Betaine production wastewater treatment method

A technology for the production of waste water and treatment methods, which is applied in the direction of biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems that waste water cannot be directly treated, and achieve shortened treatment time, small amount of sludge, Effect of reducing sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

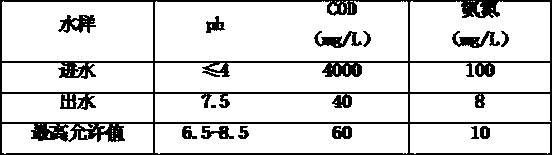

[0049] Examples, in order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples. The example uses the betaine production wastewater of Shandong Xiangweisi Biotechnology Co., Ltd. as a sample.

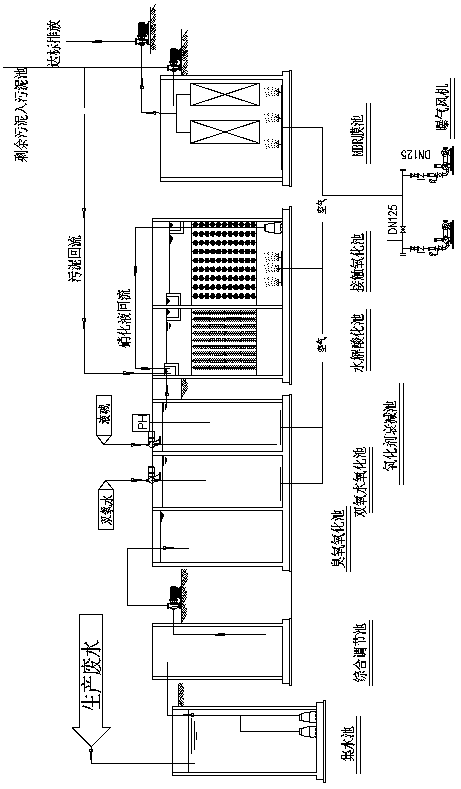

[0050] In conjunction with accompanying drawing, a kind of betaine production wastewater treatment process comprises following processing steps:

[0051] a) Ozone oxidation, after the waste water is collected by the comprehensive adjustment tank, it is pumped into the ozone oxidation tank for ozone oxidation.

[0052] b) Hydrogen peroxide oxidation, the wastewater oxidized by ozonation enters the hydrogen peroxide oxidation tank, and the oxidant hydrogen peroxide is added according to the proportion, and the oxidation treatment is carried out for 4 hours.

[0053] c) Ph callback attenuation, the wastewater after oxygen balance enters the ph callback pool, the lye dosing pump is controlled by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com