Preparation technology of high-braded-rate vertical fiber silver graphite electric contact

A preparation process, silver graphite technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems that affect the soldering rate, excessive exhaust of the solder layer, inconsistent contact temperature, etc., to improve the anti-burning ability, The effect of stable welding quality and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

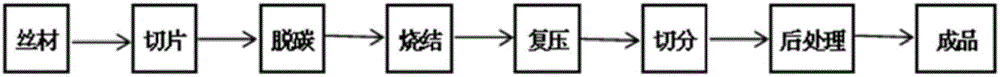

Embodiment 1

[0024] Slice the 7x7 vertical fiber silver graphite wire into 7x7x2.5mm; then put the sliced vertical fiber silver graphite into the decarburization boat, and oxidize it in a resistance furnace at 650°C for 30 minutes to obtain a 0.1mm decarburization silver layer; after decarburization The vertical fiber silver graphite is sintered in a hydrogen furnace at 900°C for 2 hours; after sintering, it is repressed, and the pattern mark is pressed on both sides, and the repressing pressure is 5.5 tons; the vertical fiber silver graphite sheet is cut into two slices to obtain a 7x7x1mm vertical Fiber silver graphite contact; after cutting, the vertical fiber silver graphite contact is ground for 30 minutes to remove knife marks, polished for 2 minutes and cleaned and dried; after drying, the drying temperature is set at 120°C for 3 hours. The vertical fiber silver-graphite contacts prepared by induction welding and resistance welding were scanned by ultrasonic waves respectively, and...

Embodiment 2

[0026] Cut the 8x8 vertical fiber silver graphite wire into 8x8x5.5mm; then put the sliced vertical fiber silver graphite into the decarburization boat, and oxidize it in a resistance furnace at 600°C for 50 minutes to obtain a 0.2mm decarburization silver layer; after decarburization The vertical fiber silver graphite is sintered in a hydrogen furnace at 800 ° C for 4 hours; then the vertical fiber silver graphite is repressed after sintering, and the pattern marks are pressed on both sides, and the repressing pressure is 7 tons; the vertical fiber silver graphite slices are cut into two, Obtain 8x8x2.5mm vertical fiber silver graphite contacts; grind the cut vertical fiber silver graphite contacts for 25 minutes to remove knife marks, polish for 2 minutes and clean and dry; after drying, set the drying temperature at 150°C for 2.5 hours . The vertical fiber silver-graphite contacts prepared by induction welding and resistance welding respectively are scanned by ultrasonic ...

Embodiment 3

[0028] Cut the 11x11 vertical fiber silver graphite wire into 11x11x4.5mm; then put the sliced vertical fiber silver graphite into the decarburization boat, and oxidize it in a resistance furnace at 700°C for 40 minutes to obtain a 0.2mm decarburization silver layer; after decarburization The vertical fiber silver graphite is sintered in a hydrogen furnace at 880°C for 4 hours; then the vertical fiber silver graphite is repressed after sintering, and the pattern marks are pressed on both sides, and the repressing pressure is 13 tons; the vertical fiber silver graphite slices are cut into two, Obtain 11x11x2mm vertical fiber silver graphite contacts; grind the cut vertical fiber silver graphite contacts for 40 minutes to remove knife marks, polish for 2 minutes and wash and dry; after drying, set the drying temperature at 150°C for 3 hours. The vertical fiber silver-graphite contacts prepared by induction welding and resistance welding respectively are scanned by ultrasonic wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com