Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Improve COD" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

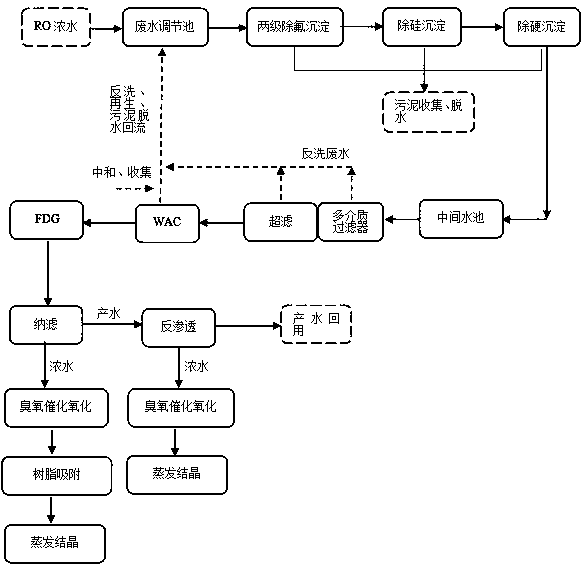

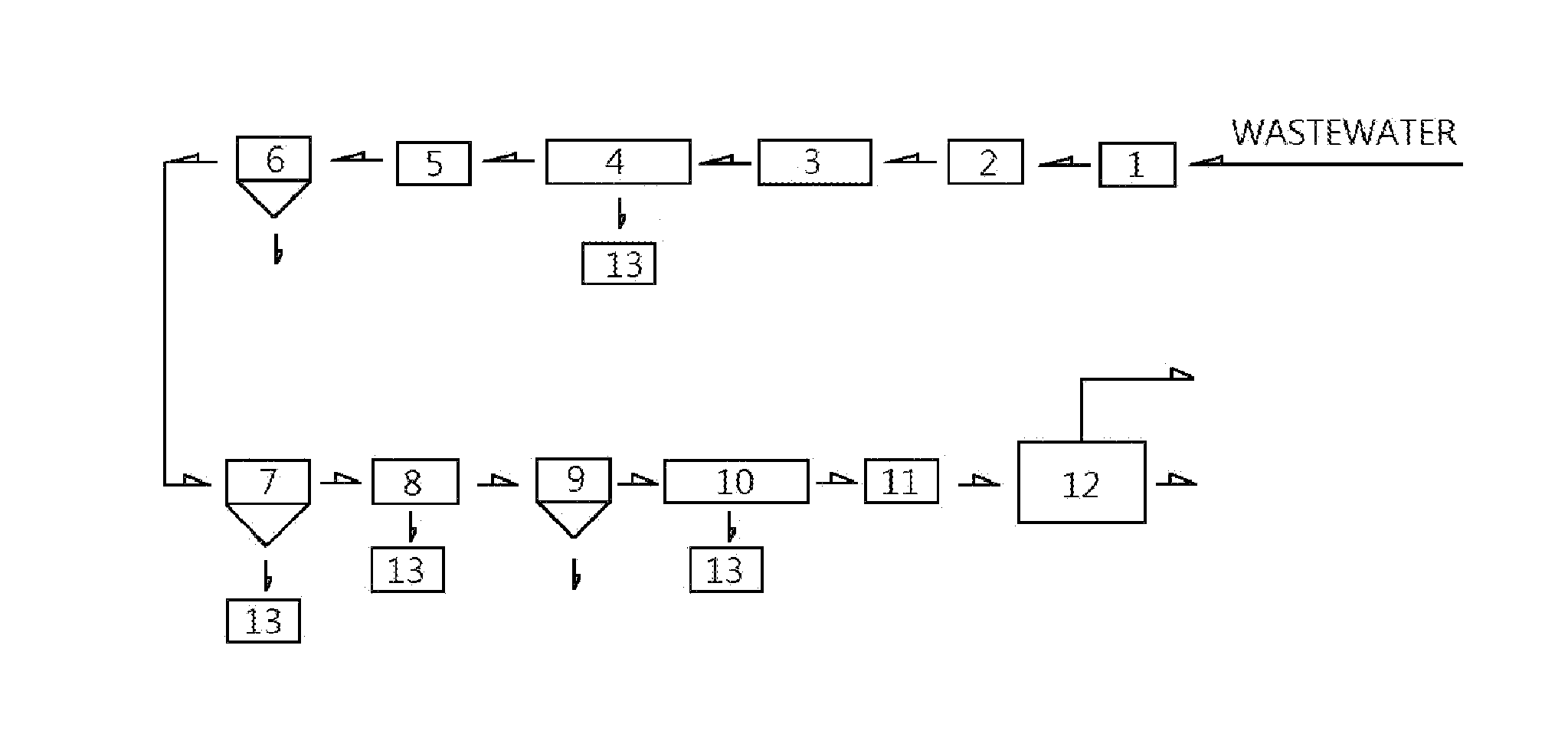

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

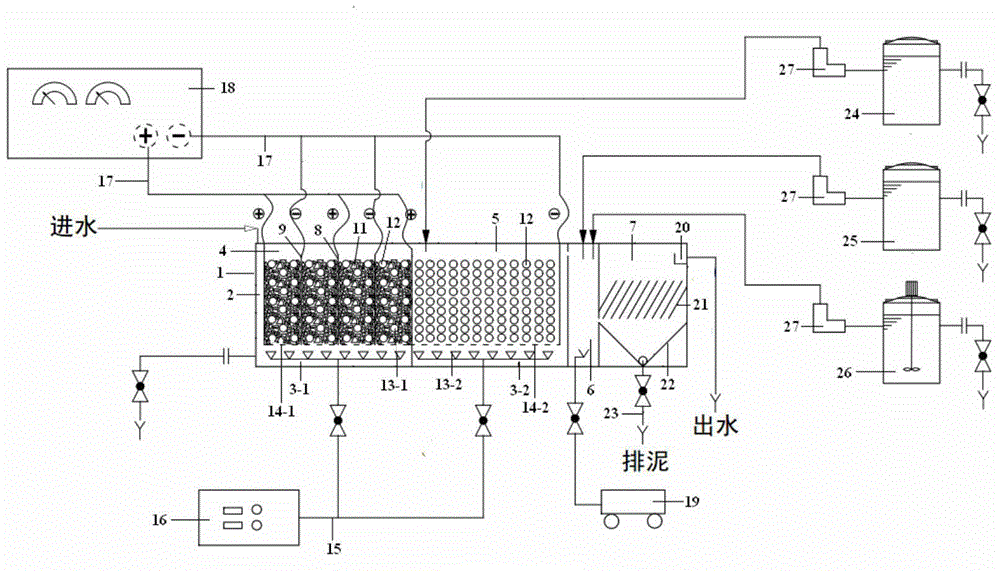

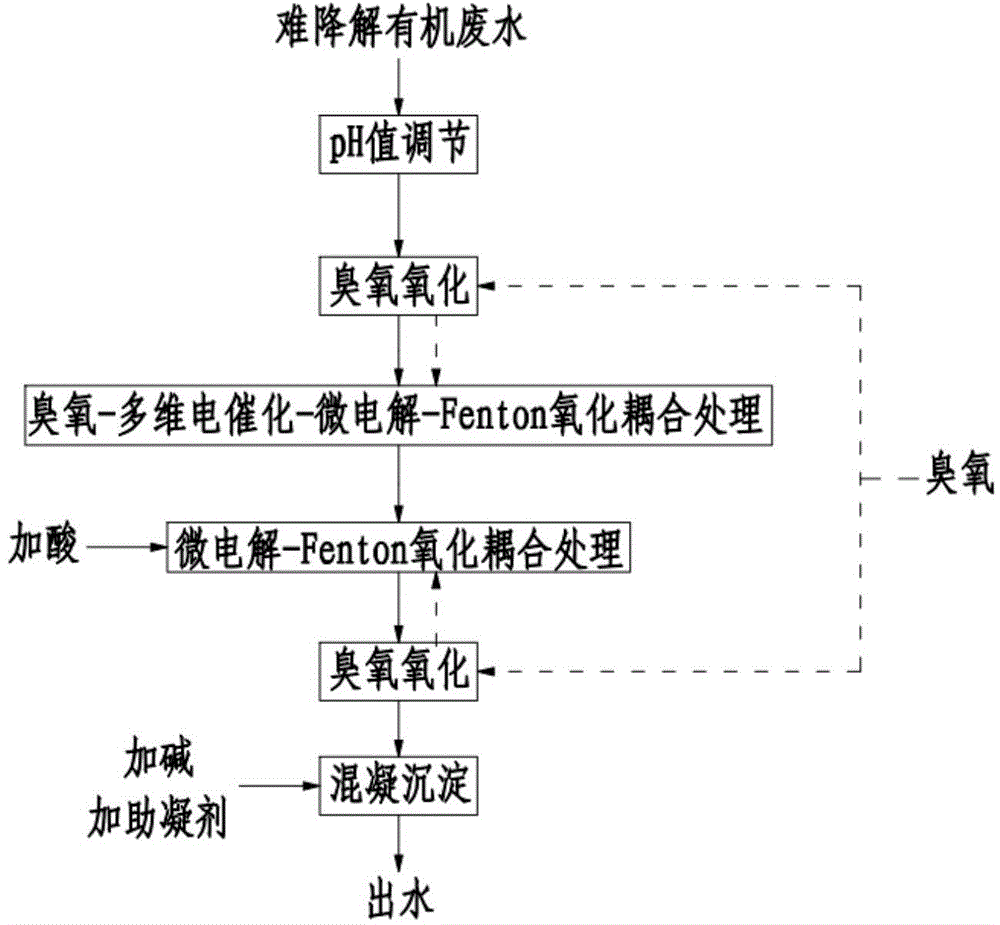

Advanced oxidative coupling device and process for treating organic wastewater difficult to degrade

ActiveCN104787941AImprove removal efficiencyLow running costWater contaminantsWater/sewage treatment by electrochemical methodsElectrolysisMulti dimensional

The invention discloses an advanced oxidative coupling device and process for treating organic wastewater difficult to degrade. A main device body comprises an ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area, an ozone oxidation-microelectrolysis / Fenton area, a coagulation area and an inclined plate sedimentation area, wherein the ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area comprises a multi-dimensional electrolysis / microelectrolysis area at the upper part and an ozone oxidation area at the lower part; the ozone oxidation-microelectrolysis / Fenton area comprises a microelectrolysis / Fenton area at the upper part and an ozone oxidation area at the lower part. The device combines four levels of advanced oxidation systems, and electrocatalytic oxidation, ozone oxidation, Fenton oxidation and a microelectrolysis reaction are mutually coupled in function, so that an organic matter difficult to degrade is subjected to multi-level oxidation to realize complete oxidative cracking; when the device is used for treating the organic wastewater difficult to degrade, the yield and the production rate of *OH are increased, the liquid phase transfer process is accelerated, the overall current efficiency of the device is increased, operation expenses are saved, flexible regulation and control of a process unit are realized, and the device can be used for treating various kinds of organic wastewater difficult to degrade.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD +1

Water quality improvement agent for aquaculture and preparation method thereof

InactiveCN108328750AUnique mineral skeleton structureIncrease surface areaBiocideWater treatment parameter controlSodium bicarbonateCalcium peroxide

The invention discloses a water quality improvement agent for aquaculture and a preparation method thereof. The water quality improvement agent is prepared from the following raw materials in percentage by weight: 5 percent to 10 percent of lactobacillus, 5 percent to 10 percent of photosynthetic bacteria, 5 percent to 10 percent of bacillus, 5 percent to 10 percent of brown sugar, 10 percent to 20 percent of activated carbon, 25 percent to 35 percent of zeolite powder, 3 percent to 5 percent of citric acid, 2 percent to 5 percent of sodium bicarbonate and 10 percent to 15 percent of calcium peroxide. According to the water quality improvement agent disclosed by the invention, organic matters in a water body of water for the aquaculture can be reduced, and the content of ammonia-nitrogen and nitrite is greatly reduced; the chemical oxygen consumption of pond bottom sludge is improved and oxygen debt of the pond bottom is alleviated; growth and proliferation of beneficial microorganismsand decomposition of organic pollutants are accelerated and the circulation of pond substances is accelerated; the proliferation of beneficial algae in a pond is accelerated so that the pond dissolved oxygen is increased; a culture water region environment is improved, healthy growth of aquatic animals is promoted, the feed coefficient is reduced and the economic benefits are increased.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

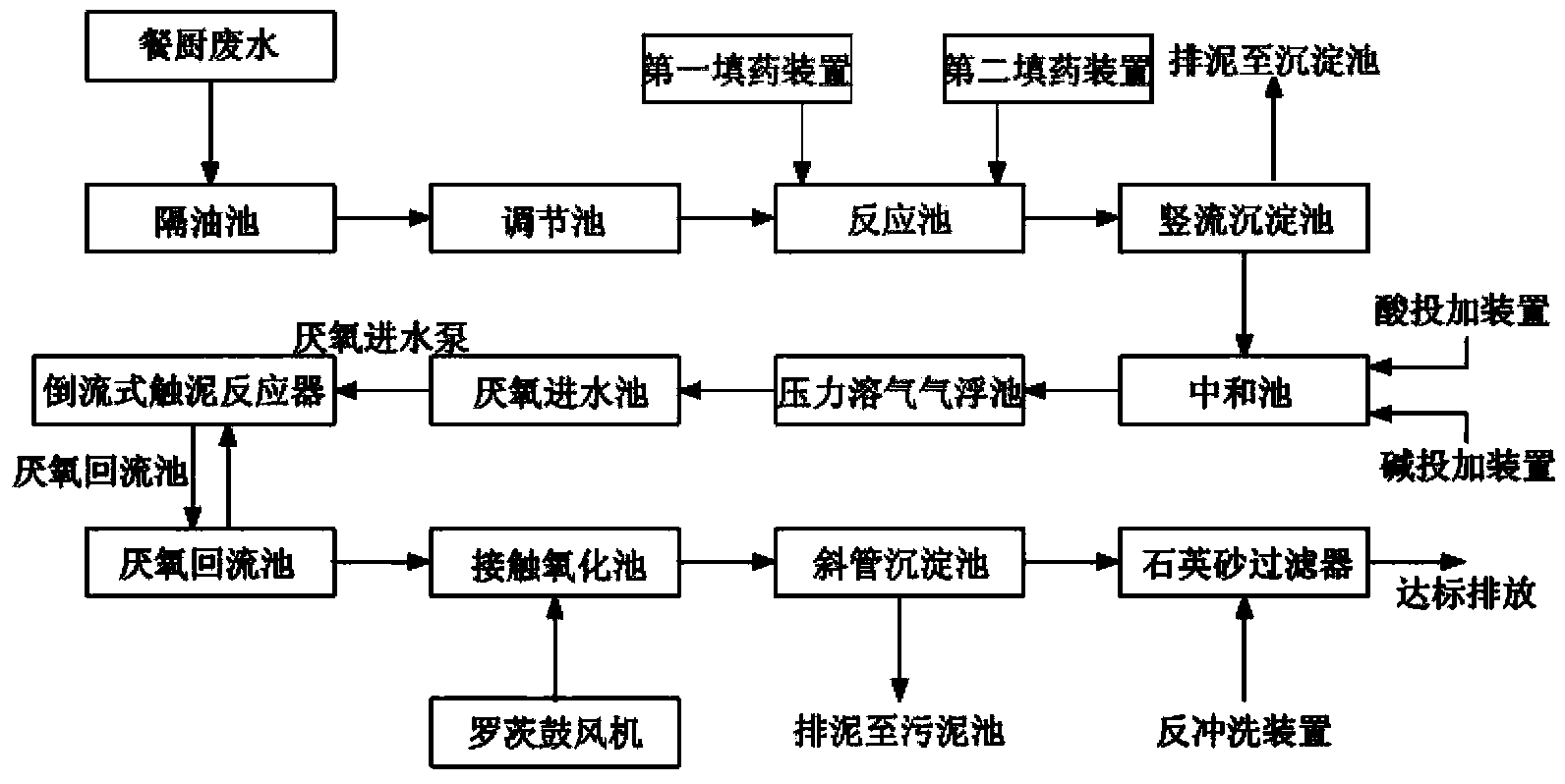

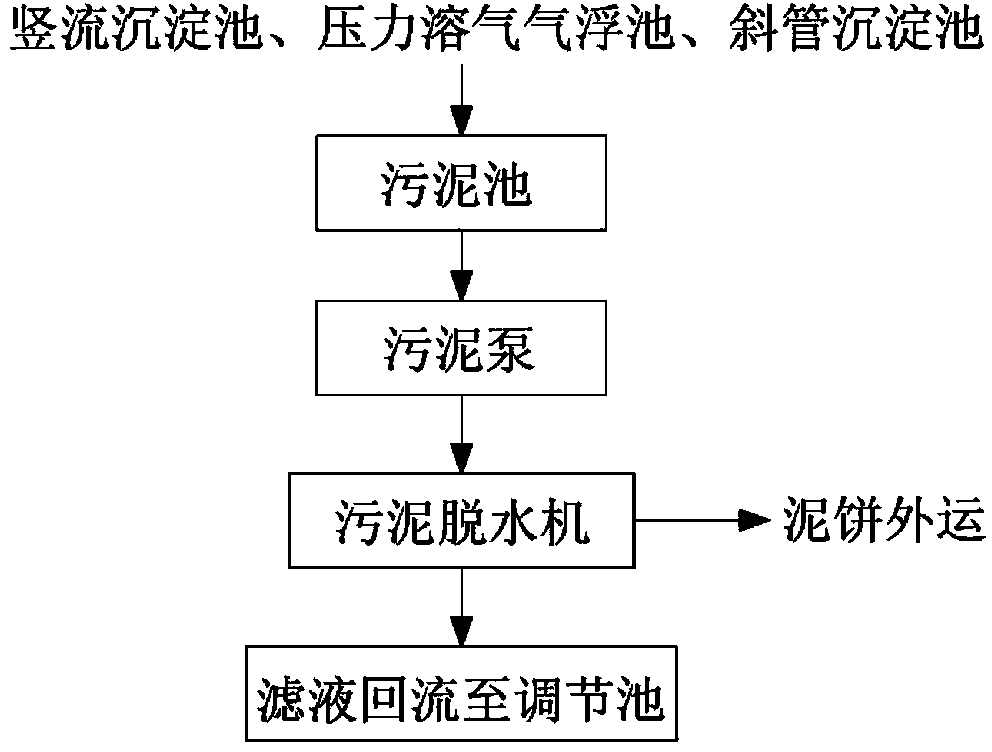

Kitchen waste filtrate treatment equipment and method

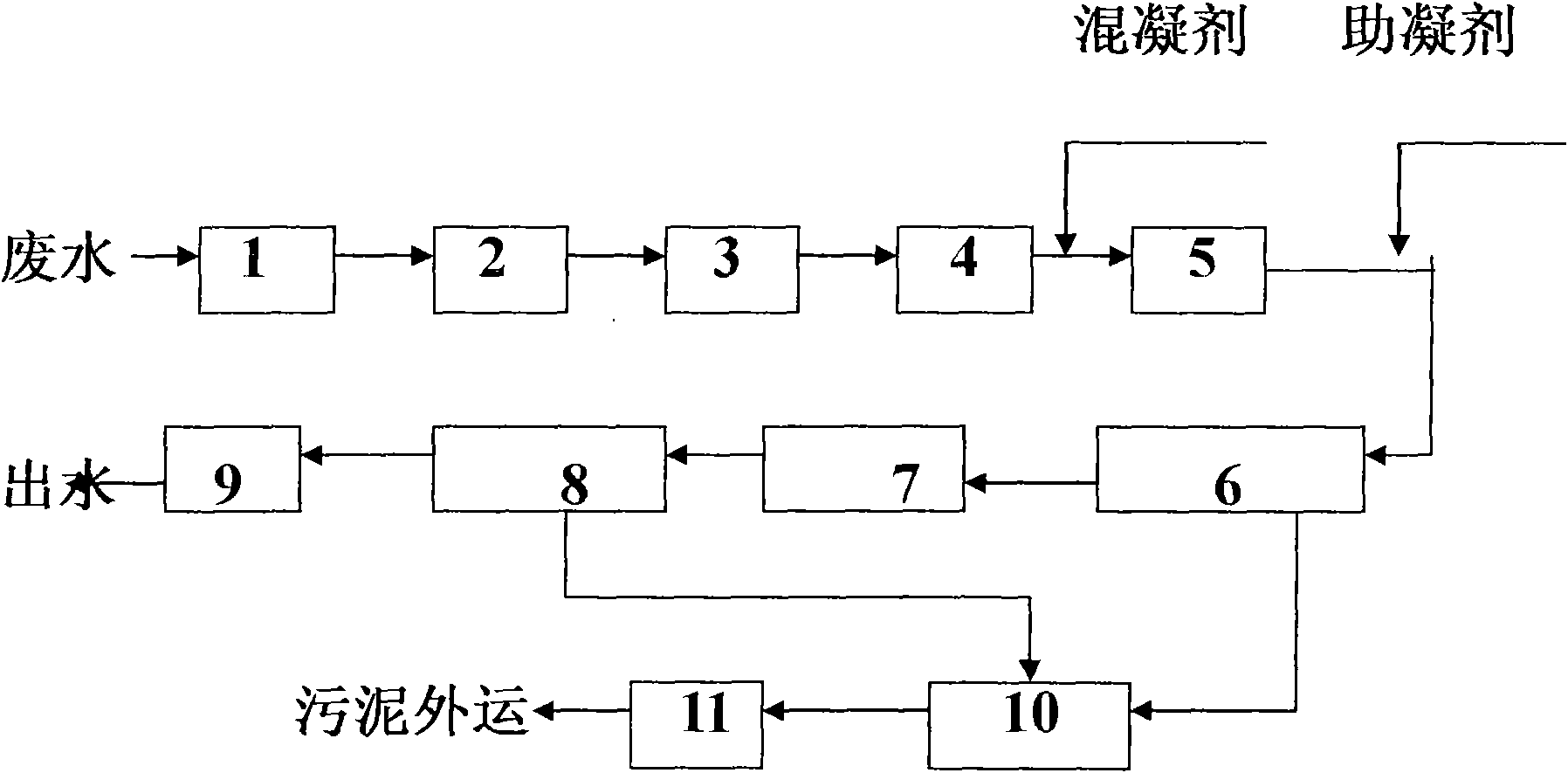

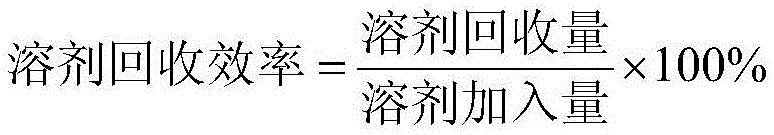

ActiveCN103435235AImprove CODHigh oil contentFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSludgeFiltration

The invention discloses kitchen waste filtrate treatment equipment and method. The treatment method comprises the steps that the kitchen filtrate firstly enters an oil separation tank used for separating oil substances from water substances; the water after separation is converged into a regulating tank and the water quality and quantity are regulated; the effluent enters a reaction tank, PAC (polyaluminium chloride) and PAM (polyacrylamide) are added to the effluent, so that fine particles in the water form a plenty of alum flocs, and then the alum flocs precipitate to be separated in a precipitation tank, thus removing most oil and scum; the effluent from the precipitation tank automatically flows into a neutralization tank, the pH value is regulated to neutral and then the effluent enters a pressure dissolved air floatation tank used for removing the scum formed by the flocculated suspended matter particles or oil particles brought on the water surface from the wastewater; then the pollutants such as organic matters, ammonia nitrogen and the like are removed by the pretreatment+anaerobic+aerobic precipitation+sand filtration technology of an exclusively added backflow sludge contact reactor; finally the wastewater reaches discharge standard.

Owner:裕英(北京)生物科技有限公司

Tanning wastewater treatment and reuse apparatus and method therefor

InactiveUS20130256224A1Reduce the amount requiredReduce consumptionTreatment using aerobic processesTreatment involving filtrationFlocculationElectrolysis

A tanning wastewater treatment and reuse apparatus includes a coarse filter, a regulation pool, a hydraulic sieve, a desulfurization pool, a first nanocatalytic electrolyzer, a flocculation pool, a first settling pool, a flotation device, a biochemical pool, a second settling pool, a second nanocatalytic electrolyzer, a fine filter, and a compressor. Also provided is a tanning wastewater treatment and reuse method includes the steps of desulfurization, first nanocatalytic electrolysis, flocculation, biochemical treatment, second catalytic electrolysis, and filtration. The invention allows high CODCr removal rate, reduced chemical agent consumption, reduced sludge formation, thorough treatment, and high water reuse rate.

Owner:BOYING XIAMEN SCI & TECH

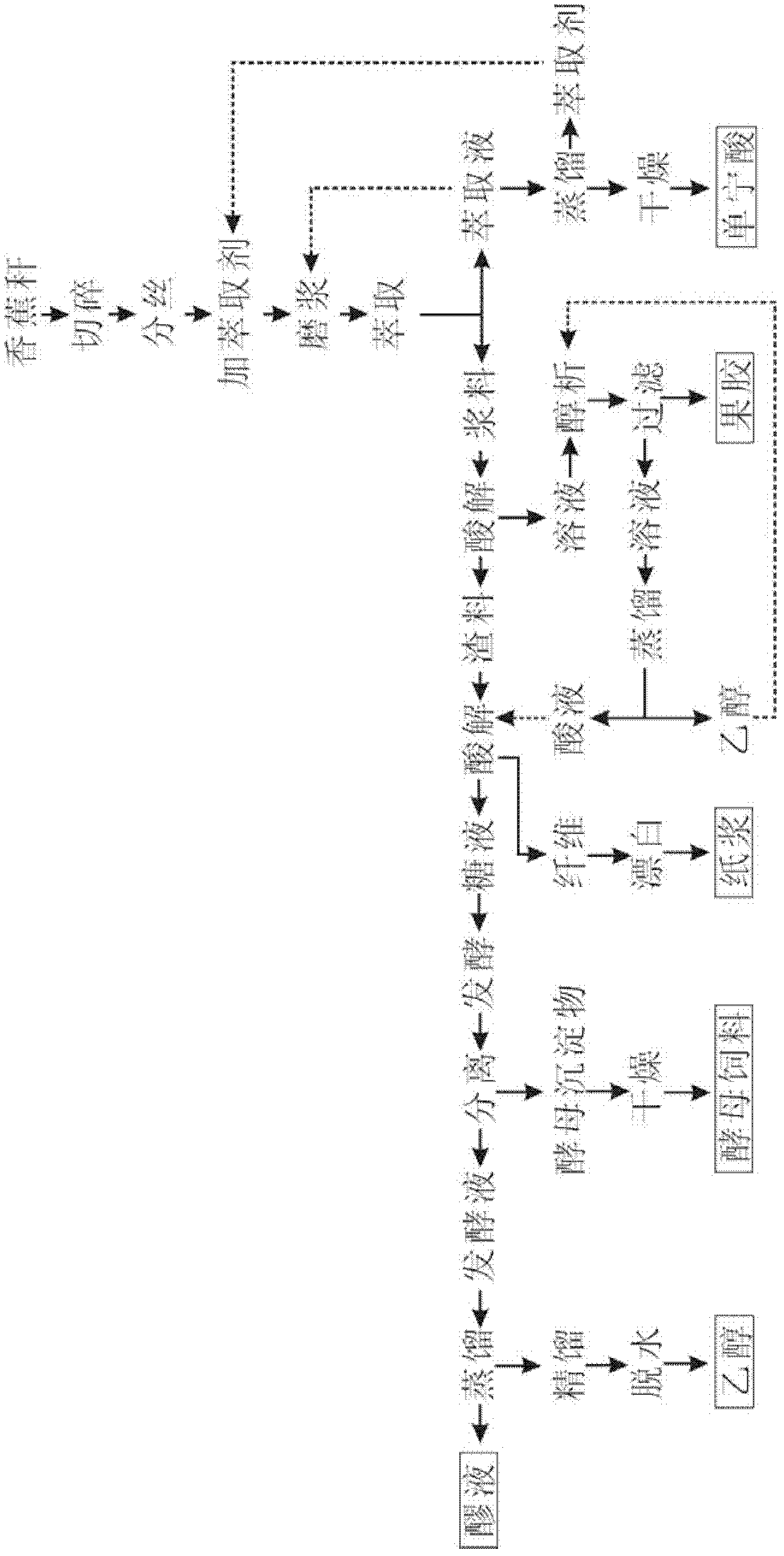

Method and technology for high-value comprehensive utilization of banana stems and leaves

ActiveCN103320476AHigh purityShorten fermentation timeEsterified saccharide compoundsNatural cellulose pulp/paperCelluloseFiber

The invention provides a comprehensive utilization method of banana stem and leaf resources. The method adopts banana stems and leaves as raw materials to successively produce tannic acid, pectin, paper pulp fibers, fuel ethanol, and yeast fodder. The method comprises the steps of: adopting banana stems and leaves as the raw materials, crushing the banana stems and leaves into a slurry form by beating via an extractant, and extracting tannin via an extracting liquid while pulping; subjecting the rest banana stem and leave slurry to acidolysis, and extracting pectin of the banana stems and leaves by stewing the banana stem and leave slurry at a normal pressure; and subjecting the remaining slurry to acidolysis, and degrading polysaccharide, starch and the other degradable substances into soluble degraded sugars by stewing at a high temperature and a high pressure, wherein the degraded sugars and reducing sugar of the banana stems and leaves constitute a soluble substance aqueous solution, so that a separation of cellulose from degradable substances is realized. The method provided by the invention can share the comprehensive utilization cost of banana stems and leaves, and can greatly increase the utilization efficiency of banana stem and leaf resources.

Owner:HAINAN BEIOU BIOENERGY DEV

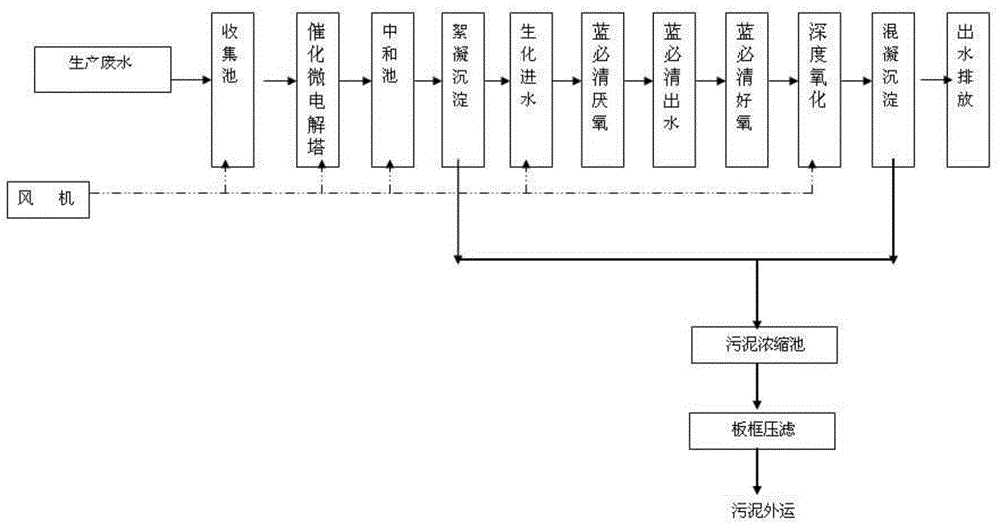

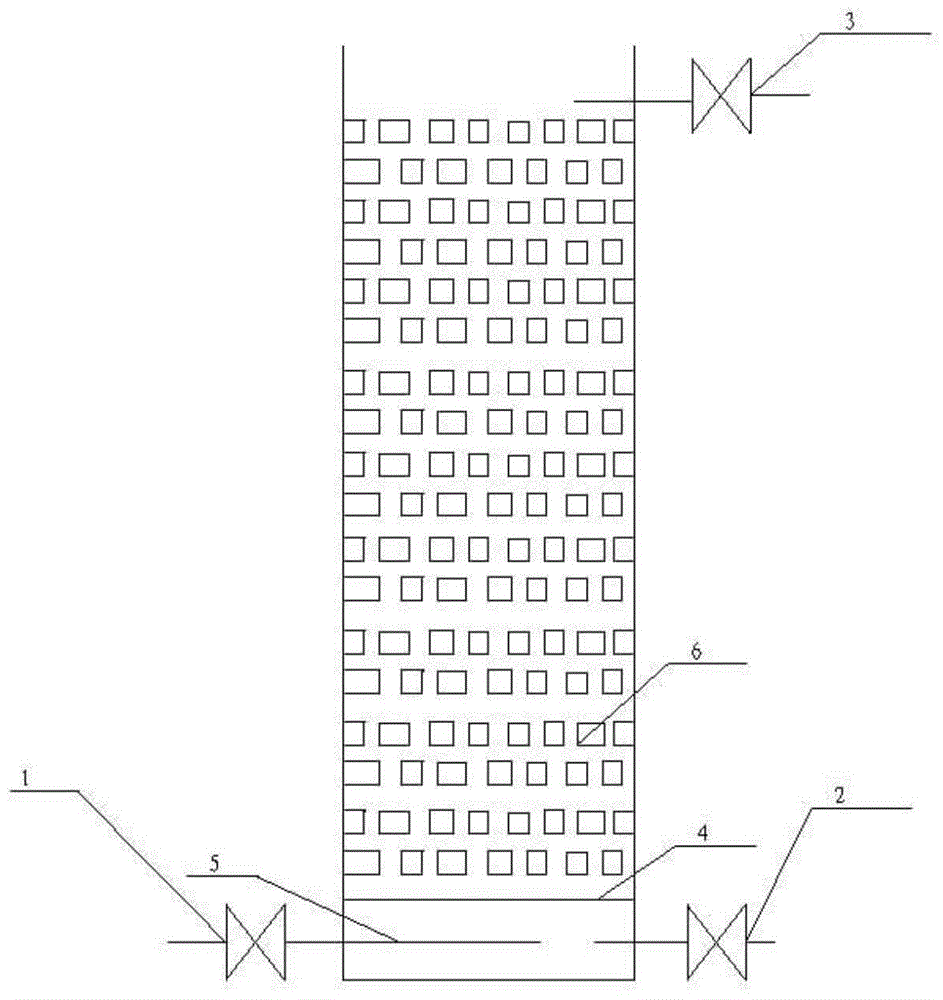

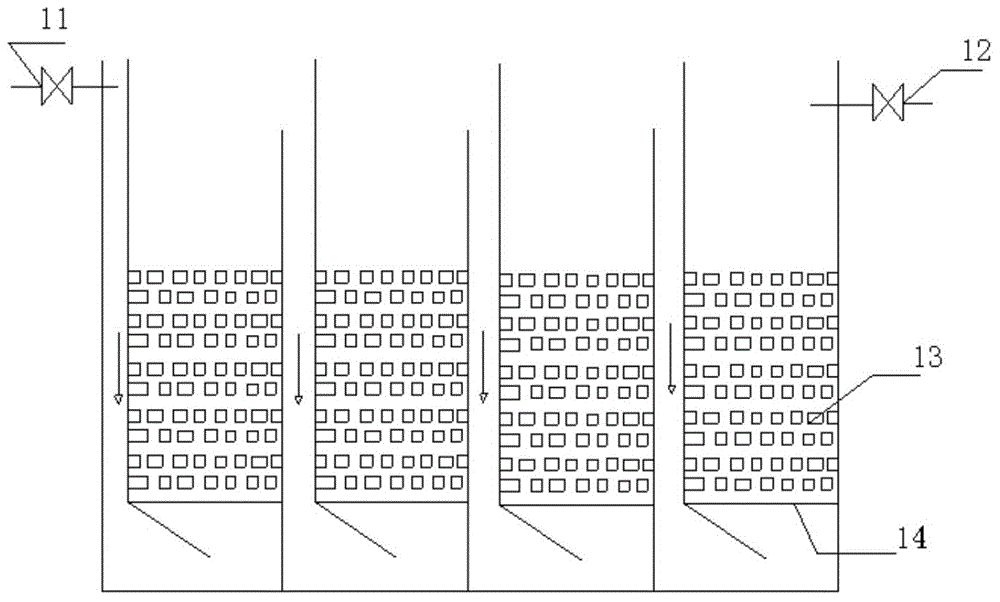

Method for treating wastewater during production of gallic acid

ActiveCN104086049ALow running costReduce lossTreatment using aerobic processesTreatment with anaerobic digestion processesGallic acid esterEmission standard

The invention discloses a method for treating wastewater during production of gallic acid so as to reach national-level emission standard. The method comprises the following steps: (1) treating wastewater during production of gallic acid through a catalytic microelectrolysis tower device and a flocculent settling technology; (2) treating flocculent-settled effluent water through (acclimated) anaerobic organism technology filled with efficient composite strain; (3) conducting aerobic microorganism technology treatment to the effluent water subjected to anaerobic treatment; and (4) conducting deep oxidization and flocculent settling to the effluent water subjected to aerobic technology and then emitting the effluent water reaching the national-level emission standard. The method solves the difficulty of wastewater treatment during the production of gallic acid, and is small in investment, low in running cost and good in treatment effect.

Owner:先微康新材料科技有限公司

Recycle method of recycled water

InactiveCN102167478AReduce alkalinityAchieve reuseSolid fuelsWater/sewage treatment bu osmosis/dialysisActivated carbon filtrationReverse osmosis

The invention discloses a recycle method of recycled water, which comprises the steps of: mixing cooked wastewater with the recycled water by the biochemically-treated and deeply-treated discharged water; and treating the mixed water through a lime+flocculation precipitating working procedure, a multi-medium filtering working procedure, a filtering working procedure by active carbon, a softening working procedure by a softener, an ultra-filtering working procedure and a reverse osmosis working procedure to obtain recycling water, wherein the recycling water is used as compensating water of circulating water, greening water, boiler water or fire fighting water. The recycle method of the recycled water can be used for wholly recycling the cooker wastewater; and the recycle method of the recycled water is used for mixing the cooked wastewater with the recycled water such as the circulating water wastewater, deoxidization station reverse osmosis concentrated water, the boiler wastewater and the like through the biochemically-treated and the deeply-treated discharged water and then treating the mixing water together, so that the quality of the recycled water is improved, the treatment difficulty is reduced, and the recycled water is high in yield and low in cost.

Owner:KAILUAN GRP +1

Meat processing waste water treatment process

InactiveCN101993168AHigh chromaImprove CODWaste water treatment from animal processingMultistage water/sewage treatmentChemical oxygen demandWater quality

The invention discloses a meat processing waste water treatment process and belongs to the technical field of sewage treatment in food production industry. The invention provides the meat processing waste water treatment process. In the invention, according to the water quality of the waste water, discharge standards and the concrete conditions of an enterprise, an air-floating, contact oxidation and filtering process is adopted for processing meat processing waste water, so that a great amount of waste water discharged during the production of a meat food processing enterprise and pollutant such as hair, animal blood, fat and oil in the waste water are completely removed. Moreover, suspended solids (SS) content and chemical oxygen demand (COD) content of the waste water are high, chrominance is high, and waste water discharge is certainly periodic, so that the treatment process has the characteristics of low power consumption and low working noises, is stably operated, is convenient to manage and is easy to operate and maintain; and the waster water is discharged after meeting the national discharge standards.

Owner:王慧怡

Recovering method for CO2 switch type solvent for treating oil-based drilling cuttings

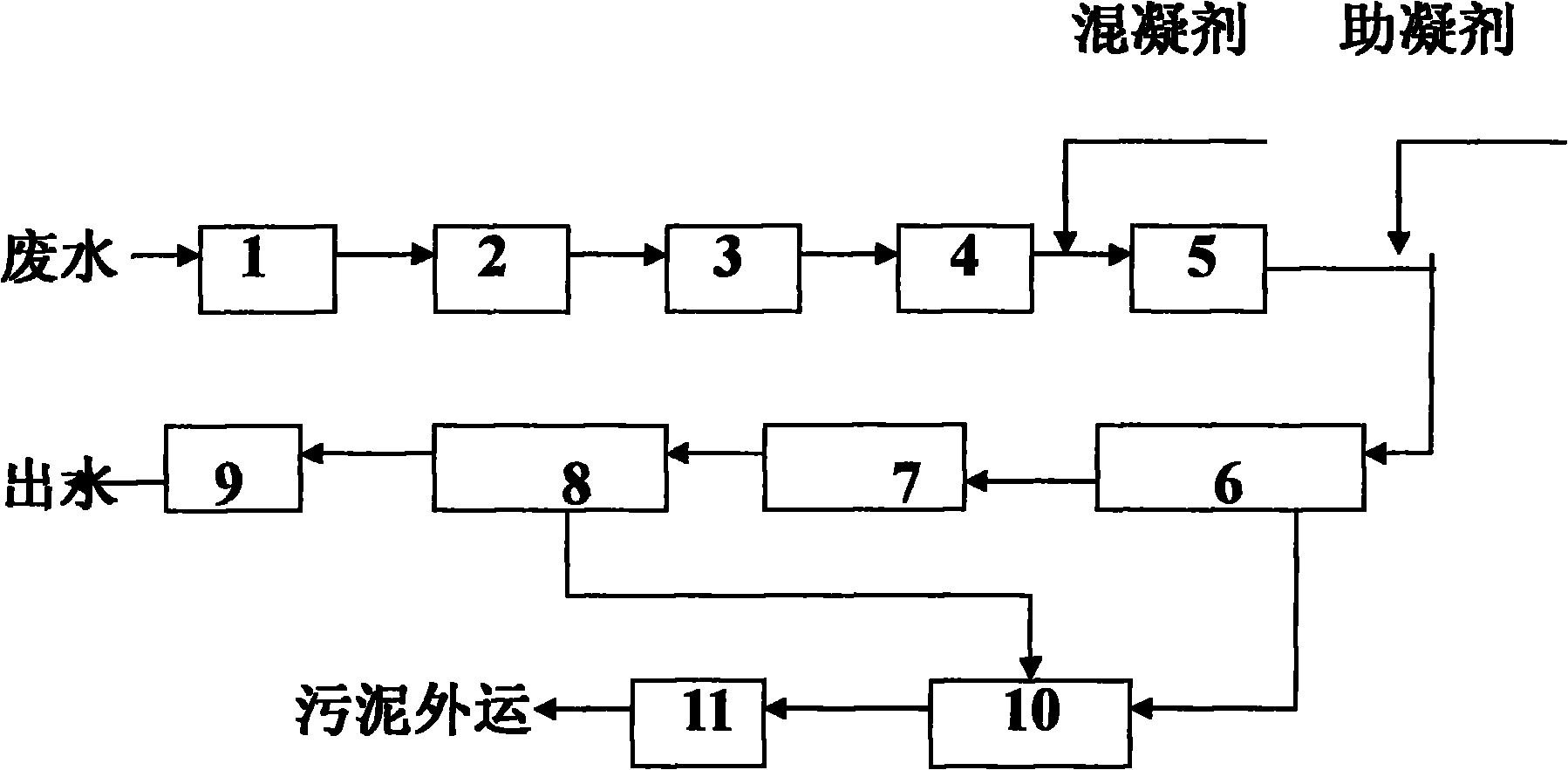

ActiveCN105925300AShort time spentImprove solvent recovery efficiencyLiquid hydrocarbon mixture productionSolventSolid phases

The invention discloses a recovering method for CO2 switch type solvent for treating oil-based drilling cuttings. The recovering method includes the steps that solid sodium hydroxide is added into the water phase containing CO2 switch type solvent and stirred to be dissolved, and an upper layer oil phase and a lower water phase are separated; solid calcium oxide is added into the water phase obtained after separation and stirred to be dissolved, an upper layer oil phase, a middle layer water phase and a lower layer solid phase are separated out; the oil phase obtained through separation is the recovered CO2 switch type solvent. The time needed for recovering the solvent is greatly shortened, solvent recovering efficiency is effectively improved, quality of wastewater obtained after separation is improved well, and the recovering method can be used for pretreating organic amine wastewater.

Owner:SOUTHWEST PETROLEUM UNIV +1

Method for treating ink wastewater

InactiveCN106986499AImprove CODGood effectWater contaminantsMultistage water/sewage treatmentChemistryTreatment effect

The invention relates to the field of environment protection, in particular to a method for treating ink wastewater. The method comprises the following steps: A, performing acid separation treatment, namely introducing ink wastewater into an acid separation tank, adjusting the pH value to 3-4, performing mechanical stirring for 15-30 minutes, leaving to stand for 30-45 minutes, and performing separation to obtain supernate A and precipitate A, and performing pressing filtration on the precipitate A to obtain pressing filtrate A; B, performing Fenton oxidation treatment, namely introducing the supernate A and the pressing filtrate A obtained in the step A into a Fenton oxidation tank, feeding Fe<2+> and H2O2, stirring, adjusting the pH value, performing separation to obtain supernate B and precipitate B, and performing pressing filtration on the precipitate B to obtain pressing filtrate B, wherein the ratio of Fe<2+> to H2O2 is (1:10)-(1:1), the stirring time is 10-20 minutes, and the pH value is adjusted to 6-8; C, performing MBR (membrane bio-reactor) reaction treatment, namely performing MBR microorganism degradation on the supernate B and the pressing filtrate B obtained in the step B, thereby obtaining purified water of which the COD (chemical oxygen demands) is less than 100, wherein the HRT (hydraulic retention time) of the MBR reaction treatment process is 4-6 hours. The technical scheme of the invention has the advantages of good organic matter treatment effect and stable effluent quality.

Owner:张颖柏

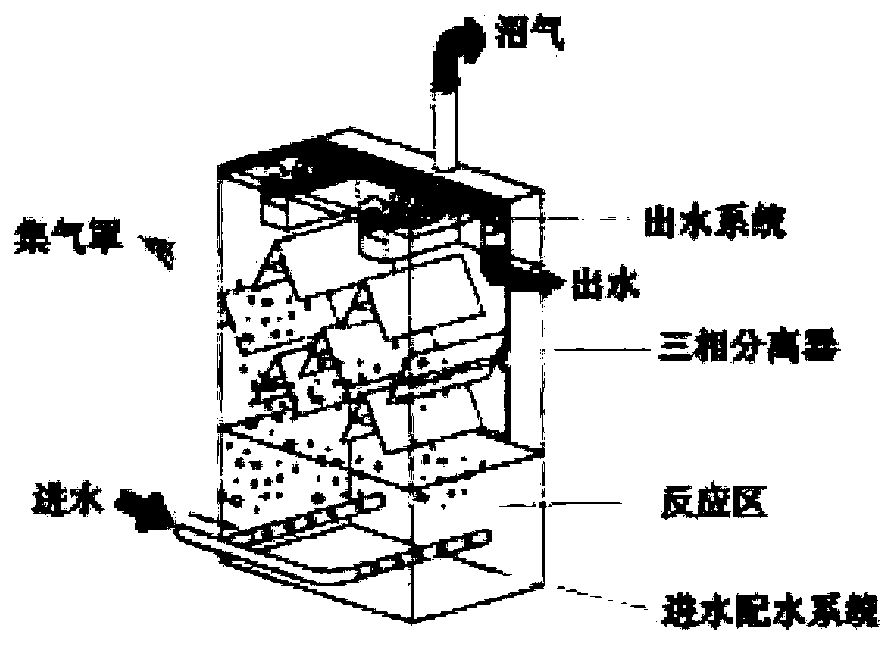

Method for treating high-concentration organic wastewater by anaerobic-aerobic deep coupling

InactiveCN111333191ALight inhibitionImprove efficiencyWater treatment parameter controlWater contaminantsActivated sludgeAmmoniacal nitrogen

The invention relates to a method for treating high-concentration organic wastewater by anaerobic-aerobic deep coupling. The method comprises the following steps: introducing organic wastewater into an anaerobic reaction unit, and sufficiently mixing the organic wastewater with anaerobic granular sludge added into the anaerobic reaction unit in advance to perform anaerobic reaction; enabling anaerobic effluent obtained after anaerobic reaction to enter an aerobic reaction unit, and removing nitrogen through a synchronous nitrification and denitrification process; flowing part of effluent of the aerobic reaction unit back to the anaerobic reaction unit and fully diluting and mixing the part of effluent with the raw organic wastewater and granular sludge to carry out anaerobic reaction, andenabling the other part of effluent to enter a next treatment process or discharging the other part of effluent after reaching the standard. According to the invention, the anaerobic and aerobic reaction units are coupled to treat wastewater; anaerobic effluent enters the aerobic unit, the DO value in the water body of the aerobic unit is controlled, denitrification is effectively completed, thereflux ratio of the aerobic effluent is controlled, and the aerobic effluent returns to the anaerobic unit again, so that the ammonia nitrogen concentration in the anaerobic reactor is reduced, the activated sludge amount in the anaerobic reactor is ensured, and the anaerobic reaction efficiency is effectively improved.

Owner:恩格拜(武汉)生态科技有限公司

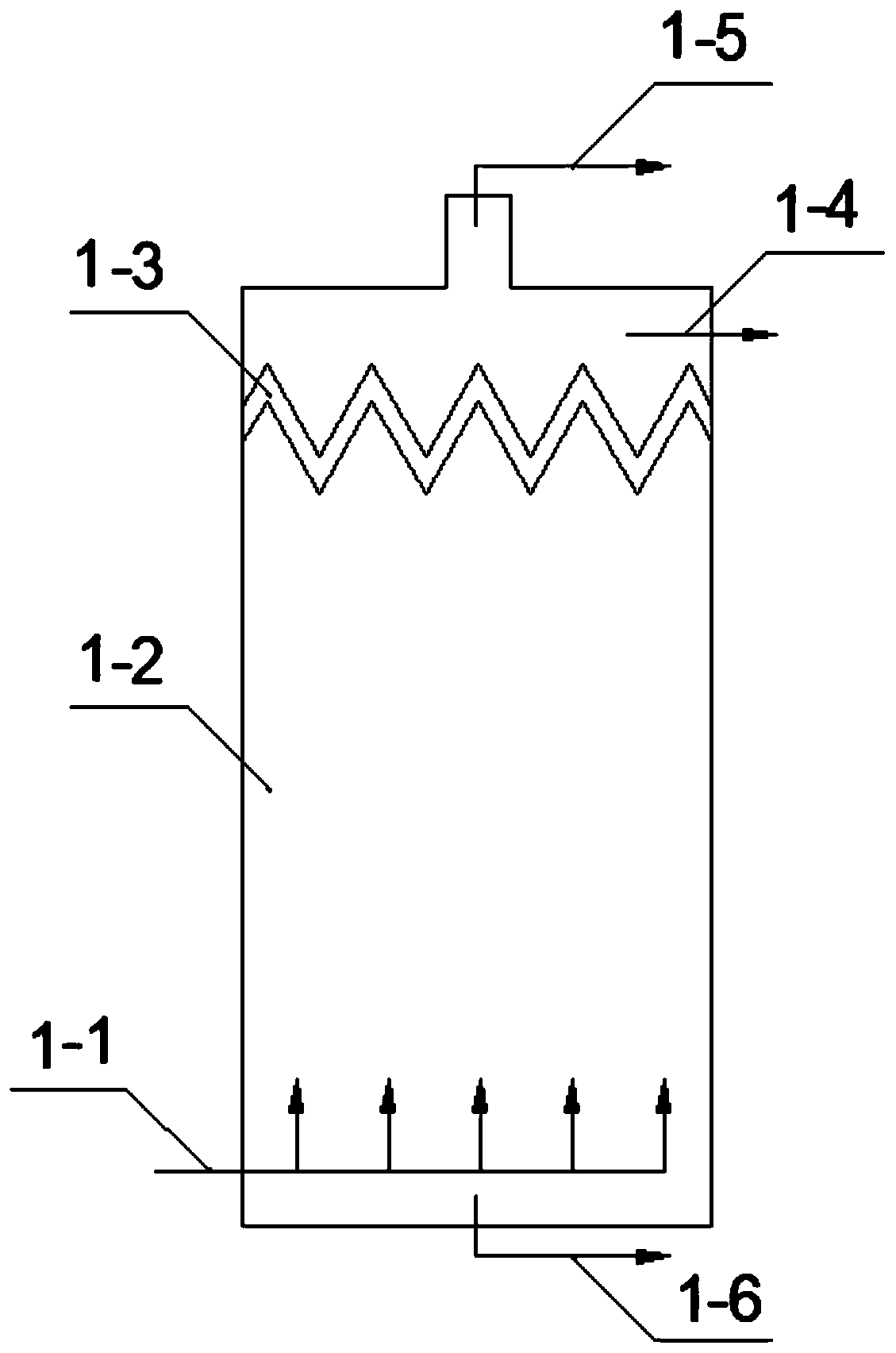

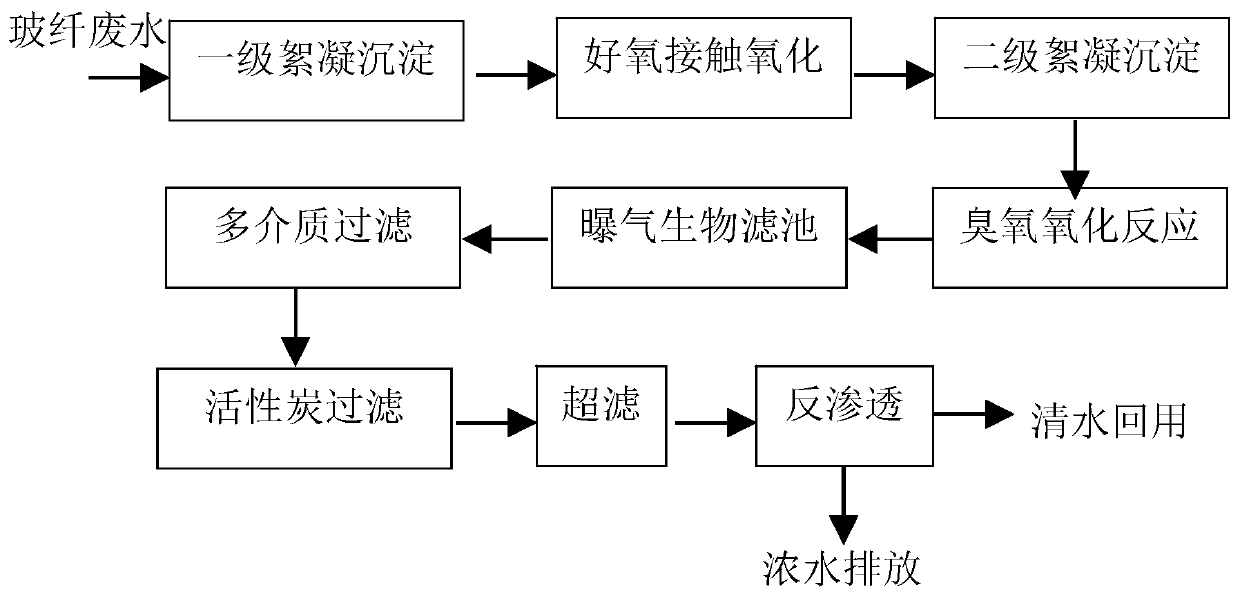

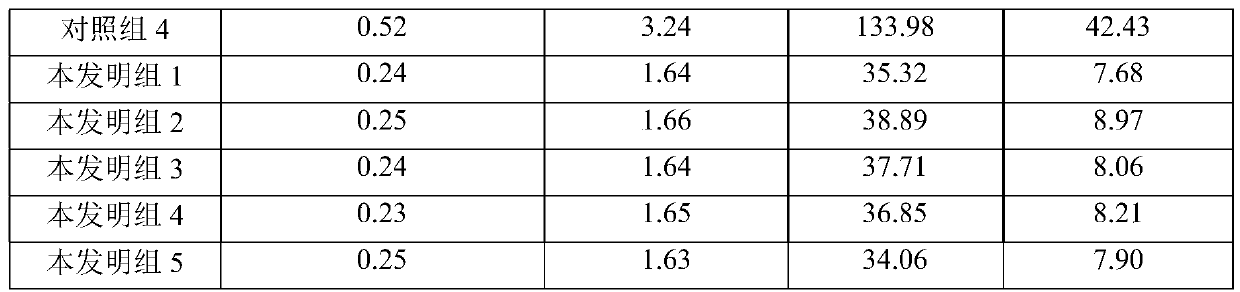

Glass fiber wastewater reusing and processing method and system

PendingCN109851156AEfficient reuseEfficient removalMultistage water/sewage treatmentUltrafiltrationChemistry

The invention provides a glass fiber wastewater reusing and processing method and system. The method comprises following steps: subjecting wastewater to primary flocculation and sedimentation; processing wastewater by an aerobic biological treatment system; subjecting wastewater to secondary flocculation and sedimentation; oxidizing wastewater by ozone; aerating wastewater in a bio-filter; filtering wastewater; adsorbing wastewater; and carrying out ultrafiltration and reverse osmosis. The aerobic biological treatment system is adopted, and an active sludge method and a bio-film method are integrated to efficiently remove COD in wastewater. The carbon and color of wastewater are efficiently removed by an ozone oxidation technology; the salt content of wastewater is not increased; through adsorption and ultrafiltration, the quality of water introduced to a reverse osmosis membrane can be guaranteed, thus the reverse osmosis membrane will not be polluted, and the reusing of the glass fiber wastewater is realized efficiently.

Owner:CISDI ENG CO LTD

Method for performing ecological restoration of hardened river banks by mangrove forest plants

PendingCN113367014AIncrease the number ofIncrease varietyWater resource protectionCoastlines protectionMangrove plantsAmmoniacal nitrogen

The invention discloses a method for performing ecological restoration of hardened river banks by mangrove forest plants. The method comprises the following steps: removing concrete hard banks on two sides of a river channel, and protecting the banks by adopting gabion retaining walls; driving tightly arranged pine piles into a riverbed, 2-3 m away from the banks, on the inner sides of the gabion retaining walls, and filling the area defined by the pine piles and the river banks with soil to form a first beach face; in a river section with a wider river channel cross section and a lower flow speed, forming a stepped slope according to terrains; planting true mangrove plants on the first beach face; and planting the true mangrove plants and semi-mangrove plants sequentially from the near-water side to the near-shore side. According to the method, the maximum water passing amount of the cross section is increased by removing the concrete river banks and adopting the terrain design of the gabion retaining walls and the stepped slope, and the flood discharging function is enhanced. The mangrove forest plants are planted on the two sides of the river, formation of different types of habitats such as the river, mangrove forests and semi-mangrove forests is promoted, various water pollution indexes such as ammonia nitrogen, COD (chemical oxygen demand) and the like are obviously reduced, and DO (dissolved oxygen) is obviously increased.

Owner:RES INST OF TROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Pretreatment method of antibiotic production waste water

ActiveCN106587445AReduce chromaReduce the pressure of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by neutralisationPretreatment methodElectrolysis

The invention provides a pretreatment method of antibiotic production waste water. The method is characterized in that the method comprises the following steps: (1) first level micro-electrolysis; (2) primary coagulating sedimentation; (3) advanced electrocatalytic oxidation; (4) second level micro-electrolysis; (5) secondary coagulating sedimentation. The method mainly aims at deficiency in the prior waste water pretreatment method in the antibiotic production process, and has the advantages of high treatment efficiency and low treatment cost; COD and chromaticity of antibiotic production waste water treated by the process reach the standard.

Owner:SHENYANG POLYTECHNIC UNIV +1

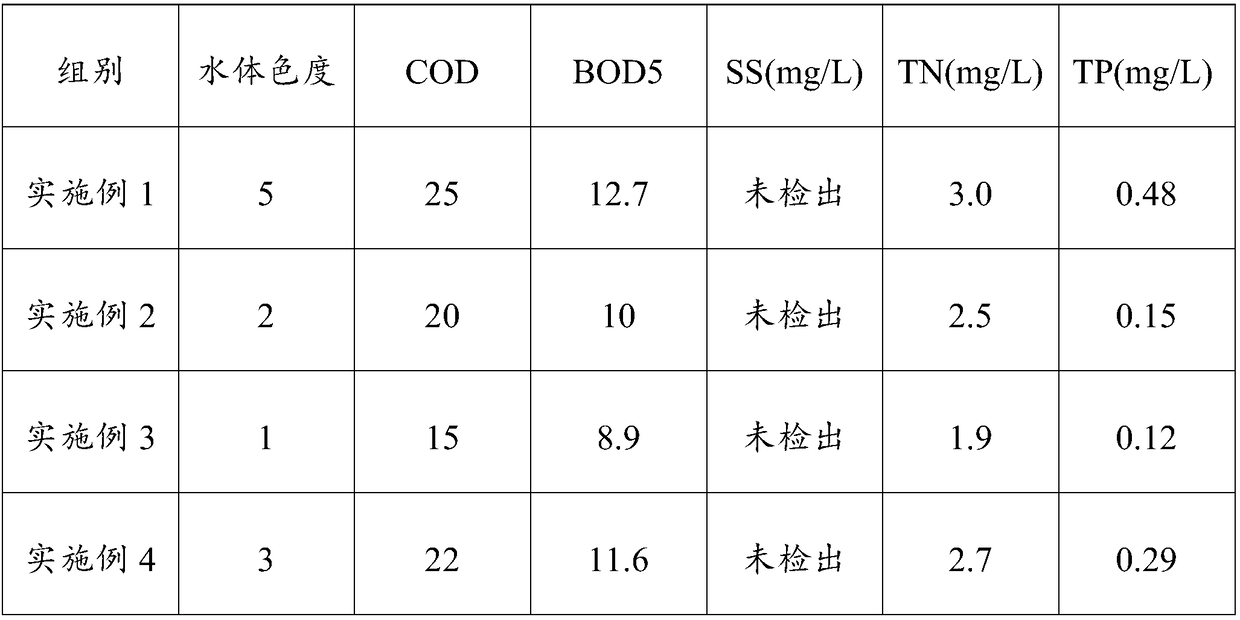

Microbial agent for improving total phosphorus indexes in polluted water body and preparation method and application of microbial agent

InactiveCN110804565AEasy to useSimple methodWater treatment parameter controlBacteriaMicroorganismMicrobial agent

The invention discloses a microbial agent for improving total phosphorus indexes in a polluted water body. The microbial agent comprises the following components in terms of 100 parts by total weight:10-35 parts of glycosaminoglycan chelate salt, 30-50 parts of bacillus pumilus and 15-40 parts of bacillus cereus. The microbial agent is capable of welling solving the problem of total phosphorus index degradation in the polluted water body, particularly has a very good treatment effect on polluted water bodies of river channels, dirt containing ponds, and the like, and has the characteristics of being nontoxic, safe, efficient, free of secondary pollution, and the like. The invention further discloses a preparation method and application of the microbial agent.

Owner:HEBEI CONSTR GROUP INSTALLATION ENGCO

Biological enzyme purifying agent for treating black-odor river and preparation method thereof

ActiveCN108585223AGood chromaImprove CODBiological water/sewage treatmentContaminated waterways/lakes/ponds/rivers treatmentSludgeBiology

The invention discloses a biological enzyme purifying agent for treating black-odor river The biological enzyme purifying agent for treating black-odor river comprises the following components in parts by weight: 20-50 parts of biological enzyme, 10-15 parts of rhodococcus erythropolis sludge flocculant, 10-18 parts of chitosan quaternary salt, 10-15 parts of grape seed extract, 5-15 parts of sweet potato extract and 10-15 parts of polyaluminium chloride and 8-12 parts of polygalanthamine. Under the combined action of a plurality of components, the water purification effect of the water body is remarkable, the quality of the water body can be obviously improved, the dissolved oxygen content in the water can be improved, the growth of the harmful bacteria is inhibited, the suspended mattersand harmful algae in the water are removed, the content of the nitrogen and the nitrate nitrogen in the water body is reduced, the water body is clarified, the odor is eliminated, the degradation ofthe pollutants is promoted, and the benign development of the water is promoted. The raw material resource used is rich, the preparation process flow of the water purifying agent is simple, the production period is short, the operation is simple, the production cost is low, and the water purifying agent is suitable for industrial production.

Owner:广东大禹水利建设有限公司

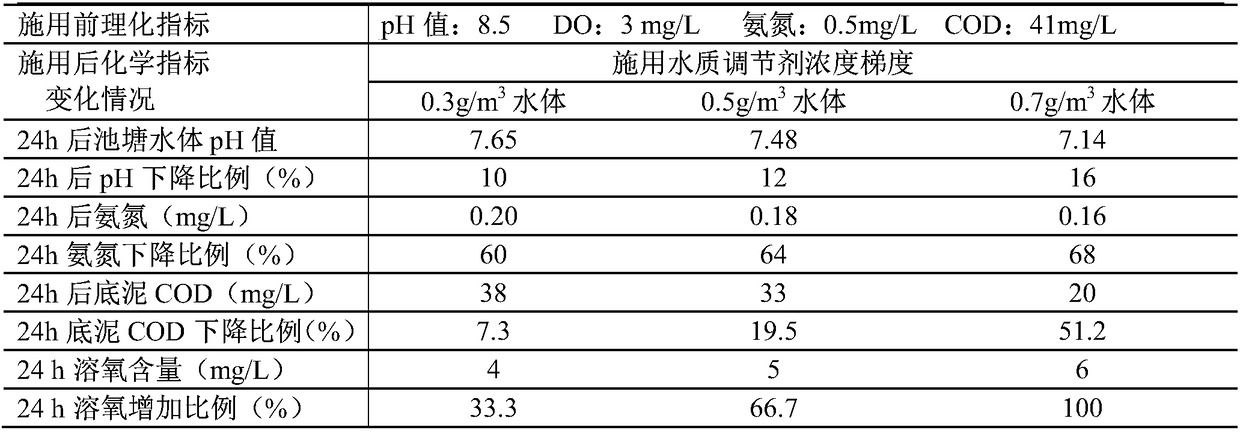

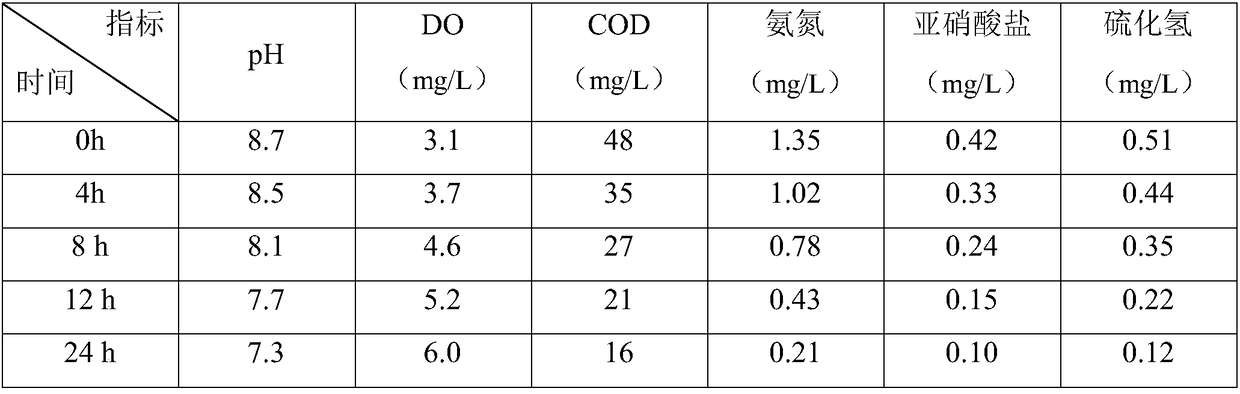

Water quality regulator for aquaculture, and preparation method of water quality regulator

ActiveCN108911161AHigh activityImprove purification effectWater treatment parameter controlWater treatment compoundsNitrifying bacteriaCatalase

The invention discloses a water quality regulator for aquaculture, and a preparation method of the water quality regulator. The water quality regulator is prepared from the following raw materials byweight: 160-200g of molasses, 20-50g of catalase, 30-60g of nitrifying bacteria, 30-50g of photosynthetic bacteria, 20-30g of bacillus subtilis, 30-70g of DL-malic acid, 60-80g of glacial acetic acid,80-100g of urea, 50-80g of chitosan, 40-50g of zeolite powder, 130-170g of humic acid, 50-70g of a radix dipsaci extract and 30-50g of a radix polygonati officinalis extract. The water quality regulator provided by the invention can accelerate the circulation of materials in a pond, inhibit the pH value rise of the water body, change the chemical processes of the formation of harmful ammonia nitrogen and nitrite, reduce the production of ammonia nitrogen, nitrite and hydrogen sulfide in the water layer and the bottom sediment, lower the chemical oxygen consumption of sludge at the bottom of the pond, reduce the health hazard of toxic and harmful chemicals on aquatic animals and promote the growth of the aquatic animals, thus having good social and economic benefits.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

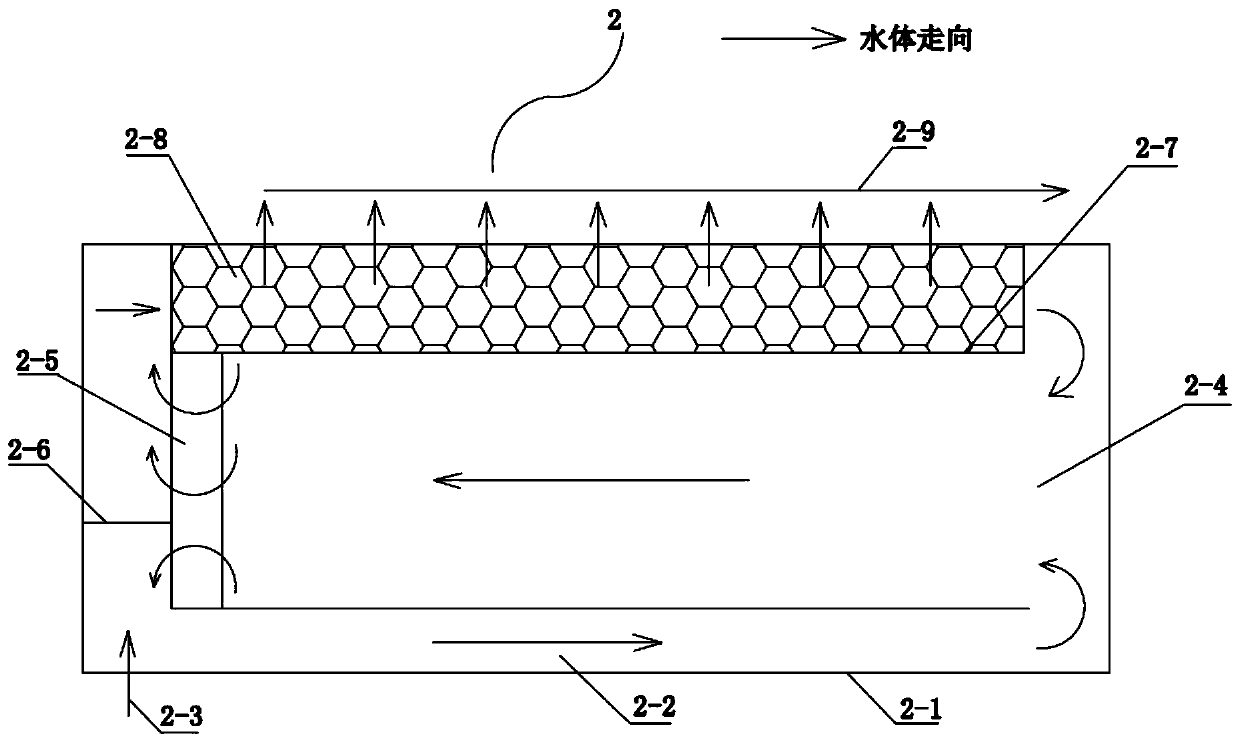

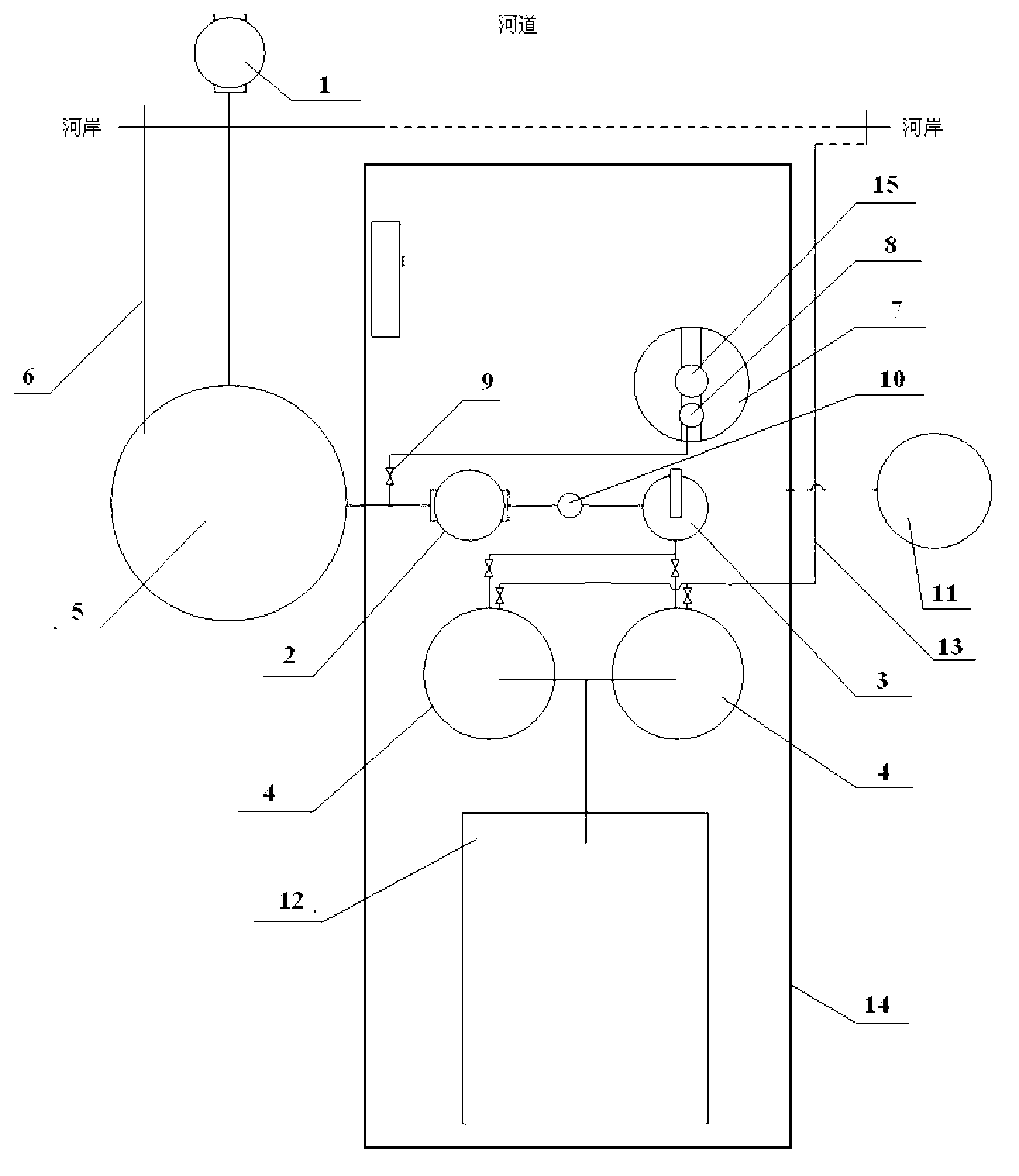

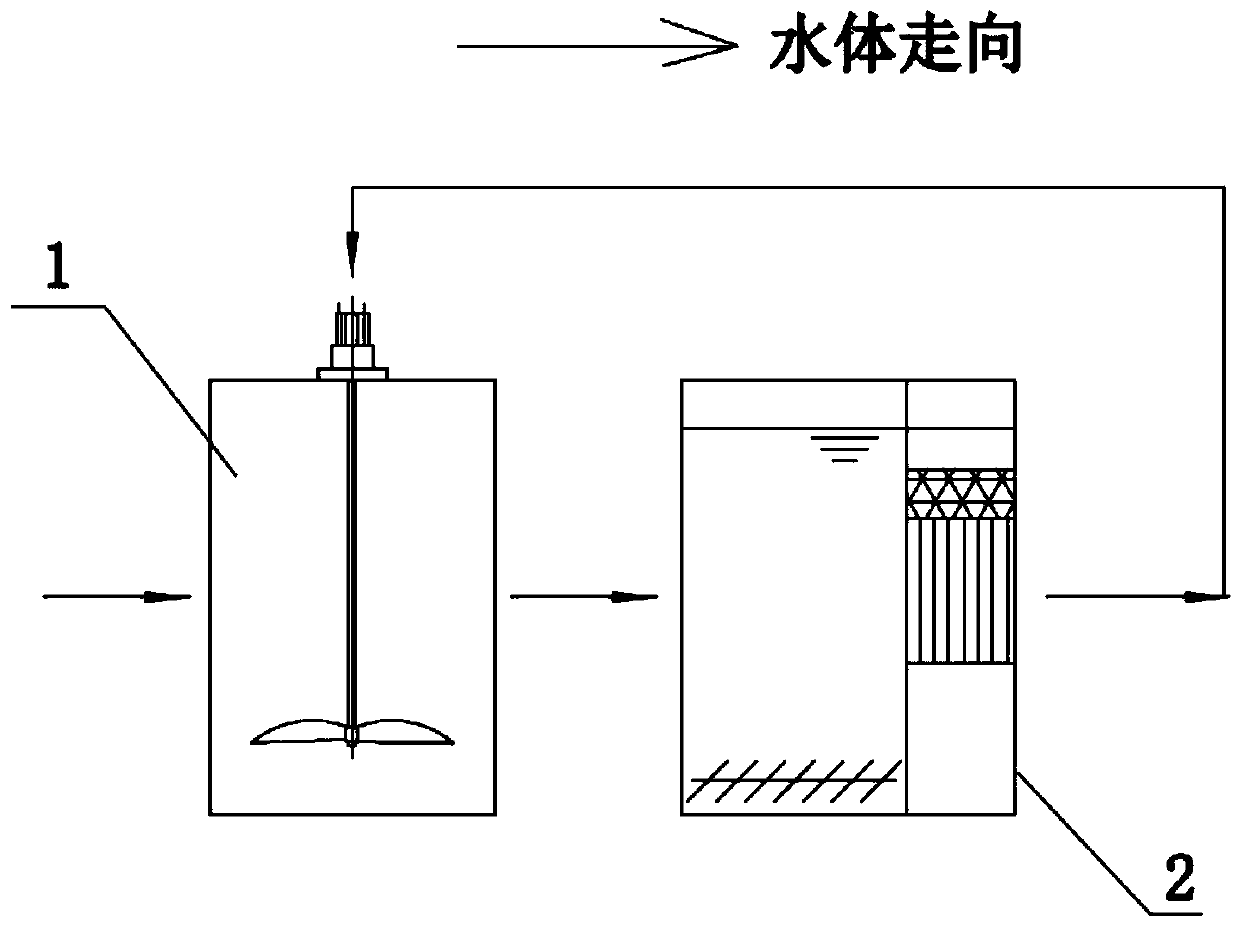

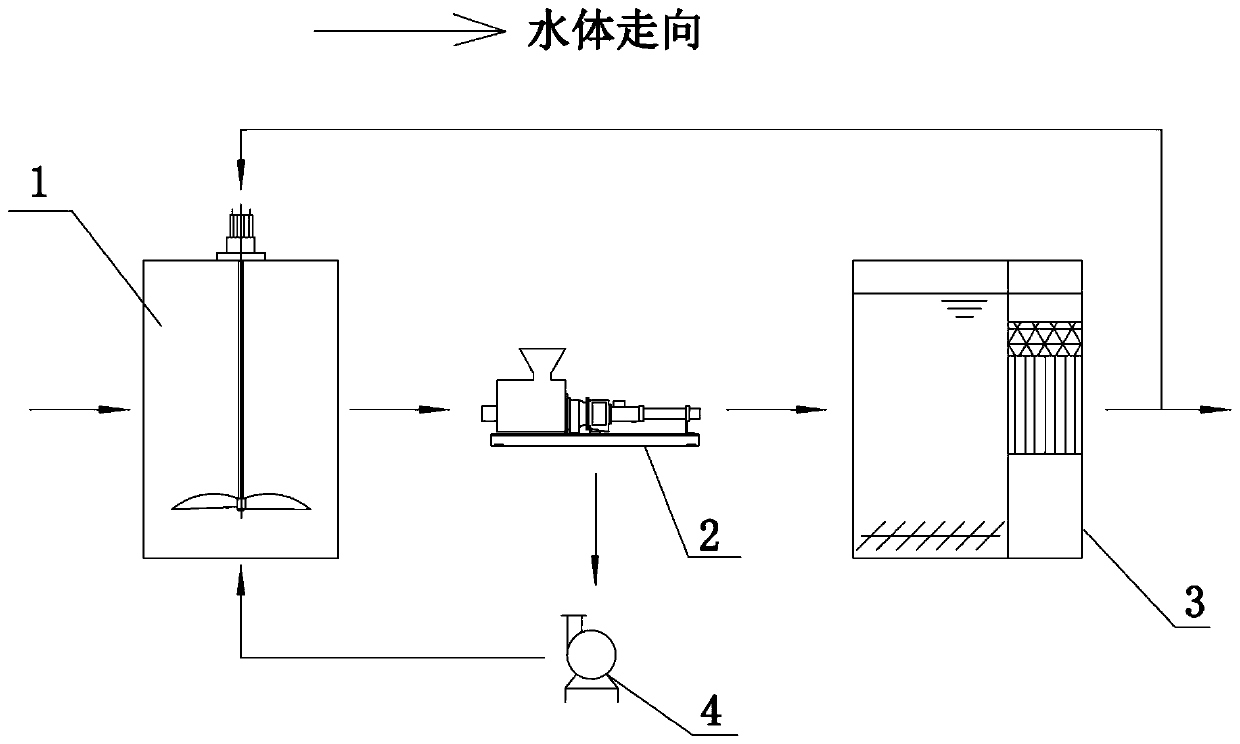

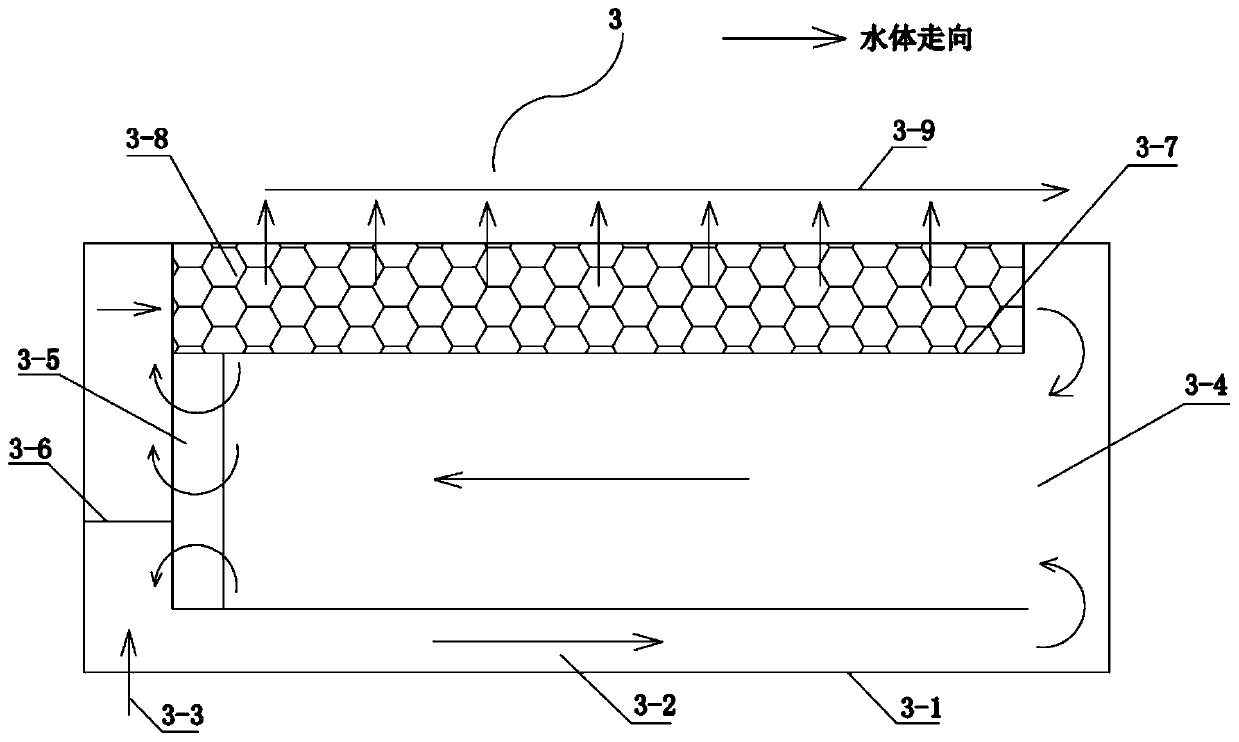

Purification system for river water or landscape water

ActiveCN103058431AImprove volumetric efficiencyThe rate of dissolved oxygen is fastWater aerationWater/sewage treatment bu osmosis/dialysisDraining tubeRetention time

The invention discloses a purification system for river water or landscape water. The purification system comprises a water pump, a pressure pump, a microfilter and a pressure dissolved air tank, wherein an outlet of the water pump is communicated with an adjusting water tank, an inlet of the pressure pump is communicated with the adjusting water tank, an outlet of the pressure pump is communicated with the microfilter, the inlet terminal of the pressure pump is further communicated with a preparation storage tank, a sludge outlet of the microfilter is communicated with a sludge storage tank, a water outlet of the microfilter is communicated with the pressure dissolved air tank, the bottom of the pressure dissolved air tank is connected with a drainpipe, and the pressure dissolved air tank is communicated with an oxygenator. The purification system provided by the invention has high volumetric efficiency; waterpower retention time of the system is generally about 6.5 to 8.0 min, treating capability per unit volume is great, and equipment is convenient to transport and has strong mobility.

Owner:TSINGHUA UNIV +1

Papermaking sewage treatment agent and preparation method thereof

InactiveCN109179694AImprove CODMeet industry requirementsWater treatment parameter controlWaste water treatment from plant processingBetaineFatty alcohol

The invention provides a papermaking sewage treatment agent and a preparation method thereof and belongs to the technical field of sewage treatment. The papermaking sewage treatment agent comprises fly ash, montmorillonite powder, tetrabutyl titanate, n-propyl acrylate, methacryloyloxyethyltrimethylammonium chloride, sodium polyepoxysuccinate, fatty alcohol polyoxyethylene ether, polydimethylsiloxane diquaternary ammonium salt, nickel sulfate, nano-titanium dioxide, papain, horseradish peroxidase, betaine, acetobacter xylinum powder, an initiator and a coupling agent. Through specific raw material combination and specific production processes, the papermaking sewage treatment agent can effectively improve the COD, SS and B / C indicators of the papermaking industry sewage, can meet the requirements of the industry and has a good application prospect.

Owner:德保县广鑫贸易有限公司

Water quality improvement agent for aquaculture and preparation method thereof

ActiveCN108821412APromote circulationSuppresses pH riseWater contaminantsWaste water treatment from animal husbandryPhosphateAquatic animal

The invention discloses a water quality improvement agent for aquaculture and a preparation method thereof. The water quality improvement agent is prepared from the following raw materials according to the weight: 150 to 200g of molasses, 30 to 50g of catalase, 20 to 30g of bacillus subtilis, 50 to 70g of DL-malic acid, 60 to 80g of citric acid, 80 to 100g of urea, 60 to 100g of potassium dihydrogen phosphate, 50 to 70g of chitosan, 50 to 80g of zeolite powder, 140 to 170g of humic acid, 50 to 70g of radix dipsaci extract and 30 to 50g of radix polygonati officinalis extract. The water qualityimprovement agent disclosed by the invention can be used for accelerating the circulation of substances in a pond, inhibiting the raising of the pH (Potential of Hydrogen) value of a water body, changing a chemical progress of formation of harmful ammonia nitrogen and nitrite, reducing the generation of a water layer and substrate ammonia nitrogen, the nitrite and hydrogen sulfide, improving thechemical oxygen demand of pond bottom sludge, reducing dangers, caused by toxic and harmful chemical substances, on aquatic animals and prompting the growth of the aquatic animals; the water quality improvement agent has good social and economic benefits.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Technology for pre-treating coal chemical wastewater through acidizing-compound flocculation process

InactiveCN109534548AHigh removal rateLarge amount of processingFatty/oily/floating substances removal devicesTreatment involving filtrationFiltrationPolyacrylamide

The invention provides a technology for pre-treating coal chemical wastewater through an acidizing-compound flocculation process. Removal rate of COD in coal chemical wastewater can reach up to 77% orabove through the processes of treatment on the basis of gravity settling and filter cloth filtration, acidizing pretreatment with concentrated hydrochloric acid and compound flocculation pretreatment with poly-ferric sulfate solution, poly-aluminum chloride solution, alum solution and polyacrylamide. The pretreatment process is simple and reliable and is economical and low-cost.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Membrane treatment method and apparatus for underground wastewater

InactiveCN103693778AHigh chromaImprove CODMultistage water/sewage treatmentContaminated groundwater/leachate treatmentAutomatic controlControl system

The invention discloses a membrane treatment device for underground wastewater. The membrane treatment device comprises a precision filter system, a booster pump system, a membrane treatment main device system, a dosing system, an instrument analysis and monitoring system, and an automatic control system 6, wherein the underground wastewater sequentially flows from the precision filter system and the booster pump system to the membrane treatment main device system through a pipeline; the dosing system is used for adding chemicals on an underground wastewater inlet; instrument monitoring points of the instrument analysis and monitoring system are respectively arranged on pipeline measuring points of the precision filter system and the booster pump system; the automatic control system is connected to an input of the instrument analysis and monitoring system, and an output of the instrument analysis and monitoring system is connected to corresponding control ends of the membrane treatment main device and the dosing system; the instrument analysis and monitoring system and the automatic control system are arranged on a same platform or in a plant, and are integrally connected through various corrosion resistant pipelines and cables; through a valve and a water pump of the membrane treatment main device system, operation under different pressures and flows is realized, so that underground water polluted in various ways is treated.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

High-sulfur and high-acid crude oil decalcifying agent and preparation method thereof

The invention discloses a high-sulfur and high-acid crude oil decalcifying agent and a preparation method thereof. The decalcifying agent comprises the following components in percentage by mass: 10%-20% of formic acid, 5%-13% of acetic acid, 30%-50% of citric acid and 17%-55% of RPL, wherein if the total amount of RPL is 100%, and the RPL comprises the following components in percentage by mass: 10%-30% of isopropanol, 10%-30% of cinnamomum camphora essential oil and 50%-70% of eucalyptus oil. The decalcifying agent has the following advantages that: (1) a small quantity of the decalcifying agent is added; (2) the decalcifying agent is low in cost; and water-soluble organic calcium slats can be generated after the decalcifying, so that the decalcifying agent is harmless to the environment. Calcium decalcified by a conventional decalcifying agent precipitates sometimes, or the chemical oxygen demand (COD) of sulphur-bearing wastewater of an oil refining atmospheric and vacuum distillation unit is obviously increased. The decalcifying agent has the advantages of cost saving, energy conservation, wastewater discharge reduction and environmental protection benefit.

Owner:JIANGSU CHUANGXIN PETROCHEM

Anaerobic-aerobic deep coupled method for treating high-concentration organic wastewater

InactiveCN110790379AHigh outputLight inhibitionWater treatment parameter controlWater contaminantsNitrogen removalBiogas production

An anaerobic-aerobic deep coupled method for treating high-concentration organic wastewater comprises the following steps: crushing and screening organic waste, and feeding the slurry from filtrationinto an anaerobic reaction unit for anaerobic fermentation to obtain biogas and biogas slurry; subjecting the biogas slurry after the anaerobic reaction to a synchronous nitrification and denitrification process in an aerobic reaction unit for nitrogen removal; and returning part of effluent from the aerobic reaction unit to the anaerobic reaction unit to be fully diluted and mixed with the raw slurry of organic waste for anaerobic reaction, while discharging the other part of the effluent into next treatment process or discharging the rest effluent on standard. According to the invention, theeffluent from the anaerobic reaction is discharged into the aerobic unit, and the DO value of the water in the aerobic unit is controlled to complete nitrogen removal; then, the effluent from the aerobic reaction is returned to the anaerobic unit again at a controlled reflux ratio for circular reaction; and therefore, the biogas production rate of anaerobic reaction can be increased, while the water quality of the effluent from the aerobic reaction can be higher.

Owner:恩格拜(武汉)生态科技有限公司

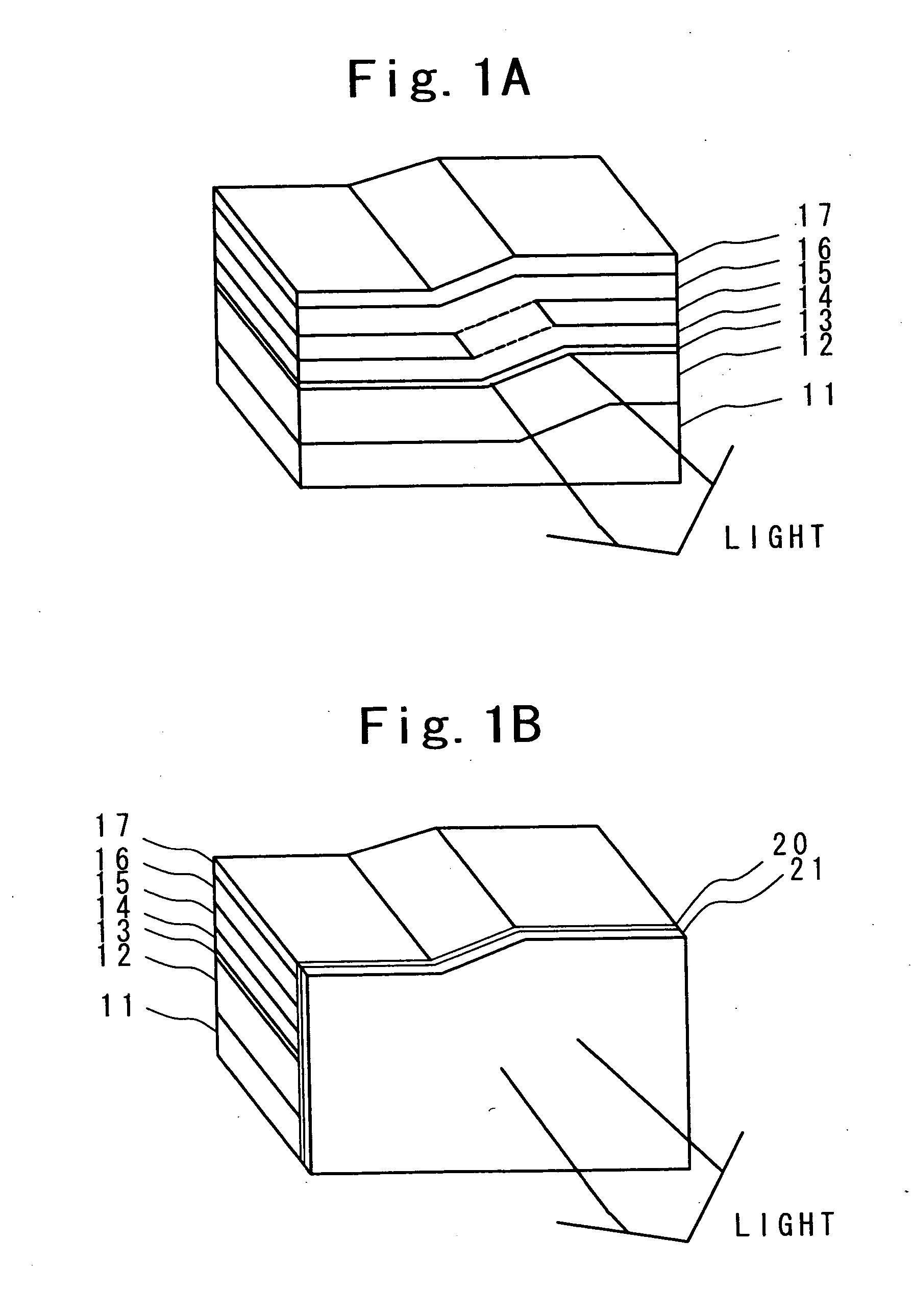

Optical semiconductor device and method of fabricating the same

InactiveUS20050040418A1Improve CODEffective preventionLaser detailsSemiconductor laser structural detailsDevice materialSemiconductor

An optical semiconductor device includes a laminated layer structure, an intermediate film formed on an end surface of the laminated layer structure, and a passivation film formed on the intermediate film. The passivation film has a quantity of ion projection than that of the intermediate film.

Owner:FUJITSU QUANTUM DEVICES LTD

Method for treating high-solid-content organic wastewater by anaerobic-aerobic deep coupling

ActiveCN110790378AHigh outputLight inhibitionWater treatment parameter controlWater contaminantsFiltrationBiogas production

The invention relates to a method for treating high-solid-content organic wastewater by anaerobic-aerobic deep coupling. The method comprises the following steps: crushing and screening organic wastes, adding a slurry liquid obtained by filtration into an anaerobic reaction unit, and carrying out anaerobic fermentation to obtain biogas and biogas slurry; introducing anaerobic outlet water into a solid-liquid separation unit for solid-liquid separation, and enabling separated biogas residues to return into the anaerobic reaction unit through a sludge backflow pump; enabling separated biogas slurry to enter an aerobic reaction unit, and removing nitrogen through a synchronous nitrification and denitrification process; and enabling part of outlet water of the aerobic reaction unit to flow back to the anaerobic reaction unit and undergo full dilution and mixing with organic waste raw slurry liquid for an anaerobic reaction, and enabling the other part of the outlet water to enter a next treatment process or be discharged after reaching the standard. According to the method, the anaerobic outlet water enters the solid-liquid separation unit, suspended solids are separated out, outlet water enters the aerobic reaction unit, the DO value in the water body of the aerobic reaction unit is well controlled, denitrification is completed, then a backflow ratio of aerobic outlet water is controlled and part of the aerobic outlet water returns to the anaerobic reaction unit again, the reaction is circulated, the anaerobic biogas production rate is increased, and meanwhile the water quality of the aerobic outlet water is higher.

Owner:恩格拜(武汉)生态科技有限公司

A kind of biological enzyme purifying agent for black and odorous river course treatment and preparation method thereof

ActiveCN108585223BGood chromaImprove CODBiological water/sewage treatmentContaminated waterways/lakes/ponds/rivers treatmentRhodococcus erythropolisPolyacrylamide

The invention discloses a biological enzyme purifying agent for treating black and odorous river courses. The parts by weight of each component are: 20-50 parts of biological enzyme, 10-15 parts of Rhodococcus erythropolis sludge flocculant, chitosan quaternary ammonium 10-18 parts of salt, 10-15 parts of grape seed extract, 5-15 parts of sweet potato extract, 10-15 parts of polyaluminum chloride, and 8-12 parts of polyacrylamide. Under the joint action of multiple components, the present invention has remarkable water purification effect, can significantly improve water quality, increase dissolved oxygen content in water, inhibit the growth of harmful bacteria, remove suspended solids and harmful algae in water, and reduce ammonium nitrogen and nitrate levels in water. Nitrogen content, clarify water body, eliminate odor, promote the degradation of pollutants, and promote the healthy development of water ecology. The present invention has abundant raw material resources, simple preparation process of the water purifying agent, short production cycle, simple operation, low production cost, and is suitable for industrialized production.

Owner:广东大禹水利建设有限公司

Anti-cracking drilling fluid rock debris curing agent and use method thereof

PendingCN112500101AImprove CODRaise the pHSolid waste managementHeavy metal chelationChemical oxygen demand

The invention provides an anti-cracking drilling fluid rock debris curing agent. The curing agent comprises the following materials: slag powder, desulfurized gypsum, beta-hemihydrate gypsum, fly ash,construction waste powder, sylvite or ammonium salt, an excitant and an organic heavy metal chelating agent. According to the anti-cracking drilling fluid rock debris curing agent and the using method, the curing agent is added into the target rock debris, so that the chemical oxygen demand (COD), the pH value, the chromaticity and petroleum substances in the rock debris are all improved. The curing strength of the rock debris is improved by 6-9 times, high-cost materials such as cement do not need to be added, the rock debris can be prevented from cracking after being cured, and the method is an environment-friendly and low-cost curing technology.

Owner:张夏艇

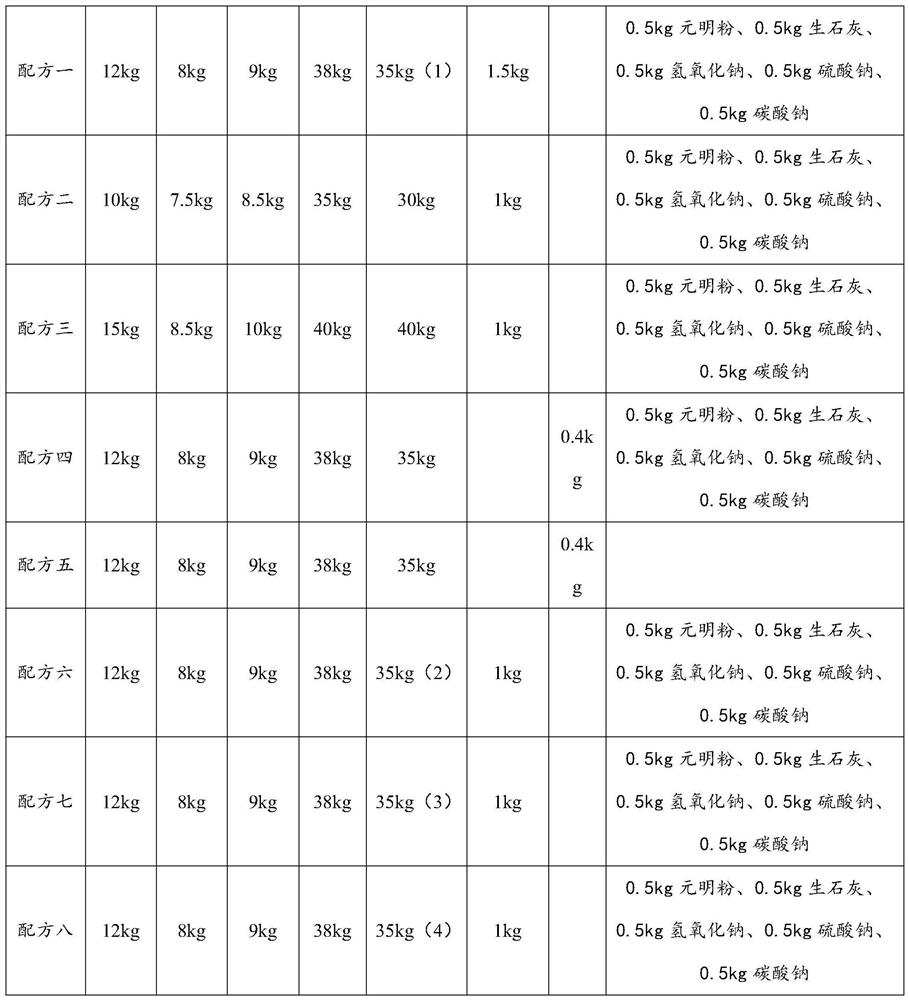

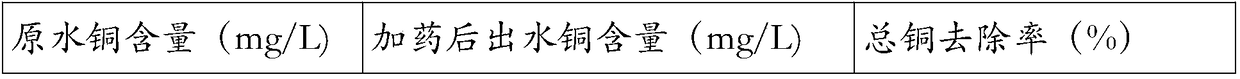

High-efficiency copper-removal mixture and application thereof

InactiveCN108178274AEasy to handleThorough responseWater contaminantsWater/sewage treatment by flocculation/precipitationEcological environmentPolyacrylamide

The invention provides a high-efficiency copper-removal mixture. The high-efficiency copper-removal mixture comprises a component A and a component B by weight percentage, wherein the component A comprises 20-40 parts of crosslinking starch, 5-10 parts of di-isopropylbenzene hydroperoxide, 15-25 parts of carbon disulfide, 20-25 parts of sodium hydroxide, and 80-90 parts of water; wherein the component B comprises 15-25 parts of polyferric sulfate, 5-15 parts of polyaluminum ferric chloride, 7-12 parts of polyacrylamide, and 60-80 parts of water. The high-efficiency copper-removal mixture has double-effect copper-removal effect, can increase the removal rate of copper ions, improves ecological environment, and has the advantages of no toxicity, environmental protection, and low cost.

Owner:珠海盛博环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com