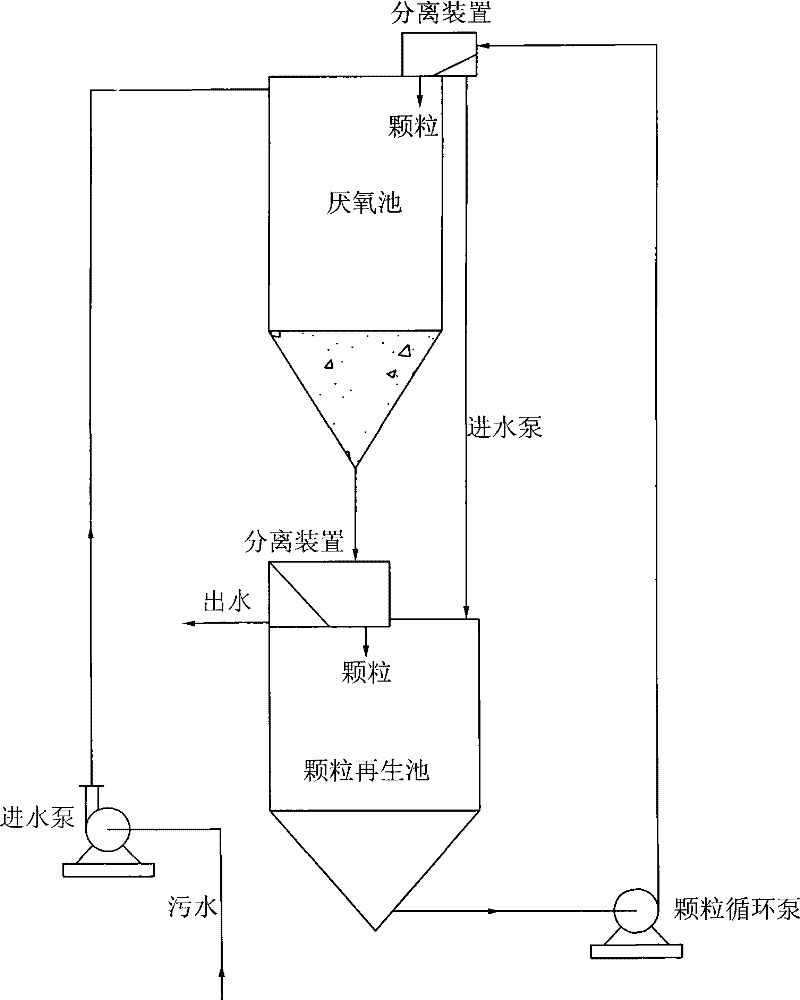

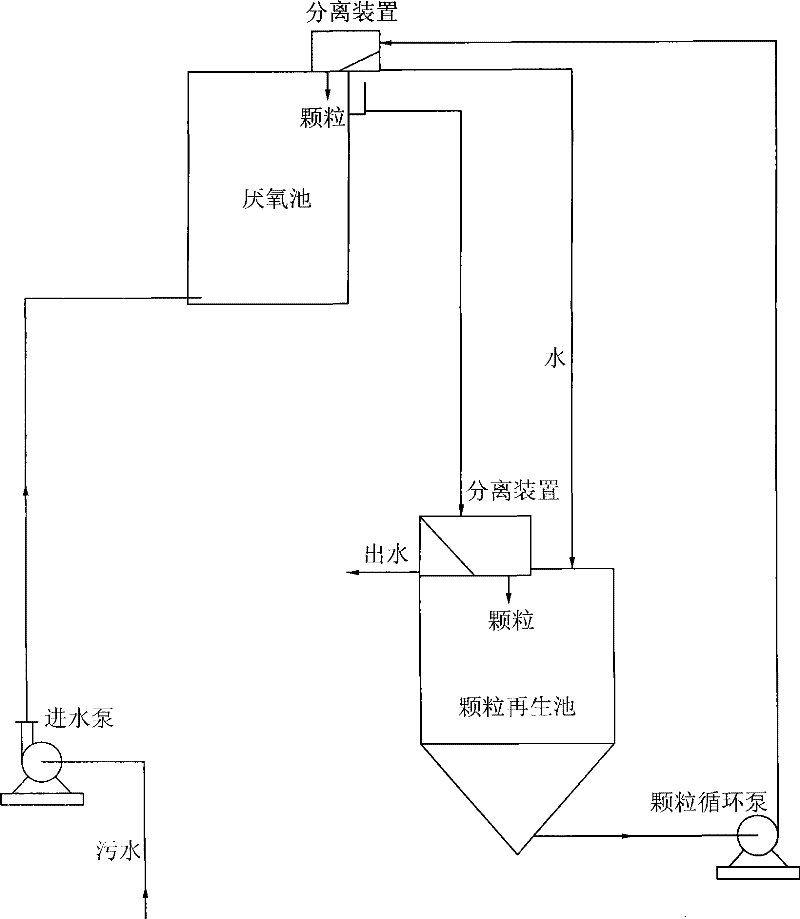

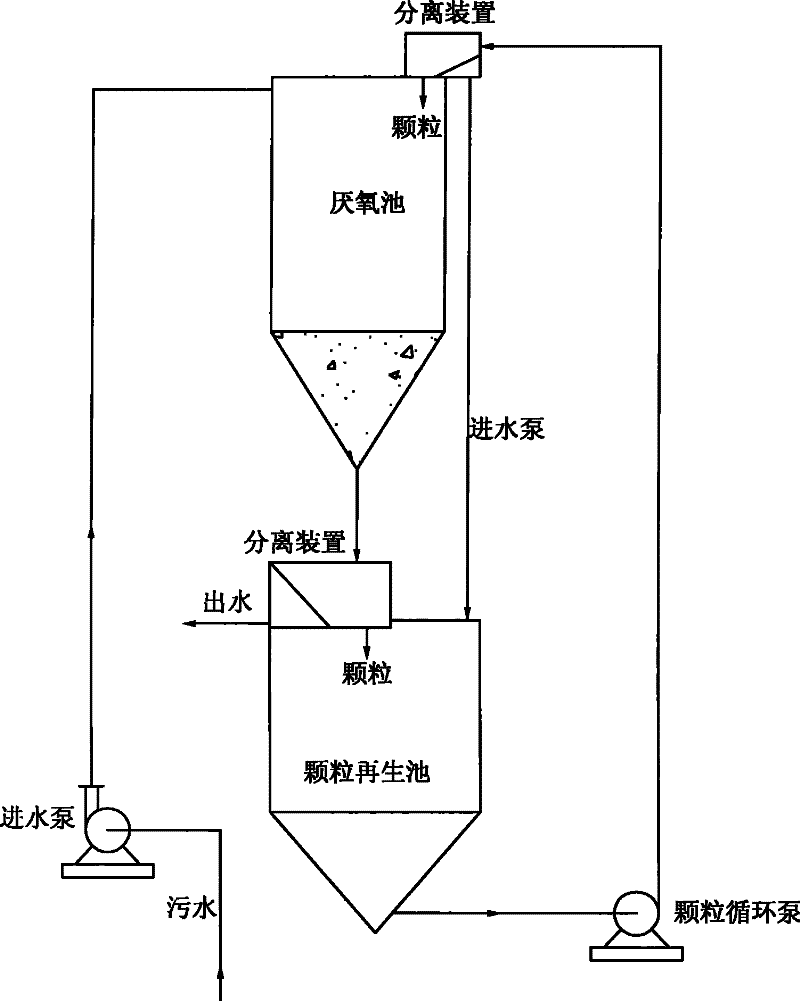

Sewage disposal method using embedding immobilization microorganism grain fluidized bed

ActiveCN101381151BNo bloating issuesTo achieve the treatment effectSustainable biological treatmentOn/in organic carrierMicroorganismSludge

The invention discloses a method for treating sewage of an embedded immobilized microorganism particle fluidized bed, wherein spherical filler particles which are embedded with microorganism flora are filled into a sewage disposal device at first and then the sewage is led into the sewage disposal device, so as to make the filler particles which are embedded with the microorganism flora roll up and down when stirred by an aerator to become fluid state; organic substances in water are transformed and degraded by enzymes which are generated by microorganisms, and mixture which flows out from the sewage disposal device enters into a solid-liquid separator for solid-liquid separation; the filler particles flow into a regenerative device for regeneration, and the spherical filler particles after regeneration are sent into the solid-liquid separator on the upper part of the sewage disposal device; and a liquid inversely flows into a mother liquor device, and the filler particles are returned back to the sewage disposal device. The method not only overcomes the defects of the prior sewage disposal method but also has the characteristics of high efficiency, strong adaptability, short adjusting period, low sludge amount, convenient assembly and maintenance, compact structure, convenient operation and so on.

Owner:ZHONGSHAN ENVIRONMENTAL PROTECTION IND CO LTD

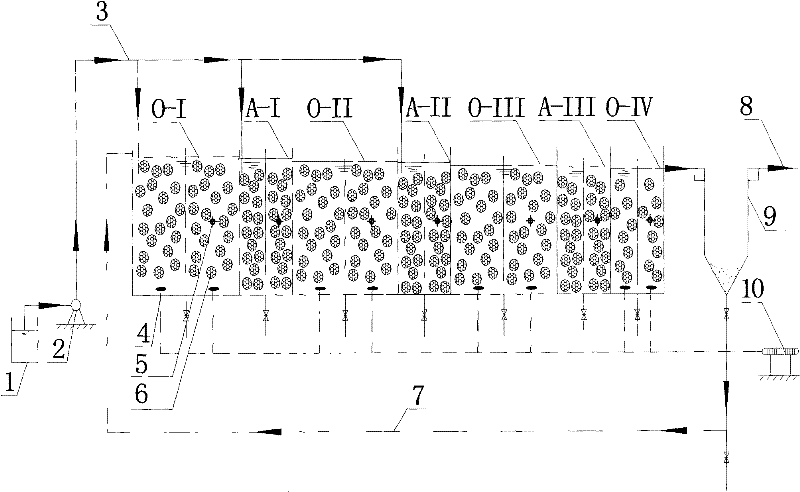

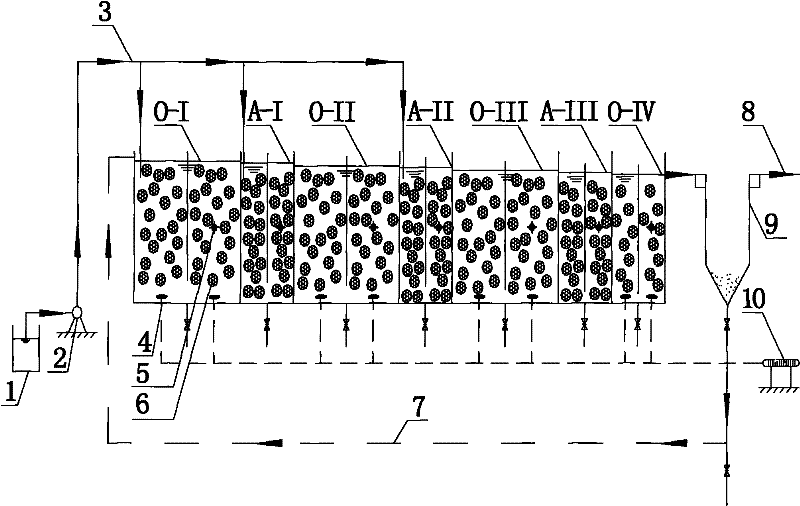

Step-feed biological nitrogen removal and sludge reduction coupling bioreactor and process thereof

ActiveCN101941776BReduce yieldGood reduction effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentNitrogen removalCoupling

The invention relates to a step-feed biological nitrogen removal and sludge decrement coupling bioreactor and a process thereof, belonging to the field of sewage treatment and aiming to overcome the technical defect that the sludge output is large, and the total nitrogen removal effect of sewage with a low carbon-nitrogen ratio is poor. The bioreactor sequentially comprises a biological reaction area and a secondary clarifier, wherein a biological reaction area sequentially comprises an aerobic area, an anoxic area, an aerobic area, an anoxic area, an aerobic area, an anoxic area, an aerobic area and an anoxic area, and the volume ratio of each aerobic area to each anoxic area is (1.5:1)-(2:1); a porous carrier is arranged inside the biological reaction area; the carrier filling volume ratio of the aerobic areas is 40-60 percent, and the carrier filling volume ratio of the anoxic area is 90-100 percent; and all the areas are respectively provided with a baffle plate. The bioreactor is divided into three water inlet stages, the secondary clarifier is provided with a water outlet pipe and a sludge discharge pipe, and backflow sludge is conveyed to the aerobic areas O-I through a pump. The TN removal ratio of the bioreactor is 75.3 percent, the COD removal ratio is 94.3 percent, and the sludge productivity is 0.102kgMLSS / kgCOD.

Owner:BEIJING UNIV OF TECH

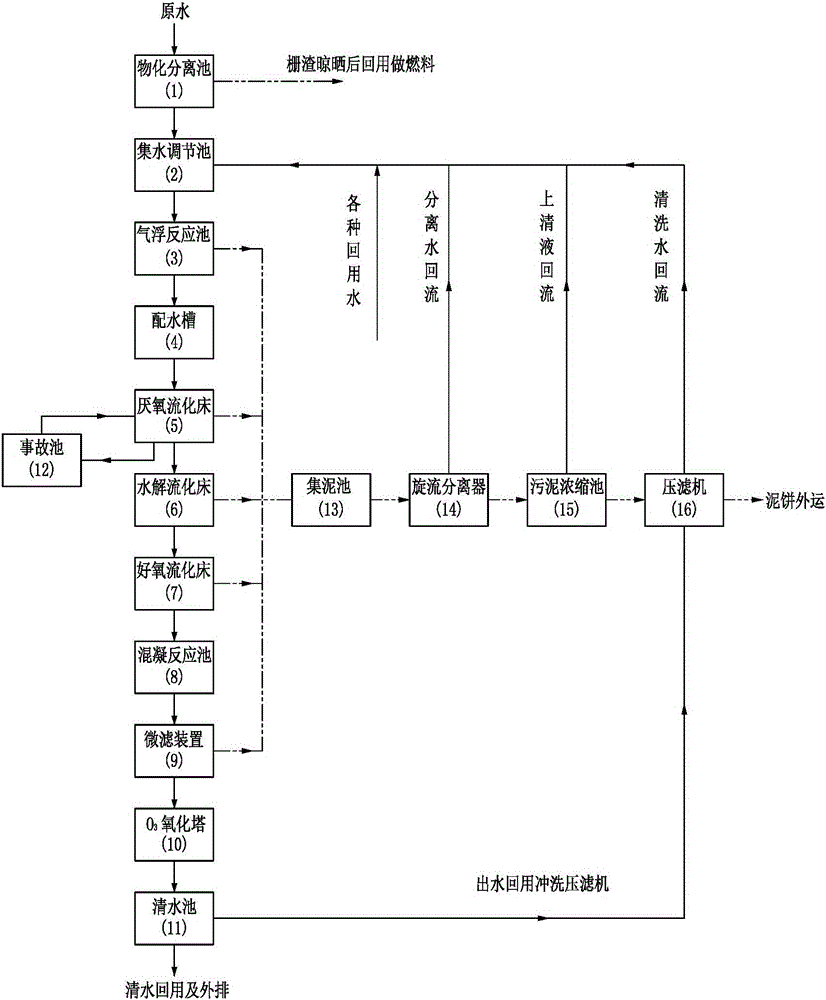

A wood-based panel waste water treatment system and process

ActiveCN104261634BHigh volume loadImprove mass transfer conditionsWater contaminantsTreatment involving filtrationSludgeFixed bed

The invention provides an artificial board wastewater treatment system and technology. The artificial board wastewater treatment system comprises a physical-chemical separating tank, a water collecting and regulating tank, an air flotation reaction tank, a water distributing trough, an anaerobic fluidization bed, a hydrolysis fluidization bed, an aerobic fluidization bed, a coagulation reaction tank, a micro-filtering device, an O3 oxidation column, a clear water tank and an accident tank, wherein the machine is characterized in that three grade biological fluidization beds of the anaerobic fluidization bed, the hydrolysis fluidization bed and the aerobic fluidization bed are combined to perform biological wastewater treatment. Compared with the conventional artificial board wastewater treatment technology by using a fixing bed and an activated sludge system, the machine disclosed by the invention is adopted for treating artificial board waste water by designing the technological parameters of relevant working procedures, and the machine has unique advantages in the aspects of treating organic waste water which is high in concentration and difficult to degrade. Key equipment of the system is small in volume, the whole system has stronger resistance to impact load, the sludge is sufficiently degraded, and the problem of sludge bulking is solved.

Owner:NANNING JINKE ENVIRONMENTAL ENG

An electrode and sodium-ion battery

ActiveCN108807850BImprove electrical performanceImprove securityCell electrodesSecondary cellsElectrolytic agentMetallic electrode

The invention discloses a novel alloy electrode and a sodium ion battery thereof. A large number of holes are made on an antimony alloy by a special method. When the antimony alloy is used as a negative electrode for sodium ions, the sodium ions enter the inside of the electrode along the holes after charging and come out of the holes when discharging. , and return to the positive electrode through the electrolyte, so as to store sodium ions to complete the battery charge and discharge function. Using sodium-based Prussian blue as the positive electrode material and the porous antimony alloy of the present invention as the negative electrode material, the porous antimony alloy negative electrode sheet is prepared by slurry mixing, coating, rolling, and slitting, and is laminated, welded, packaged, and baked , liquid injection, formation, and volume separation to obtain a sodium ion battery. In the present invention, the sodium metal and the metal electrode are first fused, and then the sodium is removed, leaving a large number of holes on the electrode. Since these holes are originally used to store sodium, when the sodium ion battery is charged, sodium can effectively re-enter these holes. Therefore, there is no expansion problem of the electrode, and the prepared sodium ion battery has excellent electrical performance and safety performance.

Owner:东莞格林德能源有限公司

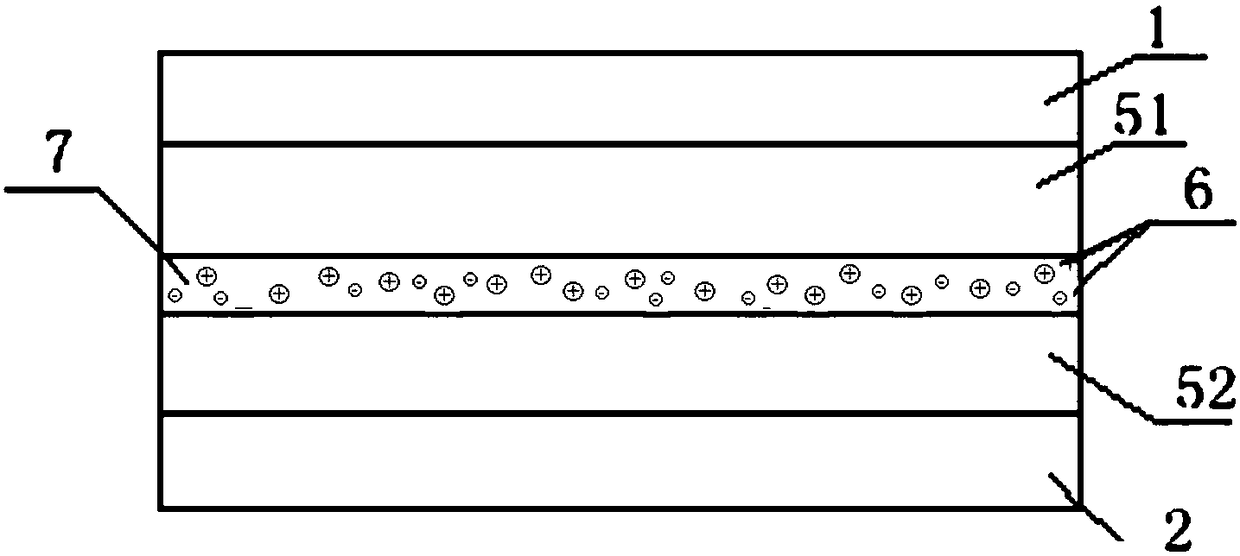

Supercapacitor and preparation method thereof

PendingCN108417408APromote migrationQuick migrationHybrid capacitor electrodesMultiple hybrid/EDL capacitorsBiomass carbonIsolation layer

A supercapacitor based on biomass carbon active substances comprises at least one capacitor unit, and the center of each capacitor unit is an isolation layer, and a carbon active layer and a current collecting layer are sequentially arranged on the two sides. The supercapacitor is characterized in that the carbon active layer comprises 10-15% by mass of biomass carbon active substances and 15-20%by mass of graphene and a binder, wherein the biomass carbon active substance is obtained by carbonizing a biomass carbon source, and the collecting layer is made of graphene paper. The supercapacitoris environment-friendly, safe, inexpensive and simply structured. Not only can the energy density of a battery be improved, but also the migration of charges is facilitated. Rapid charge and discharge are realized.

Owner:北京新希望科技发展有限公司

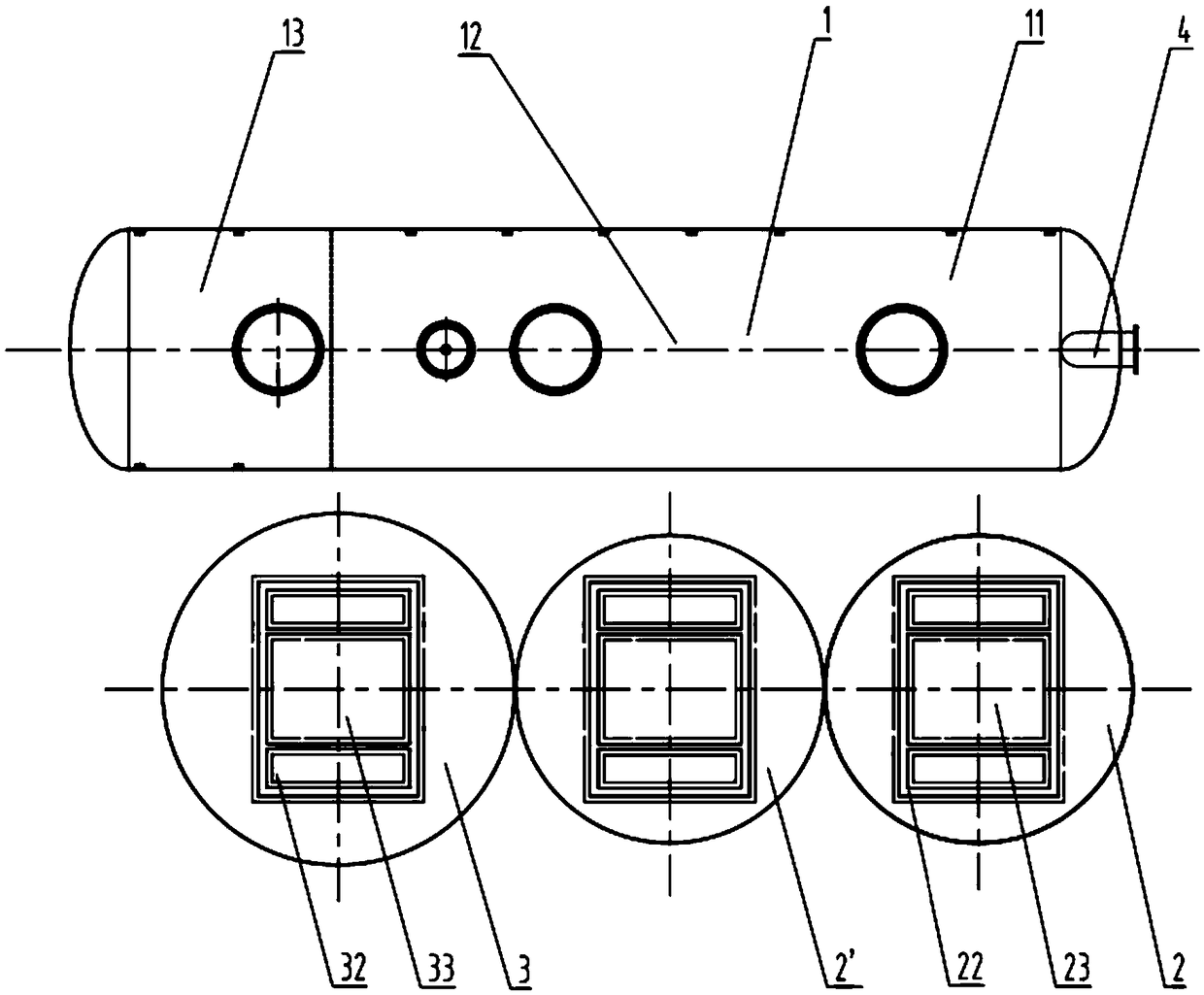

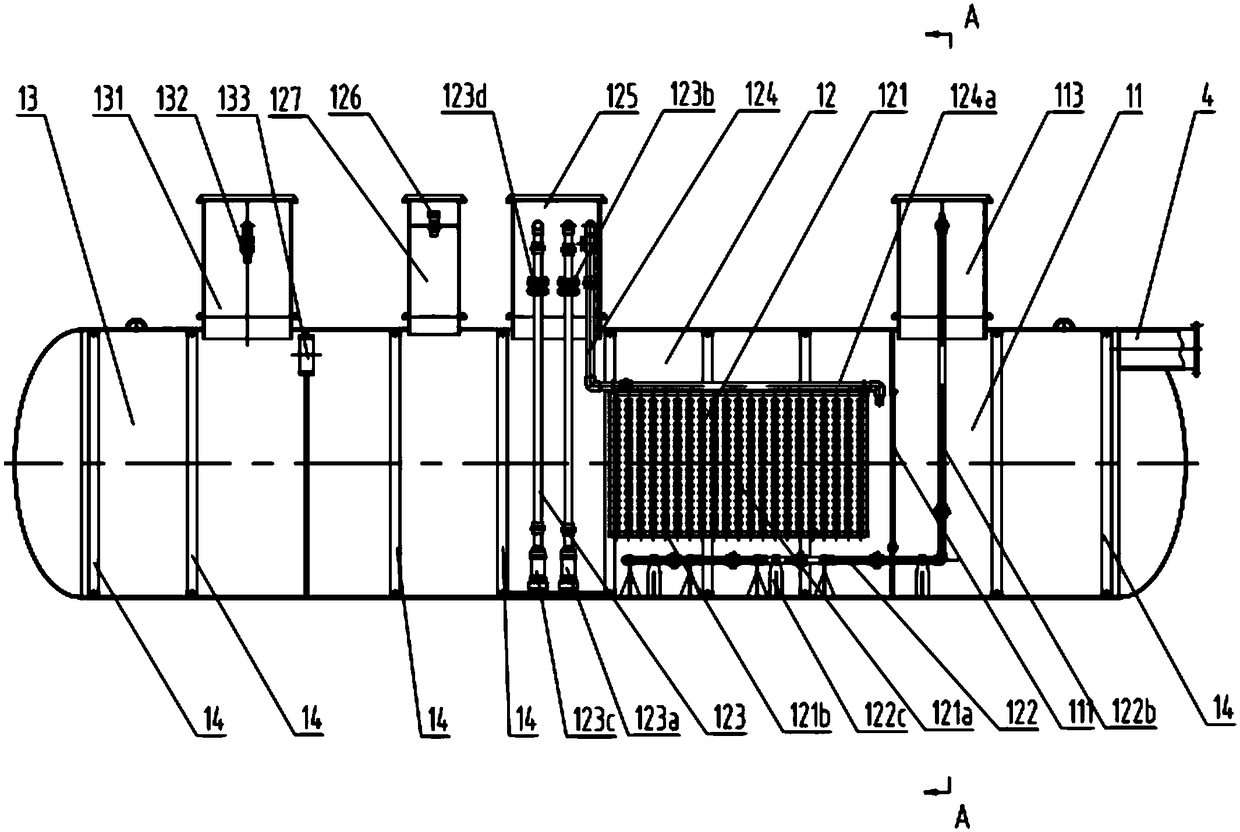

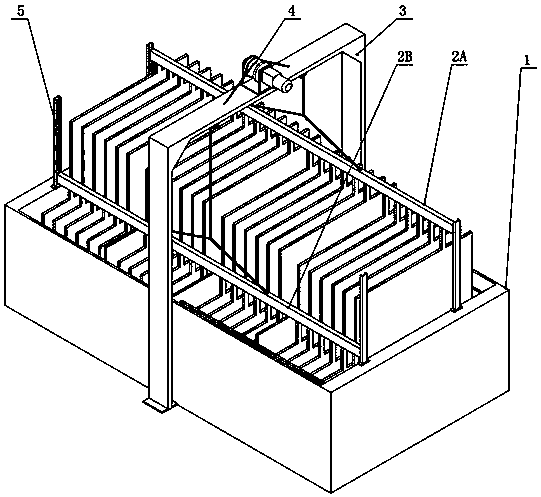

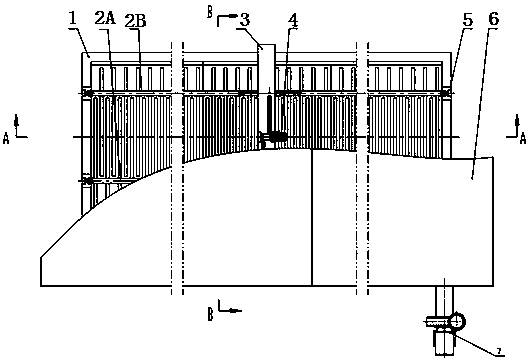

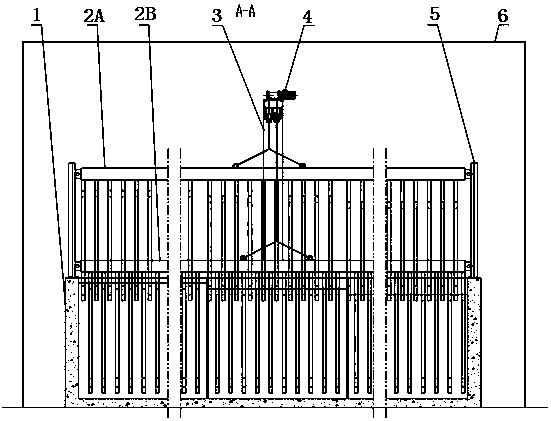

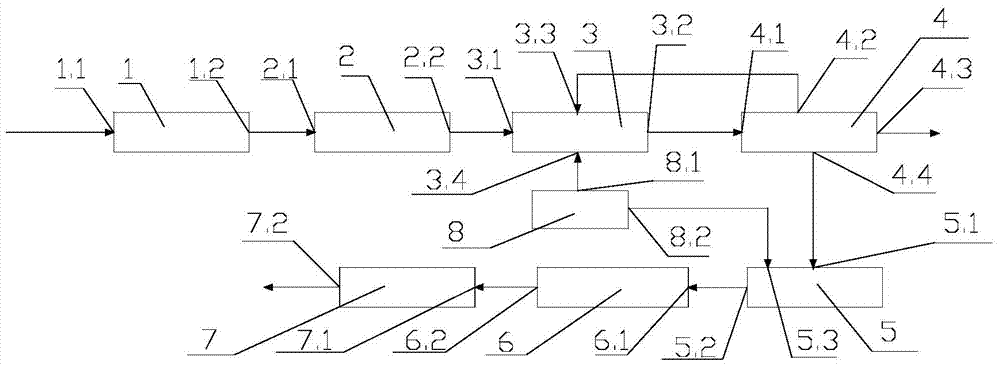

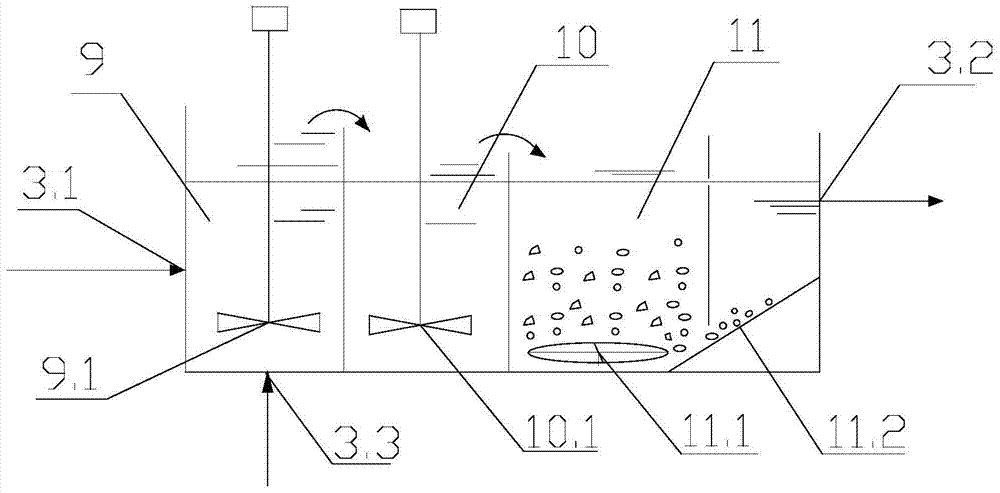

Processing technology and device for immersing lifting circulation type biofilm filter tank

ActiveCN108503018AReduce operating energy consumptionNo bloating issuesWater treatment parameter controlTreatment using aerobic processesBiological filterSewage

The invention discloses a processing technology and device for an immersing lifting circulation type biofilm filter tank. Two groups of staggeredly arranged filter curtains are adopted, the two groupof filer curtains perform periodically back-and-forth lifting and lowering in the biofilm filter tank, so that biofilms on the two groups of the filter curtains are in contact with the atmosphere andsewage water one by one, organic substances in the sewage water are absorbed when the filter curtains are immersed downwards, and oxygen is absorbed when the filter curtains are lifted upwards and exposed in the atmosphere, the oxygen is brought into the sewage water when the filer curtains are immersed downwards again to cause the turbulence of the sewage water in a water tank, and therefore thedissolved oxygen is uniformly distributed to purify the sewage water. The device for the immersing lifting circulation type biofilm filter tank comprises the biological filter tank, a load bearing frame, two groups of the filter curtains, the lifting mechanism, a pulley group, and two groups of swing resisting guiding rails. The device is simple in structure, easy to manufacture, low in cost and high in sewage water treating efficiency.

Owner:HUNAN SCIENTOP AUTOMATIC EQUIP SHARES +2

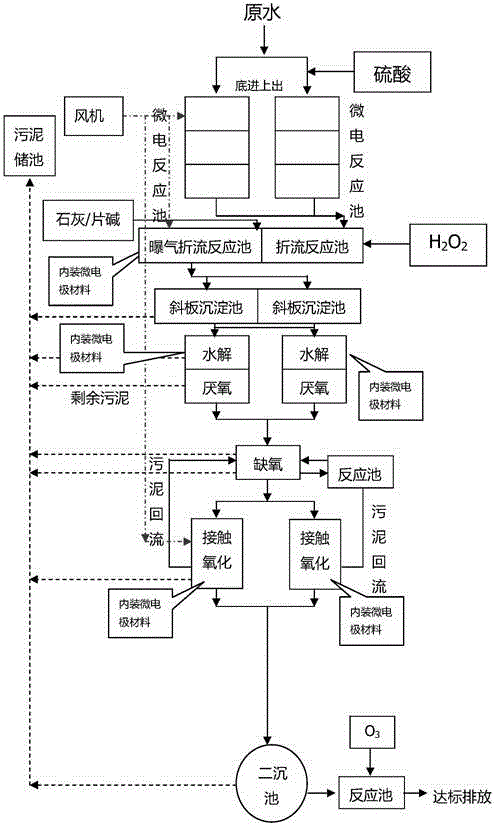

Coking Wastewater Advanced Treatment System and Its Reuse Process

ActiveCN105254123BAvoid secondary pollutionGrowth inhibitionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentBiological filterProcess engineering

The invention discloses an advanced treatment system for coking wastewater and a recycling technology adopting the advanced treatment system. The system comprises a grease removal tank, a regulating tank, a biochemical tank, a sedimentation tank, a biological filter, a multi-media filter and an adsorption device. According to the advanced treatment system for the coking wastewater and the recycling technology adopting the advanced treatment system, multiple devices are combined to form a novel advanced treatment system for the coking wastewater, other chemical agents are not needed, and secondary pollution is avoided; meanwhile, the coking wastewater treatment cost is reduced, a large amount of production water supply is saved, and an economical, practical and efficient path is provided for advanced treatment and recycling of the coking wastewater.

Owner:武汉钢铁有限公司

Cylindrical flexible packed lithium ion storage cell with aluminum-plastic composite film

InactiveCN100349322CExtended service lifeImprove use reliabilityFinal product manufactureSmall-sized cells cases/jacketsComposite filmMaterials science

This invention relates to one column polyethylene laminated film flexible lithium ion accumulator, which is characterized by the following: the shell is of polyethylene compound film packing column part; using compound metal oxidation and its compound as positive electrode materials free of imbedded lithium ion; using imbedded and removed lithium ion materials and its compound materials as negative materials and using aluminum foil as positive slice and carbide as negative materials and copper and nickel as negative slices; overlapping the isolated film, negative slices to form one column electrode board core and its outside fixed band; two end positive and negative electrode handles are parallel at one central line.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH

Automobile manufacturer wastewater treatment method

ActiveCN101456647BEasy to handleHigh activityTreatment using aerobic processesDispersed particle separationIndustrial effluentCar manufacturing

The invention relates to a method for treating wastewater and discloses a method for treating wastewater in an automobile manufacturing plant. A method of pretreatment, two-stage physicochemical treatment, biochemical treatment and advanced treatment is adopted to treat wastewater. The method for treating wastewater in the automobile manufacturing plant has little investment, small occupied area and low operating cost and has good integrated treatment effect on industrial wastewater and domestic sewage discharged from the automobile manufacturing plant.

Owner:SHANGHAI YIKE GREEN ENG

Novel alloy electrode and sodium-ion battery thereof

ActiveCN108807850AImprove electrical performanceImprove securityCell electrodesSecondary cellsCooking & bakingAlloy

The invention discloses a novel alloy electrode and a sodium-ion battery thereof. The novel alloy electrode and the sodium-ion battery thereof are characterized in that a large number of holes are formed on antimony alloy, and when the antimony alloy serves as a sodium-ion electrode, sodium ions can enter into the electrode via the holes during charging and escape out of the holes and back to a positive electrode via electrolytes during discharging, so that functions of sodium ion storage and battery charging and discharging are achieved. Sodium Prussian blue serves as the positive electrode materials, and the porous antimony alloy serves as the negative electrode materials and is processed through slurry mixing, coating, rolling and slitting to obtain porous antimony alloy negative plates, and then through laminating, welding, packaging, baking, injection, formation and capacity grading, the sodium-ion battery is obtained. According to the novel alloy electrode and the sodium-ion battery thereof, sodium metal and the metal electrode are fused, then sodium is removed to form a large number of holes inside the electrode, due to the fact that the holes are originally used for storingsodium, sodium ions can effectively enter into the holes during charging, the problem of electrode expansion can be avoided, and the manufactured sodium-ion battery is excellent in electrical performance and safety performance.

Owner:东莞格林德能源有限公司

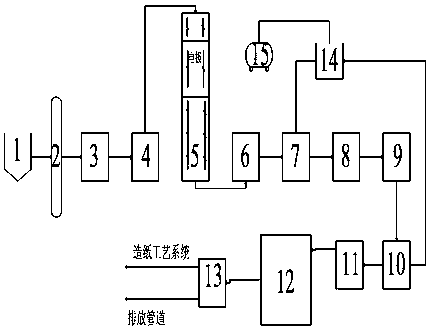

Betaine production wastewater treatment method

InactiveCN111252996AQuick responseImprove oxidation capacityTreatment using aerobic processesWater treatment compoundsBetaineSludge

The invention relates to a betaine production wastewater treatment process, which comprises the following process steps: pre-treating: collecting mixed wastewater through a comprehensive adjusting tank, pumping into an ozone oxidation tank by a pump, carrying out ozone oxidation, introducing into a hydrogen peroxide oxidation tank, proportionally adding hydrogen peroxide, oxidizing for 4 hours, adjusting the oxidized wastewater to 7 through a pH back-regulating tank by controlling an alkali adding pump with a pH meter, carrying out aeration attenuation, removing excess hydrogen peroxide in thewastewater, and introducing into a biochemical system; and biochemical treatment: feeding the pretreated wastewater into a hydrolytic acidification tank, treating by anaerobic microorganisms in the tank, then feeding into a contact oxidation tank, digesting, decomposing and degrading the organic matters in the water by aerobic bacteria, and finally carrying out mud-water separation by a membranein an MBR tank, wherein the effluent achieves discharge standard. The method has the characteristics of convenience in use, small occupied area, high treatment efficiency, low energy consumption, small sludge yield and the like.

Owner:WEIFANG BOHUA ENVIRONMENTAL TECH & ENG

A method for treating wastewater using a carrier fluidized biofilm reactor

ActiveCN105621780BImprove settlement performanceEasy to handleMultistage water/sewage treatmentActivated carbonWater discharge

The invention discloses a method for treating wastewater by using a carrier fluidized biomembrane reactor. The method comprises the following steps: sequentially treating wastewater to be treated in a biochemical reaction tank, a mixing tank and a precipitation tank, discharging a supernatant in the precipitation tank, and returning at least parts of sludge at the bottom of the precipitation tank to the biochemical reaction tank, wherein active carbon is added to water discharged from the biochemical reaction tank, and the active carbon and the discharged water are uniformly mixed in the mixing tank. The method can effectively reduce the content of suspensions in water finally obtained after treatment, and also has the advantages of excellent wastewater treatment effect, fast biomembrane formation speed, strong impact resistance, good treatment effect, and convenient running and management.

Owner:CHINA PETROLEUM & CHEM CORP +1

A treatment system for paper mill production wastewater

ActiveCN104986924BGood removal effectNo addedMultistage water/sewage treatmentWaste water treatment from plant processingConstructed wetlandIndustrial waste water

The invention discloses an industrial waste-water treating system for a paper making factory. The industrial waste-water treating system comprises a pretreatment water collecting tank, a grating, a grit tank, a physical filter tank, an ice grating, an electromagnetic adsorption tank, an air floating tank, an acidification tank, a contact oxidation tank, a secondary sedimentation tank, a reflux treating tank, an artificial wetland treating system, a recirculation storage tank, a sludge storage tank, and a belt pressure filter, wherein the temperature in ice grating equipment is minus 2-10 DEG C. The waste-water treating system adopts environment-friendly ice grating equipment with low energy consumption, and the ice grating equipment is applied for the waste-water treating technology in paper making for the first time; the waste-water treating system has an obvious removing effect on organic matters and small-sized solid suspended matters, which are unique and difficult to remove, in paper-making waste water, and chemical reagents are not added. In the paper-making waste water treated by the waste-water treating system, the removal rate of chemical oxygen demands is 98.1%; the removal rate of total nitrogen is 97.2%; the removal rate of five-day biochemical oxygen demands is 95.1%; the removal rate of suspended matters is 96.1%; the removal rate of chroma is 90.1%; the removal rate of turbidity is 98.8%.

Owner:江苏富星纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com