Step-feed biological nitrogen removal and sludge reduction coupling bioreactor and process thereof

A bioreactor, biological denitrification technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of low total nitrogen removal rate and sludge production. It can achieve the effect of good denitrification effect, high denitrification rate, good sewage biological denitrification and sludge reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific operation steps of the present invention have been described in detail in the content of the invention, and will not be repeated here.

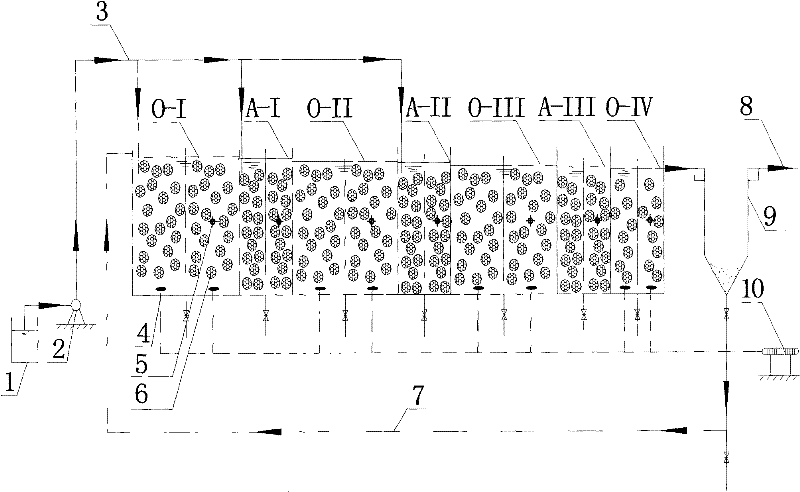

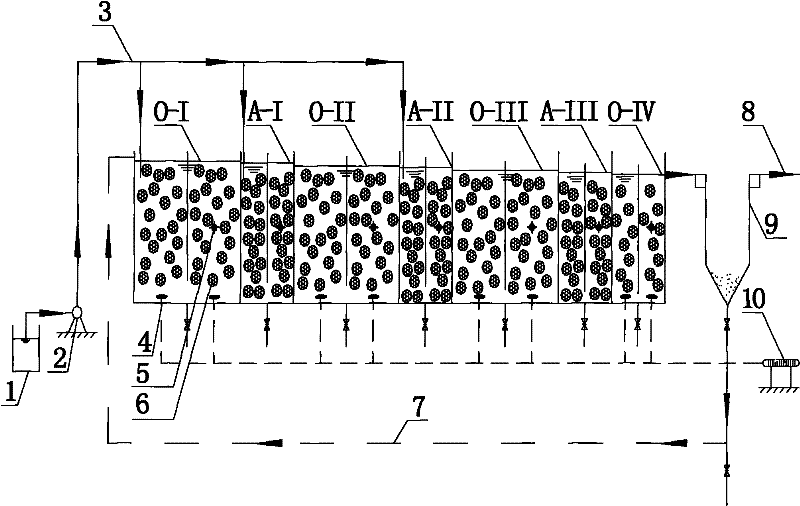

[0022] The biological reaction zone and the secondary sedimentation tank 9 are sequentially included; the biological reaction zone sequentially includes the aerobic zone O-I, the anoxic zone A-I, the aerobic zone O-II, the anoxic zone A-II, the aerobic zone O-III, and the anoxic zone A-III, aerobic zone O-IV, the volume ratio of each aerobic zone to anoxic zone is 1.5:1~2:1, a porous carrier 6 is placed inside the biological reaction zone; the volume ratio of the carrier in the aerobic zone is 40% ~60%; the volume ratio of the carrier in the anoxic zone is 90% to 100%; each zone is equipped with baffles, so that each zone is top water inlet and top water outlet.

[0023] The reactor is divided into three stages of water intake, and the three water inlet pipes 3 are respectively set in the aerobic zone O-I, the anoxic zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com