Sewage treatment method for medical institutions

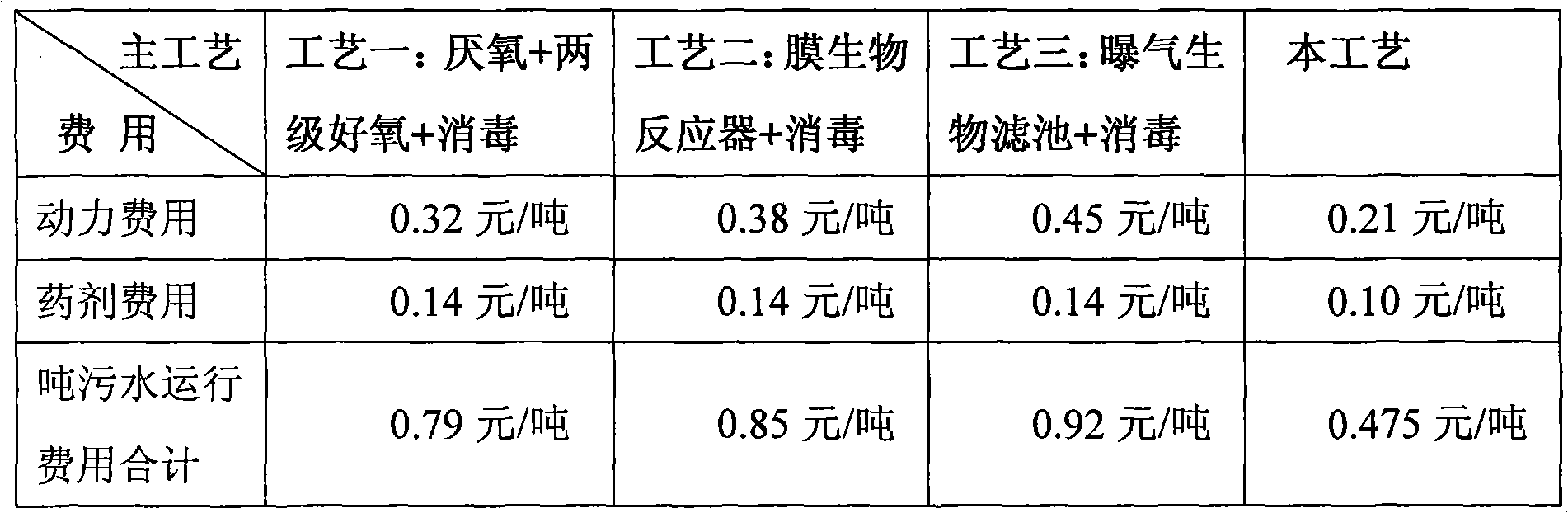

A sewage treatment method and technology for medical institutions, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Water and other problems, to achieve the effect of strong anti-shock load capacity, high sewage treatment efficiency, and simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for treating sewage in medical institutions, including sewage pretreatment, anoxic treatment, aerobic treatment, sedimentation treatment, and disinfection treatment. The specific steps are as follows:

[0014] 1) Pretreatment removes solid pollutants in sewage, adjusts water quality and quantity, and rationally absorbs feces.

[0015] 2) The sewage is lifted into the anoxic tank, and fully mixed with the backflow nitrification solution in the anoxic tank. The denitrifying bacteria use the organic matter in the sewage under the anoxic environment to reduce the NO in the backflow nitrification solution. 3- converted to N 2 Release, install packing in the anoxic tank to maintain the mixed state of sewage.

[0016] 3) After that, all sewage return sludge enters the aerobic pool from the anoxic pool, and the aeration system is arranged in the aerobic pool to aerate the pool with oxygen, and the biological contact oxidation process is adopted to make the microorgani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com