Coking Wastewater Advanced Treatment System and Its Reuse Process

A coking wastewater and advanced treatment technology, applied in the field of environmental engineering, can solve the problems of low treatment efficiency, secondary pollution, pipe network and equipment corrosion, etc., and achieve the effect of increasing microbial concentration, improving work efficiency, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

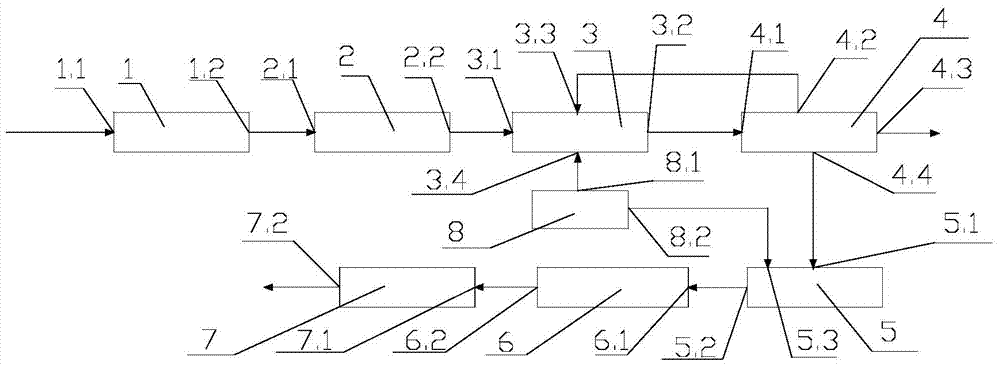

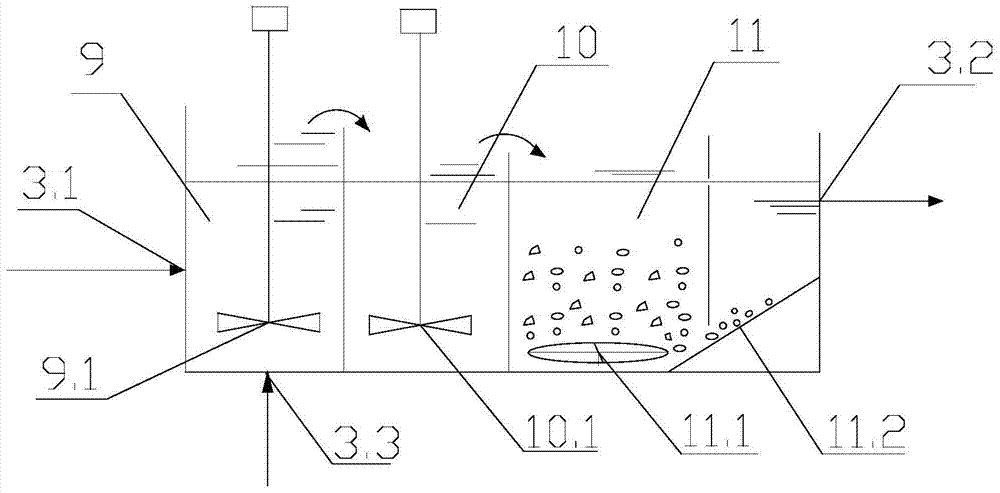

[0031] A coking wastewater advanced treatment system shown in the figure includes a degreasing pond 1, a regulating pond 2, a biochemical pond 3, a sedimentation pond 4, a biological filter 5, a multimedia filter 6, and an adsorption device 7, wherein, Degreasing tank 1 is provided with coking wastewater inlet 1.1, degreasing wastewater outlet 1.2 of degreasing tank 1 is connected to degreasing wastewater inlet 2.1 of regulating tank 2, and regulated and treated wastewater outlet 2.2 of regulating tank 2 is connected to regulated and treated wastewater inlet of biochemical tank 3 3.1, the biochemical treatment wastewater outlet 3.2 of the biochemical tank 3 is connected to the biochemical treatment wastewater inlet 4.1 of the sedimentation tank 4, the sludge return outlet 4.2 of the sedimentation tank 4 is connected to the sludge retur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com