Method for treating wastewater during production of gallic acid

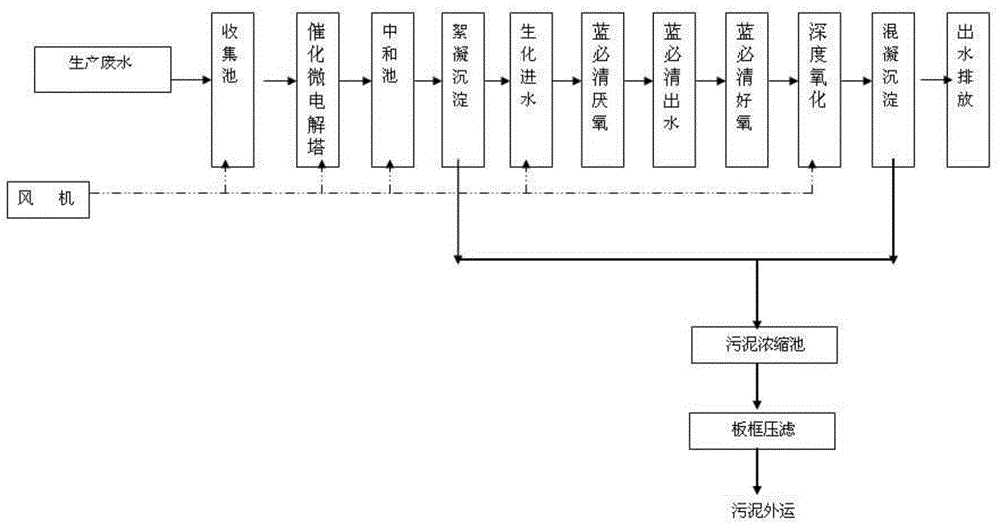

A gallic acid and wastewater treatment technology, applied in biological water/sewage treatment, water/sewage treatment, sustainable biological treatment, etc., can solve the problems of large environmental pollution, high cost, and complicated wastewater treatment process, and achieve low operating costs , low loss, high processing stability and volume utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

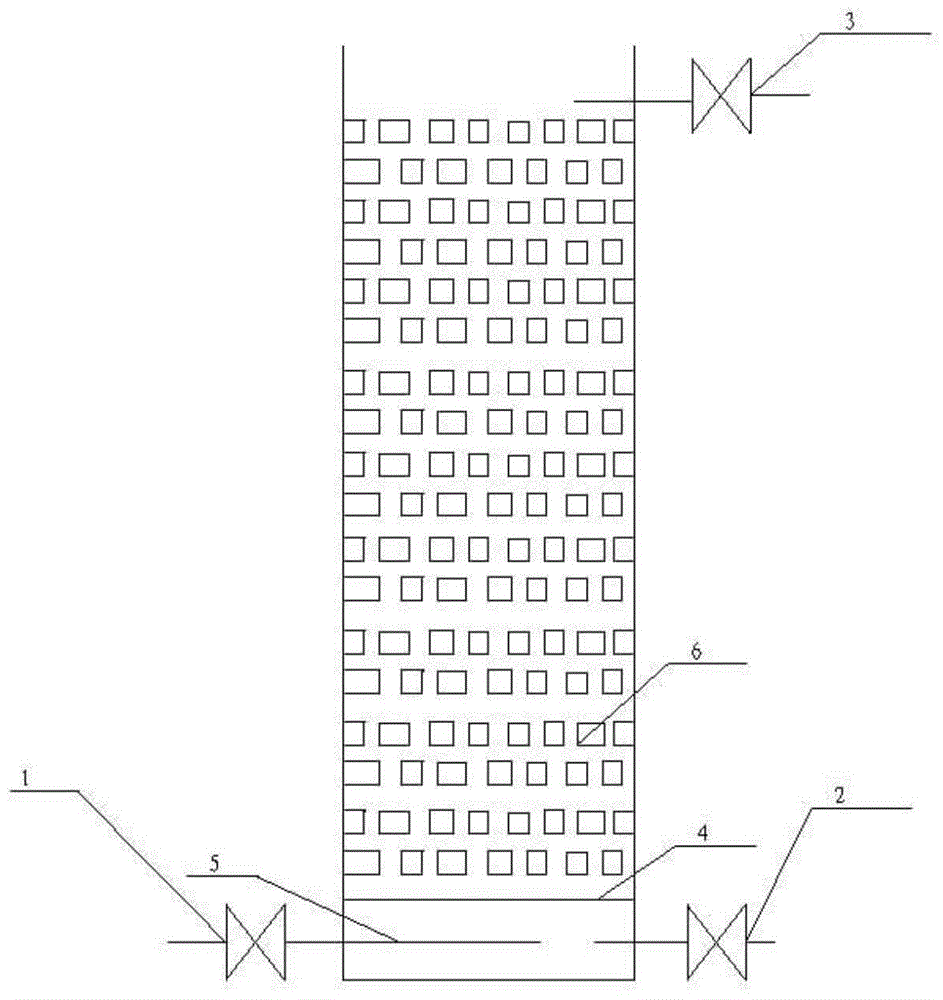

[0066] (1) The waste water produced by gallic acid is processed through a catalytic micro-electrolysis tower device and a flocculation precipitation process: get 500 milliliters of raw water and dilute it to 5 liters, add alkali to adjust the pH to 5, add 30 grams of hydrogen peroxide (content is 27%), and use a flow rate of 200 Milliliters per hour are pumped into the catalytic micro-electrolysis tower, 20 grams of lime is added to the effluent to adjust the pH to 10, and 10 milliliters of polyacrylamide (0.5%) is added to flocculate and precipitate.

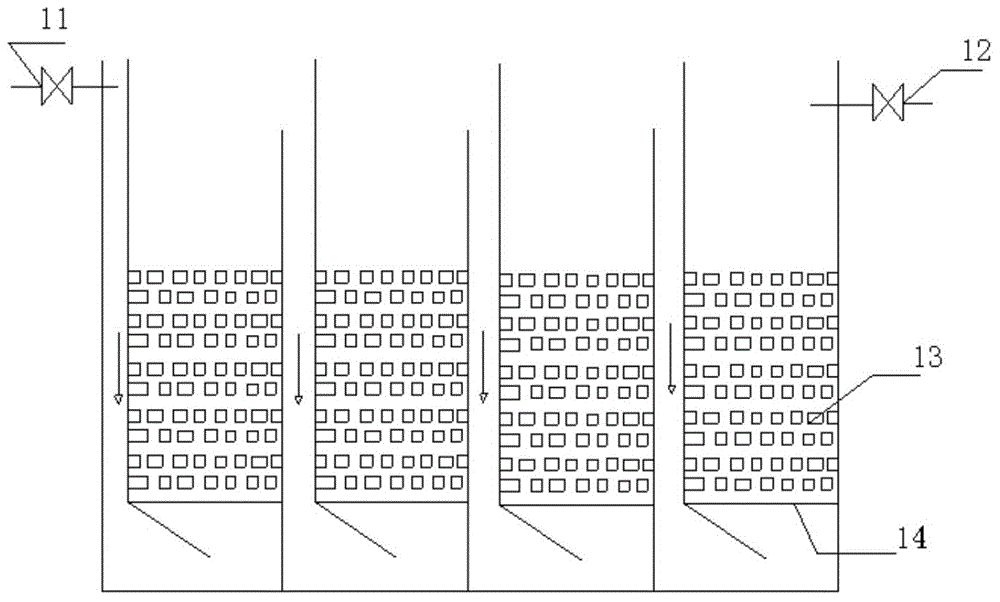

[0067] (2) The effluent after flocculation and sedimentation is treated by anaerobic biological device equipped with high-efficiency compound strains of Lanbiqing (accustomed and lifted): the effluent after flocculation and sedimentation control COD≤6000mg / L, after being equipped with Lanbiqing Clear high-efficiency composite strains (acclimated and lifted) anaerobic biological device stay for 48 hours.

[0068] (3) The effluen...

Embodiment 2

[0072] (1) The waste water produced by gallic acid is processed through catalytic micro-electrolysis tower device and flocculation precipitation process: take 500 milliliters of raw water and dilute to 5 liters, add alkali to adjust pH to 5, add 45 grams of hydrogen peroxide (content is 27%), with flow rate 200 ml / hour is pumped into the catalytic micro-electrolysis tower, 20 grams of lime is added to the effluent to adjust the pH to 10, and 15 milliliters of polyacrylamide (0.5%) is added to flocculate and precipitate.

[0073] (2) The effluent after flocculation and sedimentation is treated by anaerobic biological device equipped with high-efficiency compound strains of Lanbiqing (accustomed and lifted): the effluent after flocculation and sedimentation control COD≤6000mg / L, after being equipped with Lanbiqing Clear high-efficiency composite strains (acclimated and lifted) anaerobic biological device stays for 60 hours.

[0074] (3) The effluent after anaerobic treatment of ...

Embodiment 3

[0078] (1) The waste water produced by gallic acid is processed through catalytic micro-electrolysis tower device and flocculation precipitation process: take 500 milliliters of raw water and dilute to 5 liters, add alkali to adjust pH to 5, add 60 grams of hydrogen peroxide (content is 27%), with flow rate 200 milliliters / hour is pumped into the catalytic micro-electrolysis tower, 20 grams of lime is added to the effluent to adjust the pH to 10, and 20 milliliters of polyacrylamide (content is 0.5%) is added to flocculate and precipitate.

[0079] (2) The effluent after flocculation and sedimentation is treated by anaerobic biological device equipped with high-efficiency compound strains of Lanbiqing (accustomed and lifted): the effluent after flocculation and sedimentation control COD≤6000mg / L, after being equipped with Lanbiqing Clear high-efficiency composite bacteria (acclimated and lifted) anaerobic biological device stays for 72 hours.

[0080] (3) The effluent of Lanbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com