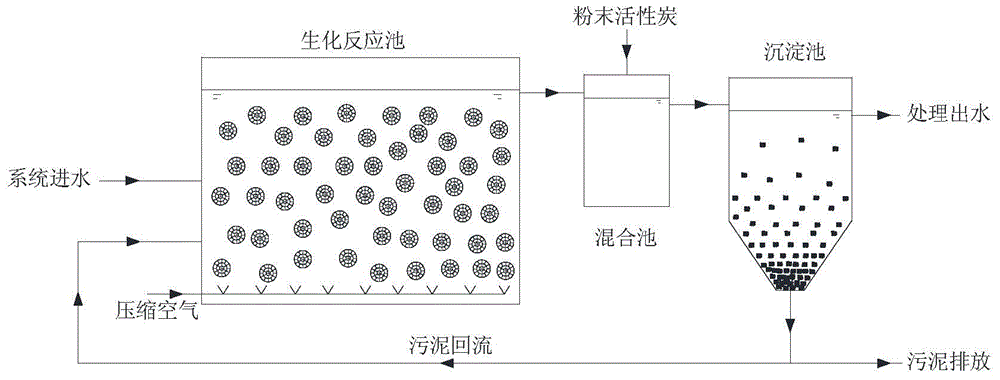

Method for treating wastewater by using carrier fluidized biomembrane reactor

A biofilm reactor and wastewater treatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the unfavorable operation and management of activated sludge method with suspended solids content, etc. Problems, to achieve excellent wastewater treatment effect, high degree of automation control, and improve the effect of sedimentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example is used to illustrate the method for treating wastewater using a carrier fluidized biofilm reactor of the present invention.

[0045] The basic situation of the wastewater to be treated (in actual production, the wastewater treatment process is a dynamic treatment process, and the indicators of the wastewater are usually within a certain range): COD is 500-600mg / L, BOD is 180-350mg / L, ammonia nitrogen 20-35mg / L, the oil content is 15-30mg / L, and the suspended matter content is 100-200mg / L.

[0046] Place a columnar suspended carrier with a diameter of 2.5cm, a thickness of 0.8cm, and a specific gravity of 0.98 in the biochemical reaction tank. In terms of cumulative volume, the filling rate of the columnar suspended carrier in the biochemical reaction tank is 35%, and a perforation is installed at the bottom of the biochemical reaction tank. Tube aeration system, the aforementioned wastewater to be treated is passed into the biochemical reaction tank for tr...

Embodiment 2

[0049] This example is used to illustrate the method for treating wastewater using a carrier fluidized biofilm reactor of the present invention.

[0050] The basic situation of the wastewater to be treated (in actual production, the wastewater treatment process is a dynamic treatment process, and the indicators of the wastewater are usually within a certain range): COD is 500-600mg / L, BOD is 180-350mg / L, ammonia nitrogen 20-35mg / L, the oil content is 15-30mg / L, and the suspended matter content is 100-200mg / L.

[0051] Place a spherical suspended carrier with a diameter of 2.5 cm and a specific gravity of 0.98 in the biochemical reaction tank. In terms of bulk volume, the filling rate of the spherical suspended carrier in the biochemical reaction tank is 25%, and a perforated tube aeration system is installed at the bottom of the biochemical reaction tank , the aforementioned wastewater to be treated is passed into the biochemical reaction tank for treatment, and the COD load o...

Embodiment 3

[0054] This example is used to illustrate the method for treating wastewater using a carrier fluidized biofilm reactor of the present invention.

[0055] The basic situation of the wastewater to be treated (in actual production, the wastewater treatment process is a dynamic treatment process, and the indicators of the wastewater are usually within a certain range): COD is 500-600mg / L, BOD is 180-350mg / L, ammonia nitrogen 20-35mg / L, the oil content is 15-30mg / L, and the suspended matter content is 100-200mg / L.

[0056] Place a columnar suspension carrier with a diameter of 2.5cm, a thickness of 0.8cm, and a specific gravity of 0.98 in the biochemical reaction tank. In terms of cumulative volume, the filling rate of the columnar suspension carrier in the biochemical reaction tank is 45%, and a perforation is installed at the bottom of the biochemical reaction tank. Pipe aeration system, the aforementioned wastewater to be treated is passed into the biochemical reaction tank for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com