Dye wastewater treatment apparatus and method thereof

A dye wastewater and treatment device technology, applied in multi-stage water treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve problems such as low TN removal rate, difficulty in achieving treatment goals, and increased operating costs , to achieve the effect of recycling resources and reducing instability and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

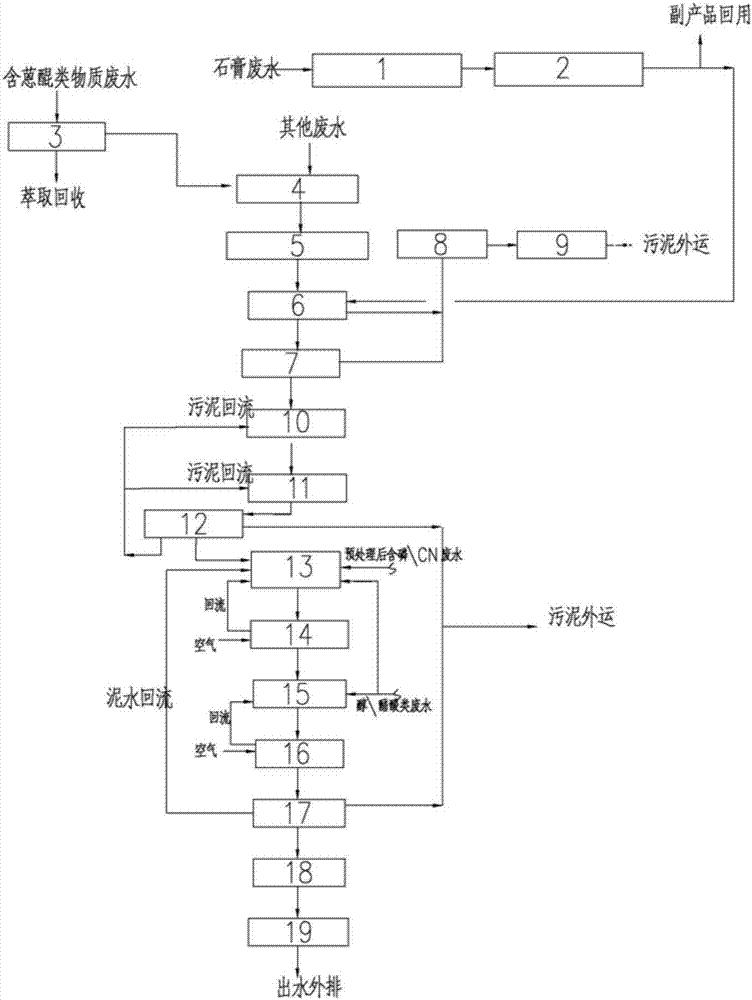

[0060] A dye wastewater treatment device, including a first settling tank 3 connected in sequence for collecting wastewater containing anthraquinones, a comprehensive wastewater collection and regulating tank 4 for collecting other wastewater, and a first sedimentation tank for oxidatively decomposing refractory organic matter. Reactor 5, the second reactor 6 for adjusting the pH of wastewater, the second sedimentation tank 7 for removing suspended solids and sediments, the biochemical adjustment tank 10 for homogenizing biochemical wastewater, the first tank for anaerobic reaction Three reactors 11 (tower type anaerobic reactor, Modified polypropylene fiber elastic filler is set inside, the filler specification ), the third sedimentation tank 12 for effectively retaining biological sludge, the fourth reactor 13 for denitrification, the fifth reactor 14 for nitrification, and the sixth reactor for secondary denitrification 15. The seventh reactor 16 for secondary nitration ...

Embodiment 2

[0075] A dye wastewater treatment device, including a first settling tank 3 connected in sequence for collecting wastewater containing anthraquinones, a comprehensive wastewater collection and regulating tank 4 for collecting other wastewater, and a first sedimentation tank for oxidatively decomposing refractory organic matter. Reactor 5, the second reactor 6 for adjusting the pH of wastewater, the second sedimentation tank 7 for removing suspended solids and sediments, the biochemical adjustment tank 10 for homogenizing biochemical wastewater, the first tank for anaerobic reaction Three reactors 11 (tower type anaerobic reactor, It is equipped with a snowflake-shaped inner ring of polypropylene branches and a combined packing made of polyester fibers pressed on the ring, with a unit diameter of Φ150×100mm), a third sedimentation tank 12 for effectively retaining biological sludge, and a third sedimentation tank for denitrification reaction Four reactors 13, the fifth reactor...

Embodiment 3

[0090] A dye wastewater treatment device, including a first settling tank 3 connected in sequence for collecting wastewater containing anthraquinones, a comprehensive wastewater collection and regulating tank 4 for collecting other wastewater, and a first sedimentation tank for oxidatively decomposing refractory organic matter. Reactor 5, the second reactor 6 for adjusting the pH of wastewater, the second sedimentation tank 7 for removing suspended solids and sediments, the biochemical adjustment tank 10 for homogenizing biochemical wastewater, the first tank for anaerobic reaction Three reactors 11 (tower type anaerobic reactor, The inner ring of snowflake-shaped polypropylene branches and the combined packing of polyester fiber pressed on the ring are set inside, the unit diameter is Φ180×100mm m / square and elastic packing of modified polypropylene fiber, packing specifications ), the third sedimentation tank 12 for effectively retaining biological sludge, the fourth reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com