Recovering method for CO2 switch type solvent for treating oil-based drilling cuttings

A switch-type solvent and oil-based drilling cuttings technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., to achieve the effects of shortening the required time, low management costs, and improving water quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

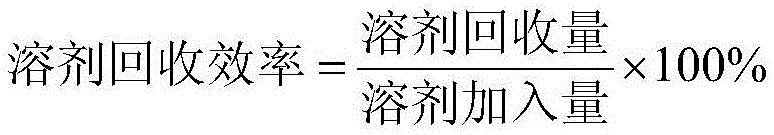

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Take a portion containing CO 2Add 2.1 g of solid sodium hydroxide to 42 g of the water phase of the switch-type solvent, stir and dissolve, and separate to obtain 6.25 g of the upper oil phase and the lower water phase. The water quality of the lower water phase is analyzed, see Table 1 for details.

Embodiment 2

[0031] Example 2: Take a portion containing CO 2 Add 4.2 g of solid sodium hydroxide to 42 g of the water phase of the switch-type solvent, stir and dissolve, and separate to obtain 8.75 g of the upper oil phase and the lower water phase. The water quality of the lower water phase is analyzed, see Table 1 for details.

Embodiment 3

[0032] Example 3: Take a portion containing CO 2 Add 2.1 g of solid calcium oxide to 42 g of the water phase of the switch-type solvent, stir and dissolve, and separate to obtain 4.38 g of the upper oil phase, the middle water phase, and the lower solid phase. The water quality of the middle water phase is analyzed, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com