Paper mill production wastewater treatment method

A technology for the production of waste water and treatment methods, which is applied in the direction of processing waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of substandard discharge and surrounding environmental impact, and achieve operating cost savings , saving floor space, and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

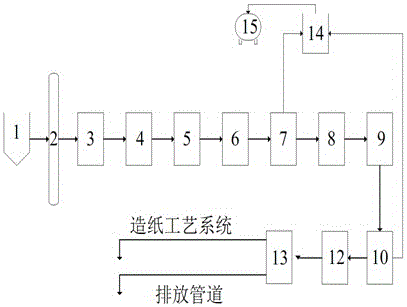

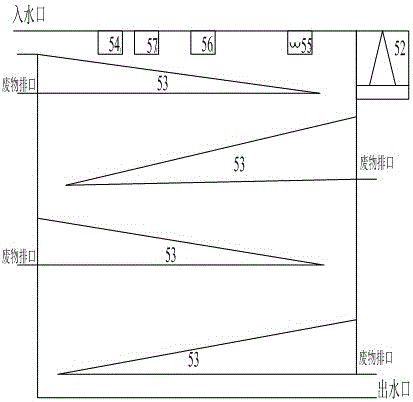

[0018] Such as figure 1 Shown is a treatment method for wastewater produced by a paper mill. The treatment system used includes a pretreatment sump 1, a grille 2, a grit chamber 3, a physical filter 4, ice grid equipment 5, an electromagnetic adsorption pool 6, and an air flotation pool 7. Acidification tank 8, contact oxidation tank 9, secondary sedimentation tank 10, artificial wetland treatment system 12, recirculation storage tank 13, mud storage tank 14, belt filter press 15. The waste water outlet of the paper mill is connected to the water inlet of pretreatment sump 1 through pipelines, the water outlet of pretreatment sump 1 is connected to the water inlet of grid 2 through pipelines, and the water outlet of grid 2 is connected to the grit chamber 3 through pipelines The water inlet and the water outlet of the grit chamber 3 are connected to the water inlet of the physical filter tank 4 through a pipeline, the water outlet of the physical filter tank 4 is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com